single layer wire rope made in china

Wire ropes can be seen everywhere around us, they are made of strands or bundles of individual wires constructed around an independent core, suitable for construction, industrial, fitness, commercial, architectural, agricultural, and marine rigging applications.

Wire rod is made from high carbon steel wires(0.35 to 0.85 percent carbon) in a hot rolling process of a required diameter, usually from 5.5mm to 8 mm.

Wire rod is drawn to the required diameter by the 1st drawing machine after descaling dust and rust, adding mechanical properties suitable for application.

Positioning the wires different or the same size lay in multiple layers and same direction, or cross lay and diameter is maintained by one-third of the rope size.

So in theory, it is very simple to manufacture wire ropes. However there are many more details that must be closely monitored and controlled, and this requires time and experienced personnel since it is a super complicated project you cannot imagine.

CIVMATS produces high quality stainless steel wire rope. Our annual production capacity is roughly 8000 tons, among which stainless steel wire rope amounts to 400 tons per month. The tolerance of our stainless steel wire rope can be as small as ±0.01mm. CIVMATS produces strictly according to ISO9001:2000. Every product delivered from CIVMATS is a reputation warranty.

Wire rope can be divided into multi-strand wire rope and single-strand wire rope. It is structured with at least two layers of steel wire or a plurality of strands spirally wound around a center or a core. Stainless steel wire rope refers to a steel wire rope made of stainless steel. In dynamic systems, stainless steel wire ropes are widely applied in the lifting of cranes and elevators, the transmission of mechanical power, the control of automobile cockpit poles and the operation of aircraft control systems, etc. In static systems, stainless steel wire ropes are also employed in various industries such as the stability of the sling bridge"s pulling support tower and the design of new railings.

Stainless steel wire rope features high temperature resistance, good fatigue resistance, excellent breaking force, long service life and durability. It is widely used in coal, petroleum, metallurgy, chemical industry, shipbuilding, bridge, electric power, rubber, military, tourism, water conservancy and light industry. The products can be produced according to ISO, BS, DIN, JIS, ABS, LR and other international and foreign advanced standards

In CIVMATS, all of our stainless steel wire ropes are packaged as per international standard to prevent any possible damage or loss. They are neatly wrapped in accurate length with securely tied rope ends. For enhanced customer experience, we also provide dedicated package as per your special requirements.

Our main grades for stainless steel wire rope are 304 and 316. We can also customize stainless steel wire rope as per your specified grades and sizes for your reference.

1. Point contact: The adjacent stainless steel wires contact in the form of point in the strands. The diameters of all the stainless steel wires, excluding the central wire are equal, and the strands are formed by layering.

2. Line contact: There is a linear contact between the adjacent layers of stainless steel wire in the strand, and the strands are made of stainless steel wires of different diameters in one process.

4. Point and line contact: There are two kinds of contact forms between the adjacent layers of stainless steel wires in the strand. The strands are made of wires of different diameters.

1. In the equipment reform of chemical, fertilizer, chemical fiber and other industries, stainless steel wire rope was used for the deployment of the updated equipment.

2. Stainless steel wire ropes are used in the applications of popular stainless steel welding rods and a considerable number of stainless steel components, springs, connecting parts, etc.,

5. Stainless steel wire ropes are also extensively used in railway electrification, decoration industry, rigging industry, fishing gear industry, automobile and motorcycle industry and other industries.

Established in 2005, Jiangsu Safety Steel Wire Rope Co., Ltd. is a professional steel wire rope manufacturer and exporter with a profound experience. The company is located in Wuxi, Jiangsu, China covering an area of 57,108.70 square meters. They have a total annual production of steel wire rope is 25000 to 30000 tons and a registered capital 13 million U.S. dollars. Jiangsu Safety Steel Wire Rope Co., Ltd. has plenty of high-quality products to offer.Toho-Rongkee

