single leg wire rope pricelist

Single Leg Wire Rope Slings are ideal for lifting and rigging. Offering capacities up to 3.2 Tonnes we can provide prices on application for larger capacities. All of our wire rope slings are proudly manufactured in the UK and can be customised online to your requirements. Any of our one leg Wire Rope Slings can be fitted with the following terminations:

We offer inspections and mobile proof test services for product verification, break testing, and load testing to ensure compliance for all wire rope slings we sell and repair. Our mobile proof test services are available throughout the United States. In addition to our mobile load testing services we have stationary test beds to service Oklahoma, Texas, Kansas, Wyoming, North Dakota, New Mexico and all surrounding areas.

All Departments1x19 Stainless Steel Strand1x7 Guy Strand6x26 Wire RopesApparelBlocks and PulleysCable RailingClearanceCordageDecalsFall ProtectionGrade 70 Transport ChainHard Hat StickersHeadwearLIFTGEAR MerchRotation Resistant Wire RopesSafety MerchSynthetic Tycan® ChainSynthetic Tycan® Chain SlingsWashington Wire RopeIMPORT- WRCManual Chain HoistsGrade 70 Binder Chains7x19 Aircraft CableWire Rope SlingsLever Chain HoistsBeam ClampsGrade 100 ChainPlate Clamps6x36 Wire RopesG100 Chain SlingsDSS - DOUBLE SWIVEL SHACKLESEB - SWIVEL EYE BOLTWeb SlingsBest SellersOffroad RecoveryOffroad Recovery RopesTowing SuppliesLoad and TransportWire RopeChain and AccessoriesClampsDSR - DOUBLE SWIVEL HOIST RINGSRound SlingsAMHHoists and ClampsWire Rope ClipsSynthetic SlingsCODIPROLifting SlingsMade in USASafety ShacklesSUPER STRONG ShacklesShacklesRigging Hardware

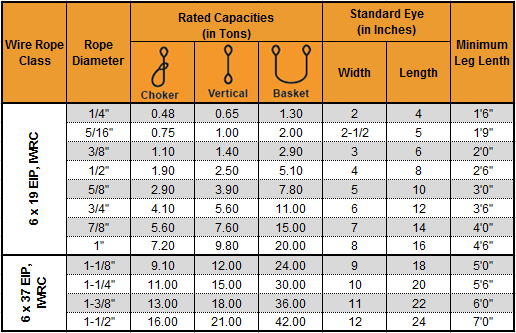

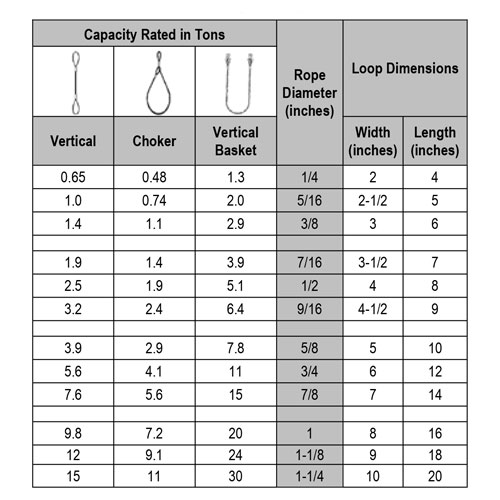

Warning: Understand specifications before using Wire Rope Slings. Failure to understand those instructions may cause death or serious injury. Wire RopeSlings should never be used beyond their certified load ratings. Avoid Shock Loads. Inspect slings for wear and tear before each use. Rated capacities are reduced when applying angular loads.

Wire Rope Material: The lifting slings are made from independent wire rope core (IWRC) offering less stretch and resistance to crushing while maintaining sling flexibility. Wire rope slings are fabricated from extra improved plow steel (EIPS).

A low quality wire rope sling can cause injury and damage. A look-alike wire rope sling often found at lower prices is also often advertised to conform to the same safety standards (if at all). Be aware that it may refer to safety ratings in effect decades ago. So for example under the same safety standard a decade ago, a wire rope sling may be rated to 100% without proof load testing while today it may be 300% with proof load testing. Be assured that we only sell the highest quality wire rope slings and our advertised safety standards conform to the current ASME standards.

Working load limits (capacity) of the wire rope lifting slings vary depending on the angle of use. The capacity is reduced as the angle of use declines. See drawing below how a 1,000 lbs sling capacity is reduced as the angle of use declines. The capacity of the sling is always highest at a 90 degree angle of use and smallest at an angle of 30 degrees (or less).

