sheave size for wire rope quotation

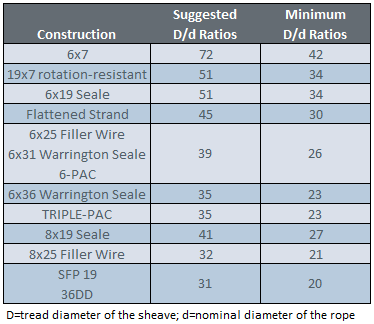

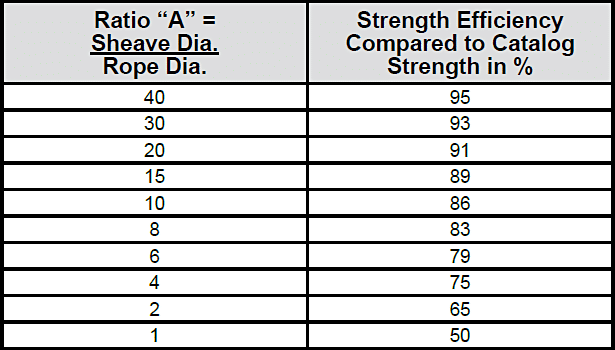

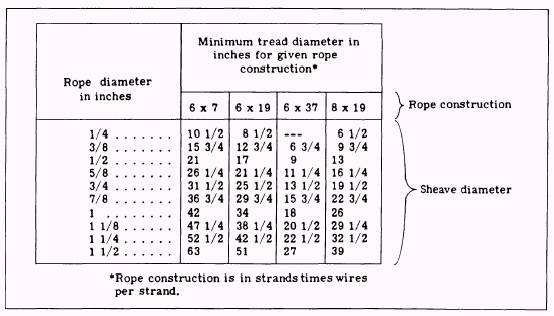

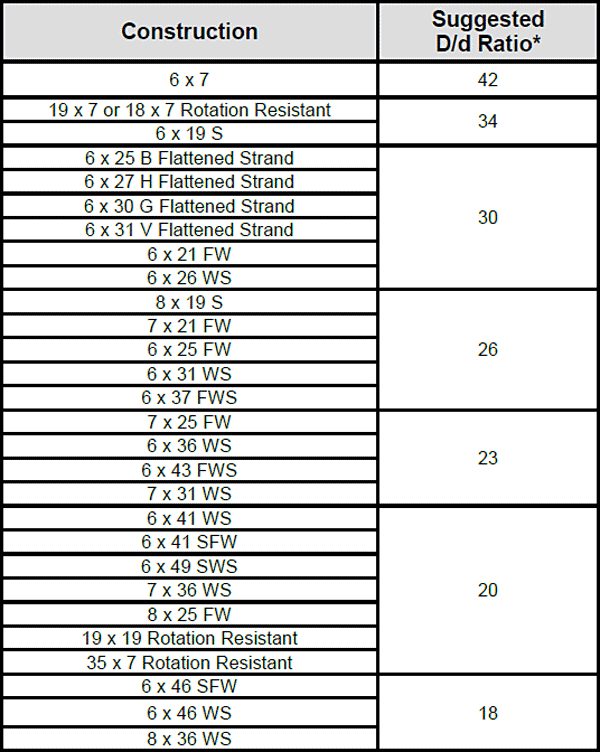

To find any tread diameter from this table, the diameter for the rope construction to be used is multiplied by its nominal diameter (d). For example, the minimum sheave tread diameter for a 1/2″ 6 x 21 FW rope would be 1/2″ (nominal diameter) x 30 (minimum ratio) or 15″.

NOTE:These values are for reasonable service. Other values are permitted by various standards such as ANSI, API, PCSA, HMI, CMAA, etc. Smaller values affect rope life.

The service life of cable and wire rope can be increased if (1) it operates over the largest possible pulley or sheave diameter, and (2) it is properly supported in the pulley or sheave groove. The working life of the individual wire strands is greatly reduced as the pulley or sheave diameter is diminished. The chart below shows minimum tread diameters over which various sizes and constructions of cable should operate.

Wire sheaves have been around for centuries, being very useful tools for various lifting, pulling and suspension applications. Read on for some basic use, maintenance and safety information on today’s wire rope sheaves.

