small wire rope sheaves factory

Johnson Wire Rope Sheaves are industry proven and are available in sizes ranging from 3" to 108", in over 250 standard models. Cost efficient, custom designs are available, with no upfront tooling or pattern charges and no premium price for small order quantities. 16" to 108" O.D. Sheaves have flame hardened, precision grooves for slow, even wear and long rope life. The integrity of Johnson’s single disc forged steel construction provides sheaves with superior strength.

All wire rope and fittings should be thoroughly inspected before use and replaced if found defective. Any alteration to Block Division’s products will void all said or implied warranties, guarantees, and liabilities.

All wire rope and fittings should be thoroughly inspected before use and replaced if found defective. Any alteration to Block Division’s products will void all said or implied warranties, guarantees, and liabilities.

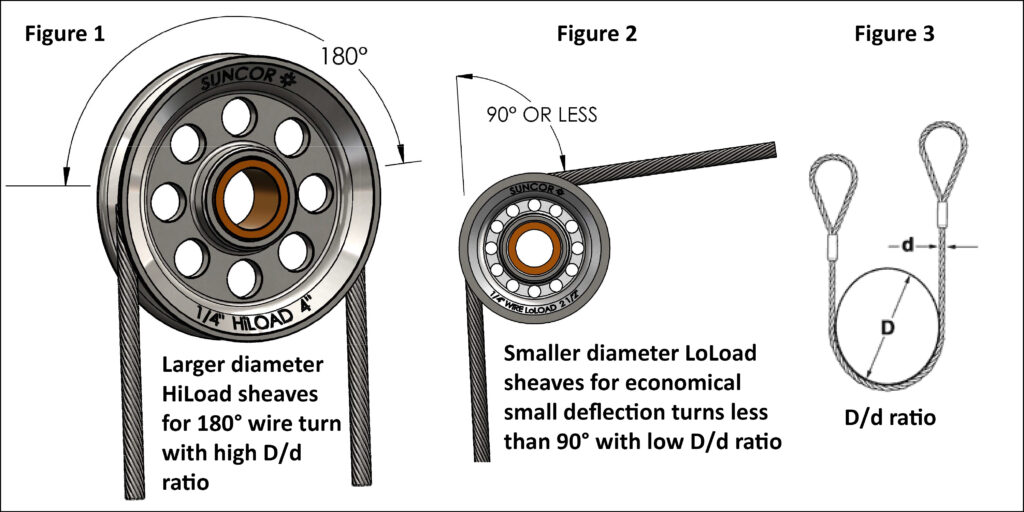

A smaller mechanical cable pulley requires the cable to make a sharper bend, thus increasing the bending stress with which the cable is subjected. Larger stainless steel cables, and cables of other material will experience greater stresses when passing over the same round belt pulley as a smaller cable, all other factors being equal. Each application, therefore, has a wire rope pulley specification based on the size and construction of the mechanical cable.

Cables are constructed of a number of strands wrapped around each other, which are themselves composed of a number of individual wires. Cable construction is, therefore, a function of the number of strands per cable and the number of wires per strand. Its design is typically expressed as a x b, where a is the number of strands per cable and b is the number of wires per strand.

Both the cable diameter and its construction determine the size of the pulley appropriate for the application. Industry testing over the years has created recommended minimum groove diameters to be used with various cable constructions. For example, the groove diameter of a pulley for a 7x19 cable should be at least 25 times the diameter of the cable. Similarly, a 7x7 cable should use a pulley with a groove diameter at least 40 times that of the cable, while a 7x49 would be recommended at 15 times the diameter of the cable. In general the more flexible the cable, the smaller the recommended groove diameter would be to maximize the cable life.

The primary tradeoff in pulley size is that a smaller pulley will wear out the cable faster, while a larger pulley may be too big for that application. Since the remaining disadvantage of using a pulley greater than the recommended size deal largely in costs, designers should use the largest size pulley that will fit that particular application. In practice, this means that most pulleys are still too small. Too often designers allow insufficient space for properly sized pulley selection, which will limit the cable’s lifespan.

Lubrication can help extend a cable’s life, especially in applications with small cables or pulleys. Sava lubricates all of its commercial cables that are less than 2 millimeters in diameter, which can double or even triple the cable’s life when the pulley is too small. All cables made to military specification (Mil-Spec) standards are lubricated.

Browse Sava’s wire rope and pulley catalog, which contains small cables as well as fittings, pulleys and tools. Sava also provides engineering and sales expertise to meet all your mechanical cable needs. Contact us today!

8613371530291

8613371530291