stainless steel wire rope terminations factory

• Based on the catalog breaking strength of wire rope, Crosby wire rope clip have an efficiency rating of 80% for 3-4mm to 22mm sizes, and 90% for sizes 24-26mm through 90mm.

• Meets or exceed all requirements of ASME B30.26 including identification, ductility, design factor, proof load and temperature requirements. Importantly, these wire rope clips meet other critical performance requirements including fatigue life, impact properties and material traceability, not addressed by ASME B30.26.

Spelter socket terminations have an efficiency rating of 100%, based on the catalog strength of wire rope. Ratings are based on the recommend use with 6×7, 6×19, or 6×36, IPS or XIP (EIP), XXIP (EEIP), RRL, FC, or IWRC wire rope. Strand constructed with minimal number of wires (e.g. 1×7) requires special consideration that socket basket be five (5) times the strand diameter or fifty (50) times the wire diameter, whichever is the greater.

Wedge socket terminations have an efficiency rating of 80% based on the catalog strength of XXIP wire rope.Meets or exceed all requirements of ASME B30.26 including identification, ductility, design factor, proof load and temperature requirements. Importantly, these sockets meet other critical performance requirements including fatigue life, impact properties and material traceability, not addressed by ASME B30.26.Type approval and certification in accordance with ABS 2006 steel Vessel Rules 1-1-17.7, and ABS Guide fo r Certification of Cranes.Basket is cast steel and individually magnetic particle inspected.Pin diameter and jaw opening allows wedge and socket to be used in conjunction with closed swage and spelter sockets.Secures the tail or “dead end” of the wire rope to the wedge, thus eliminates the loss or “punch out” of the wedge.

Eliminates the need for an extra piece of rope, and is easily installed.The TERMINATORᵀᴹ wedge eliminates the potential breaking off of the tail due to fatigue.The tail, which is secured by the base of the clip and the wedge, is left undeformed and available for reuse.

Utilizes standard Crosby Red-U-Bolt® wire rope clip.The 9-10mm through 28mm standard S-421 wedge socket can be retrofitted with the new style TERMINATORᵀᴹ wedge.Available with Bolt, Nut, and Cotter Pin. US patent 5,553,360, Canada patent 2,217,004 and foreign equivalents.Meets the performance requirements of EN 13411-6: 2003.

Loos & Co., Inc. has long been a manufacturer of high-quality wire rope fittings and accessories for a variety of industries. Our most successful wire rope products are our wire rope terminals. Our domestically manufactured wire rope terminals come in many milspec (MS) and commercial hardware styles for a range of applications. And are Made in the USA at our Naples, Florida facility. By buying our Made in the USA terminals, you are ensured a high-quality product from our craftsmen, with each purchase directly supporting the American workforce and the America manufacturing sector. If you would like to speak with one of our experts of wire rope terminals, or learn more about our other domestically manufactured products, please contact us via one of the methods below, and we will reach out to you directly.

Custom manufacturer of stainless steel wire for the automotive, medical, orthodontics, jewelry, oil and gas, temperature control, electronics, spring making, aerospace and fishing industries. Cables, guidewires, thermocouples, retainer wire and safety lock wires are also available.

Manufacturer and distributor of wire rope cable assemblies. Coated, aircraft, independent or fiber core, bridge, rotation resistant, compacted or swaged, cable laid, strand and galvanized cables are also offered. Serves the transportation, mining, railroad, construction, architectural, fitness, automotive, marine, OEM, military, display, signage, lighting, security and recreation industries.

Custom manufacturer of cable assemblies for the automotive, medical, electrical, electronics, power generation and computer and electronics industries. Capabilities include wire harnesses, automotive parts, consumer electronics, customized cables, home appliance, medical device, miniature, stainless steel wire rope, power controls and signals. Additional services such as reverse engineering, CAD/CAM design, drafting, label printing, quality inspection, kitting, 3D printing, scanning and prototype design provided. Low to high volume production offered. Blanket orders accepted. RoHS and REACH compliant. UL listed.

Custom manufacturer of cable assemblies made from alloy steel, stainless steel, aluminum, brass, nylon and PVC materials. Stainless or galvanized, nylon and PVC jacketed, miniature diameter, rotation resistant, tin over zinc, stranded and aircraft cables are available. Serves the aerospace, defense, medical, marine, electronics, power generation and transportation industries. ITAR registered.

Manufacturer and distributor of standard and custom 304 or 316 stainless steel wire rope cable assemblies. Medium-to-high tensile strength cable has seven strands made up of nineteen wires in each strand. Stock items available.