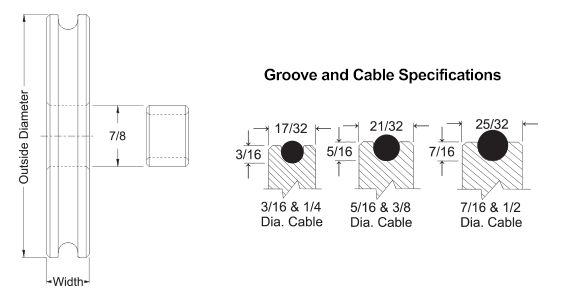

A sheave is basically a wheel with a groove or track on it which guides the wire rope over it. In its simplistic form, wire rope passes over a sheave and connects to the load. The other end of the wire is attached to a pulling device, such as a winch, to gain mechanical advantage. The threaded line over the sheave completes the device. To prevent the wire rope from leaving the groove, the minimum depth of the groove should be the thickness of the rope or cable.

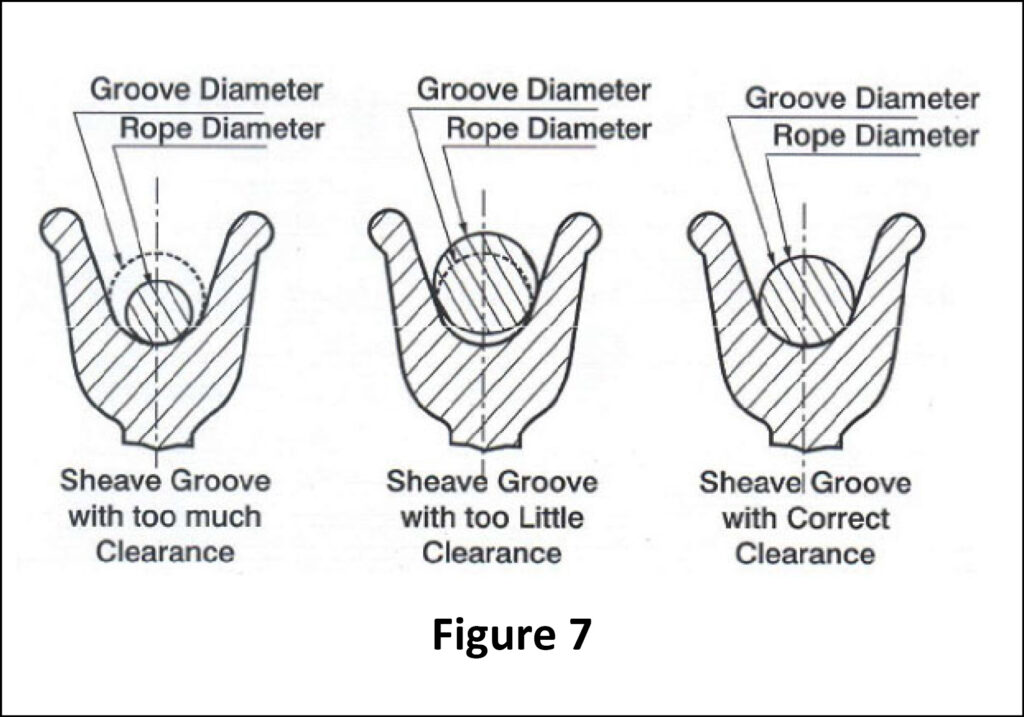

Although the rope sheave has a simple construction, its function is a little bit complicated. You have to determine the exact wire rope diameter to choose the correct sheave size. The groove on a sheave should be flared and slightly larger than the nominal diameter of the rope. If the groove is too big the wire will flatten under load; if the groove is too small, the rope will be pinched.

Wire sheaves or pulleys change the direction of the force or increase the pressure to a load. The wire never lays straight in the groove of a sheave because the attached load moves from slide to slide. The movement causes the wire rope to rub against the sides of the sheave, which in turn causes wear.

Like any mechanical system, rope sheaves require maintenance. Here’s some good points to bear in mind:Always check the sheaves to avoid delay in your operations.

