splice wire rope end to end quotation

Wire rope splicing is essentially the formation of a knot between two parts of the same rope or between two separate ropes by separating and unravelling the strands and interweaving the threads together to produce a strong joint. Splicing forms a very strong knot which stays secure even if exposed to water.

There are different types of wire rope splicing. The two more common ones areBack or end splicing – This is a type of splicing where rope end strands are directly spliced without making a loop. With this wire rope splicing, rope ends are drawn to a close to prevent fraying.

Eye splicing – This a more popular type of wire rope splicing which involves taking the working end of the rope to form a loop at the end. The end of the rope strands are unraveled, then passed over and under against the lay of the rope to interweave it back into the main length of the rope.

Wire rope splicing maintains almost 95% of the wire rope’s strength. You can employ splicing in three-strand braided ropes, or even in over 12-strand braided ropes.

Splicing lets you create a new rope of any length, alter an existing rope to suit a changing application, or repair a damaged wire rope. There are two main disadvantages to splicing – the expanding thickness of the line at the joint and the distortion in the shape of the rope.

Check the wire rope tools and accessories section of this website for more tools or fill out the enquiry form and let us help with your wire rope splicing needs.

We custom manufacture wire rope assemblies (endless loop) for conveyor lines. Our specialty is the Long splice. The Long splice is used to create a continuous or endless loop of wire rope cable frequently utilized on conveyor systems. The splice is a difficult multi-step labor intensive process in which two wire rope cable ends are joined end to end and the strands are intertwined to merge the two individual wire rope cable ropes ends.

Our proven experience can be viewed first hand in the quality of our wire rope cable splices we perform regularly for diverse clientele in the Unites States and around the world. For assistance with your unique wire rope conveyor cable splicing needs, please complete theor call us directly at

As a rigger or end-user of wire rope, it’s important to understand the types of terminations, or treatments, that can be used at the ends of a length of wire rope. These terminations are usually made by forming an eye or attaching a fitting, and are designed to be a permanent end termination on the wire rope where it connects to the load.

Wire rope is an extremely versatile mechanical device that can be used to help support and move an object or load. In the lifting and rigging industries, wire rope is attached to a crane or hoist and fitted with swivels, shackles or hooks to attach to a load and move it in a controlled matter. It can also be used to lift and lower elevators, or as a means of support for suspension bridges or towers.

In this article, we’ll explain what some of the following terms mean and how the can be used to terminate the end of a wire rope cable:Wire rope sockets—spelter sockets, swaged sockets, and wedge sockets

When you understand the construction and specifications of the wire rope you need, as well as the right type of end termination you need, you’ll be able to select the best performing and longest-lasting wire rope for the job at hand.

There are essentially two techniques that can be used to create a termination on a length of wire rope or cable:You can form an eye, or loop, in the wire rope

Eyes, or loops, can be created at one end of a length of wire rope by using a mechanical splice with a swaged sleeve, a hand-tucked splice, or wire rope clips.

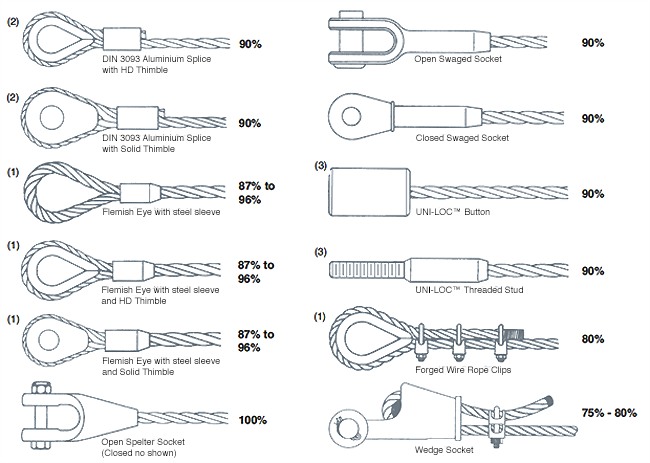

A swaged socket is applied to the end of a wire rope cable and is then forced into place using special dies and a hydraulic machine called a swager. When properly applied with the correct sized fitting, swaged sockets have an efficiency rating of 100% of the breaking strength of the rope.

A poured socket, commonly referred to as a spelter socket, attaches a termination fitting onto the end of a wire rope cable by pouring molten zinc or resin into a socket that then hardens and holds the fitting onto the end of the cable.

Due to the rigidity of this type of termination, the wires of the rope are subject to fatigue where the wires enter the socket, if the poured socket is subject to constant vibration.

Wedge sockets secure the rope to the end attachment by passing it around a grooved, wedge-shaped piece of steel and pulling it down under load into the bowl of the fixture.

Wedge sockets are popular because they can be installed in field and adjusted in field – providing 80% efficiency of rope breaking strength. Wedge sockets are popular in applications where the wire rope may be subjected to abuse and abrasion—particularly in construction and mining applications.

Wire rope clips can be used to form a load bearing eye at the end of a cable or wire rope, or to connect two cables together with a lap splice. Wire rope clips are popular because they can be installed in the field and provide 80% efficiency of the rope breaking strength.

However, the use of wire rope clips is heavily regulated by ASME B30.26 Rigging Hardware. When using wire rope clips, the end user must account for the following:When using U-bolt wire rope clips, the saddle shall be placed on the live end of the wire rope, with the U-bolt on the dead-end side—NEVER SADDLE A DEAD HORSE!

After installation, the connection shall be loaded to at least the expected working load. After unloading, the wire rope clips shall be re-tightened to the torque specifications of the manufacturer or a Qualified Person.

This type of wire rope clip is essentially a U-bolt, two nuts, and a metal base (saddle) that can be made from forged steel or cast iron. Careful consideration and attention must be given to the way U-bolt type wire rope clips are installed.

The base of the wire rope clip is made from forged steel. Forged clips are heated and hammered into the desired shape—resulting in a consistent grain structure in the steel. Forged wire rope clips are used for critical, heavy-duty, overhead loads such as winch lines, crane hoist lines, support lines, guy lines, towing lines, tie downs, scaffolds, etc.

