sheave design for wire rope pricelist

Above all else, we are an engineering firm that can take your technical requirements for sheaves and translate them into cost effective solutions to meet or exceed the performance required of your application. Selection of the proper sheave material plays an important role in ensuring strength, durability, and overall performance in your application. Sheaves Inc. has been the number one source for the wire-rope industry, designing and providing custom engineered wire rope sheaves that meet your specific needs and rigors of your application. Trust our engineering expertise, and let us suggest a suitable material in your next challenging application.

Light weight option for high speed applications. Resistant to chemicals, temperature, and corrosion. Durable in wire and cable processing applications

Our custom process sheaves are most often machined from Gar-Dur, the densest, toughest thermoplastic today. GAR-DUR properties, such as toughness and abrasion resistance with light weight, make it ideal for high speed sheaves processing wire and cable.

Manufacturing methods limit GAR-DUR material to 23″ OD and 2″ OAW. For sheaves beyond those dimensions we use virgin UHMW cut from stress-relieved sheets.

HDPE has similar properties to UHMW but lower properties and prices. Ideal for tubing, hose, synthetic rope, and similar materials that have less demanding wear and load requirements.

Ceram-P is ceramic filled UHMW recommended for high load and severe sliding abrasion. It is a shatter resistant alternative to sintered ceramic but substantially heavier and more expensive than UHMW.

Esheaves.com offers custom solutions engineered to meet the exact requirements of your application. From the strength and durability of a nylon sheave, to the rapid shipping and stock availability of Q sheaves, we will help you meet any challenge. If you don’t see the customizable options you need, we’ll engineer a complete, original solution just for you!

Know the sheave material you need? Visit the eSheaves shop to select from a variety of sizes, materials, and bearing types in stock and ready to ship.

Above all else, we are an engineering firm that can take your technical requirements for sheaves and translate them into cost effective solutions to meet or exceed the performance required of your application. For over fifteen years now, Sheaves Inc. has been the number one source for the wire-rope industry, designing and providing QSheaves™, alongside othercustom engineered wire rope sheavesthat meet your specific needs and rigors of your application. We also supply a large inventory of stock sheaves from thebest known brands in the industry. Contact ustoday or send a request for quotation, and our engineering team will work alongside you to find your custom pulley solution.

Want a sheave system to solve your design problem? Our expertise is based on decades of engineering and supplying leading manufacturers, from the simplest applications to the most demanding. We’ve supplied sheaves for both recreational and large commercial boat lifts, to military applications. No problem is too big for us, and no solution is too small for a consultation.

Esheaves.com offers custom solutions engineered to meet the exact requirements of your application. From the strength and durability of a nylon sheave, to the rapid shipping and stock availability of QSheaves™, we will help you meet any challenge. If our customizable options don’t measure up, we’ll engineer a complete, original solution just for you!

Need an individualized application solution?EShevaes.com is the trusted team of sheave engineers you can turn to. Find additional information about our customization options below. Ready to start a Custom Pulley Project? Visit our Custom Sheave Project page by clicking the link below

Contact us with your sheave requirements before freezing your equipment designs. We can offer a better sheave at a lower cost in many cases if we are consulting early in the design stage. Many times a modification of our QSheaves™ is the economical choice when certain design parameters preclude use of an off-the-shelf sheave. Even fully custom pulleys can be quite economical when the right decisions are made on materials and designs. Put our experience to use for your business.

Many applications, particularly in wire rope sheaves and in wire & cable processing, have design constraints that can’t be met by stock sheaves from us or other suppliers. In recent years, Process Sheaves LLC has developed over 300 custom engineered sheaves to meet critical customer parameters. We welcome the opportunity to work with you to achieve the most economical solution for your particular situation.

We pride ourselves on our quality products and excellent customer service, as well as our continual desire to look for innovative ways to meet your needs; achieved, for example, in our patented line of steel sheaves that allow us to provide an extensive range of 6” to 12” sheaves to be shipped the same day.

Engineering sheave solutions is what we do best and what we do all day, every day. We respond to our customers immediately with technical answers and practical solutions. If we, on the rare occasion cannot provide you with the solution you are looking for we will point you to who can. Why? Because our customers are OUR number one priority!

