single girder wire rope hoist factory

Engineered Material Handling (EMH) sets the standard for wire rope hoists. EMH manufactures its own single and double girder wire rope hoists for standard industrial applications, with standard capacities of from 2 to 50 tons. The EMH wire rope hoist provides a price to performance ratio that compares favorably with the best the industry has to offer.

Standard features include two lifting and trolley speeds, two upper and one lower precision limit switches, overload limit, heavy duty wear resistant rope guide, DC rectified brakes, and lifetime lubricated bearings and gear reducers.

Prices shown are list prices and include all electrical controls per applicable N.E.C. Specifications, NEMA enclosure with quick disconnect plugs, host completely wired an reeved. All prices are for 460/3/60 power. Adders for 208/3/60 or 230/3/60 are shown on options page. Push button station and 110V control transformer are optional. Monorail hoists furnished with flat tread wheels standard.

Single Girder electric wire rope hoist 1 ton, a modular design hoist which is filled with European characteristics. This European design is of safety and reliability, only requesting easy maintenance. It is nice to environment, reducing power cost. Of course, we also have double girder hoists to fit for different cranes.

Welcome to buy the newest and competitive price DAWSON Single Girder Electric Lifting Chain Hoist from our factory. We"re one of the leading China manufacturers and suppliers, offering you the wholesale service and the OEM service at a discount. With CE certification, our products made in China in stock are high in quality and low in price. Please be free to get the free sample from us.

A wire rope hoist is a hoist that utilizes wire rope as the lifting medium. It is often powered electrically or pneumatically. This lifting device is made up of a rope storage drum, motor(s), gear box and braking system, and is suspended from a monorail or bridge beam(s) by means of a trolley. It may also be stationary mounted.

A crane is a machine used for lifting and lowering a load, and moving it horizontally. A crane"s drives may be manual, powered or a combination of both. Cranes are typically used when there is insufficient (or intermittent) flow volume such that the use of a conveyor cannot be justified. They provide more flexibility in movement than conveyors, and less flexibility in movement than industrial trucks. Loads handled by cranes are more varied with respect to their shape and weight than those handled by a conveyor. Most cranes utilize hoists for vertical movement, although manipulators can be used if precise positioning of the load is required.

Many different types of cranes are used for material handling applications. These include overhead cranes as well as cherry picker type boom lifts, mobile and self-propelled cranes, straddle and counterbalanced (cantilevered) cranes. Portable and mobile floor cranes can be equipped with fixed or telescopic booms as well as mast rotation when equipped with outriggers. Lifting can be performed with the boom itself or a winch operated cable lift.

Meltech Single Girder cranes are provided with Meltech Wire Rope Electric Hoist which are designed and manufactured as per IS: 3938 open winch type design in modular construction which is suitable for rugged duty applications.

Rotary and Gravity Limit switches for hoist which eliminates generally used travelling rope guide operated limit switch which is susceptible for breakdown.

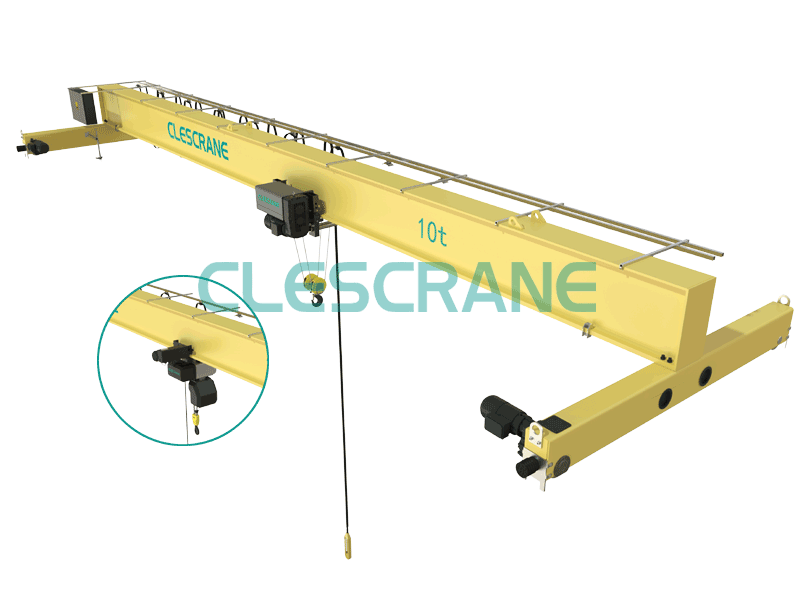

Clescrane CH series wire rope hoists feature high handling rates, cost-effective operation and maximum safety. We offer the optimum solution to meet our customers" specific requirements.

According to your special needs, we can provide many optional features, such as higher lifting height, different lifting speed, adapting different girder type, customized hook, anti-sway, dual-brake ,load display and so on.

