safe working load of wire rope sling pricelist

Wire Rope Material: The lifting slings are made from independent wire rope core (IWRC) offering less stretch and resistance to crushing while maintaining sling flexibility. Wire rope slings are fabricated from extra improved plow steel (EIPS).

A low quality wire rope sling can cause injury and damage. A look-alike wire rope sling often found at lower prices is also often advertised to conform to the same safety standards (if at all). Be aware that it may refer to safety ratings in effect decades ago. So for example under the same safety standard a decade ago, a wire rope sling may be rated to 100% without proof load testing while today it may be 300% with proof load testing. Be assured that we only sell the highest quality wire rope slings and our advertised safety standards conform to the current ASME standards.

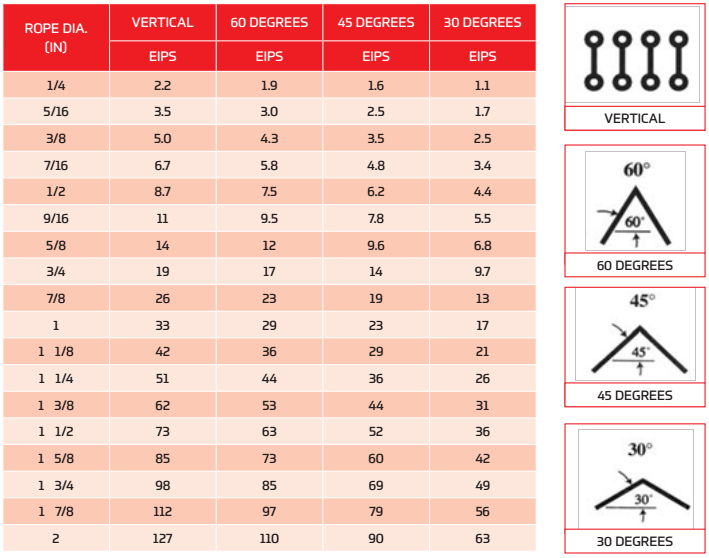

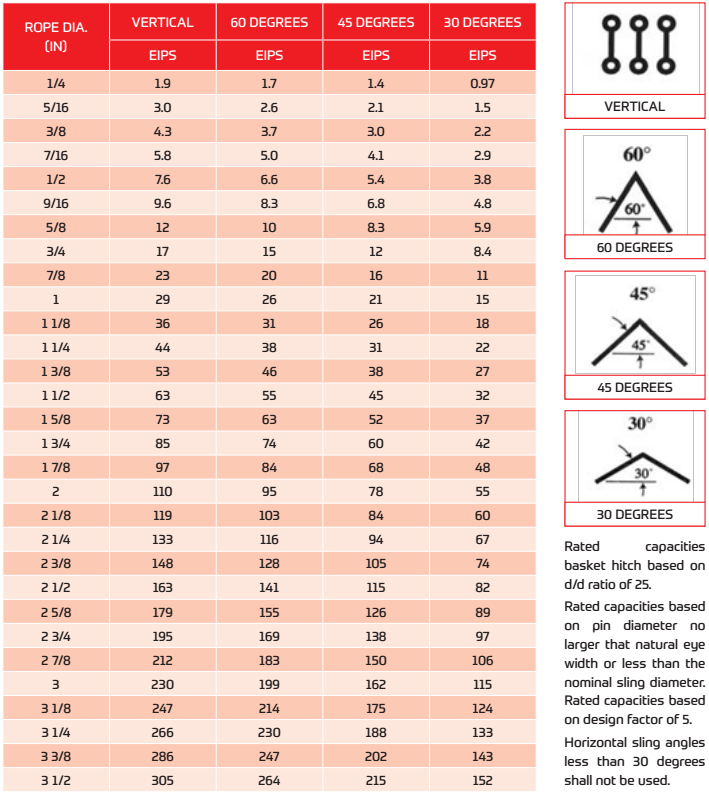

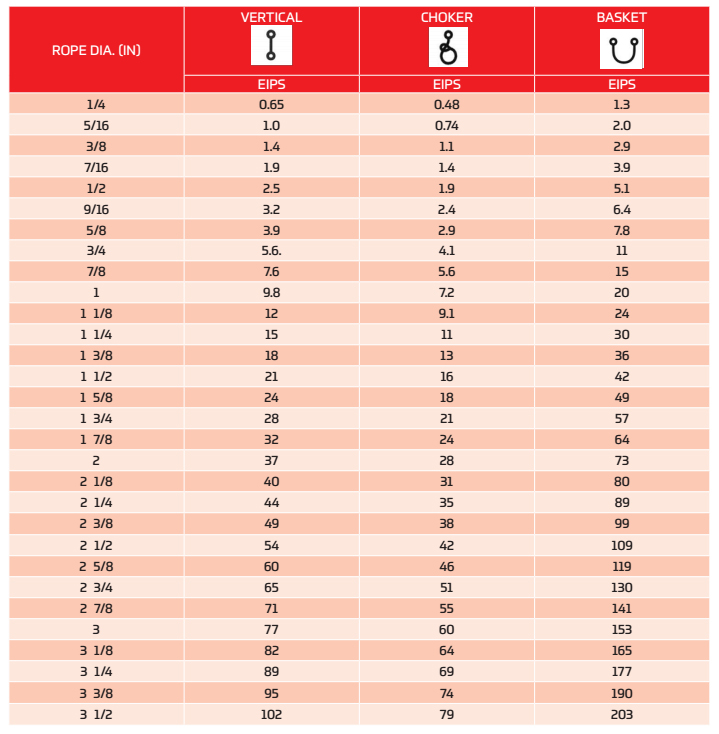

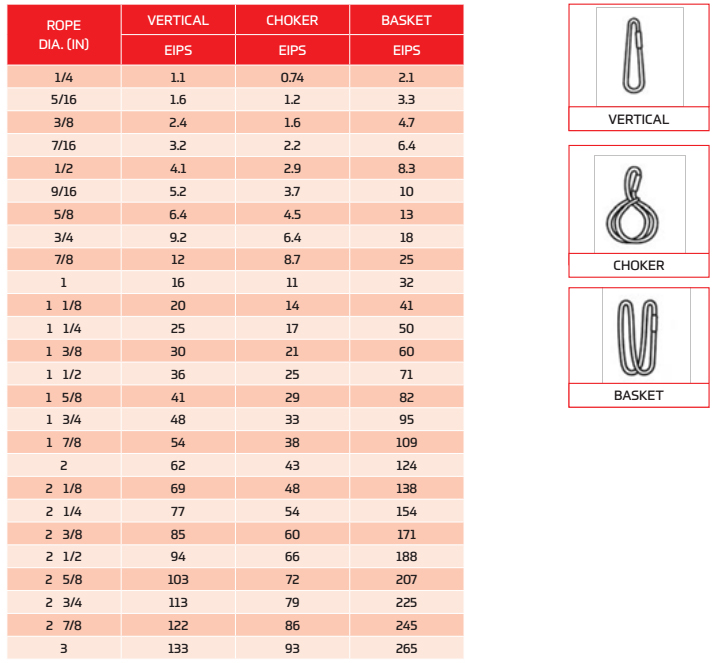

Working load limits (capacity) of the wire rope lifting slingsvary depending on the angle of use. The capacity is reduced as the angle of use declines. See drawing below how a 1,000 lbs sling capacity is reduced as the angle of use declines. The capacity of the sling is always highest at a 90 degree angle of use and smallest at an angle of 30 degrees (or less).

The chain sling has the advantage of being durable, very flexible and its length can be made adjustable. It will tolerate a wide range of temperatures; however, compared to other types, it is relatively expensive and, depending upon the grade of chain used, relatively heavy.