Custom sheaves expressly designed to meet you exact requirements can usually be shipped within 2 to 4 weeks after receipt of your order. Quotations are usually delivered within 24 to 48 hours after receipt of your inquiry.

The custom sheave design process is relatively simple. You tell us which are the constraining parameters – OD, bending radius, weight, temperature, shaft diameter, etc – and we will propose solutions. Refer to our order form under the ‘Request Quotation’ link. We must have maximum product size and minimum bending radius (Root Diameter).

It is generally uneconomical to purchase fewer than ten identical sheaves due to engineering and setup costs. The simplest sheaves (and most sheaves) require three distinct CNC operations and each step requires programming and setup time.

Materials are purchased to requirements. Very small orders for one or two pieces are relatively expensive. For less than ten sheaves, it may be more economical to modify a stock sheave. Prices for thirty or more identical sheaves will often be comparable to stock sheaves of a similar size.

For custom processing sheaves of 22” OD or less, we prefer Gar-Dur, the densest and most abrasion-resistant UHMW-PE available commercially. It is available in a variety of sizes and shape from stock, generally yellow in color. We have been using it for 15 years and have experienced excellent results. Other materials we use are:

Composites such as carbon fiber are our newest development in sheave manufacturing. We have a technical collaboration with a leading aerospace manufacturer that promises to yield lightweight, strong, sheaves with excellent wear characteristics. We have seen weight savings of 50% with no compromise in expected performance.

Due to tooling costs, these sheaves are economical only if the ultimate requirements will be 100 or more. However, sheaves of 30″ OD and larger may be very cost competitive even in smaller quantities. As our experience grows, we will post some case studies on our web site to give you concrete examples or weight and cost advantages.

Our products can be statically or dynamically balanced to suit your requirements. Normally balancing is not required because precision machining of homogeneous materials produces inherently balanced finished sheaves, requiring no dynamic balancing for 1500 RPM and above.

