sheave design for wire rope brands

Precision CNC machining, turning and milling services. Capabilities include bending, waterjet cutting, routing, forming, drilling, casting, urethane molding, additive manufacturing (3D printing) and welding. Works with rubber, polyurethane, nylon, acetal, polycarbonate, acrylic, fiberglass reinforced plastics (FRP), laminates, PVC and other plastic materials. Manufacturer of custom and standard truck parts, bumpers, gaskets, seals, bushings, trays, anti-vibration or manifold grommets, caps and vibration mounts. Bearings, sheaves, pulleys, channels, nozzles, profiles, sprockets, outrigger pads, strip doors, elbows, rollers, matting, barriers, ceramic and truck liners are provided. Prototypes, short and high runs production volumes are offered. Materials are available in the form of sheets, tubes and rods. Serves agricultural, aggregate, biomass, construction, marine, port, material handling, mining, oil, gas, retail, transportation, automotive, food and beverage industries.

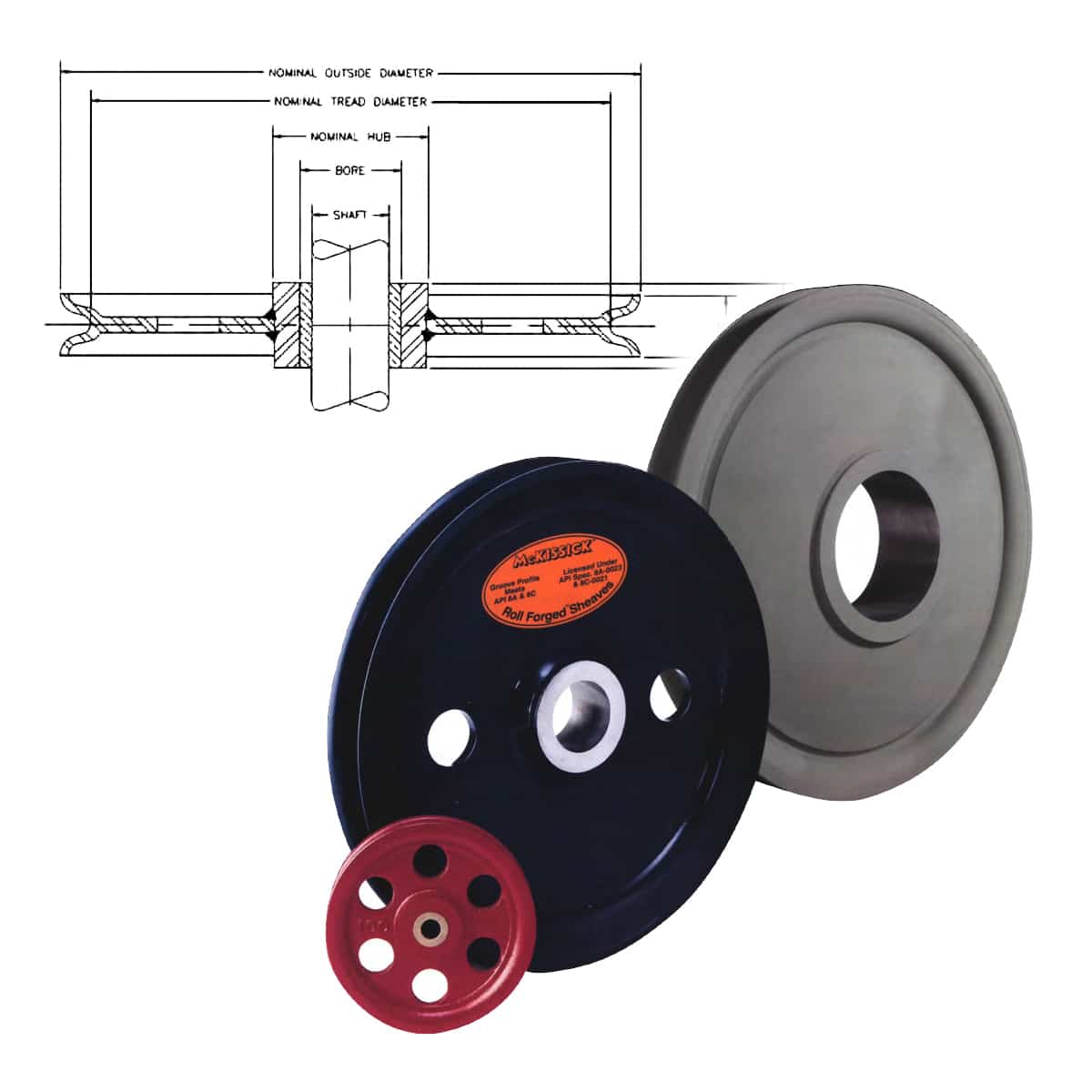

Unique upset roll forging process provides a thicker groove section for extra strength.Stepped Hubs are precisely centered and mechanically locked in place.

