sheathed wire rope free sample

We’re experts at plastic coating extrusions for wire rope and aircraft cable with decades of experience and our in-house coating process consisting of a jacketing application via pressurized extrusion. We supply nylon as well as polyvinyl chloride, also known as PVC or vinyl, coated wire rope and aircraft cable on reels, in pre-cut lengths, or fabricated into assemblies.

Please let us know if you require RoHS or REACH compliant coated wire rope. Upon special request, we can also supply coatings such as HDPE, Hytrel, and FEP.

Nantong Fasten Metals Products Co., LTD is located in the coastal open city—Nantong which is in the lower area of the Yangtze River. We are a professional corporation which produces a variety of standards and types of galvanized steel wire rope, ungalvanized steel wire rope, steel-wire, stranded wire and spring steel wire. Our products mainly exported to Southeast Asia, the United States, Europe, the Middle East, Africa and other countries.

Wire rope is also known by many other names, such as: wire, multi-strand wire, flexible wire, cable, cord, steelcord, etc. but it is essentially a collection of small filaments wound around each other in a manner that largely retains its shape when bent, crushed and/or tensioned.

It is a system for significantly increasing the strength and flexibility of steel wire and is used in almost every important application we see around us. For example: suspension bridges, tyres, brake and accelerator cables (in cars), high-pressure flexible pipes, lifting and rigging cables, electrical conductors, etc. and it comes in many different forms. Fig 2 shows just a very small sample of available designs.

With minor variations, the generally accepted method for designating a wire rope construction in the industry is by describing it numerically. For example:

Whilst "IWRC" wire ropes offer a slightly greater tensile capacity (≈7%) than those with fabric or polymer fillers, the additional strength does not come from the tensile capacity of the core filaments but from improved dimensional stability under load. And whilst they are also much more resistant to crushing, they are stiffer than fibre core ropes and therefore not recommended for applications where tension occurs under bending.

Warrington (Fig 1) is a parallel lay construction with an outer layer comprising wires of alternating large and small diameters, each outer layer having twice the number of wires as the layer immediately beneath. The benefit of this design is to increase packing and therefore strength density, however, unless the different diameter filaments are of the same strength (unlikely), this construction is limited by the strength of the weakest filaments.

Seale (Figs 1 & 2 6x36) is also a parallel lay construction but with the same number of wires in each wire layer. All the wires in any layer are the same diameter. This is an alternative to the Warrington construction, with similar benefits and disadvantages.

Regular lay constructions are used much more widely (than Lang lay) because they have excellent structural stability and less tendency to unwrap under tension (see Rotating vs Non-Rotating below). However, because it has a knobbly (undulating) surface it will wear both itself and any surface over which it is run much more quickly than Lang lay wire rope.

Lang lay constructions have a flatter surface than regular lay constructions giving them better resistance to wear and bending fatigue, especially when made from flattened (elliptical) filaments. They are, however, much less structurally stable and subject to birdcaging if the wire rope is over-bent or twisted against its wrapped direction.

"Regular Lay", multi-strand constructions are normally subject to slightly less rotation under tension (than Lang lay) due to the opposite helical direction of the filaments (within the strands) and the strands (within the rope), however, you can improve their rotation characteristics still further by;

Fillers (Fig 2) may be fabric, polymer or even smaller diameter filaments (e.g. 6x36). Whilst they contribute little to the tensile strength of wire rope, they can significantly; improve performance under bending (fabric and polymer cores only), reduce axial growth, reduce rotation in rotation-resistant constructions, improve structural stability and increase fatigue life.

This filler material should not be included in strength (tensile capacity) calculations, but must be included in those for axial stiffness (extension). If it is ignored, your calculations will reveal excessive extension as the wire rope collapses.

Suspension bridges tend to be constructed from densely packed, single strand plain "Wire Rope" constructions using large diameter galvanised filaments. Little heed is paid to rotational resistance as strength is paramount and once tensioned, they should remain in that loading condition for their design life.

Lifting & winching normally require wire ropes of good flexibility and fatigue resistance. Therefore they tend to be similar to 6x36 but with fibre core instead of the IWRC in Fig 2

Remote operating cables such as hand-brakes and accelerators on cars normally only work in tension so they need to be strong but not necessarily stiff (as they are fully contained in reinforced outer sheaths). These tend to be manufactured from large diameter "TyreCord" or small diameter single-strand "Wire Rope".

Wire rope does not obey Hooke"s law. Therefore, you cannot accurately predict how much it will stretch for any specified force. This unpredictability applies to any section removed from the same manufactured length of cord and even between cords produced to the same specification but by different manufacturers.

CalQlata has decided that the accuracy of axial stiffness (EA) of wire rope falls outside its own levels of acceptability and therefore does not include it in the wire rope calculator. The extension calculated in the Wire Rope calculator (δLᵀ) is based upon the effect of axial tension on packing density. It is therefore important that core material is not ignored when using the calculator to evaluate this characteristic.

Wire rope does not obey Hooke"s law. Therefore, you cannot accurately predict how much it will twist for any specified torque. This unpredictability applies to any section removed from the same manufactured length of cord and even between cords produced to the same specification but by different manufacturers.

CalQlata has decided that the accuracy of torsional stiffness (GJ) of wire rope falls outside its own levels of acceptability and therefore does not include it in the wire rope calculator.

1) No wire rope calculator, whether dedicated or generic, will accurately predict the properties of any single construction under a wide range of loading conditions

2) No wire rope calculator, whether dedicated or generic, will accurately predict any single property for a range of constructions under a wide range of loading conditions

The only wire rope that can be reliably analysed is that which is used for suspension bridges, because; it comprises a single strand, is very densely packed, has negligible twist, contains filaments of only one diameter, is never subjected to minimum bending and every filament is individually tensioned.

There is a very good reason why manufacturers do not present calculated performance data for construction or design proposals, because even they cannot accurately predict such properties and quite rightly rely on, and publish, test data.

During his time working in the industry, the wire rope calculator"s creator has seen, created and abandoned numerous mathematical models both simple and complex. He has gradually developed his own simplified calculation principle based upon his own experience that still provides him with consistently reliable results of reasonable accuracy.