ISO 13485 & AS 9100 certified manufacturer of standard & custom cable assemblies including stainless steel wire rope cable assemblies. Capabilities include automated electro-cutting & shearing, swaging, coiling, welding, engraving, passivation & ultrasonic cleaning, packaging, bar-coding & labeling. Wire rope cable assemblies are used in applications including aircraft, aerospace, truck/automotive, medical & lift. Services include design engineering, machining, testing, assembling & inventory management. JIT delivery available.

Manufacturer of standard and custom wire rope assemblies for the agricultural, automotive, construction, lighting, marine, medical, military, railroad and security industries. Dia. ranges up to 1/2 in. Capabilities include CNC machining, cutting, hydroforming, swaging and zinc die casting. ASTM tensile testing services are also provided. Most items available in stock.

Distributor of stainless steel products including beakers, bumpers, castings, hinges, mirrors, mouldings, washers, sinks and cable assemblies. Products such as flats, angles, channels, bar stock, rounds, squares, hexes, tubing, expanded metal, shafts & grating are also available. Capabilities include saw cutting, shearing, deburring & cutting-to-length.

Manufacturer and designer of standard and custom wire rope cable assemblies. Various configurations, cable constructions, materials and cable coatings are available, including steel and stainless steel material with coatings including PVC, nylon, PTFE, and more. Industries served include transportation, material handling, military and defense, aerospace, automation and medical. ISO 9001 Certified.

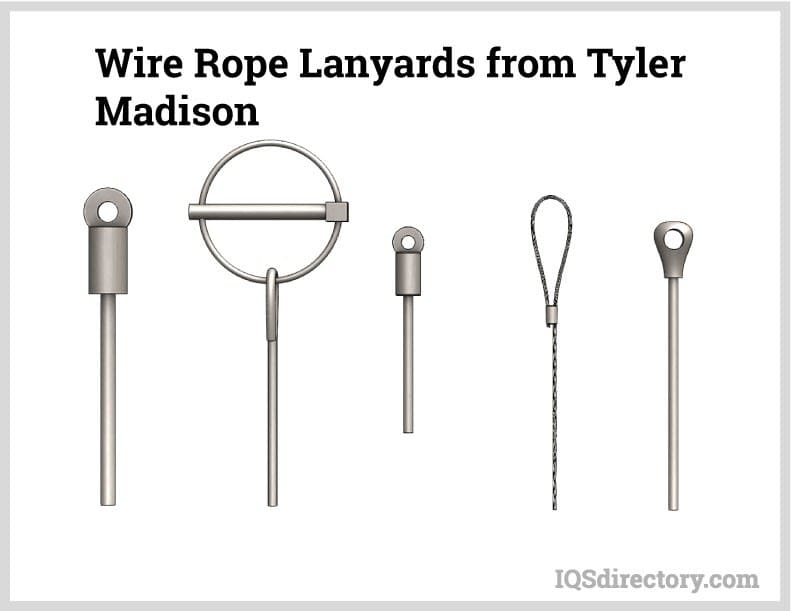

Manufacturer of standard and custom stainless steel wire rope cable assemblies including lanyards. Available with 6 in. to 12 in. length with 0.047 in. wire dia. Features include coiled wire, stop balls, hooks and yokes. Capabilities include CNC Swiss machining, light assembly and molding. Secondary services include drilling, tapping, shaving, pointing, bagging, pad printing, hot stamping, private labeling and retail packaging. Stock items and 24 hour services available.

Custom manufacturer of stainless steel wire rope cable assemblies. Stainless steel wire rope cable assemblies include bronze bushings, aluminum sleeves, threaded studs & plugs, molded & stamped eyes, nylon balls, thimbles & ball shanks.

Lean manufacturing capable custom manufacturer of molded cable assemblies including stainless steel wire rope cable assemblies. Types include coaxial wire, discrete wire, flat ribbon, power cord, patch cord and GPT/UL/PTFE cable assemblies. Types of coaxial cable assemblies such as semi-rigid, conformable, R.F., video cable assemblies are available. Capabilities including butt splicing, hot stamp marking, automatic and manual cutting, CAD designing, in-house tooling and E.D.M tooling. Products are UL listed. JIT delivery and Kanban services available.

Custom manufacturer of cable adapters. Types include DB25, DB15, DB9, RJ45, RJ12, RJ11 and centronic adapters. Various industries served include government, electronics, construction, education, manufacturing, medical, OEM, wireless, military, transportation and retail. RoHS compliant.

Distributor of wire rope products and assemblies. Product include cables, rope, fittings, reels, and assembly hardware. Serves the architectural, drilling, elevator, marine rigging, mining, agriculture, railroad, and oil and gas industries, as well as crane, winching, rigging, and general engineering applications.

