single leg wire rope factory

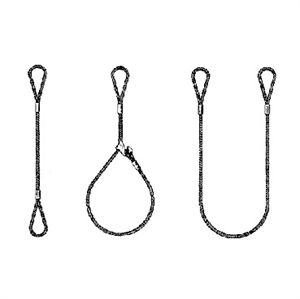

Single leg wire rope slings are just as they sound- they are comprised of a single length of wire rope. Also sometimes known as one leg wire rope slings or single leg cable slings, these heavy duty lifting slings offer some versatility as they can be manufactured with a variety of end configurations.

An eye loop is formed using a flemish eye splice, in which the rope is separated into two parts. One part contains three strands and the other three strands plus the core. These two rope parts are then re-laid back into the opposite direction, forming an eye. The entire area is then secured by a metal pressed sleeve.

Sliding Choker Wire Sling:Sliding choker wire rope slings are made of 6 x 19 EIPS wire rope and have a sliding choker hook between the two eyes that slides from one end to the other for easy hook-up. Sliding wire choker slings feature a regular eye for the top portion of the lifting sling and a thimbled eye for the portion of the sling that loops back to attach to the sliding hook. This helps prevent wear and tear on the sling eye by protecting the steel cable rope from rubbing on the hook. Our sliding wire rope choker slings are also available with a latched choker hook by special order.

Ultra Flexible Cable Laid Sling: Cable laid wire rope slings are manufactured using an ultra-flexible 7 x 7 x 7 galvanized aircraft cable to offer more flexibility than a standard steel wire cable sling. Though the cable laid sling is weaker in strength than the standard wire rope, it offers excellent corrosion resistance. Our standard cable laid metal slings have eyes on both ends but other fittings are also available, including thimbles, hooks, crescent thimbles, and slip-thru thimbles to create the custom steel strand lift sling you need.

As with all lifting slings, the rated capacities of single leg wire slings will vary based on the type of wire rope, as well as the direction and angle of the pull.

We offer inspections and mobile proof test services for product verification, break testing, and load testing to ensure compliance for all wire rope slings we sell and repair. Our mobile proof test services are available throughout the United States. In addition to our mobile load testing services we have stationary test beds to service Oklahoma, Texas, Kansas, Wyoming, North Dakota, New Mexico and all surrounding areas.

All Commercial Group riggers are trained to fabricate wire rope slings and bridles with a mechanically spliced flemished eye. The ends are secured by pressing a metal sleeve over the ends of the strands of the splice.

Looking for wholesale single leg wire rope sling to sell at your online store? Look no further than Alibaba.com for a rich catalogue of options and features. You can find your ideal drip brewer.

single leg wire rope sling have become the ubiquitous choice for anyone wanting to try a better flavor of coffee. This is owing to their ease of use and maintenance. single leg wire rope sling and the electric filter coffee machine are easy to clean. Just put soapy water on the metal filter and rinse. Same procedure applies for the kettle that is usually made of glass for a sleek and classy look. A myriad of options abound for automatic drip coffee makers. Opt to spend more and you will be introduced to popular drip coffee makers like the spinn coffee maker, cafeteira automatica and programmable coffee maker, with features like programmable brew settings, automatic timers so that you wake up to the pleasant smell of coffee in the morning, a “keep warm” setting that maintains the perfect temperature for the coffee without overcooking it, among other features.

You don"t even need electricity to make coffee with single leg wire rope sling. Compared with drip coffee pot non electric, you can even enjoy the slow, satisfying process in your own home with electric coffeemakers.Just boil water over a camping stove, put a coffee filter over your drip coffee maker, add coffee, and then brew to your heart"s content.

Wire rope slings are widely used in the lifting applications and engineering industries for extremely heavy loading. They can be used on wire rope hoist, pulley and block, crane and winch pulling equipment at dockyards and large construction sites.

They are available in single leg or multi legs like the chain slings, however, the wire rope slings are more safety than chain slings for wire rope sling can still hold the load if 1 or 2 wires are broken, while the chain sling will fail for 1 link broken result to the whole chain sling failed.

Usually, we use a less flexible or a stiffer wire rope to assembly for they are more crush and abrasion resistance than a very flexible one since wire rope slings are used in a straight line for lifting connect with a master link on one end and a hook or hooks on the other end, need more load strength than flexibility.

The diameter of a wire rope is the diameter of circle which encloses all of the wires . When measuring wire rope it is important to take the greatest distance of the outer limits of the Crown"s of two opposite strands. A measurement across the valleys will result in incorrect lower readings .

It is difficult to fix the safety factor for each type of wire rope to be used for various equipments ,as this factor depends not only on the load carried,but also on the speed of rope working, the kinds of fitting used for rope ends,the acceleration and deacceleration ,length of rope,the number ,size and arrangements of sheave drums etc. The following safty factors are minimum requirements for safety and economy in the common installation .

