single wire rope sling supplier

In the case of the "U" shaped sling, lifting is accomplished by firmly attaching the eyes to a hook or hoist, though both ends are then simultaneously lifted in order to wrap around or cradle the supplies or finished goods to be lifted.

Unlike synthetic or fiber slings, wire rope offers increased resistance to wear and abrasion and can be used for both hot and cold materials as well as in corrosive applications such as those in marine, construction, aerospace, manufacturing, assembly, transport, shipping, and other industries where wire rope slings are commonly used. Wire ropes fitted with slings in these applications also serve to improve connectivity and prevent fraying of the rope.

Like stranded wire ropes, the slings that they attach too are strictly regulated and must be inspected regularly as mechanical failure puts both machinery and employees at serious risk. To prevent such disruptions, it is important to select the proper sling for a given application.

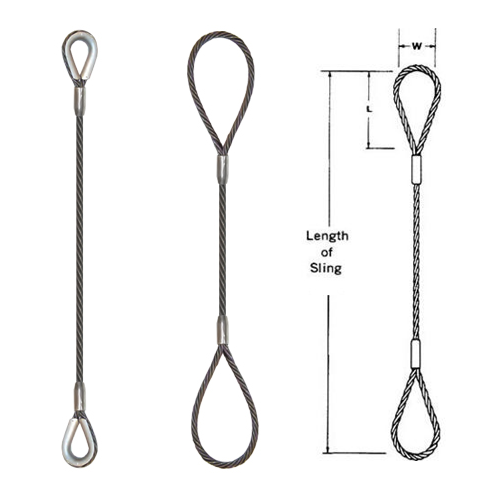

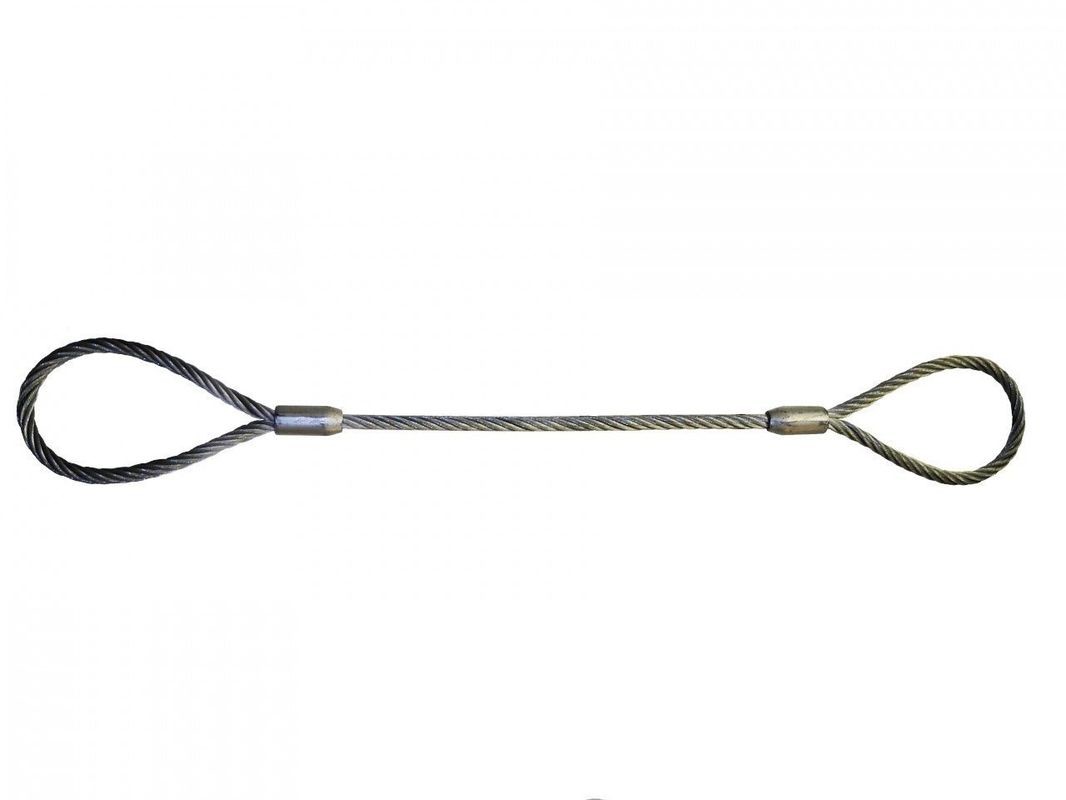

Slings are most commonly constructed simply by looping or folding the end of a wire rope back onto itself and holding it in place with a firm fitting such as a clamp. Alternatively, the folded segment of wire may be braided or twisted along the main body of rope and otherwise held in place through welding or similar processes.

The rope itself is comprised of cold drawn filaments that are twisted or braided into strands which in turn are helically wrapped around a core. The multilayered formation of wire rope acts as a safety measure as individual strands are more likely to fail than the rope as a whole, allowing the other strands to act as a backup.

Popular materials for wire rope and sling construction include aluminum, nickel alloy, bronze, copper, and titanium, although steel and stainless steel are the most common due to their increased strength and availability.

Additional considerations include the wire rope sling"s dimensions, fatigue strength, its ability to bend without distortion, to withstand abrasion, and environmental conditions as well as the intended use for the sling.

We offer inspections and mobile proof test services for product verification, break testing, and load testing to ensure compliance for all wire rope slings we sell and repair. Our mobile proof test services are available throughout the United States. In addition to our mobile load testing services we have stationary test beds to service Oklahoma, Texas, Kansas, Wyoming, North Dakota, New Mexico and all surrounding areas.