Malleable wire rope clips are used for making eye termination assemblies only with right regular lay wire rope and only for light duty uses with small applied loads, such as hand rails, fencing, guard rails, etc. The base of the wire rope clips is made from malleable cast iron, which may fracture under heavy use and does not have the desirable metal properties of steel, or the beneficial grain structure that a forged base has.

Double saddle wire rope clips consist of two saddles, each with a leg, and two nuts—one used on the top and one on the bottom. Double saddle wire rope clips can be used in either direction, so they take the guesswork out during installation when applying to the live end and the dead end of a piece of wire rope.

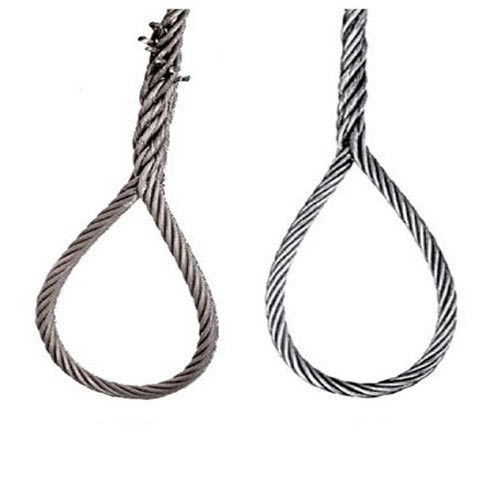

An eye splice may be used to terminate the loose end of a wire rope when forming a loop. The strands of the end of a wire rope are unwound and then the wire is bent around, and the unwrapped strands are then weaved back into the wire rope to form an eye.

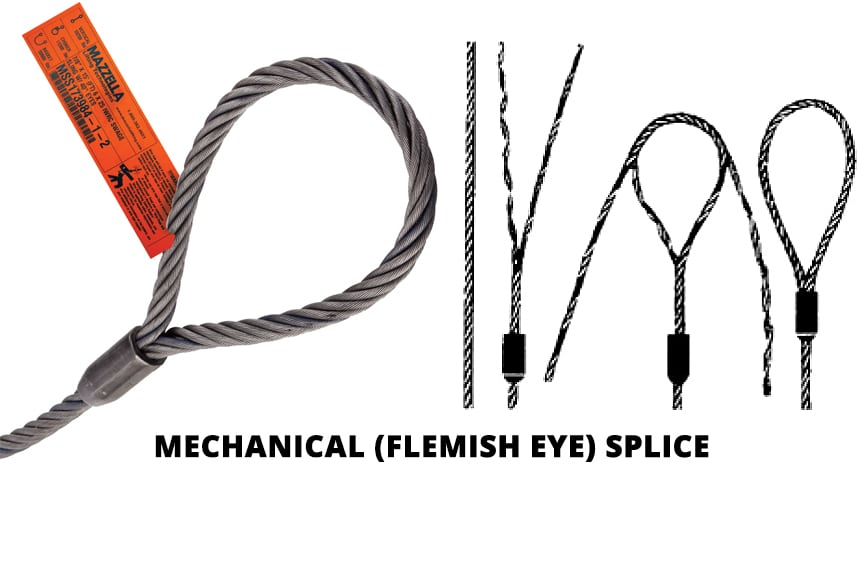

A Flemish eye splice is created when the wire rope is opened, and the strands are laid out into two parts. The two strands are looped in opposite directions and then laid back together—forming an eye, or loop, at one end of the wire rope cable. The strands are then rolled back around the rope body and a metal sleeve fitting is slipped over the splice and swaged using hydraulic machinery. This splicing method provides the most efficient use of rope capacity and is highly economical.

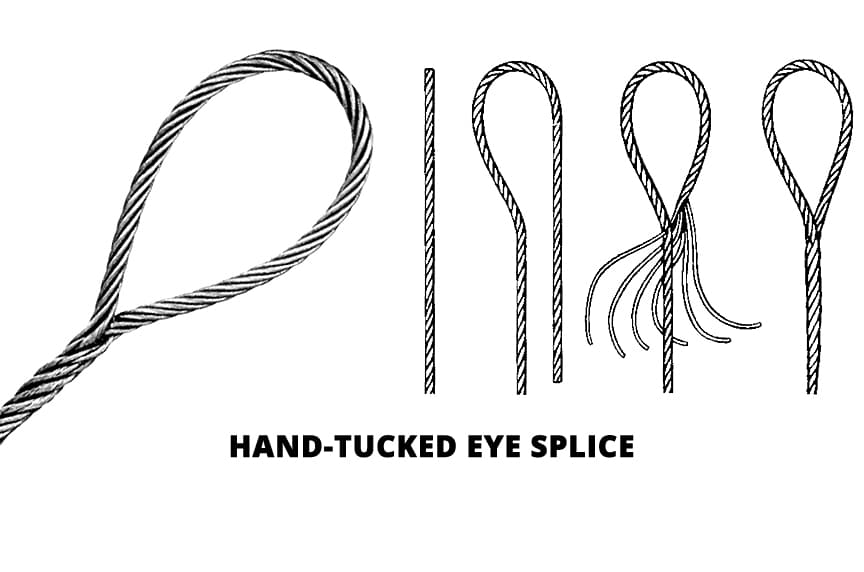

A hand tucked splice is formed when the shorter “dead” end is tucked into the longer “live” end of the wire rope—forming an eye. These types of splices allow for easy inspection of the wire rope wires and strands.

When the end of a rope is turned back and formed into an eye, a thimble is often used to keep the shape of the eye, prevent the rope from being crushed, and keep the rope from being bent at a diameter smaller than the rope manufacturer’s recommendations.

The table below will explain the efficiencies of the different types of wire rope end terminations for both independent wire rope core (IWRC) and fiber core (FC) wire rope configurations. Rope efficiency is described as the ratio of a wire rope’s actual breaking strength and the aggregate strength of all individual wires tested separately—usually expressed as a percentage.IWRCFC

*Spelter sockets in smaller rope sizes (usually less than 7/16”) may not always develop 100% efficiency and are not recommended by some rope manufacturers.

When you need to order a replacement wire rope, understanding the right type of end termination will help to make sure you get a direct replacement rope so you can get your project back on track. We hope this article gives you a better understanding of terms related to sockets, wire rope clips, and eye splices and that you understand what type of end termination may be best for your application.