Throughout our history, the dedicated team at Sheaves Inc. helped us expand our service to differing industrial sectors that required sheaves. As a result, we decided to better serve our customers needs through creating dedicated brands, such as QSheaves™,to serve our industries and markets with identifiable, focused offerings. Above all else, We pride ourselves on our quality products and excellent customer service, as well as our continual desire to look for innovative ways to meet your needs.Our brands reflect these values, and the unique industries each serves, all continue to carry on the tradition of providing responsibly engineered designs and the high quality standard of products our customers have come to expect. Whether you need a pulley for wire rope, cable manufacturing, or other lifting applications, we have everything you need all in one place.We thank all our customers who have remained loyal to us, and have seen us through our transition.

Esheaves offers the Wire Rope sheave solution to tackle any challenge you face. From strength, to availability, to like -for- like replacement, there is no heavy duty sheave application we can’t assist you with. If you need assistance selecting the best solution for your project, contact us directly to speak to a member of our knowledgeable engineering staff.

The Crosby Group has a long history of delivering quality products and innovative processes through the years. In 1978, Crosby, with the partnership of McKissick, invented the roll forged sheave. When it comes to sheave design and manufacturing processes, Crosby is still the leader in the industry, with sheave centers across the world that focus on providing products for each local market. Locations include Putte, Belgium; Singapore; Hangzhou China; and Tulsa, Oklahoma (USA).

Not only does Crosby stock key materials, it has the manufacturing capacity to provide short deliveries, as well as operational and technical support. This enables every team to learn more about the product and material they will be handling. Crosby offers roll forged sheaves that provide an upset meta flow without creating a stress zone at the splitting point. The dome-reinforced sheave design provides for a continuous weld in a circular pattern.

Sheaves produced come in: 30, 35, and 45-degree profiles. The McKissick roll-forged sheave is available in the following: plain bore, bronze bushed, roller bearing, tapered roller bearing, lubrication thru hub, key ways, set screws, full complement bearing.

All products have been tested for underwater and hard environment uses, giving the client confidence in using sheaves for all applications. In addition, Crosby has achieved API Q and TS29001 statues and are licensed to manufacture sheaves to API 8C and provide to API, DNVA, and ABS requirements.

Crosby Roll-Forged Sheaves have a reputation of reliability you can depend on. First, teams must know which type of sheave needs to be used on the job. The type of project, duration, and environment all determine the type of sheaves that is required, as well as the maintenance schedule for the product.

Designing and manufacturing sheaves requires the ability to creatively use industry experience and resources to provide the best solutions for the product user. McKissick is a name known for providing sheaves to the lifting and energy industry since the 1900s. Since its partnership with The Crosby Group, and Crosby’s invention of the roll forged sheave in 1978, the two brands continue their leadership in sheave design and manufacturing.

Knowing which type of sheave you should be using is essential. Everything from the type of equipment to the maintenance schedule must be tailored to the specific job and environment in which you are operating.

Stress failure in the weld is common in traditional hub designs, but the stepped hub design eliminates stress failure. The hub is pressed into place with metal-to-metal contact, which ensures an accurate alignment to the hub’s axis. This helps to make sure there is no wobble or lopping of the rotating sheave. With the precise alignment of both the hub and sheave wheel, this extends the life of the bearing and enables the sheave to be on the job longer.

Crosby’s hardening process is a science and has been perfected over the years. It allows for maximum hardness on wear-resistance across the contact area for the wire rope. The sheave groove is flame hardened to a minimum 35 Rockwell C for a 140 degrees contact area with the wire rope. The solid steel plate is an ideal surface for flame hardening and an acceptable fit to the wire rope. This helps to reduce fatigue and wear.

Roll-forged sheaves are available in a variety of different sizes, from 12 inches to 78 inches. We have a great selection of bearing styles that will meet your needs. For those looking for a specialty sheave, The Crosby Group can manufacture custom sheaves and make small modifications to standard sheaves.

When it comes to forming the groove and flange walls, Crosby does this in multiple steps. The upsetting and roll forging process eliminates the need to split and weaken the groove and adds strength to the groove section. We have complete confidence in our exclusive forging process. And, because it’s forged to distribute the wire rope forces evenly over an accurately formed load surface, this extends and maximizes life performance of the sheaves. In addition, uniformity of the roll forged groove adds longer wire rope.

