southwest wire rope catalog factory

Southwest Wire Rope"s Engineering Services Department provides engineered lifting devices, lift plans, and engineered load testing services under the leadership of experienced Professional Engineers with extensive experience in heavy lifting.

• Tensile Strengths are determined in accordance with Cordage Institute 1500.2. Test Methods for Fiber Rope. Minimum Tensile Strength (MTS) published assumes spliced eye tenninations at each end of the rope. Weights actually calculated at linear density under state preloaded (200d’J plus 4%. Diameter and circumference size published is nominal and reflects rope size after loading (10 cycles) to 50% ofMTS. See reverse side for application and safety information .

Plasma® 12 strand is the highest strength synthetic rope available. Plasma® 12 strand is manufactured from High Modulus Polyethylene (HMPE) that has been enhanced by Cortland’s patented recrystallization process. This process is especially effective in medium to large diameter ropes where strengths are over 50% higher and creep is significantly less than that of standard Spectra® 12 strand.

In rigging, we all know that the setup is only as strong as its weakest link. Any failure is a potentially dangerous situation that puts your entire operation in jeopardy. Every component must be relentlessly reliable. Synthetic rope is one such tool that bears heavy responsibility. While incredibly strong and durable, it often immediately supports a load; if it were to fail, the results would be catastrophic.

You will likely never seeused in a rig as they are weaker and less durable than their synthetic counterparts. With this in mind, let’s discuss the advantages of synthetic rope.

Synthetic rope is made from nylon, polyester, or polypropylene fibers. These ropes can be made using one or a combination of these synthetic fibers. Much like a natural rope, these fibers are drawn out into strands and then woven together. The end result is a durable, strong rope that can bear markedly more weight and tension than its natural counterpart.

Because of the materials used, synthetic rope is better able to withstand friction, making it more durable. It should be noted that how much you use the rope and its length of service will directly affect how long it lasts. Sporadic use could see it surviving for up to 10 years, whereas heavy use will require replacement every year or two. Synthetic rope is great for outdoor uses, as it is resistant to rot and mildew that can arise from exposure to moisture.

Synthetic rope is useful for a host of additional purposes. Its resistance to moisture makes it ideal for use in marine applications, but it has various advantages outside of the rigging sphere. It serves as an excellent climbing rope due to its abrasion resistance – it can handle rough edges of the terrain without fail. This is also what makes it perfect for rigging in film and theater. Where creative problems often require creative solutions, crews know they can rely on these ropes to hold the scene together. Synthetic rope can also be used effectively in towing and hauling applications.

has been a leader in wire rope and rigging supplies in the Gulf Coast region since 1966. We provide quality supplies and reliable service to each one of our clients so they can meet the tough demands of the industry with confidence and excellence. We are happy to share our decades of experience to help you find the best solution for whatever undertaking you have in front of you. From synthetic rope and slings to wire rope and chains, we have a comprehensive product offering to completely outfit your rig.today to level up your operation.

Wire rope is arguably the most important asset that arigging equipment providercan supply. It forms the backbone of every operation, helping to execute every lift and move heavy loads with precision and security. Withoutwire rope, the rigging, overhead lifting and securement industries couldn’t meet demands.

For these reasons, it is absolutely crucial to make sure wire rope is properly maintained.Storing wire ropesafely and intentionally will help lengthen its working life and improve the safety of your daily operations. Keep reading to discover the key considerations and tips for storing wire rope.

The best method of storing wire rope is on a reel. This helps to maintain the shape and function of the rope over time by avoiding kinks and tangles, which can damage the integrity of the rope and reduce its safety and usefulness. Reels also help centralize wire rope into space-efficient units that can be transported and even stacked.

Once spooled onto a reel, it will be simple and easy to remove the desired length of wire rope when needed. Whether you are working with drilling rigs, cranes or winches, we recommend that you have your wire rope installed and removedby an experienced professional.

Wire rope is a vital piece of equipment, and it should be stored as such. Water, salt, dust, steam, temperature extremes and chemical fumes canwreak havocon the structure and strength of wire rope. Therefore, store your wire rope supply in a cool, dry, covered, and well-ventilated place. An indoor location is best, but if you must store wire rope outdoors, make sure it is covered with waterproof material.