At Mazzella, we offer all different kinds of wire rope from all of the leading manufacturers. We sell the highest-quality domestic and non-domestic rigging products because product quality and operating safety go hand-in-hand. We have one of the largest and most complete inventories of both domestic and non-domestic rigging and lifting products to suit your lifting needs.

Determine the amount of wire rope needed for the project at hand. Include extra length for the intended application of the ferrule and stop. More rope is usually required for a side-by-side splice than for a small end loop.

Cut the wire rope to the correct size using a cable cutter or hacksaw. Use a sharp, fine hacksaw blade to make sure all cuts are clean. Keep the ends of the rope as compact as possible.

Slide the required number of ferrules onto the wire rope. For a splice, place the ferrules in a row with the ends of the two ropes passing through them in opposite directions. For a loop, pass the end of the rope back through the remaining openings in the ferrules, forming the appropriately sized loop.

Arrange the assembly carefully for swaging; once made, the connection is permanent. Leave the required amount of space between ferrules, as well as enough rope protruding from the last ferrule for the end stops. Place a stop on each of the cut ends of the wire rope to prevent the individual wires of the rope from unraveling.

Begin assembly with an end stop. Place the fitting between the jaws of the swaging tool and compress it firmly onto the wire rope. Swaging is the act of permanently attaching sleeves and fittings to wire rope. The swaging tool is a cold metal press that allows you to crimp ferrules and other attachments onto the cable. One swage, or crimp, is usually sufficient for smaller fittings.

Swage the ferrules by starting at one end and compressing the oval-shaped fitting sideways between the jaws. Use enough force to create a deep indentation. Ferrules require two or more of these compressions per fitting depending on the application.

Test the strength of the completed assembly before putting it into service to ensure all fasteners are installed correctly and that it safely performs its intended purpose.

My name is William Yang, I’m the business manager of Hilifting. I have been in Rigging industry for more than 10 year. Feel free to contact us. I’m happy to provide you the best service and products.

Understand that most of the people out from the industry always face the problem of having no idea with the terms of wire rope when receiving quotation. In this update, we will explain in the most simple way and hopefully it is applicable to anyone.

6X36 = Construction of wire rope (There are quite a lot different constructions available for different application for example like, 6X25, 6X29, 6X31, 4X39, 19X7, 8X26 etc.)

RHOL = Right hand ordinary lay, it is the wire lay direction and very important to select the right direction of wire when dealing with multi-reeving, crane and hoist application.

EIPS (1960) = Extra improved plow steel and 1960 stands for the tensile strength 1960N/mm2. The figure is telling you the grade of wire rope, lower or higher tensile strength will result in different breaking strength.

UNGALVD = Ungalvanized, the surface finishing of wire rope. Galvanized and Ungalvanized are the basic surface finishing selection with different grade of lubrication.

G411 THIMBLE EYE = Thimble eye model. Soft eye will be stated with the effective working length and the size of soft eye is based on nominal diameter x 15times according to EN131411 standard.

MECH SPLICED = Mechanical splicing is the process of using hydraulic pressure to press the aluminum sleeve or metal sleeve and a loop is formed. This phrase is always telling you the terminal of both end wire rope. It can be plain, socketed, fuse tapered or eye formed.

Wire rope could have a lot of variation upon the application which I will cover in the next update. The essay above is good enough to tell the basic and hope it helps for procurement department while dealing with steel wire rope. Last but not least, selecting the right wire rope is crucial to your company"s long term expenditure and safety purposes. Do not take the risk because of cheap.

They may look simple, but wire rope slings play a critical role in various industries, including construction, shipping, material handling, and rigging.

The unique physical properties and resistance to abrasion make it easier to use these slings with shackles, hooks, and swivels for a variety ofmaterial handling applications. They also provide strength, durability, and resistance to abrasion or elements.

However, this seemingly simple lifting device comes with a unique structure and functional properties. Let’s take a look at the complete anatomy of wire rope slings.

A typical wire rope sling consists of a wire rope made from small individual steel wires twisted together. Both ends of the wire rope are looped together individually to form a sling. The wire rope is the fundamental component of a sling.

These slings come in a variety of sizes, shapes, and tensile strengths. The most common ones are those with an eye loop swaged on both ends of the sling.

A typical heavy-duty wire rope has multiple small twisted strands made from various grades of steel. The configuration and number of these strands changes, depending on how complicated the pattern is.

Usually, a typical rope comes with hundreds of outer wire strands covering the core strand. All these strands move together as well as independently, providing the wire rope with the necessary strength and flexibility. The mechanics of this movement are quite complex.

A wire is the smallest part of a wire rope. You can use different types of metals, including stainless steel, iron, steel, and bronze to make the wires. The grade of the material used for making the wire depends on strength, abrasion resistance, and durability required for the intended application.

You can create a strand by twisting two or more wires together tightly in a precise pattern. Again, the weaving pattern will be determined by the end-application of the rope.

It is made from steel or natural and sometimes synthetic fibers. The strands go around the core, which offers support when the rope bends or is attached to the load.

As mentioned, strand patterns are critical as they determine the strength, durability, and abrasion resistance of the rope. Usually, the strand consists of the number of wires per layer, the number of layers of wires, and the size (diameter) of the wires in each layer.

As the name suggests, this type of pattern consists of only one layer of wires around the core, all having the same size or diameter. There are usually six strands covering a core, totaling the number to seven.

It comprises two layers of wires wrapped around the core. The inner layer usually has six wires, while the outer layer has twelve with equal diameter. Six filler wires with a smaller diameter are used to fill the gap between the two layers of strands.

Like the filler pattern, this one also has two layers of wires surrounding the core. However, wires in the inner layer have a smaller diameter compared to the ones in the outer layer. The outer wires rest in the troughs of inner smaller wires.

This pattern also consists of two layers of wires. However, only the inner layer has wires with a uniform diameter. The ones in the outer layer have two sets of wires, one with a bigger diameter and the other with a smaller one.

In the outer layer, the bigger wires rest in the troughs of the inner layer, while the smaller ones rest on the crests on the wires in the inner layer.

This is one of the most common types of layering patterns. In this, the strand layering and the wire layering are in opposite directions. This arrangement provides the wire rope slings with exceptional resistance to crushing forces and offers better spooling.