Every sheave starts as a single piece of solid carbon steel plate. Then, it’s flame-cut from closely checked stock to ensure that there is no inherent web/rim flaw. There’s exceptional balance and better distribution of forces with Roll-Forged sheaves. Casting can result in groove wall variations. It’s either too thick or too thin which causes uneven stresses and can lead to early failure.

Domed Roll-Forged sheaves are welded in a circular pattern. This eliminates the higher stresses created by welding ribs and other forms of stiffeners.

Domed reinforced Roll-Forged sheaves are available in sizes 24 inches and larger. Different bearing styles are available that can ideally fit your job operations.

For those in need of “extreme duty sheaves” domed Roll-Forged sheaves have the strength, fatigue, and rigidity needed for high operational stress and side loading.

Closed die forged sheaves are available in sizes from 4 inches to 12 inches. They are a highly effective solution for heavy duty operations where high loads are applied.

These sheaves are a solution for light or normal duty operations where sheaves are protected by sheave guards and minimal side loads are used. Standard roller bearings and bronze bushings are usually appropriate for these uses.

BearingsSelf-Lubricating Bronze Bushings:Appropriate for work environments in which it’s difficult to get to the bearings for re-lubrication on a regular basis.

Re-oiling self-lubricating bronze bushings will extend their life.Common or Plain Bore Sheaves:These bearings are for very slow line speeds, infrequent use, and light loads, such as hand operating or manual power hoist applications.

If operation is intermittent, they should be lubricated every 14 days.Straight Roller Bearings:Best suited for jobs requiring medium loads and high-speed operation.

Should be lubricated every 14 days for intermittent operation.Tapered Roller Bearing:These bearings are designed for use with heavy loads and work environments requiring high-speed continuous operation.

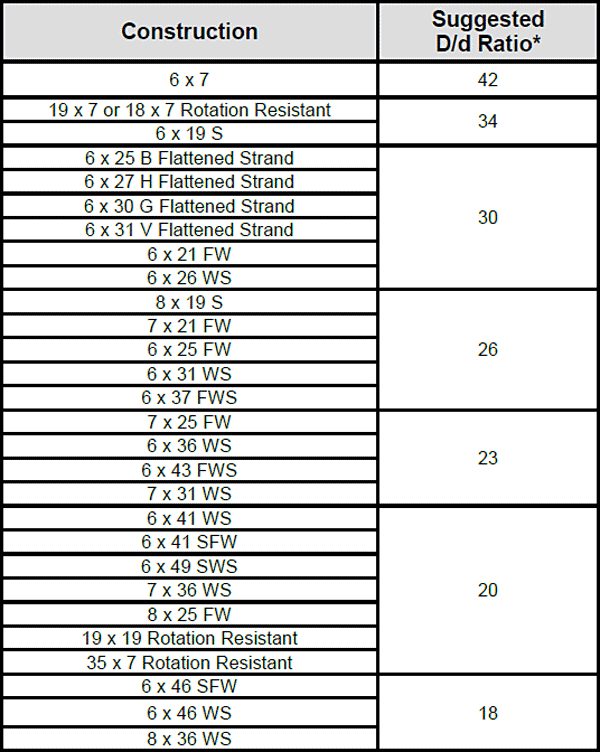

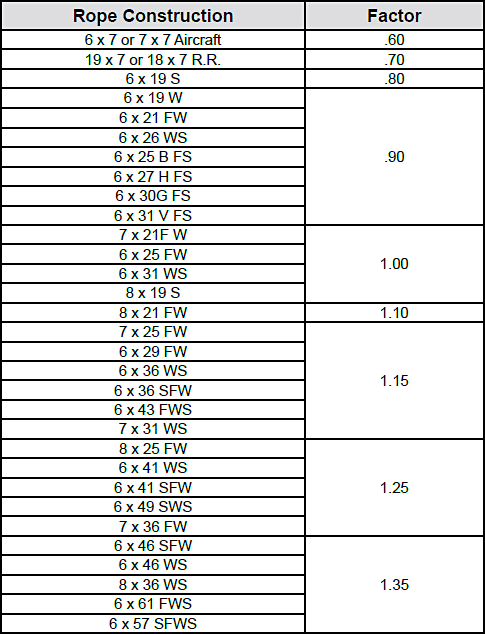

Make sure the sheave groove is matched with the wire rope diameter. Unmatched conditions can result in premature ware of the rope and sheave. The size relationship of wire rope and sheave is critical to safe and efficient performance.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

WS Hampshire fabricates many types of sheaves for applications in the heavy equipment industry. One of these settings is floating and shipboard cranes, where sheaves must withstand harsh marine environments. Sheaves also run conveyors on material processing equipment. In addition, fire trucks utilize our sheaves for rescue pulley systems.