The purpose of CalQlata"s wire rope calculator is to provide its user with the ability to obtain a reasonable approximation for a generic construction, after which, accurate test data should be sought from the manufacturer for the user"s preferred construction.

The calculation principle in the wire rope calculator is based upon changes in the properties of the wire rope that occur with variations in packing density under tension

Bearing in mind the above limitations CalQlata can provide the following assistance when generating (manipulating) the wire rope calculator"s input data and interpreting its output

Alternatively, for wire rope with multiple filament diameters, you need to find an equivalent diameter with the following proviso; you must enter the minimum filament yield stress (SMYS)

It is expected that apart from fillers, all the material in the wire rope will be identical and therefore have the same density, i.e. using different materials will result in less than "best" performance. However, if such a construction is proposed, you can calculate an equivalent density as follows:

It is expected that apart from fillers, all the material in the wire rope will be identical and therefore have the same tensile modulus, i.e. using different materials will result in less than "best" performance. However, if such a construction is proposed, you should enter the highest tensile modulus.

The wire rope calculator simply adds together the total area of all the filaments and multiplies them by the SMYS entered, which represents a theoretical maximum breaking load that would exist if this load is equally shared across all of the filaments and the lay angles have been arranged to eliminate localised (point) loads between adjacent filaments.

If the wire rope has been properly constructed it is likely that its actual break load will be greater than 80% of this theoretical value. However, given the vagaries of wire rope construction, the actual break load can vary considerably dependent upon a number of factors. CalQlata suggest that the following factors may be used to define the anticipated break load of any given construction:

The axial stiffness and strain under load will be affected by this value, hence the reason why the most reliable (predictable) constructions tend to be minimum [number of] strands and single filament diameter. The Warrington and Seale constructions and combinations thereof tend to provide the highest packing density (but lowest flexibility) and there is little to be gained from using these constructions in more than single stranded wire rope as the benefit of high-packing density will be lost with no gain in flexibility.

The anticipated second moment of area of the wire rope at tension "T" due to deformation but insignificant flattening as it is assumed the wire rope will be bent over a formed (shaped) sheave or roller.

The anticipated tensile modulus of the wire rope at tension "T" due to deformation but insignificant flattening as it is assumed the wire rope will be bent over a formed (shaped) sheave or roller.

It is not advisable to induce this bend radius in operation due to uncertainties associated with wire rope construction, especially for dynamic applications. CalQlata suggests that a similar approach to that used for the break load (Fb) above also be applied here, i.e.:

A change in diameter will occur in all wire rope, irrespective of construction, until packing density has reached a limiting value. The value provided in the wire rope calculator is that which would be expected if the construction remains intact at the applied tension "T"

Unreliability of this value increases with complexity in wire rope due to its longitudinal variability and the increased likelihood of premature failure.

The accuracy of this data will range from about ±1% for wire rope with a single strand and a single filament diameter, up to about ±15% for constructions of similar complexity to OTR cord

A change in length of any wire rope will occur due to the fact that the packing density increases with tension. This is not, however, a linear relationship.

This can be an unreliable value as illustrated by tests carried out (by the author) on two pieces of wire rope supplied by the same well-known manufacturer both of which were cut from the same length, varied in tensile capacity by only 1.5%, but the tensile modulus (and strain at break) varied by 34%. Whilst this was an extreme case, significant variations have been seen in wire rope manufactured by a number of manufacturers.

Whilst the wire rope calculator does not calculate axial stiffness (see Calculation Limitations 9) above), CalQlata can suggest the following rule-of-thumb that will provide reasonable results for most constructions at the applied tension "T":

Whilst the wire rope calculator does not calculate bending stiffness (see Calculation Limitations 8) above), CalQlata can suggest the following rule-of-thumb that will provide reasonable results for most constructions at the applied tension "T":

Low complexity means single strand and single wire diameter. Medium complexity means multi-strand and single wire diameter. High complexity means multi-strand and multiple wire diameters.

Galvanized steel ropes in 11 different thicknesses: 1mm, 1.5mm, 2mm, 3mm, 4mm, 6mm, 8mm, 10mm, 12mm, 14mm and 16mm.Equipped with eyelets, hims, as winches, or forestry rope and set for tensioning.The steel ropes are processed in Germany after the DIN-European standard 13414.

Wire rope meter in 11 different thicknesses: 1mm, 1.5mm, 2mm, 3mm, 4mm, 6mm, 8mm, 10mm, 12mm, 14mm and 16mm.Smoothed in five different constructions: 7x7, 6x19, 7x19, 6x37 and 18x7 Available as a rotary wire rope.All offered wire ropes correspond to the DIN EN 13414-1.

galvanized wire ropes with eyelets in the strengths of 1mm to 16mm according to the specifications of the DIN-European standard 13414-2 made in Germany and optimally suitable for many applications.

Our steel cables with box galvanized steel, high quality and strict DIN specifications pressed in 2mm - 16mm strength.The cheese according to DIN6899 protects the wire rope from the inside to the load absorption point.

galvanized steel ropes tension with the help of firmly connected steel cable clamps or in set with clamps, tensionersand sleep.You will receive the sets both with smoothly cut steel rope as well as with a one-sided shew of the compression.

wire rope with hook in different versions: for light suspensions with snap hooks, as choker rope with high-strength sliding hookFor forstarts, steel cable with hooks and eyelets or as a wire rope for winches.The steel ropes are processed in Germany after the DIN-European standard 13414 and are pressed with carabiner hooks, load hooks or eyelethook of Grade 8.

Our steel cables with rope stopper " are compressed from galvanized steel in 1.5mm - 12mm strength and can be opened with an open end,to be ordered a loop or kausche.The one-sided pressed round clamp according to DIN 13411-3 fulfills the purpose of a stop terminal.

forestry ropes in seven different strengths of 5mm - 16mm.Available as choker rope with high-strength sliding hook, stop rope with hook & loop, as well as with grade 8 Load hook.The steel cables are processed in Germany after the DIN-European standard 13414 and are not highly damaged.