In this type of structure, the wire layering and the core layering are in the same direction. However, the wires form an angle with the rope axis. This arrangement provides a higher resistance to fatigue and abrasion.

This is the most popular wire rope sling. In this type of loop, the spliced end of the rope is tied around the body of wire rope slings using a metal sleeve. The Flemish eye splice is best suited for six-strand ropes.

However, if you are using these loops with other types of wire ropes, you need to use aluminum or loop-back (turn-back) steel sleeves. The regular sleeves often cause an electrochemical reaction, which speeds up the deterioration process.

In this loop, an aluminum sleeve is pressed using fabrication over both rope parts. The integrity of the pressed sleeve solely determines the strength of these wire rope slings. You can also add thimbles to these slings.

This is similar to aluminum sleeve loop-back splice. However, it uses steel sleeves with a slightly smaller diameter. It can also be used for making stainless steel rope slings of a larger rope diameter.

The rope gets inserted into the fitting bore, and it then gets swagged onto the rope. With this method, you can attach open and closed sockets, buttons, threaded studs, and load hooks directly to the rope. The process results in a high-efficiency bond.

This is a type of socket that is attached to one or both ends of a wire rope to form a sling. The strength of these sockets is the actual rope strength.

As you can see, wire rope slings are a complex piece of lifting device, although they look simple. Hopefully, understanding their structure will help you know how they can offer the required strength, flexibility, and resistance to abrasion, crushing, and fatigue. It will also help you choose the right sling suitable for your application. Do tell us why and how you use these slings in your industry in the comments section.

The end of a single wire rope is bent back along the rope to form the eye, and strands are hand-tucked into the body of the rope in what is called a burnt end splice. With Burnt End splices, the ends of strands are left exposed and cut off with a torch. Upon special request, a premium splice known as a tapered and concealed splice can be provided. Slings with rope bodies larger than 1" diameter are made only with Burnt End splices. All have the same rated capacity, size for size.

The tapered and concealed splice utilizes tension in the rope body to secure strands where they are tucked back into the rope. Needs no metal sleeve to assure firm anchoring. When "tapered" and "concealed", ends of strands are tucked inward and concealed inside the rope.

A trademarked method of splicing wire rope when a thimble or eye is required at the end. The end of the wire is threaded through a non-corrosive alloy ferrule of a size convenient for the wire and then threaded back to form a loop round the thimble. The ferrule is then gripped lightly in a hydraulic press while the wire is pulled through to make the loop the required size or to lie closely round the thimble. Further pressure is then exerted to make the metal of the ferrule flow round the strands of the wire, thus holding each firmly in position, and the splice is complete.

A Talurit® splice is as strong as a fully tucked eyesplice and is more economical in the use of the rope. When making an eyesplice by hand, 30 centimetres (1 ft) of the wire is needed for tucking for every 2.5 centimetres (1 in.) of its circumference; the Talurit® method uses only 2.5 centimetres for the whole splice.

AfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBonaire, Sint Eustatius and SabaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCabo VerdeCambodiaCameroonCanadaCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos IslandsColombiaComorosCongoCongo, Democratic Republic of theCook IslandsCosta RicaCroatiaCubaCuraçaoCyprusCzechiaCôte d"IvoireDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEswatiniEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHoly SeeHondurasHong KongHungaryIcelandIndiaIndonesiaIranIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea, Democratic People"s Republic ofKorea, Republic ofKuwaitKyrgyzstanLao People"s Democratic RepublicLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacaoMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth MacedoniaNorthern Mariana IslandsNorwayOmanPakistanPalauPalestine, State ofPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarRomaniaRussian FederationRwandaRéunionSaint BarthélemySaint Helena, Ascension and Tristan da CunhaSaint Kitts and NevisSaint LuciaSaint MartinSaint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint MaartenSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth SudanSpainSri LankaSudanSurinameSvalbard and Jan MayenSwedenSwitzerlandSyria Arab RepublicTaiwanTajikistanTanzania, the United Republic ofThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkmenistanTurks and Caicos IslandsTuvaluTürkiyeUS Minor Outlying IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVenezuelaViet NamVirgin Islands, BritishVirgin Islands, U.S.Wallis and FutunaWestern SaharaYemenZambiaZimbabweÅland Islands

AfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBonaire, Sint Eustatius and SabaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCabo VerdeCambodiaCameroonCanadaCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos IslandsColombiaComorosCongoCongo, Democratic Republic of theCook IslandsCosta RicaCroatiaCubaCuraçaoCyprusCzechiaCôte d"IvoireDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEswatiniEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHoly SeeHondurasHong KongHungaryIcelandIndiaIndonesiaIranIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea, Democratic People"s Republic ofKorea, Republic ofKuwaitKyrgyzstanLao People"s Democratic RepublicLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacaoMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth MacedoniaNorthern Mariana IslandsNorwayOmanPakistanPalauPalestine, State ofPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarRomaniaRussian FederationRwandaRéunionSaint BarthélemySaint Helena, Ascension and Tristan da CunhaSaint Kitts and NevisSaint LuciaSaint MartinSaint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint MaartenSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth SudanSpainSri LankaSudanSurinameSvalbard and Jan MayenSwedenSwitzerlandSyria Arab RepublicTaiwanTajikistanTanzania, the United Republic ofThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkmenistanTurks and Caicos IslandsTuvaluTürkiyeUS Minor Outlying IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVenezuelaViet NamVirgin Islands, BritishVirgin Islands, U.S.Wallis and FutunaWestern SaharaYemenZambiaZimbabweÅland Islands

The goal of a sling inspection is to evaluate remaining strength in a sling which has been used previously to determine if it is suitable for continued use.

As a starting point, the same work practices which apply to all “working” wire ropes apply to wire rope which has been fabricated into a sling.Therefore, a good working knowledge of wire rope design and construction will be not only useful but essential in conducting a wire rope sling inspection.

But because wire rope is a rather complex machine, no precise rules can be given to determine exactly when a wire rope sling should be replaced. There are many variables, and all must be considered.

Broken Wires: For single-part slings. 10 randomly distributed broken wires in one rope lay, or five broken wires in one strand on one rope lay. For multi-part slings these same criteria apply to each of the component ropes.For the inspection, a broken wire shall only be counted once; that is, each break should have two ends.