Chongqing Toho-Rongkee Electronic and Machinery Co., Ltd is one of the best wire rope manufacturers in China that follows ISO 9001:2008, TUV, CE, SGS qualification standard on every production method and fabricated. Also offer a wide range of lifting tools, equipment, and various riggings that meet your standards. Employs over 1000 skilled workers and staff in 7 advanced factories in China.Tianli Stainless Steel Products Co., Ltd

Tianli Stainless Steel Products Co., Ltd is specialized in manufacturing steel wire ropes headquarters in Dainan Town, Jiangsu Province China. Currently having more than 50 existing employees in over 6600 square meters factory area. They can provide excellent advice and assistance to ensure you obtain the right products at the lowest cost.Guizhou Wire Rope Incorporated Company

With more than 40 years of manufacturing and technique experience, you can totally rely on Guizhou Wire Rope Incorporated Company, they have excellent production lines, modern production techniques, and excellent quality control systems. All products such as steel wire, pre-stressed wire rope, PVC coated wire rope, etc. are not only famous with excellent quality but in reasonable prices and considerate services in China. This company also receives good popularity in the overseas market.Nantong Jiaan Metal Material Co., Ltd.

Established in 2013, Jiaan Metal Material is one of the respected manufacturers of steel wire rope located in Nantong, Jiangsu, China. All the production methods, from raw material smelting, heat treatment, wire drawing, and rope twisting to physical and chemical performance examining, are under strict and scientific control based on ISO 9001 certification standard.Nantong Lili hardware products Co., Ltd.

Started in 1998, Nantong Lili hardware products Co., Ltd. continually improving and striving to provide high-grade wire rope to customers worldwide. ISO9001:2008, ISO14001:2004 certified company located in Jiangsu, China. They mainly engaged in producing steel wire rope, stainless steel wire, steel strip, stainless steel strip, spring steel strip, spring steel wire, carbon steel wire, and more.Nantong New Jianghai Internation Trade Co., Ltd.

Set up in the year 2016, Nantong New Jianghai Internation Trade Co., Ltd is an expert wire rope provider situated in Nantong, China. Owns advanced technologies and machinery to manufacture a high-class and comprehensive quality solution. They have more than 70 professional employees working and improving products according to ISO9001:2015 authentication.Jiangsu Zhongying Steel Cable Co., Ltd.

Established in 2004, Zhongying Steel Cable is one of the leading manufacturers and reputable provider of steel wire ropes situated in Nantong, Jiangsu, China. Their factory has 80, 000 square meters and the building area is about to 65,000 square meters. Workshops are equipped with advanced producing equipment and comprehensive testing facilities that’s why the partnership with them will bring business satisfaction for you.Qingdao Haito Rigging Hardware Co., Ltd

A large enterprise located in Qingdao, Shandong, China, which engaged in manufacturing rigging hardware such as steel wire rope accessories, wire rope clips, load binder, chain, wire rope, and more. They have an abundant supply of superior quality products. Founded in 2009, Haito Rigging Hardware continuously developed and improving products supported by good experience and professional employees.Gustav Wolf

With over 130 years of experience and development, Gustav Wolf is a leading superior steel wire and steel wire ropes manufacturer associated with quality and safety. Produced products according to ISO9001:2015, ISO14001:2015 certification which can meet your requirements and demands. Employs over 115 hardworking workers and staff who aim to serve customers with honesty, loyalty, and perseverance.Jiangsu Xiangchuan Rope Technology Co., Ltd.

Specialized in manufacturing high-standard wire rope, Xiangchuan Rope Technology is a dedicated supplier and manufacturer with vast experience in the field. Own a modern facility with an area of about 38, 000 square meters and employs 138 staff members and workers. Their advanced production equipment, technical know-how, skilled workers guarantee that in Xiangchuan Rope Technology you have a reliable partner.JULI SLING CO., LTD.