Stainless Steel Slings, Fiber Core Slings with reduced Work Load Limits, Cable Laid Slings with galvanized finish and larger diameter slings are also available.

When wire rope is bent around a load, or diameter, the rope strength is decreased. The D/d ratio is diameter of the object around which the rope is bent (D), divided by the diameter (d) of the rope. D/d affects slings used in basket hitches and must be taken into consideration. When the diameter of the load is 4 times the diameter of the wire rope sling the D/d ratio is 4/1 and the sling efficiency is 75% of the Basket WLL.

When it comes to using wire rope slings in or on your jobsite, there are a few things to keep in mind in order to make sure that your wire rope sling is ready for use and that it will last for years to come. For starters, be sure to designate a qualified person to inspect all of your slings, fastenings, and attachment each day before use for damage or defects. A thorough inspection of your wire sling should check for:

By regularly performing these inspections that check the condition of your rope, you’ll not only be able to give your wire rope sling the care and maintenance that it needs to work at its best, you’ll be protecting your entire team and jobsite from the potential dangers that can occur if a wire rope sling snaps during use.

Wire rope slings are widely used in the lifting applications and engineering industries for extremely heavy loading. They can be used on wire rope hoist, pulley and block, crane and winch pulling equipment at dockyards and large construction sites.

They are available in single leg or multi legs like the chain slings, however, the wire rope slings are more safety than chain slings for wire rope sling can still hold the load if 1 or 2 wires are broken, while the chain sling will fail for 1 link broken result to the whole chain sling failed.

Usually, we use a less flexible or a stiffer wire rope to assembly for they are more crush and abrasion resistance than a very flexible one since wire rope slings are used in a straight line for lifting connect with a master link on one end and a hook or hooks on the other end, need more load strength than flexibility.

Manufacture of material handling gripper slings made from 304 or 316 stainless steel, 4130 heat-treated alloy steel, exotic alloys and neoprene. Features include polyurethane plastic-covers, wire mesh construction, interwoven and tolerate abrasive loads. Suitable for handling all types of products such as coiled strips, thin-walled tubing, polished shafting, lumber, paper machine rolls, precast hollow core concrete beams, structural beams, cold drawn flats and irregularly shaped objects. Serves the marine, automotive, beverage, cement, energy, food and mining industries.

Looking for wholesale single leg wire rope sling to sell at your online store? Look no further than Alibaba.com for a rich catalogue of options and features. You can find your ideal drip brewer.

single leg wire rope sling have become the ubiquitous choice for anyone wanting to try a better flavor of coffee. This is owing to their ease of use and maintenance. single leg wire rope sling and the electric filter coffee machine are easy to clean. Just put soapy water on the metal filter and rinse. Same procedure applies for the kettle that is usually made of glass for a sleek and classy look. A myriad of options abound for automatic drip coffee makers. Opt to spend more and you will be introduced to popular drip coffee makers like the spinn coffee maker, cafeteira automatica and programmable coffee maker, with features like programmable brew settings, automatic timers so that you wake up to the pleasant smell of coffee in the morning, a “keep warm” setting that maintains the perfect temperature for the coffee without overcooking it, among other features.

You don"t even need electricity to make coffee with single leg wire rope sling. Compared with drip coffee pot non electric, you can even enjoy the slow, satisfying process in your own home with electric coffeemakers.Just boil water over a camping stove, put a coffee filter over your drip coffee maker, add coffee, and then brew to your heart"s content.

DCL Mooring and Rigging is a leading fabricator and manufacturer of wire rope slings. DCL manufactures single leg slings with all types of end pieces to customize for the job that the sling needs to accomplish.

We have them with the basic swage loop, swage thimble, swage thimble eye hook, swage thimble safety pin anchor shackle, swage hawser thimbles, open swage socket, and closed swage socket. We also have multi-leg bridles, including 2 leg bridles which use a master link at the top to hold the two separate slings together. These are perfect for lifting items that need to be attached at multiple points to properly distribute the weight of the item being lifted. 3 leg bridles and 4 leg bridles again are the same thing, just adding another separatee sling onto the master link. Adding legs increases the working load limit that the sling can hold, and also properly distributes the weight across all attached legs. Another component common on wire rope slings is poured sockets. We use a compound called wirelock to attach the wire rope sling to the socket for maximum efficiency. Wirelock is a resin compound made by Crosby, for use in pour socket wire rope sling assemblies. We also manufacture grommets which are basically slings for use in lifting an item that has no place to hook or latch onto, basically, it is an endless wire rope sling that can be fitted into specific designs to properly lift odd-shaped items. DCL also manufactures multi-part braided slings including 2-leg choker bridles, 8 part braided choker slings, tri-flex wire rope slings, gator-flex grommets, gator-max wire rope slings with parallel eyes, gator-laid wire rope slings with parallel eyes, gator-flex wire rope slings, and T & D Ultra-Flex Wire Rope Slings.

The 9-part sling is made by laying a single wire rope continuously through both eyes and the sling body. This results in a body formed with nine parts. The proven design provides internal adjustment to distribute the load among all nine parts of the sling body.

Additionally, the construction makes it possible to more easily inspect all parts of the sling before and after each lift, which is important to remember if the sling is to be used many times.

A 9-part sling construction exhibits constructional stretch of approximately 1.5% on the first loading and a lesser amount thereafter. For this reason, lifts that use two or more legs should always be made with legs that have been subjected to the same past usage when such stretch may affect the lift.

When a sling body must conform to a tight choke hitch or must bend in a tight radius, such as around a pin or post, a 9-part construction may be the most suitable since it can develop greater lifting capacity from a smaller component rope.

8613371530291

8613371530291