The wire rope sling is not quite as durable. The wire rope sling is not as flexible as chain but its greater stiffness can be an advantage if it has to be inserted through a small opening or beneath a load. However, when wrapped around a load, the wire rope sling often tends to deform permanently to the shape of the load. Wire rope suitable for slings comes in a variety of grades and constructions. In most cases looping back and securing the loop with a metal sleeve terminates the rope. This forms a loop or soft eye, the simplest form of sling end. Thimbles are used to support and protect the eye from abrasion. Wire rope is generally cheaper and lighter than chain which can be a plus, particularly for applications that require long sling lengths.

The nylon and polyester slings have the advantage of being lightweight in comparison to chain and wire rope slings. They are very flexible and relatively soft; therefore, they are suitable in applications were minimal damage to the load"s surface finish is important. The rope is made endless or terminated with an eye by means of a handmade splice. Similar to a wire rope sling, various terminal fittings are available. Without adequate protection, nylon and poly slings are susceptible to being severed when impinging on even a relatively moderate sharp edge.

Wire rope is often commonly referred to as cable; they are one in the same. Wire rope is composed of wires, strands, and a core. The basic unit is the wire, which is formed into strands. The strands are wound around the core. Various types of wire rope exist to meet a range of uses and operating conditions. These types are designated by the number of strands; the number, sizes and arrangement of the wires in each strand; and the way in which the wires and strands are wound, or laid, about each other.

Important characteristics of wire rope relate to the number and size of the outer wires. A small number of large outer wires result in better resistance to wear and corrosion. A large number of small wires result in better flexibility and resistance to fatigue.

The core acts as the axial member about which the strands are laid. Wire rope cores are made in two different forms. The one used most extensively is a wire rope of suitable size to serve as a core. It is called as independent wire rope core (IWRC). IWRC has increased tensile strength, offers less stretch, and is resistant to crushing; however, is less flexible. The other type is a wire strand core (WSC). This consists of a multiple-wire strand, and may be the same construction as the main rope strands.

Two grades of carbon steel wire are offered. The bulk of commercial wire rope lifting sling is made from improved plow steel (IPS) or extra improved plow steel (EIPS) which has a higher tensile strength.

Hand Splicing: Because no metal sleeve is required to secure the eye in the hand spliced sling, it exhibits more flexibility than mechanically splice slings of equal diameter. They have a more narrow profile and therefore can fit through tight spaces. Without benefit of a metal sleeve, lifts must be limited to applications where the wire rope sling is restrained from rotation and possible unlaying of the sling body.

Mechanical Splicing:Mechanically spliced eyes do not suffer the limitations of hand splicing, are economical, and offer the highest rated capacity of any spliced wire rope sling. This wire rope sling is fabricated by unlaying the rope body into two parts, one containing half the number of strands, the other having the remaining strands and core. The rope is unlayed far enough back to allow the eye to be formed by looping one part in one direction and the other part in the opposite direction and laying the rope back together. The strands are rolled back around the rope body and a metal sleeve is slipped over the ends and pressed (or swaged) to secure the ends to the body of the wire rope sling.

It also save energy and money. wire rope slings are made from stainless steel, and it"s also an excellent choice for installation or any production of any kind.

There are two types of wire rope sling, steel wire sling, and steel rope sling. Stocking products of different price points, be the first choice and stockists wholesale today. Check out the stainless steel wire sling price, color and design at Alibaba.

Rated load based on pin diameter no larger than one half the natural eye length or not less than the nominal sling diameter. Basket hitch capacity based on minimum D/d ratio of 25/1. For choker hitch, the angle of choke shall be 120 degrees or greater. For sling angles other than those shown, use the rated load for the next lower angle or a qualified person shall calculate the rated load. Horizontal sling angles of less than 30 degrees are not recommended. The capacity of a bridle at a 30 degree horizontal is same as single vertical leg.