For more than 33 years of experience in creating comprehensive products such as wire rope, JULI SLING earned a good reputation in the steel industry appreciated by foreign and domestics customers. JULI is recognized as a pioneer in China’s lifting and rigging industry, the standard makers in rigging field, the advocate of worldwide rigging civilization. Partnership with this company will skyrocket your business project.Nantong Julong Metal Products Co., Ltd

Nantong Julong Metal Products Co., Ltd is a large private enterprise founded in 2009 that specialized in producing any types of wire rope, headquarters in Jiangsu, China. Get 100% ideal products, at a cost-effective price here in Julong Metal. Be one of their satisfied customers such as in Europe, Africa, North America, South America, Asia, the Middle East, etc.YunFeng Steel Wire Rope Products Ltd.

Located in Jiangsu province, China, YunFeng Steel Wire Rope is a professional manufacturer of all kinds of wire rope offer in excellent quality and reasonable price to customers. They can meet customers’ demands and requirements by manufacturing all kinds of products with international standards.Sinounion Industries

Founded in 1999, Sinounion Industries is a professional Steel Wire Rope manufacturer in China. Also offer Rigging Hardware, Lifting Equipment, and various Forging & Casting products. All products are manufactured according to ISO9001, ISO14001, CE, and GS standards. The company owns a wide factory area in Qingdao, Shandong province with about 35000 square meters.Ningbo BST Metal Products Co., Ltd.

Established in 2002, BST Metal Products is one of the largest and reputable steel wire rope manufacturers in China with an area of 78,000 square meters factory workshop. Backed up by more than 350 professional people & technical engineers who have a vast experience in the field, BST Metal Products ensure great and fast production exceed the national and international guidelines.Jiangsu Yasheng Metal Products Co., Ltd.

As an ISO9001:2015, ISO/TS16949:2009, ISO9001: 2000 certified company, Jiangsu Yasheng Metal Products Co., Ltd. devoted itself to producing excellent products at a favorable cost. If you`re looking for a wire rope manufacturer, then Yasheng Metal Products is the best choice! Get 100% quality products prepared by solid technical strength and professional service team.Chongqing Geyo Machinery corporation

Geyo Machinery corporation a reliable manufacturing company that focuses on research, production, sales, and service of high-quality products. Mainly engaged in manufacturing wire rope, wire rope slings, tamping rammer, power trowel, scarifying machine, etc. They have their own advanced production facilities, expert technical team, and a professional quality control team.SHANGHAIMETAL

Started in the year 1980, SHANGHAIMETAL is a premier wire rope provider. Together with a team of experts, innovative machinery, and dedicated workers, they guarantee absolute customer satisfaction. Shanghai Metal is always passionate about working and supplying excellent services to clients throughout the world. All their products are manufactured with high-quality at a reasonable cost.Huazhuo HD Machinery

Established in 1958, Qingdao Huazhuo HD Machinery Co., Ltd. is a trusted wire rope manufacturer with a profound experience, strong workmanship, and professional service team that ensures the best product at best price offer to clients around the world. A leading supplier of high-standard wire rope, rigging hardware, marine hardware, chain, lifting tools, and other high-grade metal products.

a. Wires: steel wires for wire ropes are normally made of non-alloy carbon steel with a carbon content of 0.4 to 0.95%. The tensile forces and to run over sheaves with relatively small diameters.

b. Strand: the strand is a component of wire rope usually consisting of an assembly of wires of appropriate diamsions laid helically in one or more layers around a central element.

c. Core: the core is the central element, of fiber or steel, around which are laid helically the outer strands of wire rope. The core provides proper support for the strands under normal bending and loading conditions.

d. Wire rope is several strands of metal wire twisted into a helix forming a composite "rope", in a pattern known as "laid rope". Larger diameter wire rope consists of multiple strands.

Rotation rope and non-rotation rope or rotation resistant rope. Round strand rope, compacted rope, swaged rope. Wire rope with fiber core, wire rope with IWRC(Independent Wire Rope Core). Galvanized wire rope, ungalvanized wire rope or bright wire rope. Wire rope with plastic insert, Wire rope without plastic insert. Wire rope covered with plastic.