The wire rope sling is not quite as durable. The wire rope sling is not as flexible as chain but its greater stiffness can be an advantage if it has to be inserted through a small opening or beneath a load. However, when wrapped around a load, the wire rope sling often tends to deform permanently to the shape of the load. Wire rope suitable for slings comes in a variety of grades and constructions. In most cases looping back and securing the loop with a metal sleeve terminates the rope. This forms a loop or soft eye, the simplest form of sling end. Thimbles are used to support and protect the eye from abrasion. Wire rope is generally cheaper and lighter than chain which can be a plus, particularly for applications that require long sling lengths.

The nylon and polyester slings have the advantage of being lightweight in comparison to chain and wire rope slings. They are very flexible and relatively soft; therefore, they are suitable in applications were minimal damage to the load"s surface finish is important. The rope is made endless or terminated with an eye by means of a handmade splice. Similar to a wire rope sling, various terminal fittings are available. Without adequate protection, nylon and poly slings are susceptible to being severed when impinging on even a relatively moderate sharp edge.

Wire rope is often commonly referred to as cable; they are one in the same. Wire rope is composed of wires, strands, and a core. The basic unit is the wire, which is formed into strands. The strands are wound around the core. Various types of wire rope exist to meet a range of uses and operating conditions. These types are designated by the number of strands; the number, sizes and arrangement of the wires in each strand; and the way in which the wires and strands are wound, or laid, about each other.

Important characteristics of wire rope relate to the number and size of the outer wires. A small number of large outer wires result in better resistance to wear and corrosion. A large number of small wires result in better flexibility and resistance to fatigue.

The core acts as the axial member about which the strands are laid. Wire rope cores are made in two different forms. The one used most extensively is a wire rope of suitable size to serve as a core. It is called as independent wire rope core (IWRC). IWRC has increased tensile strength, offers less stretch, and is resistant to crushing; however, is less flexible. The other type is a wire strand core (WSC). This consists of a multiple-wire strand, and may be the same construction as the main rope strands.

Two grades of carbon steel wire are offered. The bulk of commercial wire rope lifting sling is made from improved plow steel (IPS) or extra improved plow steel (EIPS) which has a higher tensile strength.

Hand Splicing:Because no metal sleeve is required to secure the eye in the hand spliced sling, it exhibits more flexibility than mechanically splice slings of equal diameter. They have a more narrow profile and therefore can fit through tight spaces. Without benefit of a metal sleeve, lifts must be limited to applications where the wire rope sling is restrained from rotation and possible unlaying of the sling body.

Mechanical Splicing:Mechanically spliced eyes do not suffer the limitations of hand splicing, are economical, and offer the highest rated capacity of any spliced wire rope sling. This wire rope sling is fabricated by unlaying the rope body into two parts, one containing half the number of strands, the other having the remaining strands and core. The rope is unlayed far enough back to allow the eye to be formed by looping one part in one direction and the other part in the opposite direction and laying the rope back together. The strands are rolled back around the rope body and a metal sleeve is slipped over the ends and pressed (or swaged) to secure the ends to the body of the wire rope sling.

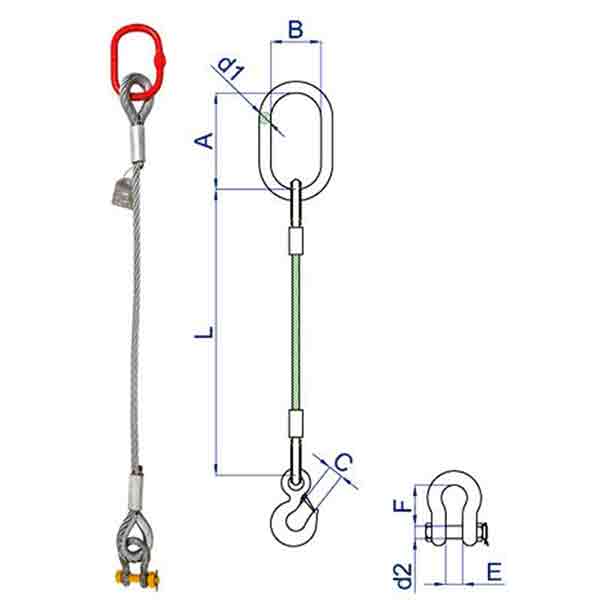

Single leg wire rope slings are just as they sound- they are comprised of a single length of wire rope. Also sometimes known as one leg wire rope slings or single leg cable slings, these heavy duty lifting slings offer some versatility as they can be manufactured with a variety of end configurations.