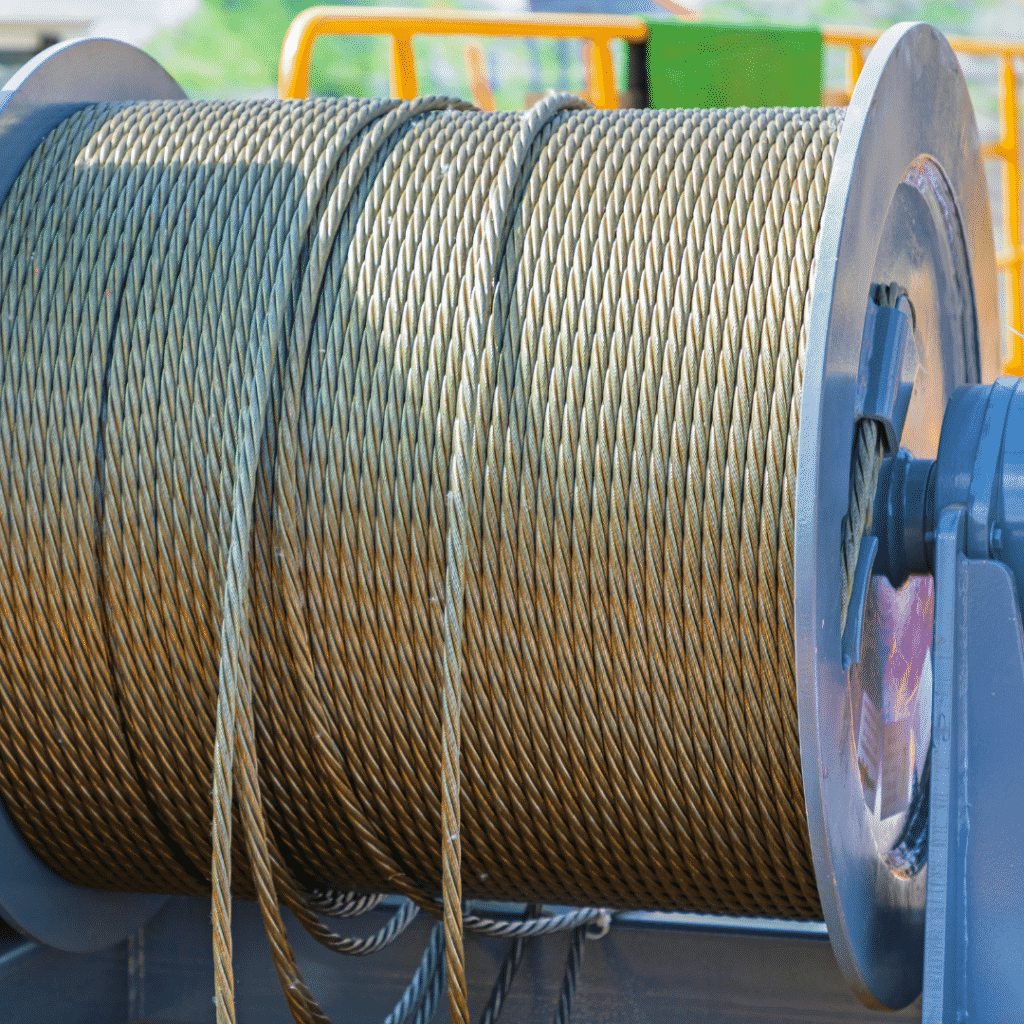

wire ropes for winches in eight different strengths: 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 14mm and 16mm.The wire ropes are made up to a thickness of 8mm annealed, so that fixing in the wind is very easy and easy to use.

Our Rotary wire ropes Get with the construction 18x7 in 5 different strengths. Through the,In opposite directed, strand layers, the wire ropes exert a low torque to an isolated load.The wire rope optimally serves as Hub - or Kranil to lift and depend on appropriate loads.

Labels With a compressed cheese according to DIN 6899 and a glow-separated end in 13 different lengths of 0.5m - 20m, optionally equipped with a wire cable holder and in the strengths of1.5mm - 8mm permanent & fast available.

Wire ropes for garage doors With a compressed cheese to DIN 6899 and a glow-separated end in individual length, optionally pressed with a M10x100 eye screw and in the strengths of 2mm- 5mm permanent & fast available.

Our steel rope sets are equipped with a steel cable and matching clamps, himming and wire ropes.You can choose from both different lengths, different strengths, as well as different equipment.

Our Fuse ropes for the event technique correspond to the BGV-C1 guidelines (security for events and production loads over persons) and can be optimal forLoads of 2kg - 100kg be used.

Our horizontal Rope locking system " SAVEKINGLINE?® corresponds to the DIN EN 795 type C? and serves as fall protection of personsFor the use on high-volume workplaces.The cable locking system is available in variable or defined length.

wire rope for a shoot for three different web lengths: 25m, 50m and 100m.The tension rope is one-sided melted and pressed on one side with a cheaper and equipped with a emergency element.

History of electrical wire & electrical wiring: how to recognize knob and tube electrical wiring and unsafe "extension cord" wiring. We provide a table giving the timeline of years of use of different types of electrical wires or wire insulation and sheathing or jackets followed by a photo guide to all types of old building electrical wires.

In this article series, we list common old building electrical wiring system safety concerns and we illustrate types of old electrical wires and devices. This article series answers basic questions about assessing and repairing the electrical service, capacity, wiring type, condition, and safety in older homes.

... With the increase of electric lighting (which today is used only to a very limited extent as compared with its inevitable future use) and the multiplication of wires, these dangers which exist now in a thousand different parts of the city will be manifolded many times." - source: Thomas A. Edison,

These rusty looking "pipes" may be the last remnants of the oldest and original electrical wiring used for underground electrical power distribution in the U.S. We describe these electrical power cables and provide images of and links to early electrical wiring and wire insulation methods in this article.

In the electrical wire history & old wire identification article below, we illustrate a variety of types of electrical wiring found in older buildings based on the wire insulation material (asbestos, cloth, plastic, metal) and the wire material itself: copper, aluminum, copper-clad aluminum, tinned copper.

Proper identification of the type of electrical wire and wire insulation is useful for those seeking to guess at the age of a building or of its electrical system, and in some instances it is helpful in assessing the condition and safety of the building wiring system, such as taking note of the presence of branch circuit solid conductor aluminum electrical wire that has not been properly repaired - a fire hazard.