Wire rope is commonly comprised of wire core and strand, which is made using various types of steel including galvanized, coated and non-coated. The steel wire ropes are also named as wire cables and steel wire, which are featured with high strength, flexibility, abrasion resistance, corrosion resistance and rotation resistance. This makes them well-suited for varieties of uses such as pulling, fixing and bearing in the marine, architectural and construction.

The wire ropes can be assembled into steel wire rope slings being used with lifting equipment or winches to meet lifting and rigging needs in different industries.

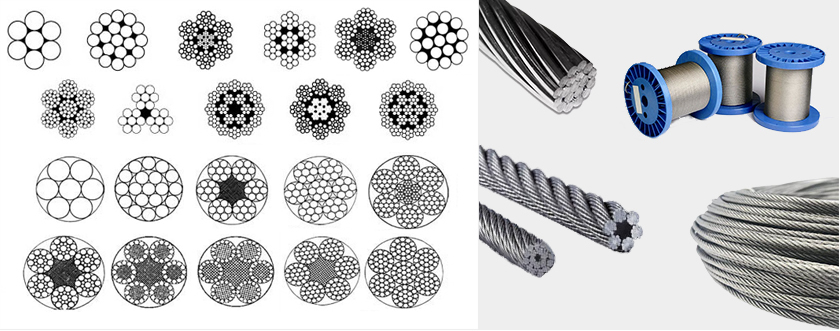

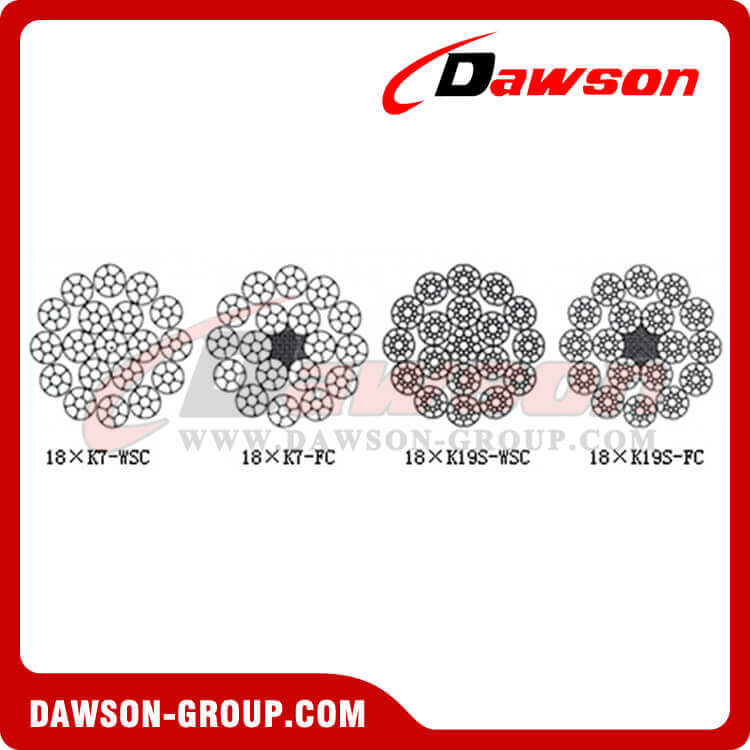

The wire ropes are classified according to the strand and wires. Shown below are just some typical types of wire ropes. Wire ropes are also available in customized constructions.

As specialist for manufacturing quality steel wire ropes over 20 years, our company can supply strong, durable and reliable ropes that capable to minimize your downtime and maximize cost effectiveness. Decades of experience we owned make us know clearly the work you do and capable to provide professional guidance.

We select the best steel or stainless steel as raw material for wire rope manufacturing. Our products are manufactured under strict quality managements and test before they leave the factory.

Our engineers can provide professional advice about picking up optimal steel wire ropes for their application, installation guidance to ensure maximum return in their wire rope system.