Manufacturer of standard & custom application wire rope assemblies including stainless steel wire rope cable assemblies. Up to 3 in. diameter including bright ropes, galvanized, stainless, nylon or plastic coated. Standard special high strength alloy & stainless terminations from .062 in. to 3.5 in. From inventory or manufactured in-house on CNC equipment. For OEMs in mining, trucking, marine, construction, farm, crane & hoist, aircraft, guard rail, cable railings, conveyor & industrial markets.

Custom manufacturer & distributor of wire rope cable & cable assemblies made from stainless steel. Specifications of wire rope cables include 1/4 in. to 1/2 in. dia., 2.94 tons to 11.50 tons strength & 0.460 lbs. weight. Wire rope cable assemblies are available with internal lubrication & high carbon steel wire. Wire rope cable assemblies are suitable for general purpose applications.

ISO 9001:2008/HUBZone certified custom manufacturer of wire rope cable assemblies made from stainless steel. Other products include control panels, power & battery cables, wire harnesses & subassemblies. Various applications include telecommunication & network infrastructure, transportation, recreational vehicles, motion & control manufacturing, heating/cooling (HVAC), electronics, energy & healthcare & medical, food service & pharmaceutical automation equipment. Kan Ban/JIT manufacturing. CSA approved. RoHS compliant. UL listed.

Custom fabricator & stocking distributor of wire rope cable assemblies made from stainless steel. Cable assemblies are available with turnbuckles, hooks, swivels, snap hooks, stake eyes, clevises, ball shanks, threaded studs, sleeves & stops, thimbles, loops, custom & ball fittings, links, wire rope clips & shackles. Cables assemblies are suitable for aerospace, petrochemical, building & construction, mining, recreational goods, automotive, consumer goods & marine industries.

ISO/TS 16949 registered manufacturer of stainless steel wire rope cable assemblies including control & O.E.M. mechanical cable assemblies up to 3/8 in. dia., miniature cable assemblies, remote actuation systems with a wide range of actuators, operators & custom cable controls, light & medium duty standard & custom push-pull/pull-pull controls. Complete design, tooling, molding & testing services available.

Distributor of stainless steel angles, bars, balls, bearings, cables, carts, circles, discs, doors, extrusions, forgings, grilles, mesh, pipe, tubes, shapes, tanks, tubing, turnbuckles, valves, walkways, & wire

Manufacturer & distributor of cable assemblies including stainless steel wire rope available in 1/4 in. to 2 in. dia. Types include galvanized mooring lines & fiber core & aircraft cables. Cable assemblies are suitable for rigging & marine applications.

Distributor of industrial rigging hardware & supplies including wire rope cable assemblies & stainless steel wire rope cable assemblies. Architectural railings & sail boat life lines & standing rigging.

Manufacturer of stainless steel wire rope assemblies & galvanized wire rope cable assemblies 1/8 in. to 1 in. Stainless steel tie rods 1/4 in. to 1.5 in. Wire rope cable assembly terminations.

Manufacturer & distributor of rigging equipment & supplies including domestic & imported wire rope, blocks, tackle, cable, sleeves, wire rope slings, rigging & logging hardware, chain & wire rope slings in stainless & galvanized steel.

Brewer Titchener, Bridon-American, CM, CM, Continental Western, Crosby, Esco, Johnson, Laclede, Letellier, MSI, MacWhyte, Miller, Morse Starrett, Muncy, Newco, Ropemaster Skookum, Samson, Thern, Ulven, WRCA, Weissenfels, Wolf

Just to keep people confused, sometimes we call it Guy Wire Cable, sometimes we call it Aircraft Cable, sometimes just Wire Rope. Choosing a Wire Rope for the first time, or even the tenth time can be a daunting task. We start off with a strange term like aircraft cable, which is deceiving if you are trying to buy a wire for construction or marine rigging rather than aerospace applications. Since aerospace was the first place where Wire Rope was used commonly, the stringent requirements associated with this industry were the guiding force behind how wire rope is broken into specific categories. Thankfully here at U.S. Rigging, we have put together a guide that should help to simplify and demystify some of the important factors associated with picking out a Wire Rope.

It may be easiest to start out using one of our premium wire ropes as an example to break things down a bit. Unless you are using your guy wire in a marine rigging application or another context that involves saltwater or extreme moisture, you are going to want to use 7x19 Nylon Coated Galvanized Wire Rope for your most heavy-duty uses. While Galvanized Steel does not resist saltwater or moisture as stainless steel does, it is very resistant to wear, corrosion, and abrasion. the 19 wire, 7 strand design of this rope means that this particular model is also engineered to be especially flexible. Just to add another element to this rope’s Nylon Coating adds resistance to friction and heat.