This series wire rope hoist is the most common low headroom hoist with small hook limit. It meets your lifting height requirements and at the same time it can help you with lowering the factory construction height, to save your investment cost.

The pulley rate of this series hoist is 2/1, and the lifting speed can be 10/1.6m/min. stress relief device is equipped to avoid the twisting of wire rope.

This series hoist is installed on one side of the girder and the wire rope drum and hook are placed on the other side. The max span can be 35m. This design can maximize use the existing room height to get the highest lifting height. The big span can effectively reduce the load on crane rails and workshop structure.

Brake systemThe brake is equipped with an automactic adjusting device to apply brake torque in proportion to the amount of lining abrasion, the auxiliary brake ensure hoist safe when then main brake stop working.

Thermal protectorAs customer required, we will adopt thermal protector inside of hoist, hoist motor will automatically stops when sensing the heat of motor coil in order to protect the motor from burning damage caused by heat due to overwork

Permanently oil bathed 3-stage planetary speed reducer with heat treated bevel geared teeth for quiet operation. Hidden inside the drum, it allows for a more compact hoist with a better approach, as well as higher capacity lifts at higher lifting heights.

Standard thermal overloads on all hoists for motor protection . NEMA 4 enclosures. Mechanically interlocked reversing starters Pendant push buttons come equipped with support wire and emergency stop button. Schneider contactors, easy to replace off the shelf components.

Single girder cranes are found throughout many manufacturing operations with heavy lifting needs. These 2 ton, 5 ton or higher capacity cranes allow for efficient, reliable, and safe operations in your facility. From EKKE, EPKE, EVKE and more, Demag single girder cranes meet the varied needs of lifting operations all over the world.

There are many types of Demag single girder cranes out there and each type of crane is denoted by a4-letter acronym. The Demag EKKE Crane is a box girder with top running end trucks. The box girder makes this crane very robust for a wide variety of lifting in many manufacturing environments. The EPKE is a beam girder with top mounted end trucks. This type of crane is commonly found when lifting requirements are lower with shorter spans. The Demag EVKE crane is built with our v-girder. The v-girder can be attached to the end trucks in a variety of configurations so the 4-letter acronym does not specify this.

Other Demag crane descriptions are for underrunning and gantry type cranes. The EDKE is an underrunning box girder crane, meaning the bridge is attached to underrunning end trucks. When this configuration is a beam girder, it is an EPDE Demag crane. Half gantry crane bridges are supported on one side with the runway supported by the building structure and the other side supported by a freestanding support running on rail and/ or wheels.

The patented V-Type girder, only from Demag, is flexible and efficient. The design of the girder cuts the deadweight of the crane by an average of 17% and reduces oscillation to double the service life compared to box girders (500,000 changes of loads). The girder allows for 30% more light in the crane area and, in outdoor applications, reduces wind resistance by 55%.

Box girders are fabricated steel structures welded together to meet the requirements of the crane. You will see these girders in single girder cranes at certain capacities and to support long spans.

Beam girders can fit the job when the span is shorter, and the capacity is lower. Commonly, the beam will be a part of a single girder crane that is top mounted on the end trucks. You may also see this girder type on underrunning cranes where the girder is mounted on the bottom of the end trucks.

Choosing the right lifting device for your crane is a critical step to the RFQ process. Overhead cranes typically use a chain hoist or wire rope hoist to meet the specific needs of the lifting operations. There are benefits for either type of hoist so partnering with an expert crane manufacturer or dealer will ensure the project will be successful.

Chain hoists can be an effective and cost-effective hoist for lifting operations. Demag DC Chain Hoists can lift loads up to 5 tons. These hoists can be attached to the bridge with a motorized trolley. The hoist is then powered with an attached pendant or radio.

As your lifting capacities grow, a wire rope hoist is an effective tool to optimize your lifting operations. A standard wire rope hoist, like the Demag DMR rope hoist, can meet your needs in a typical environment without any extreme variables like high heat or moisture. When the lifting environment does get more demanding, the DMR hoist can be outfitted with the co-axial F10 motor combination. In environments like galvanizing, you can even upgrade to the Demag DH wire rope hoist which is a robust option when environments exceed the capabilities of a standard wire rope hoist.

When you need a single girder crane, partner with an experienced crane manufacturer and crane dealer. Not only will you work with the experts who can design the application to your needs, but they will be able to come to your site to help tailor the details. These partners will assure the crane application will meet your reliability, and safety needs in the lifting area. Reach out to one of our experts to discuss your crane project.

Safety, reliability, and efficiency are all critical characteristics of lifting equipment for your operations. Every facility and lifting process is different so get to know the requirements you need in a wire rope hoist. The Demag DMR wire rope hoist is a flexible and reliable hoist that can meet your requirements through available configurations and the options to tailor the hoist to your needs. The DMR rope hoist can even include an option for very fast speed for long lifting heights so your operations can be more efficient.