If you are going to pick up steel wire ropes that suit your project perfectly, you must have an ideal about the construction about them. Our company can supply bright wire rope, galvanized wire rope, stainless steel wire rope, compacted wire rope, rotation resistant wire ropes, mining wire rope, elevator wire rope, crane wire rope and gas & oilfield wire ropes. Here are some details to solve the problem that may puzzle you whether you are browsing the web or picking up steel wire ropes.

Bright steel wire ropes mean no surface treatment is applied to the rope. Therefore, they have the lower price among these three wire ropes. Generally, they are fully lubricated to protect the rope from rust and corrosion.

Galvanized steel wire ropes feature compressed zinc coating for providing excellent corrosion resistance. With higher break strength yet lower price than stainless steel, galvanized steel wire ropes are widely used in general engineering applications such as winches and security ropes.

Stainless steel wire ropes, made of quality 304, 305, 316 steels, are the most corrosive type for marine environments and other places subjected to salt water spray. Meanwhile, bright and shiny appearance can be maintained for years rather than dull as galvanized steel wire ropes.

Steel wire ropes are composed of multiple strands of individual wires that surrounding a wire or fiber center to form a combination with excellent fatigue and abrasion resistance. These wires and strands are wound in different directions to from different lay types as follows:

Beside above lay types, alternative lay ropes which combine regular lay and lang lay together and ideal for boom hoist and winch lines, can also be supplied as your request.

Two main methods about seizing steel wire ropes in conjunction with soft or annealing wire or strands to protect cut ends of the ropes form loosening.

TEUFELBERGER high performance steel wire ropes are being used for various tasks on cranes around the world. In order to keep their quality at the highest level, a team of experts has been working continuously on upgrading existing and developing new products. In these endeavors, we work together closely with our renowned customers so as to find the perfect solution for their high demands.

Our range of services encompasses rope assembly, splicing, exchanging ropes, and even providing customized training. For these purposes, our service teams are deployed to many countries of the globe.

soLITE® by TEUFELBERGER, the first-ever fiber rope featuring a steel wire rope construction, impresses its users by providing 10% more in loading capacity and 80% less in weight than its steel counterparts. Developed together with the crane specialists at LIEBHERR, it has already taken the place of steel wire ropes in challenging lifting applications.

On 28th April 2017 Redaelli entered Teufelberger Group. Teufelberger and Redaelli both leading manufacturers of high performance steel wire ropes, unite their expertise to provide the best technical solutions for steel wire ropes and establish together a global presence.

We at Teufelberger-Redaelli understand your day-to-day challenges and solve them together with you. We develop and produce high performance steel wire ropes that create added value by enhancing the efficiency and safety of your applications. Expect more: of our innovative steel wire ropes, our services, our experienced experts in development, application engineering, and sales – all around the globe. Being a family enterprise, we attach great importance to successful, long-standing business relationships. Our commitment does not begin and end solely with the supply of premium quality steel wire ropes, but we also accompany you throughout your work processes when it comes to optimizing efficiency and costs.

We know that high performance steel wire ropes are able to unleash their full potential only if crane systems have been set up optimally and if the ropes have been installed correctly. Therefore, we also provide support during project planning, installation, and subsequent careful handling to maximize rope lifetimes. After all, the purchasing costs are just the tip of the iceberg.

At Teufelberger-Redaelli you don"t need to worry about making the right choices, as we can handle that for you. Our specialists know what matters in connection with your application and are therefore able to provide you with a clear product recommendation. Every single application requires a specific, custom-tailored solution.

Rotation-resistant and non-rotation-resistant high performance steel wire ropes from Teufelberger-Redaelli are used for a variety of applications such as:

Four manufacturing sites for steel wire ropes and a combined total of more than 425 years of rope-making experience tally up to a unique wealth of expertise and an unmatched and proven production standard. The resulting high degree of flexibility allows us to keep delivery times to a minimum.