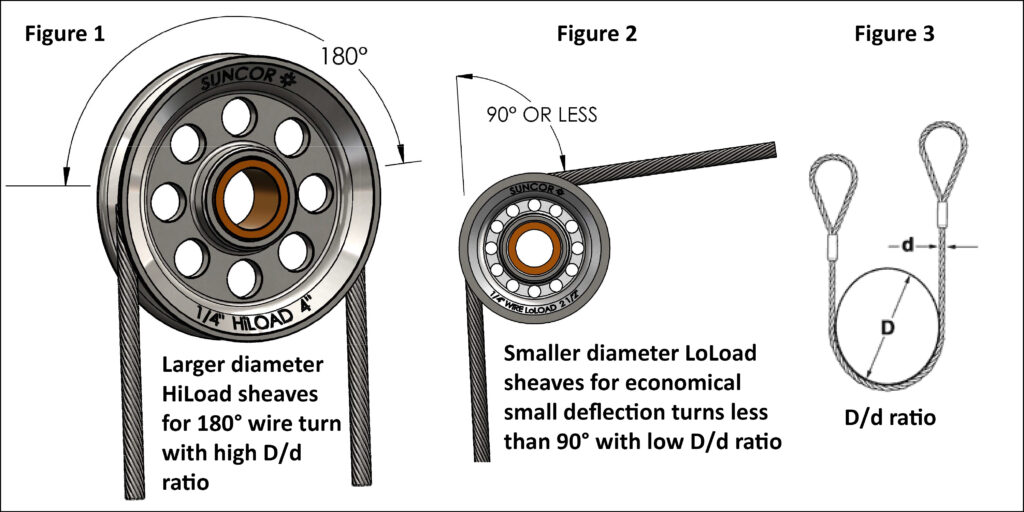

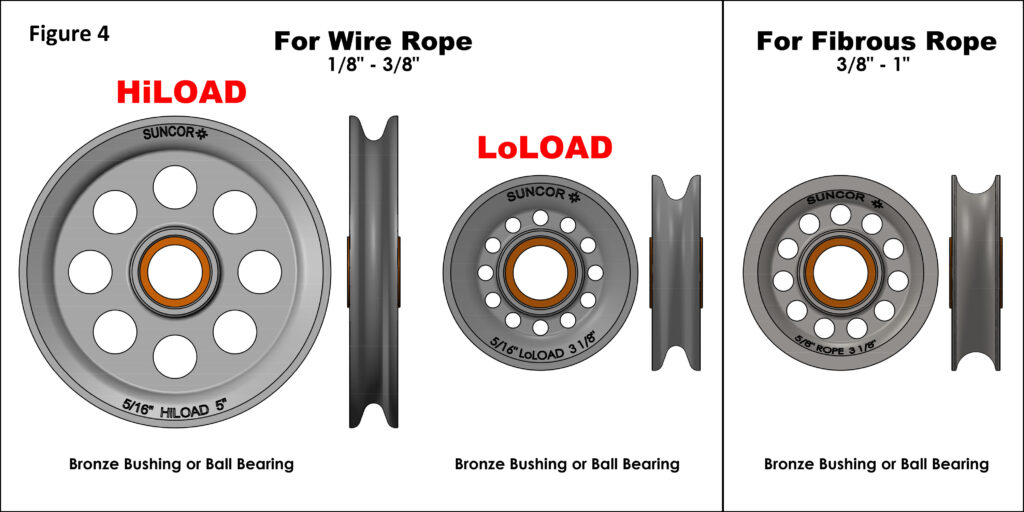

A sheave is a pulley, with a grooved wheel for holding a wire rope, belt, or rope. Wire rope sheaves are designed for holding wire ropes in place. Grooved wheels spin on a bearing or axle inside the frame of the block. This allows the wire rope to move freely, thereby minimizing wear and friction on the wire rope. Wire rope sheaves are primarily used in facilitating safe and smooth operation of overhead crane hoists. Wire ropes can wear prematurely and can cause other dangerous hazards.

Wire rope sheaves are different from standard sheaves in terms of construction and operation. They are smooth and free from defects, which may cause rope damage. The sheaves which can be momentarily unloaded has to be locked with close-fitting guards in order to guide the rope back into the groove when the load is applied again. The pockets and flanges of sheaves, which are used with hoist chains, need to be of such dimensions that the chain does not bind or catch during the operation.

Founded in 1994, Konecranes is involved in the manufacture and sale of lifting equipment. It provides overhead cranes such as standard industrial, automated cranes, overhead travelling cranes, and hoists & lifting devices. These include electric wire rope hoists, electric chain hoists, manual chain hoists, and air balancers. The company has aprroximately 17,000 employees at 600 locations in 50 countries.

China-based DGCRANE is a crane wheel manufacturer that specializes in crane designing and manufacturing. The company has exported cranes to more than 80 countries, primarily Russia, Uzbekistan, the Philippines, Bangladesh, Australia, Qatar, Tanzania, Singapore, Saudi Arabia, Pure, Brazil, and Nigeria. These cranes are manufactured using more than 300 sets of production equipment. The company has about 2000 employees.

Certex Norway US is manufacturer of lifting products, wire products, and mooring and marine equipment. It also provides services such as maintenance, inspections, technical support, and certifications. The company has presence in Bergen, Stavanger, Kristiansand, Oslo, Trondheim, Kristiansund, Harstad, Hammerfest, Florø, and Sandnessjøen. It is a part of Lifting Solution Group under Axinter Company, which is owned by Axel Johnson Group. Lifting Solution Group has its own distribution channel in more than 15 countries in Europe with around 40 outlets.

Expansion in infrastructure and industrial sectors across the globe is expected to drive the demand for wire ropes across the world. There exists replacement demand for wire ropes and wire rope sheaves. There is strong requirement of wire rope in oil & gas industry for meeting the needs of offshore exploration drilling rigs, offshore cranes, offshore winches, and land-based exploration drilling rigs and their servicing. Increasing demand from crane and lifting industry is anticipated to boost the demand for wire rope sheaves during the forecast period. Lifting products that use wire rope sheaves are container handling cranes, telescopic mobile cranes, mobile lattice boom cranes, overhead hoist/gantry cranes, bulk unloader cranes, ladle cranes, and piling cranes.