Older homes often have electrical receptacles and fixtures that are ungrounded, and many local codes do not require that they be rewired so they"re grounded. Still, grounding is worth adding to your system because it adds protection against electrical shock.

Above: two types of branch circuit electrical wire insulation are shown in our photo: braided fabric wire insulation, probably cotton covered with wax or varnish, and newer plastic wire insulation.

The braided fabric wire insulation was found on a 1960"s fluorescent light ballast, while the plastic wire was used in the branch circuit wiring for the light where that ballast was employed. The old style ballast and its wire could have dated from the 1950"s.

The table below gives approximate dates of origin and use of various types of electrical wire used in buildings. Also see the detailed article we provide for each electrical wire type, as more complete history will be provided in those articles.

Watch out: improper "repair" of aluminum wiring using connectors that do not successfully prevent overheating (CO/ALR, CU-AL-stamped devices, and the Ideal No. 65 purple Twister), may increase the fire hazard in a home and worse, may lead occupants to ignore danger signs of a possible fire, thinking that their wiring is now repaired and safe.

Pulled this stuff out of a house. Couldn"t get over how difficult it must have been to install. Aluminum sheath, cloth covered copper., three wire has loom and filler.

I suspect this was a form of pre-wired "conduit" using semi-flexible aluminum tubing. I"ve included your photo and further comments and research in the article above on this page.

Solid but flexible metal conduit (with rules about just how it may be bent) is using solid aluminum and is one of several forms of pre-wired conduit that was probably intended for use in hazardous areas.

The term "BX" stuck on later versions of flexible metal armored cable: the smaller-diameter modern "BX" wire is in the left of the photo and connects to the left side of the electrical box.

1960 CIRCLE WIRE & CABLE Advertisement [PDF] in Electrical Engineering Magazine, Issue No. 9, Sept.-1960 p. 26A - excerpt shown just above, describes Circlesheath® Type RR armored cable for use underground (buried).

This advertisement describes the company"s products as "Rubber covered wire & cable, varnished cambric cable, plastic insulated cable, neoprene sheathed cable, and cirtub EMT."

Asbestos electrical wire insulation is reported by some websites as "common" but I suspect its use was most common in applications where extra heat resistance and fire safety were a concern, such as theater wiring, electrical appliance wiring, aircraft wiring.

Dini (2006) notes that the earliest wire conduit material (ca 1910) was made of wood moldings grooved to carry the conductors and covered with a wooden cap.

In nearly all new outdoor air conditioner & heat pump installations the electrician uses a pre-wired waterproof electrical conduit whip (photo above).

Above: metal clad cable using solid aluminum semi-flexible conduit pre-wired with fabric-insulated copper conductors, contributed by reader Sean 2019/08/11.

"Pulled this stuff out of a house. Couldn"t get over how difficult it must have been to install. Aluminum sheath, cloth covered copper, three wire has loom and filler."

The photograph of copper-clad aluminum electrical wire shows the wiring sheathing markings [click to enlarge]. This NMC or non-metallic-sheathed cable electrical wire was observed in a 1974 Edina MN townhouse and was connected to an FPE electrical panel.

Unlike aluminum electrical wire used in branch circuits (a fire hazard), copper-clad aluminum wire performs about as well as copper wire and is considered safe for use in homes provided of course that the wiring has been correctly installed.

we explain that the use of zip cord or extension cord mounted on or through walls and ceilings to add lighting circuits or receptacles is improper, unsafe (a fire hazard), and is often an indication that the building does not have enough circuits for modern usage.

See details including the history of manufacturers of fabric-insulated wire along with dates, trademarks, and identifying photographs of a number of these cloth-insulated wire types.

The earliest form of electrical wiring system in buildings in the U.S. was knob and tube: separate hot and neutral wires were hung in air, spaced 2 1/2" or more apart, and insulated from contact with wood framing by ceramic knobs or where wire had to pass through a wood framing member, ceramic tubes.

at KNOB & TUBE WIRING - topic home, where we discuss assessing the condition of knob and tube wiring and issues concerning improper extensions of knob and tube circuits.

Plastic NMC began replacing both rubber wire insulation and fabric-based wire insulation in the U.S. in the 1950"s. PVC here refers to plastics based on polyvinyl chloride.

Plastic or thermoplastic nonmetallic cable such as that shown below, still referred to by many electricians as "Romex" cable, has been in use since the 1960"s and in the U.S. became very widely used in new residential construction by 1970, completely replacing fabric-based wire insulation products.

It"s fair to say that rubber in a somewhat different form was the first electrical wire insulating material, at least in the U.S., dating from Edison"s 1892 patent from which we excerpt this part of Edison"s wire insulation description:

The object of my invention is to effectively insulate wire, so that it will be waterproof and capable of being used in moist places and even under water without detriment to its insulating qualities, and also fire-proof, so that if by accident the wire becomes red-hot the insulating-covering will not be set on fire and burned, but only oxidation will result, which will leave the wire pyro-insulated.

But actually earlier electrical power cable and wiring insulation appeared as rope, tarred fabric, and even wood. However the rubber insulated wire illustrated by Edison"s 1892 patent represented the first economical branch circuit conductor wire insulation approach that could be mechanically and economically produced in high volume.

Above: This wire was a short section of extension cord that had been used to connect a permanently-mounted fluorescent light fixture to power by plugging it into a wall-mounted electrical receptacle.

In our rubber and fabric wire insulation photo below you can see that inside the outer rubber wire jacket these conductors were insulated by fabric-covered rubber.

The color codes (white = neutral, black = hot) can be faded and hard to recognize on these wires unless you strip back more of the insulating jacket. The wire shown below combines the hot and neutral wires in an external rubber jacket. But the earliest electrical wiring systems in the U.S. used the knob and tube system.

The solid copper core was wrapped in rope to insulate it from the iron pipe and the space between that cable and the surrounding iron pipe was filled with a pitch-like substance. - C.M.

In theaters where electrical wiring is often temporary, we often find surprising and possibly unsafe installations. The rubber-coated wires shown below were observed in a New York theatre and looked better than what my brother-in-law Matt, a theatre electrician, could produce.