Stainless steel wire rope is made of stainless steel raw materials by drawing and twisting. It has excellent corrosion resistance, high temperature resistance and low temperature resistance. It is widely used in petrochemical industry, aviation, automobile, fishery, precision instruments, architectural decoration and other industries. After electrolytic polishing, the surface of stainless steel wire rope is brighter and the corrosion resistance is greatly enhanced. After low-temperature heat treatment, the wire rope can achieve higher strength. There are many classification methods of stainless steel wire rope, such as steel grade, construction/structure, laying/twist direction, surface, application and breaking load/strength. The most common used steel grade is SUS304/SS304 and SUS316/SS316.

The Stainless Steel Wire Rope of Shanghai BISCO International Corporation has the advantages of high dimensional accuracy, excellent surface quality, high brightness and stable mechanical properties. If there is a need of this product, please feel free to contact us, we will provide you with a quotation within 24 hours since receiving your inquiry.

6. Constructional Symbol: 1X3, 1X7, 1X19, 1X37, 3X7, 6X7+FC, 7X7, 6X19+FC, 7X19, 6X36SW+IWRC, 6X37+FC, 7X37, 8X19, 19X7 (Single Layer、Filler Wire、Seale、Warrington、Combination)…

Stainless steel wire rope has many characteristics such as excellent corrosion resistance, heat resistance, low temperature resistance, good fatigue resistance, high breaking force, long service life and durability. It is widely used in coal, petroleum, metallurgy, chemical industry, machinery, construction, ships, aviation, vehicles, bridges, cableways, control lines, electric power, rubber, military industry, medical treatment, water conservancy, fishery and light industry…etc. Stainless steel wire rope can be produced according to international standards such as ISO, BS, DIN, JIS, ABS and LR.

2. Stainless Steel Wire Rope for Elevator: it is used in elevator equipment carrying people and things in high-rise buildings. It is required to have a tight and soft structure and small structural elongation. It usually adopts 8-strand structure

3. Aviation Stainless Steel Wire Rope: it is used for aircraft aerial rope or operation aerial rope, which is required to have high fatigue performance and corrosion resistance

5. Steel Wire Rope for Aerial Cableway and Cable Car: it is used for air transportation track. With cable car as the means of transportation, the steel wire rope is required to have a large safety factor, corrosion resistance and smooth surface of stainless steel wire rope

6. Hoisting Stainless Steel Wire Rope: it is required that the wire rope has high tensile strength, good flexibility, no rotation, distortion fatigue resistance and no looseness

7. Stainless Steel Wire Rope for Fishery: it is used for trawl, fixed net, rolling net, etc. it works in rivers, lakes and seawater environment, and requires good corrosion resistance and flexibility

Original equipment wire rope and replacement wire rope must be selected and installed in accordance with the requirements of this section. Selection of replacement wire rope must be in accordance with the recommendations of the wire rope manufacturer, the equipment manufacturer, or a qualified person.

Wire rope design criteria: Wire rope (other than rotation resistant rope) must comply with either Option (1) or Option (2) of this section, as follows:

Option (1). Wire rope must comply with section 5-1.7.1 of ASME B30.5-2004 (incorporated by reference, see § 1926.6) except that section"s paragraph (c) must not apply.

Option (2). Wire rope must be designed to have, in relation to the equipment"s rated capacity, a sufficient minimum breaking force and design factor so that compliance with the applicable inspection provisions in § 1926.1413 will be an effective means of preventing sudden rope failure.

Type I rotation resistant wire rope ("Type I"). Type I rotation resistant rope is stranded rope constructed to have little or no tendency to rotate or, if guided, transmits little or no torque. It has at least 15 outer strands and comprises an assembly of at least three layers of strands laid helically over a center in two operations. The direction of lay of the outer strands is opposite to that of the underlying layer.

Type II rotation resistant wire rope ("Type II"). Type II rotation resistant rope is stranded rope constructed to have significant resistance to rotation. It has at least 10 outer strands and comprises an assembly of two or more layers of strands laid helically over a center in two or three operations. The direction of lay of the outer strands is opposite to that of the underlying layer.