Metal Loss: Wear or scraping of one-third the original diameter of outside individual wires. This is quite difficult to determine on slings and experience should be gained by the inspector by taking apart old slings and actually measuring wire diameters.

Distortion: Kinking, crushing, birdcaging or other damage which distorts the rope structure. The main thing to look for is wires or strands that are pushed out of their original positions in the rope. Slight bends in a rope where wires or strands are still relatively in their original positions would not be considered serious damage. But good judgement is indicated.

Metal Corrosion: Severe corrosion of the rope or end attachments which has caused pitting or binding of wires should be cause for replacing the sling. Light rusting usually does not affect strength of a sling, however. In addition to these seven conditions specified by OSHA, the following are also important:

Pulled Eye Splices: Any evidence that eye splices have slipped, tucked strands have moved, or pressed sleeves show serious damage may be sufficient cause to reject a sling.

Unbalance: A very common cause of damage is the kink which results from pulling through a loop while using a sling, thus causing wires and strands to be deformed and pushed out of their original position. This unbalances the sling, reducing its strength.

Disposition of Retired Slings: the best inspection program available is of no value if slings which are worn out and have been retired are not disposed of properly. When it is determined by the inspector that a sling is worn out or damaged beyond use, it should be tagged immediately DONOTUSE. This sling should then be destroyed as soon as possible by cutting the eye and fittings from the rope with a torch. This will help assure that an employee will not mistakenly use a sling which has been retired from service.

Before use: Look for rope distortion, kinks, cut or broken strands, corrosion, heat damage, birdcaging, or crushing. Look at the end attachments for cracks, wear or deformation, hooks with twists or a throat opening increase. Look for broken or missing wires.

For cable laid and braided broken wire inspection criteria, consult the manufacturer. If an inspection reveals that such wear or damage is present, replace the sling. Frequent inspection is done by the person handling the sling before each use and must include all of the Before use Periodic inspections must be recorded at least annually for normal service, quarterly or more frequently if in severe service or nearly constant use. Periodic inspections are performed by a designated person who records the observed condition and determines when further use would be hazardous.

Any hazardous condition disclosed by an inspection shall require replacement of the wire rope sling. Repair is not an option when damage/wear seriously reduces the sling’s capacity.

Because of the greatly reduced lifting capacity, use extra when the horizontal lift angle is less than 45° and do not make lifts of less than 30° load angle. Example: A sling rated at and lifting 1,000 pounds will be damaged – and could break suddenly – when the lifting angle is less than 30o at which angle the sling’s capacity is reduced to only 500 pounds. Important: Use a longer sling to increase the angle which will also increase the allowable capacity.

I&I Sling wire rope slings are mechanically spliced. Compared to loop back or turn back slings, mechanically spliced slings are considered to be the safer option due to the backup redundancy of the splice in the eye. This splice can keep the sling eye together in a situation where the pressed sleeve fails. Flemish Eye slings are fabricated at your local I&I Sling branch location with domestically sourced wire rope. Tight length tolerances are available, wire rope slings can be constructed with +/- the diameter of the rope or in matching sets. Flemish eye slings are compliant with ASME B30.9 and can be proof tested to twice the working load limit.

Eyes are typically formed using a flemish eye splice. The ends are secured by pressing a metal sleeve over the ends of the strands of the splice. Pull follows a direct line along the center of the rope and eye. Single part body mechanical splice slings have a higher rated capacity than hand-spliced slings.

In the standard flemish eye mechanical splice, wire rope is separated into two parts: three adjacent strands to one part and three adjacent strands along with the core to the other part. The two parts are then re-laid back in opposite directions to form an eye and ends are secured with a pressed metal sleeve.

This photo shows a cutaway of a metal sleeve that’s been swaged onto a splice. Notice how metal flows into the valleys between strands to positively prevent ends from unlaying when the sling is used within its rated capacity.

Rated Capacities based on pin diameter no larger than natural eye width or less than the nominal sling diameter. Rated Capacities based on design factor of 5. Horizontal sling angles less than 30° shall not be used.

When looking for strength and durability on that next big rigging job, look no further than our array of HSI Wire Rope Slings. A wide-variety of sizes are available whether working on a small-load lift or preparing to maneuver a massively heavy element. Our slings are there to solve your hoisting, lifting and towing problems.

HSI slings are assembled in an ISO 9001:2015 certified facility where quality, safety and efficiency are priority. Audits are conducted every year by an independent third-party to determine if a manufacturer is compliant with standards before re-registration.

The wide offering of Single Leg Wire Rope Slings will surely meet your rigging needs on the jobsite. Each eye on these slings is formed using the mechanical Flemish Eye Splice. This process allows for the most efficient use of the rope capacity with top-quality steel as the pull is directly along the centerline of the rope and eye.

All Slings Manufactured by Certified Slings & Supply® are made with Flemish Eye Techniques & Mechanical Splice per ASME B30.9 and EIPS Grade Rope unless otherwise requested.

Thereturned loopis fabricated by forming a loop at the end of the rope, sliding one or more metal sleeves over the short end of the loop eye and pressing these sleeves to secure the end of the rope to the sling body. A drawback to this type of sling is that the lifting capacity of the sling depends completely upon the integrity of the pressed or swaged metal sleeve. Should the metal sleeve(s) fail or slide off, the entire eye will also fail.

The Flemish eye splice is fabricated by opening or unlaying the rope body into two parts, one having three strands and the other having the remaining three strands and the core. The rope is unlayed to allow the loop or eye to be formed by looping one part in one direction and the other part in the other direction and .laying the rope back together. The strands are rolled back around the rope body. A metal sleeve is then slipped over the ends of the splice and pressed (swaged) to secure the ends to the body of the sling. Nominal splice efficiencies are based on this splicing method. Splice efficiencies for other splicing methods should be confirmed.

Wire rope is constructed of multiple strands of wire that are twisted and braided together to form a spiral design or helix. Once the separate wires are shaped into a solid form, they become a single wire with greater strength because the individual wires equalize pressure and have greater flexibility than the individual strands.

To further enhance the strength of wire ropes, they are grouped and wound together to produce cables, which adds to their usefulness as a means of support, ability to lift, and give structural stability.