Above, we see both older fabric-covered electrical conductors and newer plastic-insulated wires in an electrical panel. The bare copper wire that is nearly black was a clue in tracking down a neutral and ground wiring failure at this building.

Above, the same rubber-insulated electrical wire discussed earlier is also used to illustrate the dull silvery colored metal wire observed where tinned copper electrical wiring is installed.

Watch out: tin-plated copper wire is a completely different product that, because its conductors sport a thin plated silver colored surface, might be mistaken for unsafe aluminum wire. It is not aluminum and it is safe unless, as with any electrical wiring, it has been damaged in some manner.

Not all rubber insulated copper wire is plated, but if you suspect that the silvery-colored wire is plated copper, it"s easy enough to determine: with the wire disconnected from any power source, scratch the silver colored surface of the rubber-insulated wire and you"ll see its red copper interior.

Plated copper wire [tinned copper wire] is relatively common in older homes, and it looks like aluminum wire. It was commonly used with rubber-based insulation. Identification can be made by careful inspection of a cut end of the wire.

In general, plated copper wire would not be present in nonmetallic sheathed cable ("Romex"), it is most generally found in metallic sheathed cable ("BX"). Cable of the "BX" type is not likely to contain aluminum wire. - Aronstein (2011)

At TINNED COPPER ELECTRICAL WIRE we provide additional discussion of how to avoid confusing tinned copper wire or tin-plated wire with aluminum wire such as the tinned copper multi-stranded wire shown below.

The heavy fabric braid wires shown in the left of this photo may be mistaken for Wireduct, also referred to as All-Weather Loom - shown below. It is not. This is a fabric- and rubber-insulated multi-strand electrical wire.

Wireduct all-weather loom wire insulation was produced in sizes from 1/4" to 2 1/2" in diameter and was described as having a flame-retardant finish and low moisture absorption.

The asbestos "wireloom" shown earlier on this page may be an example of this product too, designed for improved flame resistance in theaters. You may find wireduct or wire loom on knob and tube electrical wiring systems as well as other older building electrical wiring.

In the unfortunate electrical wiring situation shown above, a reader mailed us this photo of white (probably-asbestos) wire loom-wrapped electrical wires and splices left exposed in the floor of her attic. We caution that with this sort of electrical work visible, one must worry about what other work was done on the building by the same installer.

Wire Loom is still sold as a cabling protection sleeve made in its current (2016) form as a colored nylon flexible slit corrugated tubing or as black polyethylene flexible tubing.

As we illustrate above in Jared"s photos, asphalt-impregnated cloth wire loom is also available and is used in antique and original restoration work (photos adapted from EBay advertisements 2016/02/10). - Thanks to home inspectors Roger Hankey and Kevin O"Hornett for added details about wire loom insulation, 2016/02/09

This is an asphalt-impregnated cotton wire loom typically used in automotive applications. Some antique wire loom products or wiring sleeves are constructed with a combination of asphalt-impregnated cotton/poly paper blend coated with asphalt for moisture resistance.

Following, in order by patent date, are examples of early U.S. patents that help provide dates for types of electrical wiring and electrical wire conductor insulation and insulating sheathing.

The object of my invention is to effectively insulate wire, so that it will be waterproof and capable of being used in moist places and even under water without detriment to its insulating qualities, and also fire-proof, so that if by accident the wire becomes red-hot the insulating-covering will not be set on fire and burned, but only oxidation Will result, which will leave the wire pyro-insulated.

They must be such that the covering, when placed upon the wire, will be flexible, water-proof, and a good insulator, and such that when the wire is heated the covering will not burst into a flame at any temperature up to the melting-point of the wire.

If the wire is to be used in situations where it requires to be bent sharply and so must be very flexible, or if it is to be used in very wet places, then the minimum amount of infusible material which will make the covering non inflammable must be used; also, the amount of rubber to the infusiblc material will vary, according to the character of the latter.

My present invention relates to improvements in that class of electric cables which are especially designed for telephone service, but which are also equally adapted for telegraph purposes, the object being to provide an electric cable wherein the wires or conductors of each metallic circuit are kept equidistant from each other to produce an equilibrium of inductive effect and to provide the greatest amount of separation within the smallest possible space, thereby securing a low specific inductive capacity combined with high insulating properties.

Burley, Harry B., and Henry E. Rooney. INSULATED ELECTRIC WIRE [PDF] U.S. Patent 1,458,803, issued June 12, 1923. Application US534469A filed in 1922.

Our present invention relates to electric wires or cables of the class in which rubber or rubber compound" is used for insulating purposes. Our invention relates more specifically to wires or cables covered by a vulcanized rubber compound designed for use in the transmission of high voltages.

It is found, however, that by this method a point is reached beyond which the increase in the thickness of the wall does not give any commensurate advantages in the voltage carrying capacity of the wire or cable.

to increase their voltage carrying capacity and to render such wires or cables capable of withstanding a higher voltage without increasing the thickness of the insulating wall of wire or cable.

What kind of wiring could this be? It is long-ago decommissioned. Single conductor in a very stiff tar or rubber outer insulation with shiny crystals in it. There is also decommissioned knob and tube in some places, but this wire does not use knobs or tubes.

But in general, if there are only two wires one will be hot (usually red or black) and the other should neutral (usually white but maybe that"s your yellow-green).

Hello I have an old sewing machine, used once. Given to me by a friend. It is wired to fit into a light fitting. Is it possible to convert to a regular plug fitting. The wires are one red, one yellow with green stripe. Thanks

XLP wire is currently sold with stranded copper or aluminum conductors in larger sizes such as may be used for service entry wiring and in smaller sizes using a solid copper conductor for branch circuit wiring used where burial or resistance to moisture or to oil and gas is required.

XLP is popular for use as an alternative to EPR (Ethylene Propylene Rubber insulated wire) where a tougher insulation with more resistance to chemicals is needed.

Keep in mind that XLP wire (rated for wet or burial) can also be used in dry locations and above-ground, as it’s also rated to perform against exposure to sunlight. It can also be run in conduit, raceways, and overhead. XLP USE wire is suitable where you might have run RHH and RHW-2 in either wet and dry residential or industrial applications.