Additionally, make sure no part of the rope is touching the ground, and that the base of the wire rope reel is elevated at least a few inches in case of flooding. Water immersion can cause the wire rope to corrode and its lubricant to wear off. . When in doubt, check with your rigging equipment provider about wire rope spooling to ensure it is done right.

Inspections of various pieces of rigging equipment are required by law on a regular basis – and wire rope is no exception. Work with your rigging equipment provider to have your wire rope inspected if it has been stored for an extended period of time. A full-scalerigging inspectioncan also help you determine where and how to store your wire rope on the front-end of a project. A qualified rigging equipment inspector will be able to address the quality and condition of all your rigging and lifting gear, furnishing detailed reports on their findings.

At Southwest Wire Rope, our team has been serving the needs of the rigging, overhead lifting and securement industries with unwavering excellence for 56 years. If you’re searching for a rigging equipment provider, wire rope spooling and storage help or a certified inspector, turn to the professionals at Southwest Wire Rope. Our experienced team can provide insights and recommendations for the type of wire rope, end fittings, hardware, and operational procedures that best suit your facilities and equipment. We look forward to answering your questions and forming a lasting partnership. For more information, browse ourservice offering.

While the past six decades have ushered in sweeping changes, some things have remained the same. For that entire time, Southwest Wire Rope has remained a stalwartrigging equipment providerwith a reputation for quality and service. We’ve been providing rigging inspections, testing, and the strongest wire rope on the market for years – and we have no intention of slowing down. Here’s how we continue to uphold and define industry standards.

To ensure that each facility and piece of operating equipment is up to code, rigging inspections are required by regulators. At Southwest Wire Rope, we employ a team ofcertified inspectorsthat can investigate every aspect of a rig, from the heavy machinery down to the shackles. With attention to detail cultivated by hundreds of years of combined rigging experience, our inspection team offers industry-leading guidance and professional recommendations. Reporting fromTESSALinkasset management software adds to our comprehensive service offering.

In addition to routine inspections, the Southwest Wire Rope team also performed destructive (break) testing of up to 1.7 million pounds from two separate locations. Need field spooling? We provide on-site installation and removal of wire and synthetic ropes on drilling rigs, cranes and winches. Through our steadfast commitment to raising the bar, we make sure our clients are meeting and exceeding all industry requirements.

At our core, we are rigging equipment providers, and we strive to strengthen our offerings and expertise on a daily basis. In 1983, we introduced our trademark proprietary brand of wire rope to the market, characterized by an iconic gold strand. Nearly 40 years later, “Gold Strand” wire rope is still recognized as the strongest and most reliable wire rope on the market.

Additionally, we have acomplete offeringof wire rope fittings, synthetic and round slings, chains, and other rigging hardware. We pride ourselves on being experts in the rigging equipment space, providing not only the tools to get the job done, but also the guidance to do it right.

Our team has been serving the needs of the rigging, overhead lifting, and securement industries with an unwavering dedication to quality and excellence for over half a century. If you’re searching for a rigging equipment supplier, or need your system inspected by a certified inspector, turn to the professionals at Southwest Wire Rope. Our experienced team can provide insights and recommendations for the type of wire rope, end fittings, hardware, and operational procedures that best suit your facilities and equipment. We look forward to answering your questions and forming a lasting partnership. For more information, browse ourservice offering.

The commodity that “holds up” the rigging, lifting, and overhead securement industries is indisputably wire rope. Combining strength with flexibility, wire rope helps operations of all sizes move heavy loads where they need to go with safety and ease. Without enough properly tested and verified wire rope on hand, the output and productivity of the entire plant can grind to a standstill.

Because every project has different requirements, various types of wire rope are designed and fabricated to serve different purposes. With a variety of orientations, strengths, and load capacities, it’s important to know exactly which variety works best for your job. Here’s a breakdown of the major categories.

The “class” of wire rope refers to the number of wires that compose a strand, as well as how many strands surround the core. For example, 6×31 FC wire rope consists of 6 strands containing 31 wires each, which are wrapped around a fiber core.

General purpose wire rope– the variety most commonly used for daily rigging operations such as lifting, overhead securement, pulling, and establishing tension – most often contains six strands and an Independent Wire Rope Core (IWRC). Each of these strands can contain anywhere from 16 to 49 wires, with more wires increasing the flexibility of the rope.