The wire rope sheaves market is highly susceptible to fluctuation in prices of raw materials, as almost 95% of wire rope sheaves constitute iron or steel. These prices are fluctuated on the basis of shipping costs, market maturity, energy costs, and supply demand scenario. Thus, volatility in prices of raw materials may adversely impact the purchasing decision of wire rope sheaves, since these are heavy duty products which does not easily tend to fail as these products are tested while manufacturing to almost 1.5 – 2 times its rating capacity.

Wire rope is a preferred lifting device for many reasons. Its unique design consists of multiple steel wires that form individual strands laid in a helical pattern around a core. Wire rope comes in a variety of strand patterns including single layer, filler wire, seale, warrington, and combination. Wire rope strands can be laid around the core in different configurations including regular lay wire rope, lang lay wire rope, and alternate lay wire rope. There also many types of grades of wire rope, including: improved plow steel (IPS), extra improved plow steel (EIPS), and extra extra improved plow steel (EEIPS). Some types of wire rope is preferred over others due to the unique properties, including: rotation resistant wire rope, compacted strand wire rope, swaged wire rope, plastic coated wire rope, plastic impregnated (PI) wire rope.

Models WZ20 to WZ24 are pulleys and pulley brackets made of material EN-GJL-250(GG25), WZ25 & WZ26 pulleys made of material EN-GJL-250(GG25), pulley brackets made of steel. Special designs include pulleys with protective clips.

The depth of groove should be selected so that the rope does not rub against the flange of the sheave or each other while entering running or leaving the groove. Angle of circular arc of the bottom of groove should not be less than 120 Degrees.

The grooves on the drum should be pitched so that there is clearance between neighboring turns of rope on that drum. The recommended clearances are 1.5 mm up to rope diameter of 28 mm and 3 mm for rope diameter above 28 mm.

The groove diameter of the pulley or sheave should always be larger then actual diameter of the rope. But if the groove diameter is too large the rope will tend to flatten and if it is too small pinching or rope will take place. The correct positioning is explained as under along with the tolerance and clearances on pully or sheave groove diameters.

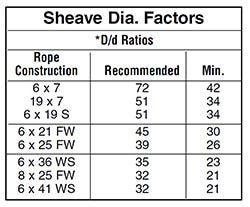

This construction is used where ropes are dragged on the ground or over rollers, and resistance to wear and abrasion are important factors. The wires are quite large and will stand a great deal of wear. In fact, this construction is sometimes called “coarse laid” because of the large wires. The 6x7 is a stiff rope and needs sheaves and drums of large size. It will not withstand bending stresses as well as ropes with smaller wires. Because of the small number of wires, with the resulting higher percentage of load carried by each wire, a larger factor of safety should be considered with 6x7 ropes than with ropes having a larger number of wires.

The 6x19 Classification of wire rope is the most widely used. With its good combination of flexibility and wear resistance, rope in this class can be suited to the specific needs of diverse kinds of machinery and equipment. The 6x19 Seale construction, with its large outer wires, provides great ruggedness and resistance to abrasion and crushing. However, its resistance to fatigue is somewhat less than that offered by a 6x25 construction. The 6x25 possesses the best combination of flexibility and wear resistance in the 6x19 Class due to the filler wires providing support and imparting stability to the strand. The 6x26 Warrington Seale construction has a high resistance to crushing. This construction is a good choice where the end user needs the wear resistance of a 6x19 Class Rope and the flexibility midway between a 6x19 Class and 6x37 Class rope.

The 6x36 Class of wire rope is characterized by the relatively large number of wires used in each strand. Ropes of this class are among the most flexible available due to the greater number of wires per strand, however their resistance to abrasion is less than ropes in the 6x19 Class. The designation 6x36 is only nominal, as in the case with the 6x19 Class. Improvements in wire rope design, as well as changing machine designs, have resulted in the use of strands with widely varying numbers of wires and a smaller number of available constructions. Typical 6x37 Class constructions include 6x33 for diameters under 1/2", 6x36 Warrington Seale (the most common 6x37 Class construction) offered in diameters 1/2" through 1-5/8", and 6x49 Filler Wire Seale over 1-3/4" diameter.