Lifting slings usually consist of chain, rope, or webbing used in alliance with a crane for lifting purposes. It facilitates moving heavy materials from one place to another while also keeping the balance of the load.

Workers practising rigging must exercise extreme cautiousness when involved in lifting processes that include using slings. Operators should receive training before participating in the lifting procedures, and you must monitor the splints frequently to avoid hazards.

Here is a brief guide to the main types of slings you can choose from as per your need. Alloy Chain Slings:Chain slings lift very hefty and enormous loads daily. However, when it comes to durability and endurance, they are the perfect fit. They can withstand high temperatures and adversities almost up to 1000°F. Once damaged, the chains are repairable and ready for use after the load testing. They are not affected by grease or oil and are tolerant to corrosion and UV rays. Wire Rope Slings:You can configure the Synthetic Web Slings:Synthetic web slings are preferable for lifting delicate and high-polished loads because it protects them from scratches, unlike other slings. Usually made from woven polyester or nylon, they make a good choice as it is cost-effective. Despite being made from soft materials, they are capable of lifting expensive and heavy loads. However, you can"t use it in conditions exceeding 194°F.

While choosing a sling, there are a few things to keep in mind. Here, is everything you must know before selecting the ideal sling:- The weight of the load:

It is crucial to determine the weight of the load before lifting it. It helps to ensure the safety of the workers present at the site from any possible mishaps. One of the ways to measure the weight of the load is to manually calculate it.

Another way can be following a load chart. A load chart helps in estimating the need for extensive calculations. It is also important to recalculate this since the lift range can keep varying. The Working Load Limit of the sling in use:

While choosing the ideal sling, it is important to keep its Working Load Limit (WLL) in consideration. It is extremely vital because the sling in use should handle the size and weight of the load.

For example, chain slings help lift bulky loads as compared to synthetic slings. However, if you end up opting for the wrong sling, it would have a risky possibility of the load getting dropped. The Environmental Factors:

Environmental factors play a major role in choosing the right sling. You need to be conscious about the details like temperature and the presence of corrosive substances.

Every sling is different and uses discrete materials. Keeping the material of the sling in mind assists in observing what goes best as per your requirement. The fragility of the materials depicts the distinct use of each. For example, chain slings are compatible with repetitive use because of their longevity. However, synthetic web slings are used for the flexibility they provide.

The working load limit (WLL) or previously known as safe working load (SWL) indicates the ultimate working load designated by the manufacturer. Exceeding the maximum limit can be threatening to the worker"s safety. Be mindful of the working load limit always being 1/3 of the breaking limit.

Some factors determining workload limit are:- Design Factor:For example, the design factor of chain slings is 4:1 whereas for wire rope sling it is 5:1.

Loading Angle:Sling to load angle can be described as the angle between the sling leg and the horizontal surface. Therefore, as the sling to load angle decreases, so does the given capacity of a sling.

So, these are the important points and factors that you have to perceive. It will give you an idea of the functionality of the slings. In the future, if you want to establish a business that involves slings, these pieces of information will help you.

At CERTEX USA, we set the standard for rigging supplies, lifting products and world-class fall protection as well as the top industrial rescue courses and critical testing services. Many companies and workers around the country rely on our expansive line of quality lifting equipment and products. From wire rope to wire mesh slings, to hoists, clamps, blocks and sheaves, CERTEX USA has the lifting equipment you will need to get the job done correctly, safely and on schedule. When it comes to rigging equipment, supplies and lifting products, you shouldn’t have to worry about choosing between the highest-quality products available and the products offered at affordable prices. At CERTEX USA, we have you covered with quality lifting products at competitive prices.

In the form, grommet sling was spliced by the wire rope with the characters of class b or ab, fiber core, nominal tensile strength 1670MPa. Depending on the different working place, we should chose the rope with different surface treated, including galvanized wire rope with lubrication, galavnized wire rope without lubrication and un-galvanized, total three choices.

