stainless steel wire rope breaking strength supplier

Type 304 stainless steel is the standard alloy for use in wire rope and cable. It has about the same strength as galvanized rope or cable but is much more corrosion resistant. It can be used in most industrial atmospheres and has acceptable corrosion resistance when used in marine and salt water.

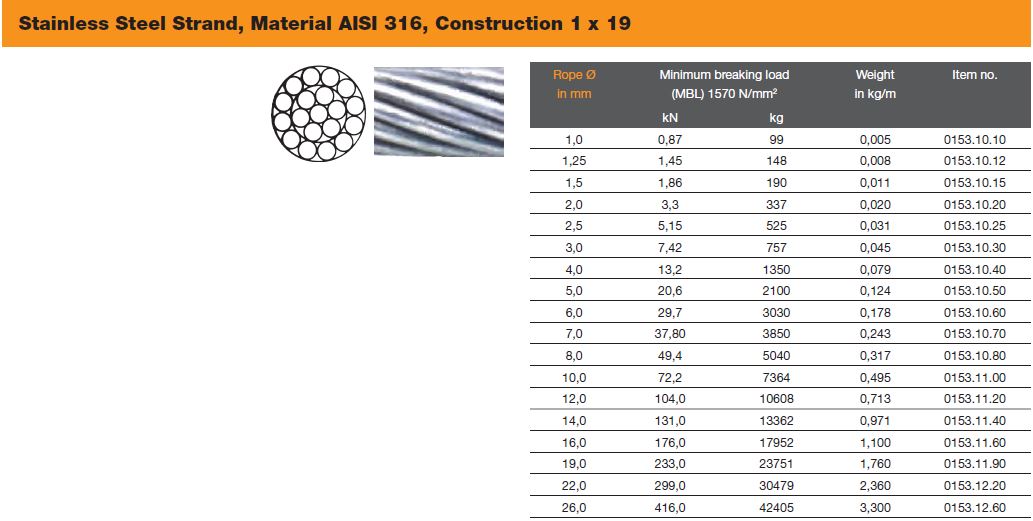

Type 316 stainless steel is the standard high corrosion resistant steel for rope and cable. It is resistant to many chemicals in the pulp and paper, photographic, food processing and textile industries. It has the best pitting resistance in marine and salt water and can be used in temperatures up to 480ºC (900ºF).

While some use these two terms interchangeably, technically wire rope refers to a diameter greater than 3/8”. Cable rope - also called aircraft cable - applies to all smaller variations.

Consequently, aircraft cable is only used for lighter-duty purposes, such as winch lines, fences, and railings, while wire rope can be using for lifting, towing, hoisting, etc. Both are ideal for outdoor environments because the strength and length remain constant regardless of whether they are wet or dry.

If you are looking for an option specifically designed for lifting, check out our wire rope slings. They come in a number of configurations - choices include leg count, end hardware, and more.

Generally composed of wires, strands, and a core shaped in a spiral pattern, wire rope is incredibly durable. Steel wires are aligned in a precise helix geometric pattern to form a strand in a process known as "stranding." A "closing" comes next, where the strands are laid around the core to form a wire rope.

The greater the diameter, the greater the break strength. Our selection of 1/8" stainless steel cable has a break strength of less than 2,000 lbs., while our 2-1/2" wire rope has a break strength of more than 600,000 lbs.!

Right hand and left hand designations indicate which way the strands wrap around the core of the steel rope, while regular lay and Lang lay designations specify which way the wires that make up the strand are formed in the helix pattern.

Regular lay means the wires are rotated opposite the direction of the strands around the core. Lang lay means the wires are twisted in the same direction as the strands wrapped around the wire rope core.

Our wire rope lay is right hand regular lay, with strands wrapped around the core to the right, and the wires making up the strand turned and rotated to the left.

Independent wire rope cores (IWRC) are made from steel, offer more support to the outer strands, and have a higher resistance to crushing. IWRC also offer more resistance to heat and increase the strength of the rope.

This refers to how many strands make up the rope and how many wires make up one strand. For instance, a 6x26 wire rope has 6 strands around a core with 26 wires making up each strand.

All wires consist of layer(s) arranged in a specific pattern around a center. Pattern designation is affected by the size of the wires, the number of layers, and the wires per layer. Wires can utilize either a single pattern style or a combination of them, known as a combined pattern:

Warrington - Two layers of wires. The outer layer has two diameters of wire (alternating between large and small), while the inner layer has one diameter.

Although wire rope is extremely strong, it can become damaged with improper use, making it unsafe to use. It"s important to have regular inspections for breaks, corrosion, overuse wear, and kinks.

Our rigging supplies category includes hardware and accessories for cranes, dredging, excavating, hoists & winches, logging, and marine uses. If you"re unsure what you need or have questions, call for help from our product specialists with expertise in wire rope/cable rigging supplies.

Your applications such as custom aircraft cable assemblies, and fittings require precision cable assemblies that are of the most reliable quality, and that adhere to stringent quality assurance standards. Expect nothing less when you work with Sava as your tungsten, nitinol, galvanized, or stainless steel cable manufacturer, an organization with decades of expertise in manufacturing cables and creating custom assemblies the world trusts every day.

It doesn’t matter how strict your precision cable manufacturing requirements or complex your applications are. As a stranded mechanical steel cable supplier serving organizations around the world, and across dozens of industries, Sava has seen and produced it for organizations just like yours. Whether it"s a reliable small cable pulley a small cable crimp or another one of our many solutions, Sava has your organization covered.

Our galvanized steel cable and steel cable accessories selection accommodate a myriad of breaking strengths, constructions, and diameters and is backed by almost 50 years of cable-making experience. As you explore our cable, be assured that our skills range from supplying FEP-coated cables for aerospace applications to designing customized assemblies for endoscopic medical devices. we are an aircraft cable supplier, medical cable supplier, and supplier of cables in many more industries.

The 6X36 Stainless Steel IWRC Wire Rope is the most flexible steel wire rope option due to its larger diameter. This makes it the optimal choice for corrosive environments, thanks to its durable construction of 36 individual wires made into 6 strands.

The independent wire rope core (IWRC) reduces friction and protects wires from wearing down and corrosion. This rope’s design promotes fatigue and rotation resistance.

If you are in the market to buy stainless steel industrial wire rope, look no further than Elite Sales. Got questions or unsure of how much you need? Send our knowledgeable team a message. We are ready to give you all the help you need to get the proper type of wire rope for your next project.

Galvanized wire rope is categorized by number of strands in its construction. We supply most of them but we concentrate on the two major categories of galvanized (and ungalvanized or bright) wire rope. These “classes” are referred to as 6x19 and 6x36. Within each category of galvanized wire rope there are different “constructions” illustrated in the tables below.

Wire rope, galvanized and ungalvanized is used for many kinds of projects and applications. No matter the application galvanized wire rope must be used properly to insure the safest working conditions. All of our galvanized wire rope is manufactured to meet or exceed Federal Specification RRW-410 and is mill certified.

All of these general purpose wire ropes are available in full reels, custom cut sizes or as part of a custom made wire rope sling. Contact us today for more information.

Galvanized wire rope also comes in different strength categories (IPS and EIPS) and different cores (FC or fiber core and IWRC or independent wire rope core). Relevant data for each is listed in the table below.

8613371530291

8613371530291