Type III rotation resistant wire rope ("Type III"). Type III rotation resistant rope is stranded rope constructed to have limited resistance to rotation. It has no more than nine outer strands, and comprises an assembly of two layers of strands laid helically over a center in two operations. The direction of lay of the outer strands is opposite to that of the underlying layer.

Type I must have an operating design factor of no less than 5, except where the wire rope manufacturer and the equipment manufacturer approves the design factor, in writing.

A qualified person must inspect the rope in accordance with § 1926.1413(a). The rope must be used only if the qualified person determines that there are no deficiencies constituting a hazard. In making this determination, more than one broken wire in any one rope lay must be considered a hazard.

Each lift made under § 1926.1414(e)(3) must be recorded in the monthly and annual inspection documents. Such prior uses must be considered by the qualified person in determining whether to use the rope again.

Rotation resistant ropes may be used as boom hoist reeving when load hoists are used as boom hoists for attachments such as luffing attachments or boom and mast attachment systems. Under these conditions, all of the following requirements must be met:

The requirements in ASME B30.5-2004 sections 5-1.3.2(a), (a)(2) through (a)(4), (b) and (d) (incorporated by reference, see § 1926.6) except that the minimum pitch diameter for sheaves used in multiple rope reeving is 18 times the nominal diameter of the rope used (instead of the value of 16 specified in section 5-1.3.2(d)).

The operating design factor for these ropes must be the total minimum breaking force of all parts of rope in the system divided by the load imposed on the rope system when supporting the static weights of the structure and the load within the equipment"s rated capacity.

Wire rope clips used in conjunction with wedge sockets must be attached to the unloaded dead end of the rope only, except that the use of devices specifically designed for dead-ending rope in a wedge socket is permitted.

Prior to cutting a wire rope, seizings must be placed on each side of the point to be cut. The length and number of seizings must be in accordance with the wire rope manufacturer"s instructions.

It is the goal of LKS Wire Rope to provide manufactured rigging products and hardware which are competitively priced and delivered on time with zero defects at quality and service levels that are consistent with the expectations of our customers. We fully understand that to do so is good business. The success of LKS Wire Rope depends on our commitment to associate involvement, continual improvement, and improved business performance goals.

Wire ropes are structural components made of twisted wire that are widely employed in diverse areas. The safe usage of wire ropes is directly related to the production lifetime and personnel safety. Therefore, it is of great significance to develop an online detection and quantitative inspection system for wire ropes [1]. ElectroMagnetic Testing (EMT), the advantages of which include low cost, high reliability, and suitability for online detection of wire rope, has been widely used in wire rope application. EMTs include eddy current testing, magnetic particle testing, Magnetic Flux Leakage (MFL) detection, magnetic memory detection, microwave detection, and other methods. Among these, the MFL method can detect the surface and internal defects of wire rope, and has been greatly developed for its simple structure and portability [2].

In a traditional MFL detection, wire rope is magnetized to saturation, after which a magnetic probe is used to measure the MFL distribution. According to the form of the magnetic field source, there are two techniques: coil magnetization [3,4] and permanent magnet magnetization [5,6,7,8,9,10]. Singh [3] designed a magnetized device consisting of a variable-current saddle-shaped coil. This apparatus can be adjusted by controlling the magnitude of the current, but the device cannot be continuously used for the massive heating of the coil. Jomdecha et al. [4] improved a coil device of solenoid structure instead of traditional coil magnetizer. The magnetic field strength can be adjusted by changing the magnetizing current or magnetizing coil number. The multiple symmetrical yoke structures were composed of circumferentially distributed wire rope to magnetize its uniform saturation [5,6,7,8]. Wang et al. [9] considered the effects of different lift-off distances on detection accuracy during the magnetization process, and proposed an improved magnetization device. Xu et al. [11] used the finite element analysis method to optimize the structure of the excitation device, which was then validated by the experiment.