This chart is purely an attempt to illustrate the relative characteristics of different constructions of wire rope as indicated in the text . No numerical scale is shown or intended .

Established as a Partnership firm in the year 2009, we “Mass Moving Systems” are a leading Wholesaler Trader of a wide range of Safety Shoes, Industrial Wire, Safety Gumboots, etc. We are dealers of high-quality Safety and Lifting equipment, Materials handling equipment and Industrial & Personal Safety equipment. We offer the most comprehensive list of equipment and accessories in a most cost-effective manner. These include lifting equipment and accessories such as Overhead Cranes, Hoists, Chain blocks, Pulling and Lifting Machines, Geared trolly, Steel wire ropes, Mooring ropes, Slings, D-shackles, Bow Shackles, U Clamps, tackles, PP ropes, nylon ropes industrial safety products such as helmets, Safety Shoes, Gumboots, Masks, Gloves, Safety harness, Traffic Safety Accessories. Our technical expertise provides reliable Solutions to every customer. We are part of a network of shops & manufacturing/servicing units at various places in Tamandu and Kerala. Please contact us for any of your needs in this field. We guarantee our best service to our esteemed customers.Established in the year 2009, Mass Moving Systems in Edapally, Ernakulam is Dealers of Lifting & Mooring equipment, Materials handling equipment and Industrial & Personal Safety equipment in the Ernakulam. This well-known establishment acts as a one-stop destination servicing customers from both local and other parts of India. Over the course of its journey, this business has established a firm foothold in the industry. The belief that customer satisfaction is as important as their products and services, have helped this establishment garner a vast base of customers. This business employs individuals that are dedicated towards their respective roles and put in a lot of effort to achieve the common vision and larger goals of the company. Our shop is at Koonamthai, Opposite to Milma, Metro Pillar NO 362, Near Pathadippalam Metro Station. Our shop open from 9:30 AM to 7:00 PM in all working days. We are closed on Sundays.

Wire rope slings are made of steel wire ropes and processed by a wire rope press. The ropes mainly used for hoisting, traction, tensioning and load-bearing are called pressed steel slings. The pressed steel wire rope sling has the characteristics of high strength, light weight, stable work, and not easy to be broken suddenly. It is widely used in steel, chemical, transportation, port, construction and other industries

2 In addition to the wear of the outer layer of the steel wire sling, the wire rope sling is mainly broken due to metal fatigue caused by repeated bending when bypassing the hook and the suspended object. Therefore, the ratio of the diameter of the hook or the suspended object to the suppressed steel wire rope determines the suppressed steel sling An important factor in service life.

3 The wire rope sling is mainly used in the transportation that requires high-strength ropes such as lifting and pulling. It is strictly forbidden to stand under the suspended object or pass on the object during use.

www.magicartcranes.comLooking for single leg wire rope sling? With wide experience and expertise, STONIMAGE is well-known as one of the largest manufacturers and suppliers in China. We are equipped with a professional factory which can guarantee you the high quality, high precision and reliable performance of our products.

Wire rope slings have been used extensively for years and were once the industrial lifting sling of choice. Wire rope slings, sometimes referred to as wire cable slings are more robust and durable than nylon slings and also have higher temperature limits.

Wire rope slings with an independent wire rope core (IWRC) can withstand contact and exposure temperatures up to 400 degrees (F). Wire cable slings with fiber cores should never be exposed to temperatures in excess of 180 degrees (F). Wire rope slings of all types should never be used at temperatures below -40 degrees (F). Wire rope rigging slings with fiber cores (FC) are rated at reduced capacities when compared with an equivalent size, wire choker with an independent wire rope core (IWRC). They are generally fabricated from 6 x 19 or 6 x 37 construction wire cable. The constructional numbers refer to the number of strands (6) that are helically wound around a core. The core supports the strands of the wire rope lifting sling and can either be an independent wire rope core (IWRC) or a fiber core (FC) made from hemp or sisal. Smaller diameter wire rope slings feature 6 strands with 19 wires in each strand. Larger diameter industrial lifting slings will generally feature 6 strands with 37 individual wires in each strand. The 6 x 37 construction is more flexible than the 6 x 19 construction, but not as abrasion resistant.

Wire cable lifting slings used by the crane, rigging and material handling industries are available in many different styles and constructions to meet your needs. Custom made slings and special order slings are shipped daily from our factory. The most popular wire lifting slings are Single Body slings featuring a 6 x 19 or 6 x 37 Construction, Extra Improved Plow Steel (EIPS) Wire Rope with an Independent Wire Rope Core (IWRC). These slings are sometimes referred to as wire chokers, Permaloc wire rope slings, wire cable slings, Flemish eye slings, single leg slings, eye and eye slings or eye & eye slings due to the loop or eye that is formed on each end of the wire sling.