General purpose wire rope can range in diameter from ¼ inch to 6 inches, with larger diameter ropes having breaking strengths of hundreds or even thousands of tons. For a detailedwire rope strength chart, consult our cataloghere.

Most cranes and some overhead lifting and securement devices require specialized wire rope that prevents the load from rotating. This is often achieved by having layers of compacted strands, oriented in a tightly-knit pattern around a core and layed in alternating directions. For example, the Oliveira NR Maxipact PPI contains 18 outer strands, forming wire rope that can be effectively implemented in a non-rotating environment at temperatures from -50°C to +80°C.

Compacted varieties of crane wire rope provide increased fatigue resistance, strength, stability, and abrasion resistance. Often considered thestrongest wire ropeon the market, these types of wire rope are perfect for mining, industrial, construction, logging, and oilfield applications.

Other rotation resistant varieties come in 19×7 and 8×19 classes with an IWRC; for more detailed information, view thewire rope strength chartand select Wire Rope > Crane.

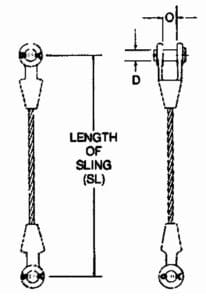

Finally, in addition to customized lengths and types of wire rope, a qualified rigging equipment provider can also supply pre-fabricatedwire rope slings. These slings are outfitted with eyes or sockets that affix the load to a lifting device. Wire rope slings come in dozens of orientations, sizes, and diameters, allowing for ultimate customization when outfitting your rigging operation. Check out the catalog or connect with a rigging equipment professional for guidance and to place your custom order

The professionals atSouthwestWire Rope have been serving the needs of the rigging, overhead lifting, and securement industries with an unwavering dedication to quality and excellence since 1966. If you are in the market for industry-leading lifting gear, or need your system inspected by a certified inspector, turn to the pros at Southwest Wire Rope. Our experienced team can provide insights and recommendations for the type of wire rope, end fittings, hardware, and operational procedures that best suit your facilities and equipment. We look forward to answering your questions and forming a lasting partnership. For more information, browse ourservice offeringand get in touch.

Cut to precision lengths in dozens of diameters, customizedwire ropecan help bring your operation to the next level. For more than 50 years, the team at Southwest has been helping the industry’s biggest players outfit their facilities with the best wire rope in the business. Our technicians can work alongside you to help determine the optimal thickness and orientation for your operation.

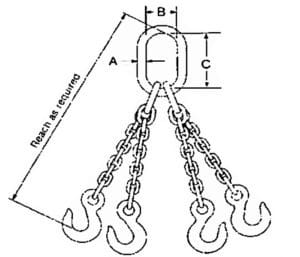

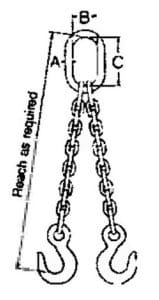

Not all chains are created equal. Every chain is tested to ensure it lives up to the Southwest legacy. Our team is familiar with every major type of chain configuration and linkage, so we can help you secure heavy loads and maximize your lifting potential while keeping your crew safe.

When it comes to lifting gear, every sling, strap, link, wire rope strand, and piece of hardware is vital to the overall success of the operation. Investing in customized below-the-hook products that are expertly fitted to your unique needs and capacity will help make your facility safer and your equipment more effective.

The professionals atSouthwesthave been serving the needs of the rigging and lifting industries with an unwavering dedication to quality and excellence for years. If you are in the market for industry-leading lifting gear, or need your system inspected by a certified inspector, turn to the pros at Southwest Wire Rope. We look forward to answering your questions and forming a lasting partnership. For more information, browse ourservice offeringand get in touch.

A proof load test is just what it sounds like: it proves whether a piece of rigging equipment can bear the load it is designed to. The test is administered in a controlled, measured fashion with a particular multiple of the maximum designed load (generally 1.1 to 1.5 times) and a specified length of time. After the test is completed, the operator will issue a certification confirming the workable load of the wire rope or other rigging component in question.

Whether the rig is overdue for a full inspection, the newly minted wire rope is being put to the test, or older equipment is being evaluated to determine if it is still fit for use, a proof load test is an immensely valuable tool. Every rigging component in the operation should be tested regularly, and a proof load test is one of the most complete and strenuous methods for doing so. Testing also helps keep the rigging equipment and the business as a whole within the boundaries of the OSHA, Department of Labor, and manufacturers’ codes that govern the industry.