Alternate Lay, sometimes referred to as reverse lay, is a stranded rope where the type of lay of the outer strands is alternately regular lay followed by lang lay such that three of the outer strands are regular lay and three are lang lay. Alternate lay wire rope has the extra flexibility of lang lay in combination with the structural stability of regular lay. It unites the best features of both types of wire rope. Alternate lay is made with relatively large outer wires to provide increase of abrasion resistance to scrubbing against sheaves and drums. Finer inside wires and flexibility enable alternate lay ropes to absorb severe bending stresses. It is well suited to winding applications where abrasion and crushing can occur. Alternate lay wire rope applications include boom hoists and numerous types of excavating equipment like clamshells, shovels, cranes, winches and scrapers.

The 8x19 Classification rotation resistant ropes are recommended for hoisting unguided loads with a single-part or multipart line. The eight outer strands are manufactured in right lay, with the inner strands being left lay. These ropes are slightly stronger and significantly more rugged than the 19x7 construction. However, the rotation-resistant properties of the 8x19 rotation-resistant ropes are much less than those of the 19x7 construction. These ropes are manufactured in right regular lay in the 8x19 Seale and 8x25 Filler Wire constructions.

19x7 is recommended for hoisting unguided loads with a single-part line. The rotation-resistant properties of this rope are secured by two layers of strands. The inner strands are left lay, while the 12 outer strands are right lay, which enables one layer to counteract the other layer"s rotation. The rotation-resistant characteristics of the 19x7 wire ropes are superior to those of the 8x19 Class wire ropes.

SFP 19 is recommended for both multipart load and single-part fast line applications where rotational stability of the lifted load is needed, such as for use as a long fall on offshore pedestal cranes, rough and all terrain cranes, and crawler cranes. SFP 19 provides:

Fatigue Resistance. Improved fatigue properties are derived through the combination of the flexible 19x19 construction and die drawn strands. The drawn strand surfaces minimize the interstrand and interlayer nicking that take place in round rotation resistant ropes.

Abrasion Resistance. Die drawn ropes provide improved abrasion resistance as compared with round wire ropes because of the greater wire and strand bearing surfaces contacting sheaves and drums.

Resistance to Drum Crushing. SFP 19 wire ropes are resistant to the effects of drum crushing due to the compacted strands and smoothness of the rope surface.

Superior Rotation Resistance. The SFP 35 rope is the most rotation resistant rope manufactured by WW. Due to its rotation resistant properties, SFP 35 may be used with a swivel in both single part and multipart reeving.

Flexibility. SFP 35"s multiple strand construction provides increased flexibility which improves service life and high speed spooling. The compacted compacted multiple strand construction also reduces sheave and drum abrasion and provides excellent resistance to drum crushing.

6-PAC is recommended for use where the rope is subjected to heavy use or where conditions are extremely abusive, such as offshore pedestal, crawler and lattice boom equipped truck crane boom hoist applications. 6-PAC is also recommended for winch lines, overhead cranes, multipart hoist lines where rotation-resistant ropes are not required, and other applications where flexibility, high strength and resistance to crushing are important, and a cost-effective 6-strand rope is desired.

Fatigue Resistance. Improved fatigue properties are derived from the combination of 6-PAC"s flexible constructions and the compacted strands. The compacted strand surface minimizes the interstrand and interlayer nicking that take place in standard 6-strand ropes.

Abrasion Resistance. 6-PAC"s compacted strand design provides improved abrasion resistance as compared to standard 6-strand ropes because of the increased wire and strand surfaces contacting sheaves and drums.

Drum Crushing. 6-PAC dramatically increases the amount of wire contact with the drums and sheaves, reducing the wire rope, sheave and drum wear normally associated with standard wire rope.

Recommended for applications where abrasion and fatigue resistance is required, such as for winch lines, chokers, skylines, and haul backs, as well as any application where a swaged rope is used

8-PAC is recommended for hoist ropes for steel mill ladle cranes and hoist and trolley ropes for container cranes, or other hoisting applications with heavy duty cycles or where severe bending occurs.