There are different grades and strengths of steel used to manufacture the individual wires that make up the sling. The most popular for sling fabrication is (EIPS). Metallurgists continue to improve the tensile properties of steel with new, corresponding designations such as EEIPS (Extra-Extra Improved Plow Steel). Single leg, Flemish Eye/Mechanical Splice, Wire Slings provide additional security, superior to return loop wire slings should the swage sleeve become damaged during use. Single Body Wire Cable slings are available in 15 different types which feature different combinations of plain loops, three types of thimbles (crescent, standard and slip through) and rigging hooks. Thimbles greatly improve sling longevity by protecting the rope at connection points. We offer two types of single leg wire slings that feature a sliding choker hook that is placed between the sling eyes. Industrial lifting slings with sliding choker hooks make removal of the cable sling from the load, quick and easy. Type 14 lifting slings feature a lifting loop on one end and a thimble on the opposite end to engage the sliding choker hook. Type 15 lifting slings features plain loops each end. View the 15 single leg wire sling types available .

We will not sell you a sliding choker hook without a hook latch, but there are many that will! Stainless Steel Wire Rope Slings provide the sling user with improved corrosion resistance and are also readily available. Cable Laid Wire Rope Slings with a galvanized finish are also available. Cable Laid Wire Slings are much more flexible than equivalent sized, single body wire slings. The flexibility of industrial lifting slings that feature a cable laid construction is a direct result of the small diameter, aircraft cable used in the fabrication of the wire sling. Size for size, cable laid lifting slings are not as strong as equivalent sized, single body, wire chokers. Cable laid wire slings can be equipped with many of the same options available for single body slings.

In addition to our standard lifting slings, custom made slings are also readily available. Cable laid slings are also referred to as Ultra flexible cable laid slings, steel strand and E-Z Flex Cable Laid wire rope slings. Wire Rope Bridle Slings are available in two leg bridle, three leg bridle and four leg bridle designs. A master link is used to collect the multiple wire cable sling legs, while providing a connection point to the hoist line. Bottom “connectors” such as masterlinks or eye hoist hooks (with latches) are most commonly used to engage the load. Custom made bridle slings are also readily available.

In addition to wire bridles we also offer a complete line of strand laid grommets and swaged socket assemblies. Slingmax® Wire Rope Slings are as revolutionary to wire cable slings as Twin-Path® Extra, high performance fiber slings are to polyester roundslings. That makes sense, because both products are patented inventions from the mind of Dennis St. Germain, Sr. Without a doubt, Mr. St. Germain has done more for the sling, crane and rigging industries than any other. It all started years ago with the Tri-Flex® Sling which provides professional riggers with a great combination of strength and flexibility. Tri-Flex® wire rope slings provide substantial savings due to the materials used and the tremendous labor savings realized in the fabrication process. Tri-Flex® cable slings were also the genesis of T&D Ultra-Flex® slings which are used extensively in the power generation, transmission and distribution industries.

Gator-Laid® wire rope slings and Gator-Max® wire cable slings are the most efficient, heavy lift slings available. Both the Gator-Laid® wire slings and Gator-Max® lifting slings feature 12 parts of wire in the sling eye and meet all the requirements of the Wire Rope Technical Board and the United States Navy. Gator-Flex® wire rope slings and Gator-Flex® wire rope grommets are heavy lift slings used extensively by the oil and gas industries for both land based and off shore rigging. Gator-Flex® wire slings offer sling users the greatest flexibility available for a heavy lifting sling. Gator-Flex® grommets not only provide flexibility, but can be fabricated for applications requiring minimum sling lengths.

Like all of our nylon web slings and polyester round slings, wire rope slings need to be inspected on a regular basis to ensure the safety of sling users. Poor inspection practices can lead to devastation, injury and death. Please refer to the inspection and usage information that is available in our Rigging Resource Guide or on our web site. Read and understand the warnings that accompany all our products. Remember, ignore a warning leads to much mourning.

All wire chokers shipped from Lift-It have a heavy duty, metal sling tag attached. There is no additional charge for this as we have always felt it is our duty to provide robust sling tags. Others may use cloth or synthetic materials which sometimes come off the sling, before it’s even used! Others fill in the information with magic marker that is not so magic. The tag is just as important as the wire cable, the way the Flemish eye is fabricated and the way the mechanical sleeve is swaged. If a vendor wants to charge you extra for a metal tag, run as fast and as far as you can from them and contact the sling experts at Lift-It Manufacturing, where profit margins are not maximized by supplying labels that should be used on clothing.

While wire cable slings are more robust and durable than nylon lifting slings or polyester roundslings, wire slings are not cut proof. Wire slings need to be protected from damage like all industrial lifting slings. Only materials of sufficient strength, thickness and construction must be used to prevent damage. Do not use gloves or cardboard. Use protection devices that have been designed to resist the effects of cutting and abrasion. Wire Rope Saddle Protectors are readily available; Click Here

8613371530291

8613371530291