Choose different capacity wire rope to splice the grommet sling, it"s breaking load is different. Shall calculate the sling"s breaking strength according to the steel wire rope construction.

Min Breaking load of grommet sling is 5 times of that working load. Accroding to the requirements of the industry, other safety factors also can be applied. The safety factory of the following operation can be executed with the strandar GB/T30587-2014, such as the load weihght is accurate calculated or meassured, hoist operation is to be monitored and controlled and dynamic coefficient are limited. The same, when the diameter is 60 mm or less than, take the safety factor of 5, the diameter from 60 to 150 mm take the safety of (6.31-0.022D), when the diameter is greater than 150mm, safety factor should not be less than 3.

We offer Wire Rope Sling that are mainly used for transporting and shifting of load.These are highly acclaimed for features like durability, hardness and tensile strength. The sling is used in construction, marine and automobile industry. The range is also customized as per specification of client.

How much does a wire rope sling cost? How much does a shackle or a web sling cost? These are legitimate questions that we hear every day from prospective customers looking to purchase rigging products for their next lifting project.

Similar to other consumer goods like cars, electronics, and appliances, there are several factors that can raise or lower the price of rigging equipment. Our intention in this article isn’t to beat around the bush, but instead we want to provide you with some practical guidelines, as well as influential factors that can affect the cost of lifting and rigging products, including:Where do you buy your rigging gear?

Like most products and services, rigging gear can be purchased from a traditional brick and mortar location, or can be purchased online through a specialty supplier or catalog and supply house with an e-commerce site. If you’ve done some research and looked at different online suppliers, you’ll notice that there can be a huge disparity in pricing between the same types of rigging products for sale online and in a physical rigging shop.

For instance, a common Eye and Eye 2” Wide, Two-Ply Web Sling (EE2-802 X 10’) had the following prices listed on three different e-commerce websites: $24.00, $32.00, and $42.00. That same web sling was being sold for $26.00 at a brick and mortar rigging shop.

Rigging shops have long been the stalwarts of the lifting and rigging industries. Rigging shops typically have a showroom or storefront with a wide selection of sling hooks, shackles, chain, synthetic slings and wire rope. They also traditionally buy the raw materials for wire rope, webbing, steel and chain and have a shop where they can make the lifting and rigging products themselves.

The variety of rigging equipment and expertise that the rigging shops offer is unparalleled as you can speak directly with a knowledgeable salesperson to get a product recommendation. They also offer added convenience—if they have the part(s) that you’re looking for in stock, you can stop in that same day and walk out the door with what you need. This also eliminates the added expense of paying for freight to ship rigging equipment that can be large and heavy.

But do they have the best prices? Sometimes they do, but most of the time they fall somewhere in the middle of the price spectrum. The same web slings we mentioned earlier had prices ranging from $24.00 to $42.00 from three e-commerce retailers. A rigging shop might fall somewhere in the middle around $26.00 for that same web sling.

Many rigging shops pride themselves on carrying product in bulk and in a full range of sizes and configurations. While this is convenient for the customer, it also increases the shop’s inventory carrying costs, which get passed on to the end-user as a premium item price increase.

If you’re looking for the added benefit and expertise of speaking with a knowledgeable salesperson, want to browse an extensive inventory, and may have an immediate need for a piece of rigging hardware, chain sling, roundsling, or wire rope, then a rigging shop might be your best bet.

More and more, it’s becoming commonplace to order rigging gear from online retailers. For those that don’t need product variety, or value in-store sales expertise, many rigging shops and industrial suppliers are offering their products for sale through their websites, as well.

A common 1/2” X 10’, 6 X 25 Wire Center, Wire Rope Sling comes in at $29.00, $43.00, and $67.00 from three different online retailers. So, why is there such a wide pricing range for what appears to be the same product?