Pay attention to the sheave groove and the edges of the flange. Any fractures or cracks can cut the rope during operation. General wear on the surface of the sheave could result in a reduction in groove surface, creating an uneven load-bearing surface.

Centuries ago, sheaves were commonly used for sailing. Today, wire rope sheaves find usefulness in many industrial and lifting applications. And Wire Rope Australia actively participates in many of these industries as a supplier of wire rope, wire rope sheaves and a full range of wire rope fittings.

Have a steel sheave, pulley, wire rope, or application question?Ready to start a new project? Have a requirement you need met? Know your sheave specification and need custom pricing? You’ve found the right resource. eSheaves engineers are ready to answer your inquiry, work on your request for quote, or assist with the particulars of a new custom engineered project.

Looking for pricing?Visit the eSheaves shop to to see individual item pricing and to order from stock today. For larger inquiries, or to request additional information, choose the option that most closely matches below and let us know how we can help.You can also reach us via email through [email protected], or by calling us directly at 800-321-5667.

Have a sheave, pulley, wire rope, or application question?Ready to start a new project? Have a requirement you need met? Know your sheave specification and need custom pricing? You’ve found the right resource. eSheaves engineers are ready to answer your inquiry, work on your request for quote, or assist with the particulars of a new custom engineered project.

Looking for pricing?Visit the eSheaves shop to to see individual item pricing and to order from stock today. For larger inquiries, or to request additional information, choose the option that most closely matches below and let us know how we can help. You can also reach us via email through[email protected], or by calling us directly at 800-321-5667.

Selecting the right size for sheaves will help prevent frequent wire rope damage which in some instances occurs after just one run. Many common operational issues including the wireline getting dislodged or losing its strength are caused by improper sheave sizing and alignment problems. Our experts offer 3 valuable tips to eliminate stress failure, improve equipment safety and efficiency, as well as increase the lifespan of your sheaves and wire rope.

Pay attention to sheave groove size and diameter: When sheaves for your wire rope are too large or too small, there is greater stress on both resulting in spooling trouble and premature wear. For instance, grooves that are too large have proven to cause the wire rope to flatten and unbalance leading to the wire breaking. When properly sized, the groove provides maximum support to the rope lowering the sheave bearing pressure and increasing sheave and rope lifespan. Typically the groove diameter should exceed that of the wire rope by 5% while groove depth should be one-and-a-half times the rope diameter. A groove angle between 30° and 45° offers the best support for the wire rope. Specific dimensions and angles may vary depending on your application.

Ensure sheave groove hardness: The hardness of sheaves is a factor that is often overlooked. Since the wire rope is hard, the pressure it exerts on the groove can lead to corrugations if the sheave is not properly hardened. To avoid this, ensure your steel cable sheaves are flame hardened. (A simple way to determine if your grooves are worn out is by using a sheave gauge.) At Rockett Inc., we can provide flame hardening for wear resistance along the contact area.

Correct sheave groove alignment: Poor alignment of your sheaves wears out the wire rope and sheave flange. This is because the rope comes into constant contact with the flange creating stress on the rope, abrasion damage and fatigue breaks. Any alignment issues should be corrected immediately.

To avoid operational problems, opt for custom made steel sheaves. This way the sheaves for your wire ropes are tailored to your specific requirements instead of the other way around. As an experienced sheave manufacturer with a state-of-the-art facility in Mississippi, Rockett Inc. offers comprehensive custom solutions for diverse industrial and commercial needs.

Should you have a specific requirement, our experienced engineers can work closely with you to design and manufacture the product your application requires. Precision engineering and state-of-the-art metal fabrication equipment result in a closer tolerance fit to the wire rope to reduce fatigue and wear. Inspection at every stage of our manufacturing process ensures that the final output meets your specifications.

Need assistance with designing sheaves for wire rope? We are always happy to help. Our team can work directly from your drawings and specifications, or offer 3D CAD design and engineering support optimized for practical, cost-effective results. Over the years, we have produced the most diverse range of custom steel cable sheaves for our clients across the globe. Having the ISO 9001:2008 Certification means we take pride in quality and customer satisfaction.

5″ Sheave, industrial quality, 5/8 wide machined sheave with oil impregnated bushing grooved for 3/8 wire rope. Clear galvenized zinc; safe work load of 1850 lbs; weight 2.9 lbs. Option includes changing to 1/2″ id (internal diameter) bronze/steel oil impregnated bushing.