A key factor in wire rope is the lay of the strands, which can be regular or lang. With regular lay, or right and ordinary lay, the strands are wound from left to right with the wires laid in the opposite direction of the lay of the strands. With lang lay, the wires are wound in the same direction.

The structure and design of wire rope produces a final product that has superior strength, excellent strength flexibility, and the ability to handle constant bending stress as well as being weather resistant.

Wire rope is one of those products that has found a place in a wide variety of industries since it can be adapted and shaped to fit several applications. It can be found as a tow cable for boats and airplanes or in the movie industry as a harness for stunt artists. The varied uses of wire rope have made it an essential part of operations that require a rope with strength, endurance, and flexibility.

In the aerospace industry, wire ropes, or Bowden cables, connect pedals and levers in the airplane cockpit to send power to aircraft systems to control the airplane. The things that are controlled by wire ropes are propeller pitch, cowl flaps, and throttle. Wire ropes on aircraft are insulated to avoid vibrations.

Wire rope is extensively used in the auto industry for a wide variety of applications due to its versatility and strength. It is used for raising windows and opening and closing sunroofs. Other uses include steering wheels, cables, exhausts, springs, sunroofs, doors, and seat components. In the manufacturing process, wire rope is used to hoist vehicles, move large body parts, and on hoists and cranes.

The construction industry has a greatest reliance on wire rope because of the need to lift and lower heavy loads. Wire rope used in construction must have extremely high strength and exceptional performance for safety reasons and efficiency. Larger versions of wire rope are used for suspension bridges and supporting concrete columns.

The main use of wire rope in food processing is for lifting, moving loads, and other heavy tasks. Finished products or raw materials require being moved in storage units and processing centers. The strength and endurance of wire rope makes it possible to move these materials. Wire rope for food processing must be able to withstand regular chemical cleaning.

As with other industries, the oil and gas industry needs strong and reliable equipment for moving heavy equipment. In ocean drilling, machinery is dropped into the ocean using wire rope to securely hold devices to be dropped to extreme depths. Wire ropes are designed to withstand the extreme pressure and stress required. A further use of wire ropes for drilling operations is to maintain stability in the drilling lines. One of the unique features of oil rig wire rope is its length, which can exceed 10,000 feet.

A very common use for wire rope is mooring and towing of sea and freshwater boats and vessels. In the shipbuilding industry, wire rope is used to secure lifeboats as well as lower them into the water. On sailboats, wire rope is used to lift and lower sails. The benefit of using wire rope is its resistance to corrosion and rust caused by salt water and ocean mist.

The skiing industry, much like heavy equipment industries, uses wire rope to hold cars, lifts, or chairs to transport skiers up the mountain. This type of wire rope comes in several varieties depending on the size of the mountain. The benefits of wire rope for skiing is its dependability, guaranteed safety, and reliability. The main challenge of wire rope for use in sports is the weather conditions it must endure.

Since the beginnings of amusement parks, wire rope has been an essential part of attraction construction. It is used to bring roller coaster cars to the top of the ride, hold swings, and pull various vehicles through attractions. One of the main concerns of public amusement parks is safety since rides are filled with powerful machinery designed to operate continuously.

Making the dangerous and exciting shots in movies requires well planned safety precautions. One of the aspects of that planning is wire rope that is designed to protect performers when they are engaged in dangerous and life threatening shots. Dependable wire ropes are ideal since they have the flexibility, strength, endurance, and versatility to be adapted to any conditions.

In architecture and design, wire rope has been used for guard rails, balustrades, and roof construction. In innovative green buildings where plants grow along the surface of the building, the plants grow along specially designed vertical wire ropes that are capable of withstanding weather conditions.

A common use of wire rope is in railings, which are safe, durable, and provide a pleasing aesthetic appeal. The use of wire rope for railings provides protection without obstructing the view from a building. This aspect of wire rope is one of the reasons that it is used for large architectural projects since it blends into the structure without interiors with the architectural design.

The types of wire rope are determined by the number of wires in each strand and how many are in the rope, which is defined by a two number system with the first number being the number of wires and the second being the number of wires in each strand. For example, a 6x19 wire rope has 6 wires in 19 strands.

There are a wide variety of products that are produced using wire rope. The demand for wire rope products is due to its strength, durability, and reliability. Since the basic purpose of wire rope is to lift and move heavy materials and items, the most common type of wire rope product is the wire rope sling.

Though the construction of wire rope slings is very similar for all types, there are certain variations applied to slings to adjust them to fit different applications. Slings are configured in various ways to fit different types of loads. These changes are referred to as hitches.

Choker Hitch: In the choker configuration, one eye of the sling is attached to the lifting hook. The second eye is looped over the first sling eye to form a noose shape or choke. The load is placed in the choke loop.

Bridle Hitch: The multiple leg or bridle hitch style has more than one wire rope sling attached to equalize the load and control balance. They reduce load damage by using fixed points on the load and offer easier rigging when hooked into fixed lifting points. .

Single Part Wire Rope Sling: The eye for a single part wire rope sling is formed by looping the wire rope back on to the rope. The end of the rope is attached by a clamp or being woven by hand or mechanically into the rope body. Single part wire rope slings use a single wire rope to produce the sling.

Braided Wire Rope Sling: A braided wire rope sling is made by braiding wire ropes to form a sling. The increased number of strands enhances the strength of the sling and its load capacity. Braiding can be done with three to nine wire ropes.

Cable Laid Wire Rope Sling: Cable laid wire rope slings are made from combining several smaller wire ropes to form a flexible, easy to handle, and kink resistant sling.

Woven Eye Wire Rope Sling: For the woven eye version of a wire rope sling, the eye is formed by weaving the wire rope into itself after forming the loop. It is designed to reduce the chance of the sling catching or being hung up when lifting.

Thimble Wire Rope Sling: To add to the strength of wire rope slings and lessen the stress on a small area of the eye, a thimble, a U shaped piece into which the wire rope fits, is placed in the eye, which helps the sling to retain its natural shape. The thimble is positioned to prevent the hook or load from coming in contact with the wire rope.

Endless Wire Rope Sling:Endless wire rope slings are adaptable slings without a set wear point. They can be manufactured in a wide range of sizes and are used in applications where headroom may be a problem. Endless wire rope slings are made by splicing the ends of a piece of wire rope together or by tucking strand ends into the body to form a core with a tucked position the opposite of the core position. They are also referred to as grommet wire rope slings.