Superior Performance. 8-PAC has higher breaking strength and gives superior performance in difficult hoisting applications compared to standard 6-strand and 6-strand compacted ropes.

Abrasion Resistance. 8-PAC compacted strand design provides improved abrasion resistance as compared to standard 6 and 8 strand ropes because of the increased wire and strand surfaces contacting the sheaves and drums.

SUPER-PAC is a double compacted product ideal for applications where abrasion and drum crushing are an issue. When compared with standard ropes, SUPER-PAC provides: Better resistance to multi-layer drum crushing. SUPERPAC dramatically reduces the damage at cross over points on smooth face drums, such as those found on many boom hoist systems on mobile cranes. This is achieved by compaction of the strands and the rope, making a tough but flexible product.

Superior Fatigue Resistance. SUPER-PAC is engineered for overall performance, its wire tensile strength being the key to its superior fatigue resistant properties. In addition to contribution to SUPERPAC’s EEEIP breaking strength, the wire used in the manufacture of SUPER-PAC remains ductile, minimizing the occurrences of external and internal wire breaks caused by operating stresses.

TRIPLE-PAC was developed for the most demanding hoist applications. TRIPLE-PAC offers the extra high strength and crushing resistance needed for applications such as boom hoist ropes, boom pendants and multipart load lines.

TRIPLE-PAC provides superior abrasion and fatigue resistance as compared with most compacted ropes due to WW’s unique design of compacting the IWRC, individual strands and the rope itself. Other benefits include:

High Strength. TRIPLE-PAC is designed to provide a nominal strength of 35% above EIP. WW achieves this strength through selected grades of steel and TRIPLEPAC’s unique design and manufacturing processes.

Superior Resistance to Multilayer Drum Crushing. TRIPLE-PAC provides superior resistance to crushing through its design. Its triple compaction provides a denser cross section, enabling the rope to withstand the rigors of multilayer spooling. Damage at the cross over points is also significantly reduced.

BXL is infused with a specially- engineered polymer, creating a well-balanced matrix. BXL is recommended for numerous hoist, marine and logging rope applications. BXL provides: Fatigue Resistance. Improved fatigue resistance is derived from the cushioning and dampening effect of the polymer on the wires and strands. BXL also evenly distributes stresses which may lead to fatigue breaks.

Abrasion Resistance. The polymer acts as a barrier between the individual strands, preventing penetration of any adverse material. BXL distributes and reduces contact stresses between the rope and sheave, reducing wire rope wear.

Service Life. BXL minimizes corrugation and wear normally associated with standard rope usage by restricting water and dirt penetration and eliminating pickup of abrasive materials.

This rope is particularly suitable where severe conditions of crushing and abrasion are encountered on the drum or where a higher strength design factor is required than can be obtained with a similar round rope.

The triangular strand shape not only provides better resistance to crushing, but also offers a greater exposed surface area for contact with sheaves, drums or underlying layers of spooled rope. This feature, in connection with the use of Lang lay construction, distributes the abrasive wear over a greater number and length of wires. The smooth surface of the rope also helps minimize wear on drums and sheaves.

ROEPAC is a three strand compacted rope with high breaking strength and stable construction making it perfect as a pulling rope for overhead transmission lines and underground conduits. It’s flexibility and flat surface provides snag-free guidance of the attached lines.

Abrasion Resistance. Compacted design provides improved abrasion resistance compared to standard 6 strand ropes because of the increased wire and strand surfaces contacting the sheaves and drum.

Multi-layer drum systems should use strand- or swage compacted Python® rope constructions having a steel core. The higher fill factor of such rope constructions will offer a greater resistance to crushing and flattening than conventional rope types. This is particularly important for boom hoist ropes on lattice boom cranes at the cross over point from one rope winding to the next.

Cranes equipped with multi-layer drum systems which require rotation-resistant or non-rotating rope are best served with Python Compac® 18 and Python Compac® 35. To further reduce drum crushing have the rope layers wound onto the drum with about 5-10% of the WLL and avoid that the first layer unspools and re-spools without tension. This would cause a ‘soft’ bottom layer which will flatten rather quickly.

8613371530291

8613371530291