If the sheaves we carry in our regular stock are not the right size for your purposes, please contact us for pricing on custom work. Or, you may fill out an order form with your specs and we"ll gladly put together a quote for you.

Manufacturing sheaves for wire rope is our primary business. We have the capability to manufacture your sheaves to your design and specifications or you can choose your wire rope sheave from our large inventory.

Our wire rope sheaves are made from quality materials and machined to precise dimensions and tolerances in order to meet our high standards. In addition, we offer many other options to satisfy your sheave requirements, including choice of material, heat treating of the groove, case hardening, grease fittings, keyways and set screws, plating and many more. We also carry bearings and bronze bushings.

Choose from our stock sheave sizes or we can manufacture your wire rope sheaves to your design and specifications. SELECTING FROM OUR STOCK SIZES OFFERS YOU QUICKER DELIVERY AND ECONOMY, or we can stock for your ongoing requirements. Please complete this form and we will gladly quote.

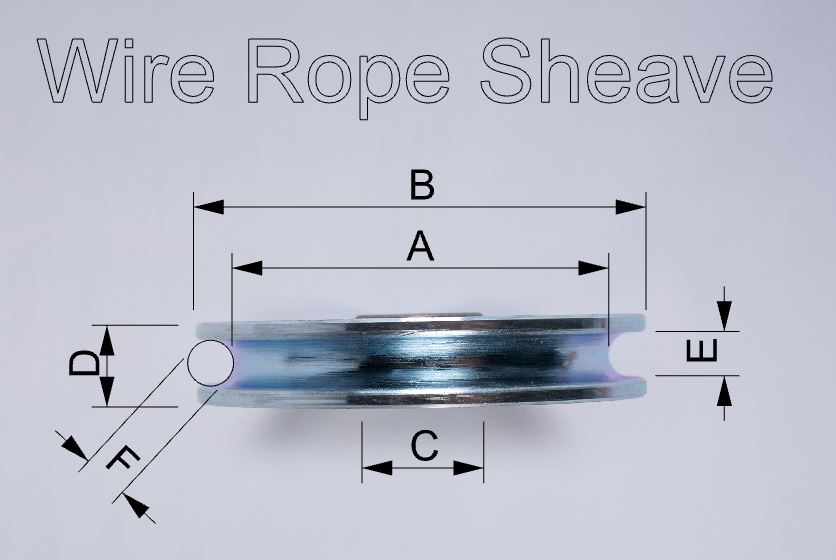

Drawings are appreciated although not required when you order sheaves, whether custom or stock. Please provide as many measurements as you can using our quote/order form as a guide. We will contact you to be clear on your needs before preparing our quote.

Manufacturing sheaves for wire rope is our primary business. We have the capability to manufacture your sheaves to your design and specifications or you can choose your wire rope sheave from our large inventory.

Our wire rope sheaves are made from quality materials and machined to precise dimensions and tolerances in order to meet our high standards. In addition, we offer many other options to satisfy your sheave requirements, including choice of material, heat treating of the groove, case hardening, grease fittings, keyways and set screws, plating and many more. We also carry bearings and bronze bushings.

Choose from our stock sheave sizes or we can manufacture your wire rope sheaves to your design and specifications. SELECTING FROM OUR STOCK SIZES OFFERS YOU QUICKER DELIVERY AND ECONOMY, or we can stock for your ongoing requirements. Please complete this form and we will gladly quote.

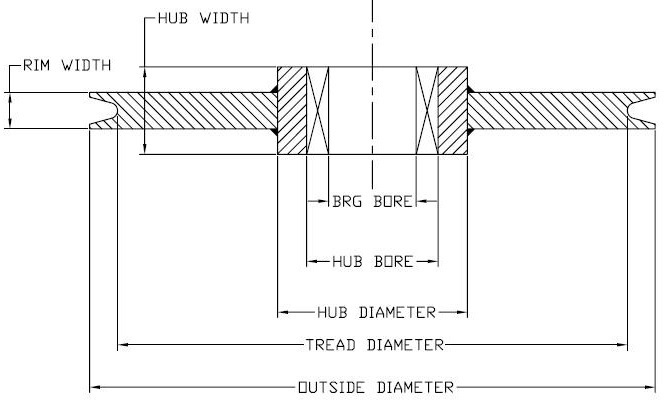

This information is needed in order for usto be able to manufacture a sheave for you. If Bushings or Bearings are needed, please contact your distributor or the Renfroe factory and provide specific information. If you want us to quote and/or provide bearings, you must give us the bearing manufacturer name, and part numbers.