Coiled wire rope is made from bundles of small metal wires that are twisted into a coil. It comes in many varieties and is easy to store since it does not require a spool. Coiled wire rope is produced in coils. When it is not in use, it springs back into a coil, which makes it easy to handle.

Cable wire rope is a type of high strength rope, made of several individual filaments. These filaments are twisted into strands and helically wrapped around a core. One of the most common types of wire rope cable is steel cable.

Push pull wire rope assemblies are used to send force and are used in the aircraft, exercise, medical, automotive, and office equipment industries. Unlike using a single heavy wire, push pull assemblies made with wire rope are stiffer and have a larger bend radii for smoother motion of the wire.

Wire rope assemblies include wire rope and various parts and components that have been added to the wire rope to enhance its function. The connectors for a wire rope assembly are designed to connect the assembly to hooks, equipment, or machines as well as other wire rope assemblies. The central part of a wire rope assembly is the wire rope, which determines the type and kind of work the assembly can perform.

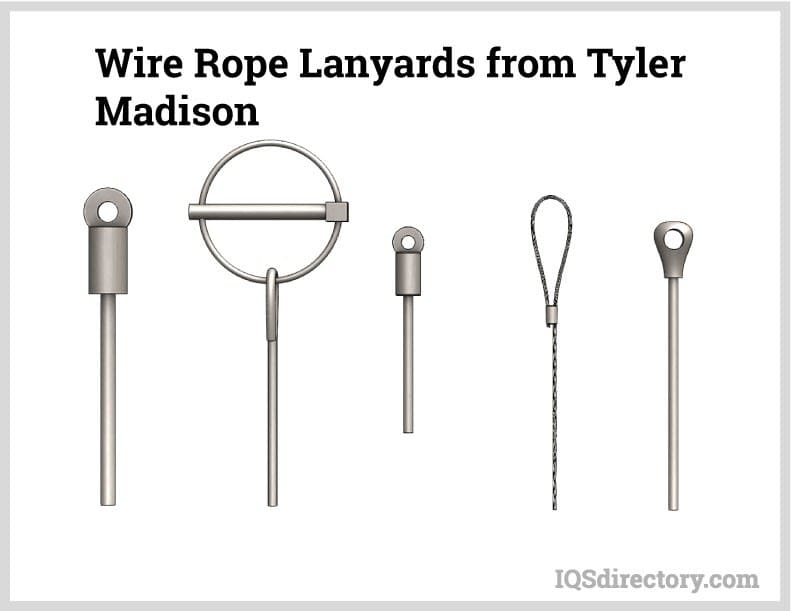

Wire rope lanyards are a standard wire rope product that have a multitude of uses. They are produced using the same process that is used to produce wire rope with the same numbering categorizing system. Lanyards are used to hold fasteners, hardware, or components to prevent loss of an item or prevent injury.

As can be seen in the image below, lanyards come with a variety of connectors to specifically fit an application. Custom designed lanyards are designed for unusual and unique functions where a standard lanyard will not fit. The variety of connectors allows the lanyard to be easily connected.

Ends Fittings or Terminals: The nature of the end fitting depends on the function of the lanyard. All manufacturers have a wide assortment of end fittings to choose from. They include stamped eyes, ball ends, ball shanks, stops, sleeves, thimbles, threaded studs, and strap forks and eyes, to name a few. The image below has a few examples of end fittings terminals.

In many ways, wire rope is a form of machine with multiple moving parts. Normally, when we think of a machine, we imagine a device with a motor, drives, and gears. Wire rope does not have any of those components but does fit the definition of being a complex mechanism. It has moving parts that work together to move heavy materials and loads.

The main function of wire rope is to do heavy lifting, which is very dependent on wire rope slings. The type of sling is determined by the quality of the wire rope used to form them and whether several ropes have been braided or wound together.

Wire is the smallest part of wire rope but makes up the various strands. The composition of the wire can be steel, iron, stainless steel, copper, or other types of metal wires and are produced in different grades. The individual wires can be coated or bright, meaning uncoated.

Strands are sets of wires that are twisted together and are placed in a helical pattern around the core. The size of the wire determines its abrasive qualities with larger wires being more abrasive and less flexible than smaller ones.

The core is the center of the wire rope and serves as a support for the strands and helps the wire rope keep its position when it is under stress or bearing a load.

Lubrication is applied during the manufacturing process to reduce friction between the wires and strands as well as protection from corrosion and rust. The tight winding of the wires enhances the ability of the wire rope to retain the lubrication which is essential to its longevity.

The purpose of applying lubricant is to limit the friction between the cables to increase the useful life of the wire rope. In certain applications, such as space travel, lubricants can be hazardous and cause equipment to malfunction. In those instances, non-lubricated wire rope is used, which is referred to as dry wire rope or cable.

Of all of the products that are made from wire rope, slings are the most common and widely used. These looped wire ropes come in different varieties and grades depending on the type of wire used. Also, to enhance wire sling performance, several wire ropes may be wound together to form a sturdier and more reliable sling.

Flemish splicing is a method for repairing a wire rope and involves breaking the wire rope in half and tying it back together. In the Flemish method, the wire rope is tied back on itself and swaged down a sleeve over the unbroken wire rope to create the new eye.

Prior to placing the wire rope into the holding device used to shape the eye, a steel compression sleeve is placed on the rope, which will be used to secure and hold the eye.

Once the proper size is achieved, the unwound strands are rewound in the reverse order of their former positioning. If the wire rope has a right hand lay, it is rewound using a left hand lay. The opposite is true if the wire rope has a left hand lay, then it is rewound using a right hand lay. By using this technique, a friction mold is formed for the splicing of the sling.

Anti-rotational wire rope resists the forces of rotation by having opposing layers of helical stands. By winding the wire rope with oppositional strands, the wire rope is guaranteed to not unwind in clockwise or counterclockwise directions. The key to anti-rotational wire rope is to ensure that the outer diameter is static.

In the manufacture of anti-rotational wire rope, counter stranded filaments have vacant spaces between them. To make the wire rope anti-rotational, it is tightly twisted in the counterclockwise direction, which tightens the spaces between the filaments. If the wire rope is turned in a counterclockwise direction, the strands tighten around each other creating a spring force.