In sum, XLP-use wire is similar to other XHHW building wire except for its additional rating for burial. In some references this same wire might be referred to as RHH/RHW wire meeting UL 854 for SEC applications.

A friend just replaced an old undergroung (urd) service that was 4/0 copper with a #2 open neutral direct buried. The cable says rome-xlp wire cable. The house was built in the 60"s I would guess & they were upgrading the service.

A doorbell wire or "bell wire" will normally be low-voltage, 24VAC, powered by a low voltage transformer somewhere in your home, often near the electrical panel.

If the damage is just at that connection and if you have enough spare length, cut back the damaged wire. Or if necessary, it"s reasonable to wrap it in electrical tape.

We purchased a home, and any wire we can see looks new. I went to pull off the nest doorbell to update it to use our account, and found the following wires. Notice the bare wire section. I wrapped it in electrical tape for now. What kind of wire is this, and should I be concerned?

Hows it going trying to see if anyone else has came across this very very old Lead/’possibly silver infused & or plated. Ive never in my life seen anything like it. And its thin stranded wire wirh just paper wrapped aroound each indiviual wire.

Without being on site with a voltmeter to test each wire to be absolutely certain that we know how they are used I"m afraid it"s a bit dangerous for me to tell you what someone else connected.

You"ll see that wires are sent from the incoming Supply voltage to the ballast and from the ballast to the terminals on the fluorescent light fixture and perhaps through a starter cartridge.

We live in a mid-50s strawberry box home and redoing the electrical. There"s an old disconnected 8 gauge fabric wire that travels from the basement (where the panel is) to the 2nd floor (and possibly to the attic. Does know anyone know what it could have been used for?

The electrical safety with respect to the absence of a grounding conductor (ground wire) in knob and tube wiring and in an insulated wire that pairs the hot and neutral wires together but still with no ground, is identical.

- the condition of the wire and its insulation: if the insulation is damaged then it is less safe than when new and in some positions and conditions - such as where someone could touch it and be shocked or where there could be a fire risk - would be unsafe.

- my OPINION and that of some others in the field is that knob and tube wiring, because the hot and neutral wires were run separately and separated by several inches, was inherently safer than wires run together in the same jacket, should both wire sets suffer equal extent of damage to their insulation.

That"s because the K&T wires are not only so far apart at most locations as to significantly reduce the risk of a hot-to-neutral short, but also because even where they are supported on or pass through wood framing, the wires are carried on porcelain insulators.

Arguing with myself by adding a dose of real-world conditions: knob and tube, generally never declared as "illegal", may in many buildings be at greater risk of overheating and thus risking a fire because over the ensuing life of a building from its original installation - run in open air - the K&T wires may now be completely covered by added-on building insulation.

That addition violates the original design that depended on being suspended in air to handle the heat generated by use of the circuit. The result exposes the wires to overheating and damaged insulation and thus increased hazard.

Watch out: for an inch or so (at least) back from its connection to the device the insulation is damaged and partly-lost on at least the neutral wire. I can"t see the rest of the wire"s insulating jacket - check outside the electrical box and along the wiring passage.

@Inspectapedia Com Moderator, Thank you for your reply! I believe it to be tinned copper wire. How much of a risk is the cloth jacket with the degraded rubber insulation inside? Do you believe this type of wire to be as much of a risk as knob and tube wiring?

Condition: fabric itself isn"t innately a defect, it"s the condition of the wire that matters: cracked, damaged, missing, burned, overheated, rat-chewed insulation - needs new wiring in those cases

Watch out: Old electrical wires using rubber insulation are often sporting cracked fragile rubber that may crumble when the wire is handled. Poor-condition rubber wire insulation may reach that state from age alone or from having been exposed to harsh conditions or to overheating.

I bought a house built in 1936, and the previous owner claimed the knob and tube wiring was replaced. Sadly, about 50% of the wiring is as pictured below. Ungrounded and with cloth fiber insulation. It has a black cloth jacket, with two cloth insulated wires inside and a fragile rubber-like insulation against the copper. It"s everywhere in the house

. I"m concerned about the safety of this wiring and I would like to know if this is likely from 1936. I can"t see any knob and tube wiring in the basement or the attic. These wires are simply put through holes in the joists or stapled to the sides of them. I see some more modern wire with a cloth outer jacket and modern plastic insulation, which I guess was from the 1950"s or so, but the majority is as pictured.

Before that there were some standards such as requirements for wire insulation and wire sizes versus current or amps the wires could safely carry (without overheating to cause a fire) earlier, at least in New York by the NY Board of Fire Underwriters in 1881, and more national wiring standards were in place by 1893.

(The very first national electrical code in the United States, produced by the National Board of Fire Underwriters, was completed by 1897 but without wire color codes).

The electrician might, in the wire cable entering the electrical panel, find the neutral wire and follow in the panel it to its connection on the neutral bus.

Now back at the electrical box the ground wire will show continuity to ground using it an ohm-meter or continuity tester, and the neutral wire should not, since it has been disconnected at its other end.

Aronstein, Jesse, and Wilfred E. Campbell. "Failure and overheating of aluminum-wired twist-on connections." Components, Hybrids, and Manufacturing Technology, IEEE Transactions on 5, no. 1 (1982): 42-50.

Aronstein, Jesse, and Wilfred E. Campbell. "The influence of corrosion inhibitor and surface abrasion on the failure of aluminum-wired twist-on connections." Components, Hybrids, and Manufacturing Technology, IEEE Transactions on 7, no. 1 (1984): 20-24.

Dini, David A., Thomas Z. Fabian, and J. Thomas Chapin. "An analytical study of some physical properties of wire and cable samples collected from older homes." [PDF] Underwriters Laboratories Inc (2006). David Dini, Northbrook, Ill. Tel: 1.847.664.2982;

The utility model has a towed body 3, and it can keep the stable of whole hydrophore.Submersible pump 1 is equipped with in the middle and lower part in this towed body 3, and the latter"s afterbody connects a cable 14, and the joint of this cable 14 must be sealed with water-fast glue, guarantees safe and reliable.Sensor 2 is equipped with in the middle and upper part in this towed body 3, the latter"s a end connects a cable 13, the water inlet of water pipe 4 is communicated with the water delivering orifice of submersible pump 1, and this water inlet and water delivering orifice are fixed together with pipe collar 5, water pipe 4 protrudes upward towed body 3, the upper end of suspension hook 7 by cementing in together with marine glue between shackle 9 and the nylon cable tie 10, places the top of water pipe 4 by wirerope 8.Suspension ring 6 hang on the coupler body of suspension hook 7, and the lower end of suspension ring 6 is connected with two hangers on towed body 3 tops by two wire rope; Cable 13 and 14 places a side of water pipe 4 by adhesive waterproof tape 11,12.