When doing some rigging cost comparisons, you may notice that the lowest prices seem to come from the websites that only sell lifting and rigging equipment. However, these lifting and rigging websites tend to focus on the common “bread and butter” lifting and rigging equipment and may not have a large inventory of rigging products to select from. They may also make up for their low prices by bumping up the cost of their shipping and handling fees.

Online suppliers with the more expensive wire rope and web slings tend to be larger catalog and supply houses that offer an impressive array of all types of industrial products, including rigging gear. They also offer the convenience of selling items like gloves, eye protection, spray paint, etc.—an added convenience factor that allows you to buy everything that you need from one source.

Catalog supply houses may also offer prepaid freight, or have cheaper shipping rates since they move so much product in and out the door that they receive volume freight discounts that they can then pass on to the customer.

Basic lifting and rigging gear has many options and price ranges as we noted above. When you get into non-standard sizes and lengths, your choices of where to buy are reduced due to the special nature of these products, and this leads to an increase in price, as well.

Size is always a factor when it comes to the cost of lifting and rigging products. For example, a 1-ton screw pin anchor shackle can be found for around $9.00 per piece, a 9.5-ton shackle sells for around $80.00 a piece, and a 25-ton shackle can run close to $300.00 per piece. Simply put, the more steel and more material required to produce the product, the more it’s going to cost you.

This is also true for lengths of wire rope and chain. Larger diameter wire rope, and larger and longer lengths of chain and wire rope, often fall out of the “standard” product range of suppliers other than rigging shops. If a shop has to special order a piece due to a non-standard size or length, that extra time and effort to acquire the piece will get passed on to the customers as a price markup.

The complexity of the rigging products you buy also has an effect on your cost. A simple 1-ton 4’ lifting beam can be mass-produced by a supplier and can be bought in a range anywhere from $600.00 to $800.00. A beam that has to be specially-engineered due to non-standard lifting points, bail heights, load engagement requirements, etc., can easily double the price of a standard beam. The engineering of specialty items requires additional labor, and smaller raw material batch purchases, which add up to additional costs to make a small production run or fabricate a custom one-off piece.

High-performance and specialty items also cost more. For instance, 3/4″ 6 X 37 with wire center rope would cost around $2.50 per foot. A high-performance cable like a 3/4” Dyform 18 would cost about $4.50 per foot. But in the right application, the Dyform 18 will last much longer to justify the higher initial cost, and may also save labor costs because the customer won’t have to perform cable changes as frequently.

However, highly-trained lifting specialists are compensated for their time and knowledge applied to a lifting project and therefore will increase the cost of your rigging solution. Unfortunately, you’re not going to solve your problem by e-mailing a catalog house or e-commerce rigging website’s customer service team. Their businesses are built to move rigging hardware, wire rope slings, chain slings, and synthetic slings out the door in a quick and efficient manner.

They’re not necessarily set up to offer support, troubleshoot, or help solve lifting challenges. Utilizing a lifting specialist might cost you more upfront, but will save you time and money in the long run by increasing your lifting efficiencies and providing a solution that will get the job done safely.

The cost of imported vs. domestic rigging products is a bit more involved and complicated. You have to determine if you are comfortable with an import product based on the country of origin and also make sure that it meets the same quality standards and specifications as its domestic counterpart.

Generally, imported products are cheaper in price, and in many cases, the quality is comparable to products made domestically. For instance, an imported 1/2” x 10’ 6 X 25 swaged wire rope sling would cost about $20.00—the same sling made by a company who manufactures their rigging gear in the United States would charge around $30.00.

For companies that import their rigging products, their business is built on offering their customers standard run-of-the-mill rigging products in the most popular sizes and configurations. Their manufacturing locations are built to churn out product in large batches and operate with little to no overhead. By doing so, an import supplier can offer their products at a discounted price. Unfortunately, they can’t offer their customers much in terms of variety or customized solutions.

The amount, or the quantity of pieces that you’re buying, can also greatly influence how much you pay for lifting and rigging equipment. If you buy from the right source, you may save more per item, or per foot, the more that you buy.