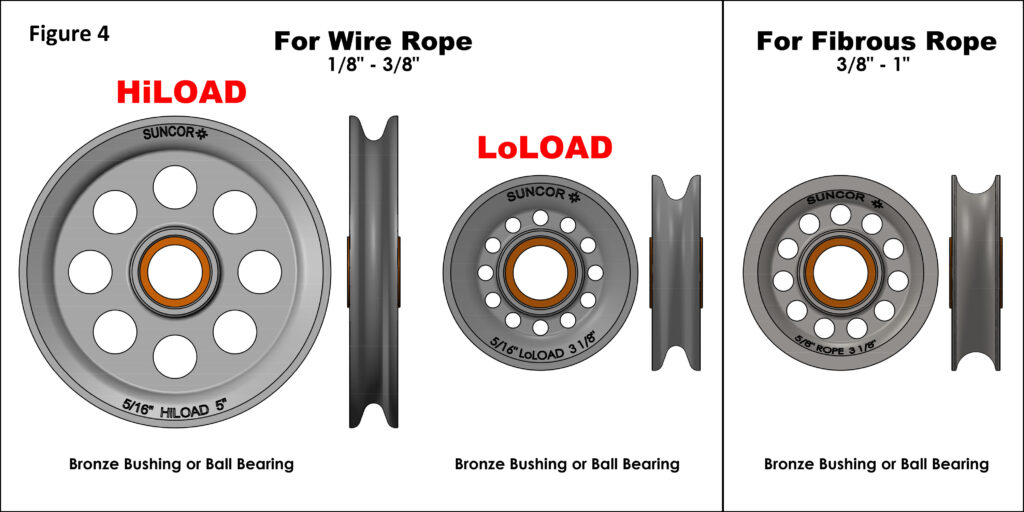

Sheaves are widely used throughout the industry for a variety of pulling and lifting functions. Sheaves are available in a variety of materials including steel, plastic, or stainless steel. There are many configurations available including HiLoad sheaves, LoLoad sheaves, fibrous rope sheaves, and wire rope sheaves. You can source sheaves with bearings or bushings and some sheaves come very specialized.

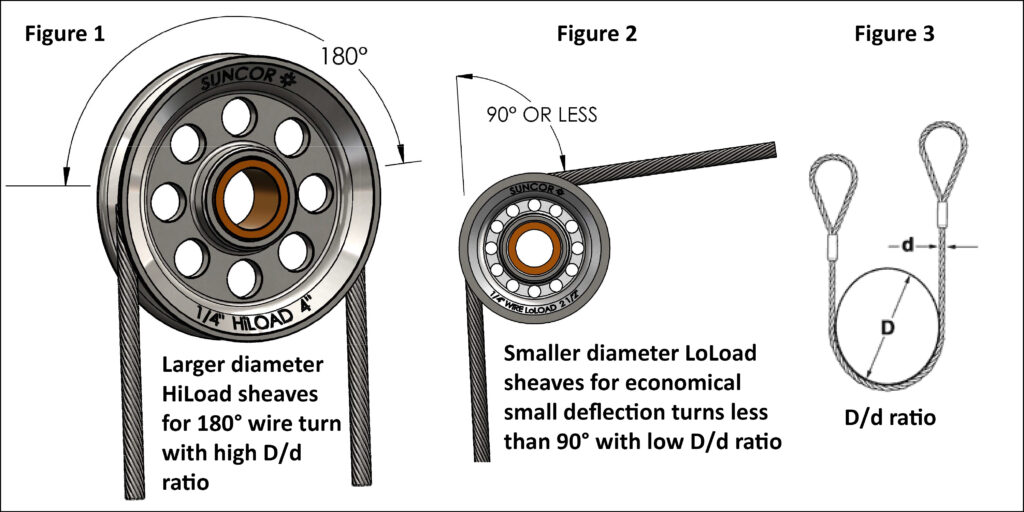

HiLOAD indicates a premium, larger diameter sheave suitable for 180° degree rope turns (see Figure 1) with a high D/d ratio, which is the ratio of the diameter around which the rope is bent, divided by the body diameter of the rope (see Figure 3). LoLOAD indicates a smaller diameter sheave designed for economical small deflection turns less than 90 degrees with a lower D/d ratio (see Figure 2).