When using the pollution-free hydrophore of this pull-type, one worktable at first is set on the boat deck, configure power supply, connect depth of water tester, automatic stamper or computer, the above lifting crane of one two tonnage is set simultaneously, is preferably whilrley crane, and the hand winch of a simple and easy coil pipe, water pipe 4 and cable 14, cable 13 dishes on winch, are got final product with manually discharging suitable length according to the pollution-free hydrophore underwater penetration of pull-type.During work the pollution-free hydrophore of pull-type is hung on the steel wire rope hook on the crane by wirerope 8, suspension ring 6, require to start crane according to the trial of water sampling and fluctuate and control underwater penetration, can gather the water sample of different aspects easily by fluorescent screen reading on the monitoring instrument.Entered by the water gathered inlet opening, be collected through submersible pump 1, water pipe 4 from towed body 3 front portions.For preventing that cable 14, cable 13 from twining with wire rope water pipe 4 under water, adopt nylon cable tie that water pipe 4, cable 14, cable 13 threes are bundled, and be hooked on the sling cable with shackle, utilize the weight entry of body and suspension hook, core hangs up counterweight below the pollution-free hydrophore of pull-type in case of necessity, cause pollution-free hydrophore to produce bigger gradient under water with regard to having avoided because of the resistance of ship"s speed and water like this, promote after hours, with manually unloading ring, be separated from wire rope and shake winch, will get final product on the water pipe dish.

More often than not, the terms wire and cable are used to describe the same thing, but they are actually quite different. Wire is a single electrical conductor, whereas a cable is a group of wires swathed in sheathing. The term cable originally referred to a nautical line of multiple ropes used to anchor ships, and in an electrical context, cables (like wires) are used to carry electrical currents.

Whether indoors or outdoors, proper wire and cable installation is of paramount importance - ensuring a smooth electricity supply, as well as passing electrical inspections. Each wire and cable needs to be installed carefully, from the fuse box to the outlets, fixtures and appliances. The National Electrical Code (NEC) and Local Building Codes regulate the manner of installation and the types of wires and cables for various electrical applications.

Some factors that will affect your choice of electrical wiring include color, label information and applications. The information printed on the electrical wire covering is all that you need to choose the correct wire for your home. Here’s some detailed information on the various features of electrical wire, which will help you choose the correct composition:

Each application requires a certain wire size for installation, and the right size for a specific application is determined by the wire gauge. Sizing of wire is done by the American wire gauge system. Common wire sizes are 10, 12 and 14 – a higher number means a smaller wire size, and affects the amount of power it can carry. For example, a low-voltage lamp cord with 10 Amps will require 18-gauge wire, while service panels or subpanels with 100 Amps will require 2-gauge wire.

Triplex Wires : Triplex wires are usually used in single-phase service drop conductors, between the power pole and weather heads. They are composed of two insulated aluminum wires wrapped with a third bare wire which is used as a common neutral. The neutral is usually of a smaller gauge and grounded at both the electric meter and the transformer.

Main Feeder Wires : Main power feeder wires are the wires that connect the service weather head to the house. They’re made with stranded or solid THHN wire and the cable installed is 25% more than the load required.

Panel Feed Wires : Panel feed cables are generally black insulated THHN wire. These are used to power the main junction box and the circuit breaker panels. Just like main power feeder wires, the cables should be rated for 25% more than the actual load.

Non-Metallic Sheathed Wires : Non-metallic sheath wire, or Romex, is used in most homes and has 2-3 conductors, each with plastic insulation, and a bare ground wire. The individual wires are covered with another layer of non-metallic sheathing. Since it’s relatively cheaper and available in ratings for 15, 20 and 20 amps, this type is preferred for in-house wiring.

Single Strand Wires : Single strand wire also uses THHN wire, though there are other variants. Each wire is separate and multiple wires can be drawn together through a pipe easily. Single strand wires are the most popular choice for layouts that use pipes to contain wires.

To determine the correct wire, it is important to understand what ampacity and wattage a wire can carry per gauge.Wire gauge is the size of the wire, ampacity is how much electricity can flow through the wire and wattage is the load a wire can take, which is always mentioned on the appliances..

Non-Metallic Sheathed Cable : These cables are also known as non-metallic building wire or NM cables. They feature a flexible plastic jacket with two to four wires (TECK cables are covered with thermoplastic insulation) and a bare wire for grounding. Special varieties of this cable are used for underground or outdoor use, but NM-B and NM-C non-metallic sheathed cables are the most common form of indoor residential cabling.

Underground Feeder Cable : These cables are quite similar to NM cables, but instead of each wire being individually wrapped in thermoplastic, wires are grouped together and embedded in the flexible material. Available in a variety of gauge sizes, UF cables are often used for outdoor lighting and in-ground applications. Their high water-resistance makes them ideal for damp areas like gardens as well as open-to-air lamps, pumps, etc.

Metallic Sheathed Cable : Also known as armored or BX cables, metal-sheathed cables are often used to supply mains electricity or for large appliances. They feature three plain stranded copper wires (one wire for the current, one grounding wire and one neutral wire) that are insulated with cross-linked polyethylene, PVC bedding and a black PVC sheathing. BX cables with steel wire sheathing are often used for outdoor applications and high-stress installations.

Unshielded Twisted Pair Cable : Like the name suggests, this type consists of two wires that are twisted together. The individual wires are not insulated, which makes this cable perfect for signal transmission and video applications. Since they are more affordable than coaxial or optical fiber cables, UTP cables are often used in telephones, security cameras and data networks. For indoor use, UTP cables with copper wires or solid copper cores are a popular choice, since they are flexible and can be easily bent for in-wall installation.