Wire Ropes are measured by two factors - how many wires are included in each line and how many strands are included within these wires. If you try to read this sentence too many times, it may give you a headache, so here are some examples.

When you are choosing your wire cable, there is a general rule of thumb. Large wires generally stand up very well to abrasion but are not as resistant to fatigue as smaller wires. the size of the rope will help to determine both its strength and flexibility.

For the most part, Galvanized Steel is a little easier on your wallet than Stainless Steel and it will take a lot of abuse without much damage to show. However Galvanized Steel is not quite as strong as Stainless Steel and it can’t be used in jobs where the rope may be exposed to saltwater or excessive moisture.

If you really need to save some cash, bare guy wire cables can hold up pretty decent in some applications. However, if you want your cable to hold up against the elements and friction, you are going to want to look into something with some kind of coating on it. You can choose between a Nylon Coat or Vinyl Coating.

As specialist for manufacturing quality steel wire ropes over 20 years, our company can supply strong, durable and reliable ropes that capable to minimize your downtime and maximize cost effectiveness. Decades of experience we owned make us know clearly the work you do and capable to provide professional guidance.

We select the best steel or stainless steel as raw material for wire rope manufacturing. Our products are manufactured under strict quality managements and test before they leave the factory.

Our engineers can provide professional advice about picking up optimal steel wire ropes for their application, installation guidance to ensure maximum return in their wire rope system.

If you are going to pick up steel wire ropes that suit your project perfectly, you must have an ideal about the construction about them. Our company can supply bright wire rope, galvanized wire rope, stainless steel wire rope, compacted wire rope, rotation resistant wire ropes, mining wire rope, elevator wire rope, crane wire rope and gas & oilfield wire ropes. Here are some details to solve the problem that may puzzle you whether you are browsing the web or picking up steel wire ropes.

Bright steel wire ropes mean no surface treatment is applied to the rope. Therefore, they have the lower price among these three wire ropes. Generally, they are fully lubricated to protect the rope from rust and corrosion.

Galvanized steel wire ropes feature compressed zinc coating for providing excellent corrosion resistance. With higher break strength yet lower price than stainless steel, galvanized steel wire ropes are widely used in general engineering applications such as winches and security ropes.

Stainless steel wire ropes, made of quality 304, 305, 316 steels, are the most corrosive type for marine environments and other places subjected to salt water spray. Meanwhile, bright and shiny appearance can be maintained for years rather than dull as galvanized steel wire ropes.

Steel wire ropes are composed of multiple strands of individual wires that surrounding a wire or fiber center to form a combination with excellent fatigue and abrasion resistance. These wires and strands are wound in different directions to from different lay types as follows:

Beside above lay types, alternative lay ropes which combine regular lay and lang lay together and ideal for boom hoist and winch lines, can also be supplied as your request.

Two main methods about seizing steel wire ropes in conjunction with soft or annealing wire or strands to protect cut ends of the ropes form loosening.

Our fork and jaw end fittings must be machine swaged for proper hold strength. Lexco takes pride in our assembly work and will quote any assembly you need per your specification or design print.

Lexco® Cable supplies both commercial grade and MIL SPEC (MS20667) fork ends. Typically machined from 304 stainless steel, they are available in various sizes to accommodate cable from 1/16” to 1” in diameter.

Commercial and military grade fork ends must be machine swaged for proper hold strength. Please contacta Lexco® sales representative to receive an assembly quote.

As a rigger or end-user of wire rope, it’s important to understand the types of terminations, or treatments, that can be used at the ends of a length of wire rope. These terminations are usually made by forming an eye or attaching a fitting, and are designed to be a permanent end termination on the wire rope where it connects to the load.

Wire rope is an extremely versatile mechanical device that can be used to help support and move an object or load. In the lifting and rigging industries, wire rope is attached to a crane or hoist and fitted with swivels, shackles or hooks to attach to a load and move it in a controlled matter. It can also be used to lift and lower elevators, or as a means of support for suspension bridges or towers.

In this article, we’ll explain what some of the following terms mean and how the can be used to terminate the end of a wire rope cable:Wire rope sockets—spelter sockets, swaged sockets, and wedge sockets

When you understand the construction and specifications of the wire rope you need, as well as the right type of end termination you need, you’ll be able to select the best performing and longest-lasting wire rope for the job at hand.

There are essentially two techniques that can be used to create a termination on a length of wire rope or cable:You can form an eye, or loop, in the wire rope

Eyes, or loops, can be created at one end of a length of wire rope by using a mechanical splice with a swaged sleeve, a hand-tucked splice, or wire rope clips.