The best way to keep your employees safe during a proof load test is to entrust the entire ordeal totrained professionals. Proof load tests are incredibly dangerous if not done with the proper equipment and control measures, as breakage can occur.

AtSouthwest Wire Rope, we provide proof load testing and destructive (break) testing of various lifting devices up to 1.7 million lbs. Proof load testing can be performed using specialized rigging and custom built test jigs that replicate the ultimate field installation of complex and highly engineered products. As you can imagine, this specially designed equipment is operated by industry veterans. By outsourcing the tests to an industry partner like Southwest, you can keep your crew out of harm’s way.

In reality, the advent of performing the test and verifying the strength of the equipment is also keeping your crew safe. Using wire rope or lifting gear until failure is a dangerous proposition and never recommended. Instead, get your equipment certified with a proof load test and gain the peace of mind your professionals deserve.

The professionals atSouthwesthave been serving the needs of the rigging and lifting industries with an unwavering dedication to quality and excellence for years. If you are in the market for leading rigging and lifting gear, need your system tested, or are simply looking for an expert opinion, turn to the pros at Southwest Wire Rope. We look forward to answering your questions and forming a lasting partnership. For more information, browse ourservice offeringand get in touch.

When it comes to lifting gear, one faulty sling, strap, link, wire rope strand, or other piece of hardware can put the entire operation in jeopardy. Investing in equipment that isand is backed by the quality and reputation of awill help ensure your machinery runs smoothly. Codes were developed in the first place to protect your crew from dangerous breakage, equipment wear, and malfunctions, so starting with the best materials is the most effective way to ensure you’re always in line with recent codes.

A destructive or “break” test measures the tensile strength of wire rope by using magnetic and hydraulic arms to pull opposite ends of the rope apart. The test continues until the wire strands begin to fail, and eventually, the wire rope gives out. This is an extremely loud and dangerous endeavor – a break test should never be conducted without the proper equipment and certifications. Work with an industry provider who can conduct a wire rope break test usingin a safe and controlled setting. The results of this test will be printed on a load testing certification, which will help you satisfy regulations.

The professionals athave been serving the needs of the rigging and lifting industries with an unwavering dedication to quality and excellence for years. If you are in the market for leading rigging and lifting gear, need your system tested, or are simply looking for an expert opinion, turn to the pros at Southwest Wire Rope. We look forward to answering your questions and forming a lasting partnership. For more information, browse ourand get in touch.

We’ve all heard that a chain is only as strong as its weakest link. In the rigging business, one faulty sling, strap, link, or wire rope strand, or piece of rigging hardware can jeopardize your entire operation. Investing in equipment that iscrafted to lastand backed by the quality of aleading supplierwill help ensure your machinery runs smoothly and your crew is protected from breakage or equipment wear.

When you first went into the rigging business, you were undoubtedly required to develop a comprehensive set of safety procedures that relate to facility management, personnel, and equipment operation. As your team has grown and your inventory has changed, it’s important to keep your safety protocols updated. If you need help developing safety procedures tailored to your rigging operation and equipment,get in touchwith the team at Southwest today.

The professionals at Southwest have been serving the needs of the rigging and lifting industries with an unwavering dedication to quality and excellence for years. If you are in the market for leading rigging equipment, need your rigging system tested, or are simply looking for an expert opinion, turn to the pros at Southwest Wire Rope. We look forward to answering your questions and forming a lasting partnership. For more information, browse ourproductsandservicesorcontact a reptoday.

One of the most reliable ways to increase the strength of a rigging operation is by investing in high-quality wire rope. Formed from a steel core and wrapped with concentric wire strands, wire rope is an extremely versatile asset that can bear hundreds of thousands of pounds of load, yet remain flexible. For more than 50 years,Southwest Wire Ropehas been supplying some of the strongest and most recognizable wire rope products on the market.

To determine the true strength of wire rope, though, we need to put it to the test. Destructive or “break” testing can be dangerous, but is a useful measuring tool to gauge the strength of wire rope. Here’s everything you need to know about break testing.