Ribbon Cable : Ribbon cables are often used in computers and peripherals, with various conducting wires that run parallel to each other on a flat plane, leading to a visual resemblance to flat ribbons. These cables are quite flexible and can only handle low voltage applications.

Cable size is the gauge of individual wires within the cable, such as 14, 12, 10 etc. – again, the bigger the number, the smaller the size. The number of wires follows the wire-gauge on a cable. So, 10/3 would indicate the presence of 3 wires of 10-gauge within the cable. Ground wire, if present, is not indicated by this number, and is represented by the letter ‘G’.

Safety is very important, and if your installation of wires and cables is not proper, it could lead to accidents. Before you start any electrical project that includes wiring and cabling, you need to obtain permission from your local building inspector. Once the job is done, get the installation inspected for compliance with local codes and regulations.

Basic guardrail components come in a variety of materials and configuration options. It is common for employers to use material available or produced at the worksite. Upright supports may be made from wood, formed metal, pipe, or composites. Wire rope is sometimes used for the top rails and midrails.

Premade guardrails are particularly susceptible to damage if not handled properly when disassembled and stored. Specific handling instructions are typically included in the manufacturer’s recommended procedures for disassembling and storing the guardrail components. If railing components are bent, broken, or missing, the guardrail may not be effective. Damage is more likely to occur if the components are dropped when disassembled, transported in vehicles, or stored in areas not protected from conditions that could cause corrosion or distortion.

Covers for permanent holes are typically built for a specific purpose (e.g., permanent access points, manhole covers, and trap doors) and are only effective when they are properly designed and secured in place.

A warning line system is a barrier erected on a flat or low- sloped roof to warn workers that they are approaching an unprotected roof side or edge (see 29 CFR 1926.500(b); 29 CFR 1926.501(b)(10); Figure 11). A warning line system includes a line (rope, wire, or chain) and supporting stanchions (see 29 CFR 1926.502(f)(2)).

PFAS components will be marked by the manufacturer with pertinent information specific to the equipment, such as warnings, serial/model number, capacity, and the materials used to make the component (see Figure 14). Information (e.g., proper use, maintenance, inspection) about fall protection components is typically provided in equipment manuals.

Many factors can contribute to a workers’ risk of falling from an elevated work area. Examples include precarious work positions, excessive leaning or reaching, improper work practices, unstable structures, trip hazards, slippery surfaces, and distractions.

When guardrails are not an option, personal fall protection equipment is helpful in some situations, but only when properly selected, worn, and attached to an adequate anchor point.

A personal fall arrest system was not a good choice in this case. In the illustration below, the trusses were not fully installed, braced and sheathed, so they did not form a sufficiently strong anchor point. The structure collapsed when it received the sudden force of the falling worker.

A lanyard is a flexible rope, wire rope, or strap which generally has a connector at each end for connecting the body belt or body harness to a deceleration device, lifeline, or anchorage point (see 29 CFR 1926.500(b)). Some manufacturers offer adjustable length lanyards. Effective lanyards are maintained in a clean, intact condition, and inspected prior to each use for wear, tear, and any obvious distortion or signs that the fall arrest (energy-absorbing) system has been activated (see 29 CFR 1926.502(d)(21)).

Lifelines function as an extension of an anchorage system, allowing an employee to move up and down (vertical lifeline) or back and forth (horizontal lifeline) across a work area. A sliding fitting (rope grab or shuttle) connects to the line and a lanyard connects the worker’s harness to that sliding fitting.

Even when a PFAS works properly, the fallen worker is still in danger. The worker"s body weight places pressure on the harness straps, which can compress the veins, and cause blood to pool, in the lower extremities and reduce blood return to the worker"s heart (see Figure 17). This condition is called suspension trauma, also known as harness hang syndrome. In medical terms, this results in orthostatic intolerance. If the pressure is not reduced promptly, the worker can lose consciousness within minutes. (See Suspension Trauma/Orthostatic Intolerance, OSHA Safety and Health Information Bulletin.

With proper personal fall protection equipment, training and practice, a fallen worker can take steps to minimize suspension trauma. Self-rescue methods allow a fallen worker to temporarily relieve pressure on the legs or in some cases to even lower himself or herself to the lower level. Self-rescue methods are discussed in detail in Washington Industrial Safety & Health Division"s Fall Protection Responding to Emergencies.

No further calculations are necessary. The free fall distance can be reduced by moving the anchor above the D-ring. For example, if a section of truss has been stabilized and sheathed, the anchorage point might be moved above the worker’s head.

A competent person sees that the trusses in the adjacent section have been installed, fastened in place, and sheathed, and are stable enough to serve as an anchorage. An anchor is installed 2 feet above the back D-ring on the worker"s harness. What is the total fall clearance distance?

Both a personal fall arrest system and a guardrail system with a minimum 200 pound top rail capacity (when the platform is supported by ropes); guardrail system only (when the platform is supported by the frame structure)

Typically used on a house roof after it is sheathed or fully constructed. They are typically left in place after the job is completed for future repairs.

Used before a structure is fully framed. A spreader is a method a qualified person may use to improve anchor point lateral stability before trusses are fully sheathed.

Rope lifeline attaches to an anchorage at the top and hangs vertically down through the work area. Movable rope grab attaches to the rope. Lanyard connects the rope grab to workers’ harness. To move up and down the work area, the worker can slide the rope grab up and down the lifeline, then relock it in place. If the worker falls, the rope grab locks onto the rope to break the fall. This system’s effectiveness depends on how well the worker is trained to reposition the rope grab while moving about. The grab can slide off the end of the rope if the rope is too short, if a knot is not tied near the end of the rope, or if the grab is not installed properly.

The lifeline is wound on a reel and automatically extends or retracts to take up slack in the line as the worker moves about. A sudden extension in the line activates a locking mechanism that typically includes a deceleration device. Some self-retracting lanyards can be set to restrict the distance traveled and so can also function as part of a properly designed fall restraint system.

Thimbles provide a protective interface between the eye of a rope loop and a connector. They are used to prevent pinching or abrasion of the rope. The thimble needs to be firmly seated in the eye of the rope loop.

8613371530291

8613371530291