Work load is important for both wire rope and fibrous rope sheaves, but work load limit (WLL) is critical with wire rope sheaves due to the comparative increased capacity of wire rope.

Quality sheaves should meet ASME B30.26-2610 and exceed the minimum 4:1 design factor. In most instances, the WLL for Suncor sheaves is significantly higher than comparable products and proof loads (or max WLL) are twice the WLL. Generally, twice the WLL of the wire represents the wire maximum load with a 180° wire wrap around the sheave.

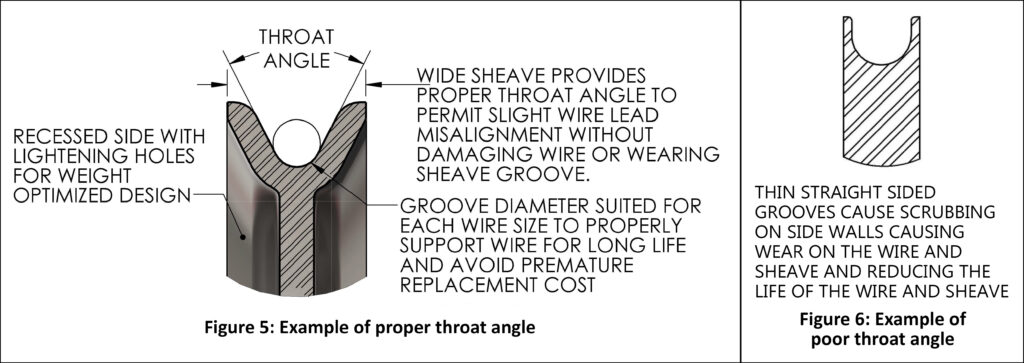

A critical, and often overlooked area, is the wear exerted on the sheave during use. Throat angle, groove diameter, and sheave size are three significant factors of wear for sheaves. Sheaves are often designed with thin straight sided grooves which can cause scrubbing on the side walls and unnecessary wear on the rope and the sheave (see Figure 6). Suncor’s sheaves were designed with wide sheave grooves that provide a proper throat angle to permit slight rope lead misalignment without damaging the rope or wearing the sheave groove (see Figure 5).

The groove diameter is critical for proper wire rope support under load and has a significant effect on the overall safety and lifespan of the sheave and rope. If the sheave groove diameter has too much clearance, it will not support the rope properly leading to distortion, increased fatigue, failure, and costly repair. Conversely, if the sheave groove diameter has too little clearance the rope will not fit properly causing excessive wear and accelerated abrasion, which results in lost performance (see Figure 7).

Sheaves facilitate the smooth and safe operation of overhead crane hoists. Damaged sheaves can wear ropes prematurely and cause other dangerous hazards, such as binding wire rope. Konecranes technicians are trained to identify and correct problems with sheaves and other parts of hoisting equipment.

Sheaves carrying ropes which can be momentarily unloaded shall be provided with close-fitting guards or other suitable devices to guide the rope back into the groove when the load is applied again.

The sheaves in the bottom block shall be equipped with close-fitting guards that will prevent ropes from becoming fouled when the block is lying on the ground with ropes loose.

In using hoisting ropes, the crane manufacturer"s recommendation shall be followed. The rated load divided by the number of parts of rope shall not exceed 20 percent of the nominal breaking strength of the rope.

Rope clips attached with U-bolts shall have the U-bolts on the dead or short end of the rope. Spacing and number of all types of clips shall be in accordance with the clip manufacturer"s recommendation. Clips shall be drop-forged steel in all sizes manufactured commercially. When a newly installed rope has been in operation for an hour, all nuts on the clip bolts shall be retightened.