Put simply, a destructive or break test measures the tensile strength of wire rope by using magnetic and hydraulic arms to pull opposite ends of the rope apart. The test continues until the wire strands begin to fail, and eventually, the wire rope gives out. This results in an extremely loud explosive noise and frayed metal remnants, which can be extremely dangerous. At the conclusion of the test, the true strength of the rope is evident based on the load reading at the point of breakage.

A break test should absolutely never be conducted without the proper equipment, certified staff, and safety protocols. If you are unsure whether you can perform a break test at your rigging site, then the answer is undoubtedly no. Only specialized machinery operated by trained professionals is fit to manage a destructive test, and attempting a DIY test is a recipe for a regulatory violation and a potential safety hazard.

The only way to know the true strength of a piece of wire rope is to perform a break test in a certifiedtesting facility. As wire rope specialists, the team at Southwest is trained in conducting safe, effective tests of all of our products. If you need your wire rope certified, are curious about the capacity of your rigging system, or are interested in stronger products, we can help. In addition to testing, Southwest is a leader in on-site rigging inspections, rental equipment, field spooling, and other services. Get in touch with a rigging professional today to learn how we can helpoutfityour rigging operation for maximum performance.

The professionals at Southwest have been serving the needs of the rigging and lifting industries with an unwavering dedication to quality and excellence for years. If you are in the market for leading rigging equipment, need your rigging system tested, or are simply looking for an expert opinion, turn to the pros at Southwest Wire Rope. We look forward to answering your questions and forming a lasting partnership. For more information, browse ourproductsandservicesorcontact a reptoday.

One such way that many operators attempt to increase output is by increasing the capacity of each load. More productive loads means jobs get completed faster and more efficiently, and the next project can begin. So, how can we increase the strength and speed of our operation through better lift capacity? Keep reading to hear some ideas from the veterans atSouthwest Wire Rope.

At Southwest Wire Rope, we’ve spent the past56 yearsbecoming experts in fabricating the highest quality rigging and lifting products on the market. From rope and chains, to synthetic web and round slings, along with all the hardware you’ll need, we can help you outfit your crane with the best equipment to ensure it’s running at maximum capacity. If you need guidance on which attachments work best for you, we’re here to help.

The professionals at Southwest have been serving the needs of the rigging and lifting industries with an unwavering dedication to quality and excellence for years. If you are in the market for leading rigging equipment, need your rigging tested, or are simply looking for an expert opinion, we can help. We look forward to answering your questions and forming a lasting partnership. For more information, browse ourproductsandservicesorcontact a reptoday.

Since 1966 Southwest Wire Rope has expanded to become a recognized global wire rope supplier serving diversified markets with material handling, lifting & mooring products at five full-service locations. Large, full-range inventory includes their trademark “Gold Strand” wire rope; bright, galvanized, stainless steel & vinyl coated cable; plus wire rope slings & a variety of fittings & hardware.

We offer a large inventory of import & domestic wire rope including specialty, general purpose and galvanized options. In addition to our traditional green and white wire rope, we provide a full line of wire rope fabrication through 3.5 inch diameter including proof testing. Southern Wire also offers an extensive line of synthetic slings including web and poly-round slings, private labeled with a custom name and contact information.

Wire rope winches by Columbus McKinnon – Pfaff-silberblau Wire rope winches: safely upwards. Wire rope winches from Columbus McKinnon offer variable and always innovative solutions for efficient lifting, pulling and positioning of loads. The designs and options of these wire rope winches are as diverse as their uses by the customer. The lifting technology has proven its worth in industry, trade, stage technology and even under extreme climate conditions, e.g. in the offshore area. What is the possible lifting load? How is the wire rope winch installed and how is it coated? The robustly...

Wire rope winches Table of Contents Wire rope winches Page Electrical wire rope winches BETA SL § BETA EL DGUV V17/18 (BGV C1) / BGV D8 PLUS: applications § - Stadthalle Gersthofen - Tbilisi Centre of Music and Culture, Tiflis - Königsgalerie Duisburg Manual wire rope winches Overview § Console-mounted wire rope winch SW-K LB § Wall-mounted wire rope winch SW-W ALPHA § Wall-mounted wire rope winch SW-W § Console-mounted aluminum wire rope winch SW-K GAMMA § Compact aluminum wire rope winch with free-wheeling SW-KAL § Manual wire rope winch OMEGA § Console-mounted wire rope winch SW-K LAMBDA...