The tails and stray wires of the wire rope have to be straightened and properly formed before applying the compression sleeve. Once the sleeve has been placed, it is carefully checked to be sure that it is accurately engaged.

Prior to placing the wire rope sling in the swaging die, the die has to be thoroughly lubricated. Once the die is set, the wire rope‘s compression sleeve and the wire rope are compressed using several hundred thousand pounds of force. The swaging process alters the dimensions of the wire rope and compression sleeve to form a tight connection for the correct diameter for the sling connection. As force is applied, the compression sleeve is turned so that pressure is evenly applied.

There are several types of metal wires that are used to produce wire rope, which include steel, stainless steel, galvanized, aluminum, nickel alloy, bronze, copper, and titanium. Carbon steel is the most common type of wire rope material.

Wire ropes are made using uncoated bright wire, which is high-carbon steel. The type of steel depends on the requirements of the wire and its tensile strength and its fatigue and wear resistance.

Galvanized wire rope is treated with zinc to prevent corrosion and can be used in harsh conditions and environments. It is a cost effective alternative to stainless steel but does not have the same corrosion resistance. Galvanized wire rope is stronger than stainless steel of the same grade and size. Vinyl coated galvanized wire rope is easy to handle and flexible.

Stainless steel wire rope is corrosion and rust resistant. It is available in types 316 and 304 with 316 having greater corrosion resistance. Stainless steel wire rope can be used for marine applications, acidic environments, and other demanding conditions. It is produced with the appropriate tolerances and composition to meet the needs of the application.

Multiple strands of copper are braided into a round hollow shape, which is pressed into the desired width and thickness. Copper wire rope has exceptional flexibility, an exceptional life span and can be used as part of electrical components.

Bronze wire rope inhibits sparking and is corrosion resistant. It is made from preformed wire to ensure that it maintains its shape and does not unravel when cut. Bronze wire rope is abrasion resistant and very flexible with a crush resistant core.

Inconel wire can be used in applications that reach temperatures as high as 2000° F and is oxidation and corrosion resistant. It is non-magnetic and has excellent resistance to chloride based corrosion cracking. Inconel wire rope can be used with nuclear generators and chemical and food processing.

Titanium wire rope comes in several grades with grade two being 99% pure. It is easily formable and weldable. Titanium wire rope is commonly used in chemical processing and marine hardware.

For wire rope to perform properly, it needs to have proper care. Wire rope is an essential tool necessary to perform a wire range of lifting and moving jobs. It is important that it be handled, treated, installed, stored, and treated correctly to prolong its life and perform to the highest standards.

Seizing should be completed on both ends of the wire rope, which will protect it from loosening. If this is done improperly, the wire rope can become distorted. Wire rope that is properly seized evenly distributes the load.

Wire rope is stored on reels or coils and has to be carefully handled when it is being removed. To ensure excellent performance, the wire rope should not be dropped during removal. If the reel or coil is dropped or damaged, it can make handling the wire rope difficult and cumbersome. As the wire rope is removed from the reel, check to see that the reel is rotating as the wire is removed.

Wire rope is depended on for heavy lifting and is trusted to keep a load and people safe. As with all heavy duty equipment, wire rope must have a regular inspection schedule and be visually assessed during use.

Broken Strands – An easy way to check for broken strands is to run a cloth over the length of the wire. Broken strands that are found in critical areas, such as parts that pass through pulleys or sections that are regularly flexed, rubbed, or constantly worked must be replaced and repaired.

Internal wear – This can be tested by flexing the wire rope, which indicates if the interior has deteriorated, experienced fatigue, or become distorted.

For wire rope to perform at the highest level, it has to be stored in a well ventilated environment that is dry, covered, and not in contact with the floor. The avoidance of high moisture or damp conditions is an absolute necessity. While the wire rope is in storage, it should be moved regularly to keep the lubricant from wearing off.

Though lubricant is applied during the manufacturing of wire rope, it wears off during use. Lubrication is the key to the performance of wire rope because it helps prevent abrasion as the wires rub against one another. Relubrication should be applied after the original lubricant has worn off.

Wire rope is a tool and must be cleaned regularly as with any form of machinery. This can be accomplished with different types of petroleum solvents and a wire brush. Mechanical methods of cleaning can include compressed air or a steam cleaner. Once the cleaning process is completed, the wire rope should be lubricated for protection.

There are several substances that can harm a wire rope. They include salt water, brine, acid, various gasses, and humidity. To avoid the intrusion of these negative effects, when a job is completed and the wire rope is to be stored, it should be cleaned, lubricated, and placed in proper storage.

When wire rope is being removed from a spool or being spooled, the operation must be performed smoothly with the spool rotating at a constant speed and rhythm. This will help prevent kinking or binding.

When a wire rope shows a reduction in diameter, has broken wires, kinks, nodes, flattened surfaces, out of place outer wires, damage from heat exposure, corrosion damage, or the formation of unexpected loops, it should be removed and replaced or be repaired.

Wire rope is regulated by the Occupational Safety and Health Administration (OSHA) as part of the regulations for cranes and derricks in construction as part of 29 CFR 1926.1413, which went into effect on November 8, 2010.

The inspection of wire ropes is on three levels: shift, monthly, and annually. Shift and monthly inspections can be completed by an approved operator, while annual inspection must be completed by certified personnel.

As with the shift and monthly inspections, the annual inspection follows the guidelines for the shift inspection. This inspection must be completed by certified personnel. The entire surface of the wire rope has to be inspected, with attention to:

Annual inspections can be excused if it is not possible due to the wire ropes setup or configuration or the location of the work site. It must be completed within six months. If any deficiencies are found, the wire rope must be repaired or removed. For some deficiencies, it is possible to keep the wire rope in use but have them regularly monitored.

Wire rope is a form of metal tool that is constructed of multiple strands of wire that are twisted and braided together to form a spiral design or helix.

To further enhance the strength of wire rope, they are grouped and wound together to produce cables, which adds to their usefulness as a means of support, ability to lift, and give structural stability.

The types of wire rope are determined by the number of wires in each strand and how many are in the rope, which is defined by a two number system with the first number being the number of wires and the second being the number of wires in each strand.

8613371530291

8613371530291