Wherever exposed to temperatures, at which fiber cores would be damaged, rope having an independent wirerope or wire-strand core, or other temperature-damage resistant core shall be used.

Replacement rope shall be the same size, grade, and construction as the original rope furnished by the crane manufacturer, unless otherwise recommended by a wire rope manufacturer due to actual working condition requirements.

Konecranes wire rope inspections can help crane users extend the life of hoist ropes. Ropes, sheaves and other reeving system components are inspected for compliance with crane standards, and to determine if they have flaws that could hinder safe operation. Contact us today to schedule an assessment.

*The foregoing OSHA regulations are not intended to be a comprehensive overview of all applicable regulations pertaining to the designated topic. State laws may mandate different safety and maintenance standards. Accordingly, please consult applicable state laws as well as original equipment manufacturer specifications for further guidance. The statements and descriptions contained herein constitute the opinion/recommendation of the seller and are not intended to create any express warranties.

Pulleys are manufactured from various materials, including many industrial plastics and a variety of metals. When advising mechanical engineers on the right pulley choice, the pulley manufacturers must advise on the diameter of the pulley, to ensure that the right size is paired with the right mechanical cable. Doing so, ensures prolonged cable life and reduces the potential for a mechanical failure to occur within sensitive, mission-critical or even life-saving motion control systems. However, not all manufacturers can produce the quality of cable pulleys thatCarl Stahl Sava Industries has for 50 years now.

No matter the pulley"s application, size plays a vital role in determining the quality and performance of the motion control system. For any application, pulley specifications are determined by several factors, including the cable"s diameter, its construction and the load it’s meant to support.

The pulley’s groove diameter and its radius play into the overall size considerations when pairing a pulley with mechanical cable. Too wide a groove and the cable may fail prematurely. Too narrow, and the cable may be pinched and fail prematurely.

There are recommended groove diameters-to-cable diameter ratios for each cable construction. Most flexible cables, such as a 7x49 construction suggest a 15x ratio to maximize life. As stranding constructions simplify, the ratios increase. For instance, 7x19 wire rope has a 25x ratio, while 7x7 cables have a 40x ratio. Use these ratios as a basis for maximizing the cable life. But this is only one variable that needs to be carefully balanced along with the load requirements and materials used.

Getting the mating of the pulley and cable correctly configured requires mechanical design engineering experience that Sava’s been perfecting for five decades. Ask us to help you get this critical detail just right.

On the other hand, large pulleys are not suited for most applications. Using a pulley that is bigger than the required size is mainly disadvantageous when it comes to the costs involved and the space required.

Engineers can design a pulley that will fit a particular application’s requirements. Many times, designers and manufacturers do not allow for a large enough pulley, for example, which will limit the cable"s life span. It is therefore important to maximize the pulley’s groove diameter wherever possible for maximum service life as suggested by the pulley ratios.

If you find that your cable is failing too quickly in your application because the pulley is too small, the cable’s life may be extended by lubricating it. Sava lubricates all of its miniature stainless steel cables that are extruded with nylon. If you find that you"ve been using a small pulley for the wrong application, you can extend the cable"s lifespan by lubricating it. By lubricating your mechanical cables, you will ensure you get as much as twice or three times the life of an otherwise single lifespan cable if the pulley is small.

If possible, cables and pulleys should be selected to avoid metal-to-metal contact. Too often, such combinations result in premature cable malfunction due to abrasion. Coated cables are suitable where metal pulleys are involved while bare cables are suited for plastic pulleys.

If you"re looking for high-quality wire pulleys, trust the industry experts at Sava and view our catalog of cables, fittings and tools. Our sales and engineering expertise gives us an edge and allows us to meet your cable needs.Contact us today and let us guide you.

Turned Black Delrin Sheave is 1" OD x 1" wide x 1/4" ID. As used on a variety of stanchion mount furling line blocks,and in other applications. With Rope Groove for up to 3/4" line.

wide x 1" ID, and mounts on a single 1" axle. Special Narrow Sheave with wire/rope V-groove, for line up to 9/16" diameter, and wire to 7/16". Breaking Strength is 66,000 lbs..

8613371530291

8613371530291