Electrical wire rope winches Electrical wire rope winch BETA SL Short times to delivery are followed by long periods in operation: the electric wire rope winch BETA SL in its standard design works permanently reliably due to enclosed worm gear pairs or spur gears with high-quality brake motors. The electric wire rope winches BETA SL are available with a contactor control system including a gear limit switch. Equipment Motor protection type IP 55 § Maintenance-free worm gear pairs or low-maintenance spur gear with § milled and ground gears – running in oil bath Grooved rope drum § Very §...

Electrical wire rope winches Electrical wire rope winch BETA SL Technical data Art. no. Size Capacity 1st layer Contactor control with gear limit switch Rope speed Rope capacity A B C F G H L M Ø Ø 1st layer top layer [mm] [m] [m] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] *recommended rope: DIN 3069 FE-znk-1960 sZ-spa **Size SLO to motor fan over (worm gear)

Electrical wire rope winches Electrical wire rope winch BETA EL The robust and elegant electric wire rope winches BETA EL are used for lifting, lowering and pulling all types of loads in all applications. The proven technology and the high quality standard of the electric wire rope winch BETA EL guarantee trouble-free, reliable and durable operation. The construction kit system permits high flexibility: the electric wire rope winches BETA EL with their many options can be combined very well into an individual solution. The use of high-quality components offers safety and long service lives....

Electrical wire rope winches Electrical wire rope winch BETA EL Technical data Size Rope speed 1st layer Rec. rope Rec. strength rope Ø* Rope capacity 1st layer *recommended rope: DIN EN 12385-2 19x7 WC -B-sZ Technical drawing see page 9.

Electrical wire rope winches Electrical wire rope winch BETA EL DGUV V17/18 (BGV C1)/BGV D8 PLUS Lifts loads over persons perfectly safely: the BETA EL with DGUV V17/18 approval lifts and positions equipment and decorations precisely in trade, industry and public use. The BETA DGUV V17/18 is also used in theaters together with the tried and tested DELTA theater winch. The electric wire rope winch BETA EL DGUV V17/18 is also offered in the BGV D8 PLUS design for positioning of structural elements. Equipment and processing Tensile loads from 160 – 1200 kg § Additional equipment as in the rope...

Electrical wire rope winches Electrical wire rope winch BETA EL DGUV V17/18 (BGV C1)/BGV D8 PLUS Technical data BETA EL DGUV V17/18 Size Rope speed 1st layer Rec. rope Rope capacity Ø* 1st layer Technical data BETA EL BGV D8 plus Size Rope speed 1st layer Rec. rope Rope capacity Ø** 1st layer [mm]

Electrical wire rope winches Electrical wire rope winch BETA EX The electric wire rope winch models BETA EX have been constructed for special uses. They are operationally safe where there is a danger of igniting explosive atmospheres (mixtures of air, gases, vapors or dust/air mixtures). Since the electrical wire rope winches can be used in very different surroundings, the matching winch for each application can be assembled easily with our flexible construction kit system. Equipment and processing Load § 320 – 7500 kg Maintenance-free, spur gear with oil bath lubrication § High-grade...

Electrical wire rope winches Electrical wire rope THETA The compact Pfaff-silberblau THETA series offers reliable safety, besides being suitable for a wide range of applications and very easy to use. Its high safety standard is achieved, amongst other things, by a mechanical double safety drum brake, separate from the drive, for safe and firm holding of the load. Factory-specified features make this safety electric wire rope winch interesting for many applications, such as construction sites, in building technology or sports facilities – and thus also for individuals, craftsmen, local...

Electrical wire rope winches Application Hans Segmüller Polstermöbelfabrik, headquartered in Friedberg, uses a total of 21 Pfaff-silberblau BETA EL electric wire rope winches with radio control to move the decoration in the foyer of their furniture store in Pulheim in order to create an informative and appealing ambience for an inspiring shopping experience. The BETA EL with a BGV C1 approval wire rope winches are divided into four groups, which allows each specific area (zones) to be attractively and individually designed. Via a radio transmitter, up to eight wire rope winches per zone can...