If you do a little bit of research online, you’ll see that some of the companies that sell lifting and rigging equipment offer quantity discounts and some do not. You may see some promotions like “free shipping for orders over $50.00!” If you buy rigging equipment with some regularity, then you know that $50.00 is not a high bar to reach. You may recall from earlier in this article that one 9.5-ton shackle costs around $80 per piece, so you can hit that minimum pretty easily with the purchase of only one part.

E-commerce sites that offer deals like free shipping on lifting or rigging equipment seem to target the smaller end user—mostly contractors or small construction companies that make up a large portion of the rigging buyer’s market.

The shops that are going to offer the most significant discount to their customers will be the brick-and-mortar rigging shops. They can, and will, offer substantial discounts for a large-quantity order, or for their high-volume customers.

Let’s face it, medium to large users of rigging equipment are not going to order their rigging products online—they will overwhelmingly buy from rigging shops because they can utilize their staff’s expertise, and also take advantage of rush or same-day delivery—two things that online sellers of rigging equipment and industrial equipment just can’t compete with.

If you’ve ever worked in a retail or service-based environment, you already know the typical customer response to the question, “when do you need it by?” The answers are often, “yesterday!” or “as soon as you can get it to me….today.” No matter what the answer is, the theme in the lifting and rigging industry is usually, “I need it now.”

So, now the pressure is on the seller to deliver the product within their customer’s time frame, or else risk losing the business. One thing that many people don’t understand is that it costs a company more money to structure itself to handle rush orders, same or next-day deliveries, and emergency repair or replacement for rigging equipment. Some of these added expenses include:Maintaining a large and diverse inventory to ensure product is in stock and available for fulfillment

These extra expenses to the seller may present themselves in the form of an additional fee for rush delivery and fulfillment on your order, or you may see it as a higher cost in freight. And you know what? You may be okay paying a few extra dollars for a sling from a local rigging shop if you know that they’re equipped to deliver an emergency replacement if your equipment were to break or fail.

Bottom line, rush orders increase the cost of your rigging products. However, if you have smaller quantities, know what you want and can wait a few days to receive your equipment, then the online rigging stores and catalog and supply houses are still a very viable option for you.

The least expensive option isn’t always the smartest buy. Research, due diligence, and working with industry experts will lead you to the best product for your application and ultimately, the best bang for your buck in the long run.

At Mazzella, we provide ideal lifting solutions—offering all styles of lifting slings, rigging hardware, wire rope, overhead cranes and hoists, and engineered lifting devices. We also have locations all across the United States—fully stocked with different sizes and configurations of rigging products for your next project.

All Departments1x19 Stainless Steel Strand1x7 Guy Strand6x26 Wire RopesApparelBlocks and PulleysCable RailingClearanceCordageDecalsFall ProtectionGrade 70 Transport ChainHard Hat StickersHeadwearLIFTGEAR MerchRotation Resistant Wire RopesSafety MerchSynthetic Tycan® ChainSynthetic Tycan® Chain SlingsWashington Wire RopeIMPORT- WRCManual Chain HoistsGrade 70 Binder Chains7x19 Aircraft CableWire Rope SlingsLever Chain HoistsBeam ClampsGrade 100 ChainPlate Clamps6x36 Wire RopesG100 Chain SlingsDSS - DOUBLE SWIVEL SHACKLESEB - SWIVEL EYE BOLTWeb SlingsBest SellersOffroad RecoveryOffroad Recovery RopesTowing SuppliesLoad and TransportWire RopeChain and AccessoriesClampsDSR - DOUBLE SWIVEL HOIST RINGSRound SlingsAMHHoists and ClampsWire Rope ClipsSynthetic SlingsCODIPROLifting SlingsMade in USASafety ShacklesSUPER STRONG ShacklesShacklesRigging Hardware

8613371530291

8613371530291