Medical: extrusion equipment, scopes, surgical robots, surgical tables, recovery beds, strand annealing furnaces, wire drawing equipment, traction equipment

Industrial nylon sheaves offer many benefits, especially compared to metal sheaves:Lightweight construction: Compared to metal sheaves, nylon sheaves are much lighter, reducing the overall weight of the system without compromising durability.

Longer cable/rope life: Nylon sheaves are more elastic and allow a larger contact surface area between the groove and the rope or cable, distributing the load more evenly and reducing stress. As a result, the entire system benefits from reduced maintenance and cost savings.

Reduced operating costs: Because nylon sheaves last longer than metal sheaves, they do not need to be replaced as often. Facility managers can also order lubricated grades of nylon sheaves, eliminating the need to purchase and apply lubrication separately.

Nylon sheaves are strong, durable, and reliable in heavy-duty lifting operations. WS Hampshire custom-fabricates nylon sheaves, replacing traditional metal sheaves. Since the 1890s, WS Hampshire has been providing custom nonmetal solutions with our CNC machining, stamping, punching, vacuum forming, rotary die, and assembly services. Today we specialize in replacing conventional materials with ones that are a better fit for their application, saving our customers time and money.

Sheave Wheels are available in a wide range of standard sizes. In addition, sheave wheels to meet your special design requirements can be produced in virtually any size, configuration and surface finish condition. These sheave wheels are made from carbon and alloy steels for long life. Most of our sheaves are used in liftingread more...

Manufactured using carbon, cast iron, cast steel, alloy steel and other requisites, we provide a wide range of superior quality Block Wire Rope Sheaves. Owing to their high durable finish standards, these sheaves are used in variety of materialread more...

To become one of the remarkable market names, we are exquisitely involved in rendering an inclusive array of Rope Sheaves. In order to acquire utmost level of client credibility and trust, these are accessible with us in a range of provisions at inexpensive costs. Together with this, our facility of customization has earned usread more...

Westech Rigging Supply rigging and safety gear is only intended to be used by competent trained professionals. Misuse of the rigging and safety gear can result in serious injury up to and including loss of life. As such, Westech Rigging Supply disclaims liability for any misuse or incorrect product selection by our customers.

Rigging and safety gear purchased from Westech Rigging Supply should be used in strict accordance with all industry and OSHA standards. At no time should rigging or safety gear be used beyond its certified load ratings (aka Working Load Limits). Normal wear and tear should be expected with use of rigging and safety gear; therefore, all gear should be thoroughly inspected before each and every use. Worn or unsafe rigging and safety gear should never be used.

Stepped hub design proves better.The McKissick hub is stepped to eliminate stress failure in the weld, common in traditional hub designs. The hub is pressed into place with complete metal-to-metal contact. This helps ensure an accurate alignment to the hub’s axis so there’s no wobble or lopping of the rotating sheave. The precision aligned hub/sheave wheel combination adds to the bearing life and keeps the sheave on the job longer.

Closed die upset and roll forged – not split.Upsetting and roll forging forms the groove and flange walls in multiple steps, eliminating the need to split and weaken the groove. This exclusive forging process adds extra strength to the critical groove section. You can count on a McKissick sheave to give maximum life performance, because its forged to distribute the wire rope forces evenly over an accurately formed load surface. Plus, uniformity of the roll forged groove adds longer wire rope life.

McKissick roll forged sheaves are available in a full range of sizes fom 305mm to 1829mm, and bearing styles and prices that best fit your application. Crosby also manufactures custom McKissick sheaves and can make minor modifications to standard sheaves as needed for special applications.

Solid steel – no castings.Every McKissick sheave starts as a single piece of solid carbon steel plate. It’s flame - cut from closely checked stock, so there’s no inherent web/rim flaw as you find in cast sheaves. There’s better balance and better distribution of forces with a McKissick roll forged sheave too. Casting can result in groove wall variations - either to thick or to thin - causing uneven stresses and early failure.

Flame hardened groove.Crosby’s hardening technique is a science. It provides a precise maximum hardness for wear-resistance across the wire rope contact area. The McKissick sheave groove is flame hardened to a minimum 35 Rockwell C for a 140°, contact area with the wire rope. The solid steel plate provides the ideal surface for flame hardening an a closer tolerance fit to the wire rope fatigue and wear.

McKissick sheaves come in a variety of sizes to suit your specific applications. Check the tables for the size, bearing style etc. that best fit your application. For applications that require unique specifications Crosby can make minor modifications to many of the sheaves listed at a reasonable charge. We can also custom design and manufacture sheaves to your exact requirements. Contact Certex Sales to order McKissick sheaves and include the stock number and quantity. For special requirements or custom designed sheaves, furnish the following important information:

8613371530291

8613371530291