The Demag DMR wire rope hoist is flexible to meet your needs up to 50 tons. There are configurations for single and double girder cranes, foot mounted for crane modernizations or non-standard trolley gauges, monorail or low headroom applications, and drum and rope without a bottom block. No matter what configuration or options needed, the DMR is versatile and can include options to meet your requirements.

Even upon its initial design and launch back in 2016, the DMR wire rope hoist was designed to be flexible to meet a wide range of customer needs. Its performance lifting characteristics maintain a low cost of ownership while making your lifting operations more efficient and effective. The DMR was designed for operation in harsher environments using the tried-and-true Demag FG microspeed units, or Co-Axial F10 motor option. This combination includes a conical rotor lift motor connected to a conical rotor creep motor. This allows for a wide range of lifting speeds and makes your lifting very precise.

Standard lift heights of the Demag DMR include 39 feet, 65 feet and 98 feet. Stocked locally in the USA are the 39 and 65 feet lift heights with 98 available for order from the factory. The DMR rope hoist was built to offer our customers options for control. Controls can be Demag pendants or radios, but you can also integrate your preferred controls with additional interfaces. Available with 2-speed or variable frequency control, or VFC control, you’ll find the requirements you need for lifting in your operations.

Not all operations are the same. Certain parts of your lifting processes may have to lift a component a long distance. Long lift heights can be found in a variety of industries and operations like steel processing, concrete, and other general manufacturing operations. If it is important to have a very fast lifting speed for these heights, there is a standard DMR wire rope hoist to do the job.

When your operations need variable speed lifting, or VFC control, with a very fast lifting speed, the Demag DMR wire rope hoist can deliver. Demag offers very high lifting speed up to 41 feet per minute as a standard option, without the need for a custom design. Adding customization to meet your lift speed needs, it makes the solution more expensive.

Most configurations of Demag DMR wire rope hoist offer the very high lifting speed, but we will focus on the EK-DMR single girder hoist. The EK-DMR is available with fast, full load lifting speed up to 41 feet per minute with integrated controls on-board with the trolley. These very high lift speeds are available in the EK DMR models 3 – 10. Having a hoist with very fast lift speeds can allow your operations to be more efficient by allowing for more lifts within a period of time with less operator wait time during the lift, compared to standard lift speeds available.

In addition to the fast, full load lifting speed with integrated controls on-board with the trolley, an additional feature to consider is ProHub. ProHub increases lifting speed up to 50% if the capacity of the load is 30% or lower of the rated capacity of the hoist. This can make your operations even more efficient when you need to lift lighter components with the same hoist.

The Demag DMR wire rope hoist gives you a variety of options to make your operations safer and more efficient. You now have access to a standard wire rope hoist option for lifting at very high lifting speed without the need for customization. When you don’t need to customize your hoist to meet your lifting speed needs, you’ll likely be able to meet a lower budget range. If this DMR with full load fast lifting speed with integrated controls on-board with trolley sounds like a hoist to fit your needs, reach out to us to talk through your requirements.

HD Europe standard single girder overhead crane is our new designed crane for the low workshop and high lift height requirements. It has many advantages such as: strong rigidity, light dead weight, excellent structure design, etc. it could save your factory space and investment effectively. Its technology is advanced and design based on international standard: Din (Germany), FEM (Europe), and ISO (International). Its special and special travel structure is your best choice.

HD electric single girder overhead crane could widely used to handle materials in many industries" workshop and warehouse. As machine making. Stock. Logistics. Food. Paper, The, electronics industry workshop and other material handling situations. The lifting hoist adopts M5 working class with double lifting speed. Motor with ABM German brand motor. Travel motor used N & auml; hen European brand in a motor gear motors. Cross and long travel are variable travel speed. Electric parts adopt Siemens brand. The protection class is IP 54 high class. The working class can reach to A5/M5 class under ISO standard.

Sparkline Manufactures & Supplies a wide range of Single Girder EOT Crane with different configuration as per customer requirements. We offer Single Girder EOT Crane with Chain…

We are manufacturer of eot cranes, wire rope hoist, jib crane, gantry crane, underslung crane in Pune, Bangalore, chennai, kolkata, dahej, ankleshwar, surat

Our Hoist and eot cranes designs are as per latest manufacturing technology and design equivalant to german, italy or european standard. premium quality compared to other local manufacturer.

Single girder gantry crane general-purpose material handling equipment with wide applications, which is usually used in factories and mines, workshops, station logistics sites, ports, docks, etc.

2. Based on the different connection methods of main beam/girder and end carriages, this crane can be designed to meet any clearance needs and maximum lifting height of the

8613371530291

8613371530291