In a testing system, the magnetic field is converted into an electrical signal by a magnetic-to-electric convertor, such as an induction coil, a fluxgate, a Hall element, or a magnetoresistive sensor. Cao [12] proposed a detection device based on a Printed Circuit Board (PCB) split differential coil, obtaining a sum of MFL circumferential distribution signals. The device is useful for a certain span in the axial direction of the wire rope, but it is not sensitive to small width defects and circumferential defect information. Jomdecha et al. [4] improved the traditional induction coil by designing an induction coil array, with coils arranged on the circumferential wire rope. This system solved the problem of MFL circumferential information loss. Zhao et al. [13] designed a detection device in which 30 Hall sensors evenly surround the circumferential wire rope. This device can effectively obtain the information of the circumferential MFL distribution, but the Signal-to-Noise Ratio (SNR) of the collected signal is low. Peterka et al. [14] presented the results obtained by tracking the magnetic flux around the cable end and the signal runs from a particular design. Additionally, they investigated scanning elements placed above artificial defects created close to the cable end.

The signal that is collected by magnetic sensors contains ample background noise, so it is necessary to filter system noise. Cao et al. [12] proposed an algorithm for adaptive parameter spatial notch filtering to suppress strand wave, and the wavelet packet was used to filter out the high-frequency random noise. Zhang et al. [15,16] used the wavelet based on compressed sensing to denoise the strand wave and high-frequency noise, and then further proposed a channel-balance method based on the Hilbert-Huang transformation. Zhang et al. [17] used a spatial filter to reduce noise and smoothen the defect image. Zhang et al. [18] pretreated the MFL grayscale and effectively suppressed the noise interference. Tian et al. [19] combined the wavelet transform and the morphological transform to create a morphological filter algorithm that suppressed the interference associated with the baseline drift in the wire rope signal.

There are some problems among the existing MFL methods for defect detection in wire ropes:the excitation devices are cumbersome and inconvenient, the defect cannot be positioned in the circumferential direction, the wire rope is magnetized unevenly, and the SNR is low. A device to detect wire rope surface remanence strength was designed to solve these problems, and this solution is described in this paper. The wire rope was magnetized by permanent magnets, and the MFL information of the wire rope surface was collected after magnetization with giant magnetoresistive sensors, arranged evenly around the circumference of the wire rope. A wavelet filtering method based on Ensemble Empirical Mode Decomposition (EEMD) was used to denoise the original signal. The two-dimensional defect signal was processed and analyzed by digital image technology. To achieve quantitative classification, the defect image characteristics were extracted to express the MFL distribution information. The processing data were normalized to obtain the MFL grayscale image. The cubic spline interpolation was used to improve the circumferential resolution. The method of modulus maxima was used to locate and segment defects from the MFL image. The wavelet super-resolution reconstruction method was used to improve the resolution of the segmented image. Image descriptions of area, rectangle, elongation, and seven invariant moments were extracted as the feature vector of the defect, which was the input of a Back Propagation (BP) neural network, used to classify the defects.

Rotation resistant wire rope refers to a series of steel ropes which minimizes the tendency to spin or rotation under load. These wire ropes boast special design - the outer layer is twisted in the reverse direction of inner layers for counteracting torsional forces generated from multi-layers of strands.

To achieve the resistance against the spin and rotation, all wire ropes are composed of at least two layers of strands. In general, more layers a rotation resistant wire rope has, more resistance it will boast. For example, 2-layer ropes is much easier to spin and rotate than 3-layer ones. Meanwhile, if one end of free rotation is allowed, 2-layer rope can only develop 55% to 75% of its breaking strength comparing with 95% to 100% of 3-layer ropes.

The 3-layer rope with more outer strands is capable to distribute more radial pressure onto inner layers and ideal for larger mobile such as all tower cranes.

Wire ropes with 8 to 10 strands & 2-layer constructions without reversely twisted inner strands have very similar appearance to rotation resistant wire ropes, but they are not.

Rotation resistant wire ropes are considered to be less stable needing to be handled and installed with great care. They must be taken to avoid high loads with small diameter sheaves.

8613371530291

8613371530291