An eye loop is formed using a flemish eye splice, in which the rope is separated into two parts. One part contains three strands and the other three strands plus the core. These two rope parts are then re-laid back into the opposite direction, forming an eye. The entire area is then secured by a metal pressed sleeve.

Sliding Choker Wire Sling:Sliding choker wire rope slings are made of 6 x 19 EIPS wire rope and have a sliding choker hook between the two eyes that slides from one end to the other for easy hook-up. Sliding wire choker slings feature a regular eye for the top portion of the lifting sling and a thimbled eye for the portion of the sling that loops back to attach to the sliding hook. This helps prevent wear and tear on the sling eye by protecting the steel cable rope from rubbing on the hook. Our sliding wire rope choker slings are also available with a latched choker hook by special order.

Ultra Flexible Cable Laid Sling: Cable laid wire rope slings are manufactured using an ultra-flexible 7 x 7 x 7 galvanized aircraft cable to offer more flexibility than a standard steel wire cable sling. Though the cable laid sling is weaker in strength than the standard wire rope, it offers excellent corrosion resistance. Our standard cable laid metal slings have eyes on both ends but other fittings are also available, including thimbles, hooks, crescent thimbles, and slip-thru thimbles to create the custom steel strand lift sling you need.

As with all lifting slings, the rated capacities of single leg wire slings will vary based on the type of wire rope, as well as the direction and angle of the pull.

It also save energy and money. wire rope slings are made from stainless steel, and it"s also an excellent choice for installation or any production of any kind.

There are two types of wire rope sling, steel wire sling, and steel rope sling. Stocking products of different price points, be the first choice and stockists wholesale today. Check out the stainless steel wire sling price, color and design at Alibaba.

How much does a wire rope sling cost? How much does a shackle or a web sling cost? These are legitimate questions that we hear every day from prospective customers looking to purchase rigging products for their next lifting project.

Rigging shops have long been the stalwarts of the lifting and rigging industries. Rigging shops typically have a showroom or storefront with a wide selection of sling hooks, shackles, chain, synthetic slings and wire rope. They also traditionally buy the raw materials for wire rope, webbing, steel and chain and have a shop where they can make the lifting and rigging products themselves.

If you’re looking for the added benefit and expertise of speaking with a knowledgeable salesperson, want to browse an extensive inventory, and may have an immediate need for a piece of rigging hardware, chain sling, roundsling, or wire rope, then a rigging shop might be your best bet.

A common 1/2” X 10’, 6 X 25 Wire Center, Wire Rope Sling comes in at $29.00, $43.00, and $67.00 from three different online retailers. So, why is there such a wide pricing range for what appears to be the same product?

Online suppliers with the more expensive wire rope and web slings tend to be larger catalog and supply houses that offer an impressive array of all types of industrial products, including rigging gear. They also offer the convenience of selling items like gloves, eye protection, spray paint, etc.—an added convenience factor that allows you to buy everything that you need from one source.

This is also true for lengths of wire rope and chain. Larger diameter wire rope, and larger and longer lengths of chain and wire rope, often fall out of the “standard” product range of suppliers other than rigging shops. If a shop has to special order a piece due to a non-standard size or length, that extra time and effort to acquire the piece will get passed on to the customers as a price markup.

High-performance and specialty items also cost more. For instance, 3/4″ 6 X 37 with wire center rope would cost around $2.50 per foot. A high-performance cable like a 3/4” Dyform 18 would cost about $4.50 per foot. But in the right application, the Dyform 18 will last much longer to justify the higher initial cost, and may also save labor costs because the customer won’t have to perform cable changes as frequently.

However, highly-trained lifting specialists are compensated for their time and knowledge applied to a lifting project and therefore will increase the cost of your rigging solution. Unfortunately, you’re not going to solve your problem by e-mailing a catalog house or e-commerce rigging website’s customer service team. Their businesses are built to move rigging hardware, wire rope slings, chain slings, and synthetic slings out the door in a quick and efficient manner.

Generally, imported products are cheaper in price, and in many cases, the quality is comparable to products made domestically. For instance, an imported 1/2” x 10’ 6 X 25 swaged wire rope sling would cost about $20.00—the same sling made by a company who manufactures their rigging gear in the United States would charge around $30.00.

At Mazzella, we provide ideal lifting solutions—offering all styles of lifting slings, rigging hardware, wire rope, overhead cranes and hoists, and engineered lifting devices. We also have locations all across the United States—fully stocked with different sizes and configurations of rigging products for your next project.

The wire rope attachments (Style 1520) are to be used by simply hooking the attachment through the hole in the tag, then put into the sleeve inside the eye, and swage it.

8613371530291

8613371530291