Manual wire rope winches Overview The most important criteria for quick product selection Selection criteria per product model: Max. § possible lifting capacity Attachment/consoles/wall attachments § Coating (inner-outer attachment): alu, galvanized, stainless steel, painted § Console-mounted wire rope winch SW-K-LB, galvanized design Console-mounted wire rope winch SW-K-LB-VA, stainless steel design Wall-mounted wire rope winch SW-W ALPHA Wall-mounted wire winch SW-W Aluminum console wire rope winch SW-K GAMMA Compact aluminum wire rope winch SW-KAL with free-wheeling Console-mounted wire...

Wire ropes are essential for safety purposes on construction sites and industrial workplaces. They are used to secure and transport extremely heavy pieces of equipment – so they must be strong enough to withstand substantial loads. This is why the wire rope safety factor is crucial.

You may have heard that it is always recommended to use wire ropes or slings with a higher breaking strength than the actual load. For instance, say that you need to move 50,000 lbs. with an overhead crane. You should generally use equipment with a working load limit that is rated for weight at least five times higher – or 250,000 lbs. in this case.

This recommendation is all thanks to the wire rope safety factor. This calculation is designed to help you determine important numbers, such as the minimum breaking strength and the working load limit of a wire rope.

The safety factor is a measurement of how strong of a force a wire rope can withstand before it breaks. It is commonly stated as a ratio, such as 5:1. This means that the wire rope can hold five times their Safe Work Load (SWL) before it will break.

So, if a 5:1 wire rope’s SWL is 10,000 lbs., the safety factor is 50,000 lbs. However, you would never want to place a load near 50,000 lbs. for wire rope safety reasons.

The safety factor rating of a wire rope is the calculation of the Minimum Break Strength (MBS) or the Minimum Breaking Load (MBL) compared to the highest absolute maximum load limit. It is crucial to use a wire rope with a high ratio to account for factors that could influence the weight of the load.

The Safe Working Load (SWL) is a measurement that is required by law to be clearly marked on all lifting devices – including hoists, lifting machines, and tackles. However, this is not visibly listed on wire ropes, so it is important to understand what this term means and how to calculate it.

The safe working load will change depending on the diameter of the wire rope and its weight per foot. Of course, the smaller the wire rope is, the lower its SWL will be. The SWL also changes depending on the safety factor ratio.

The margin of safety for wire ropes accounts for any unexpected extra loads to ensure the utmost safety for everyone involved. Every year there aredue to overhead crane accidents. Many of these deaths occur when a heavy load is dropped because the weight load limit was not properly calculated and the wire rope broke or slipped.

The margin of safety is a hazard control calculation that essentially accounts for worst-case scenarios. For instance, what if a strong gust of wind were to blow while a crane was lifting a load? Or what if the brakes slipped and the load dropped several feet unexpectedly? This is certainly a wire rope safety factor that must be considered.

Themargin of safety(also referred to as the factor of safety) measures the ultimate load or stress divided by theallowablestress. This helps to account for the applied tensile forces and stress thatcouldbe applied to the rope, causing it to inch closer to the breaking strength limit.

A proof test must be conducted on a wire rope or any other piece of rigging equipment before it is used for the first time.that a sample of a wire rope must be tested to ensure that it can safely hold one-fifth of the breaking load limit. The proof test ensures that the wire rope is not defective and can withstand the minimum weight load limit.

First, the wire rope and other lifting accessories (such as hooks or slings) are set up as needed for the particular task. Then weight or force is slowly added until it reaches the maximum allowable working load limit.

Some wire rope distributors will conduct proof loading tests before you purchase them. Be sure to investigate the criteria of these tests before purchasing, as some testing factors may need to be changed depending on your requirements.

When purchasing wire ropes for overhead lifting or other heavy-duty applications, understanding the safety dynamics and limits is critical. These terms can get confusing, but all of thesefactors serve an important purpose.

Our company has served as a wire rope distributor and industrial hardware supplier for many years. We know all there is to know about safety factors. We will help you find the exact wire ropes that will meet your requirements, no matter what project you have in mind.

The special design’s properties allow it to be more resistant to the normal complaints about winch wires: bad spooling, kinks, birdcaging, and many other names used on the river.

The design also allows it to be handled easier than other wires in multiple applications on the river: winch wires, face and wing wires, stationary and barge wires. The wire rope is much more flexible than any other rope ever used in this application. And if you want more strength, or prefer to downsize to a lighter wire, just ask for Gorilla Superstrand!!

8613371530291

8613371530291