A swaged socket is applied to the end of a wire rope cable and is then forced into place using special dies and a hydraulic machine called a swager. When properly applied with the correct sized fitting, swaged sockets have an efficiency rating of 100% of the breaking strength of the rope.

A poured socket, commonly referred to as a spelter socket, attaches a termination fitting onto the end of a wire rope cable by pouring molten zinc or resin into a socket that then hardens and holds the fitting onto the end of the cable.

Due to the rigidity of this type of termination, the wires of the rope are subject to fatigue where the wires enter the socket, if the poured socket is subject to constant vibration.

Wedge sockets secure the rope to the end attachment by passing it around a grooved, wedge-shaped piece of steel and pulling it down under load into the bowl of the fixture.

Wedge sockets are popular because they can be installed in field and adjusted in field – providing 80% efficiency of rope breaking strength. Wedge sockets are popular in applications where the wire rope may be subjected to abuse and abrasion—particularly in construction and mining applications.

Wire rope clips can be used to form a load bearing eye at the end of a cable or wire rope, or to connect two cables together with a lap splice. Wire rope clips are popular because they can be installed in the field and provide 80% efficiency of the rope breaking strength.

However, the use of wire rope clips is heavily regulated by ASME B30.26 Rigging Hardware. When using wire rope clips, the end user must account for the following:When using U-bolt wire rope clips, the saddle shall be placed on the live end of the wire rope, with the U-bolt on the dead-end side—NEVER SADDLE A DEAD HORSE!

After installation, the connection shall be loaded to at least the expected working load. After unloading, the wire rope clips shall be re-tightened to the torque specifications of the manufacturer or a Qualified Person.

This type of wire rope clip is essentially a U-bolt, two nuts, and a metal base (saddle) that can be made from forged steel or cast iron. Careful consideration and attention must be given to the way U-bolt type wire rope clips are installed.

The base of the wire rope clip is made from forged steel. Forged clips are heated and hammered into the desired shape—resulting in a consistent grain structure in the steel. Forged wire rope clips are used for critical, heavy-duty, overhead loads such as winch lines, crane hoist lines, support lines, guy lines, towing lines, tie downs, scaffolds, etc.

Malleable wire rope clips are used for making eye termination assemblies only with right regular lay wire rope and only for light duty uses with small applied loads, such as hand rails, fencing, guard rails, etc. The base of the wire rope clips is made from malleable cast iron, which may fracture under heavy use and does not have the desirable metal properties of steel, or the beneficial grain structure that a forged base has.

Double saddle wire rope clips consist of two saddles, each with a leg, and two nuts—one used on the top and one on the bottom. Double saddle wire rope clips can be used in either direction, so they take the guesswork out during installation when applying to the live end and the dead end of a piece of wire rope.

An eye splice may be used to terminate the loose end of a wire rope when forming a loop. The strands of the end of a wire rope are unwound and then the wire is bent around, and the unwrapped strands are then weaved back into the wire rope to form an eye.

A Flemish eye splice is created when the wire rope is opened, and the strands are laid out into two parts. The two strands are looped in opposite directions and then laid back together—forming an eye, or loop, at one end of the wire rope cable. The strands are then rolled back around the rope body and a metal sleeve fitting is slipped over the splice and swaged using hydraulic machinery. This splicing method provides the most efficient use of rope capacity and is highly economical.

A hand tucked splice is formed when the shorter “dead” end is tucked into the longer “live” end of the wire rope—forming an eye. These types of splices allow for easy inspection of the wire rope wires and strands.

When the end of a rope is turned back and formed into an eye, a thimble is often used to keep the shape of the eye, prevent the rope from being crushed, and keep the rope from being bent at a diameter smaller than the rope manufacturer’s recommendations.

The table below will explain the efficiencies of the different types of wire rope end terminations for both independent wire rope core (IWRC) and fiber core (FC) wire rope configurations. Rope efficiency is described as the ratio of a wire rope’s actual breaking strength and the aggregate strength of all individual wires tested separately—usually expressed as a percentage.IWRCFC

*Spelter sockets in smaller rope sizes (usually less than 7/16”) may not always develop 100% efficiency and are not recommended by some rope manufacturers.

When you need to order a replacement wire rope, understanding the right type of end termination will help to make sure you get a direct replacement rope so you can get your project back on track. We hope this article gives you a better understanding of terms related to sockets, wire rope clips, and eye splices and that you understand what type of end termination may be best for your application.

At Mazzella, we offer all different kinds of wire rope from all of the leading manufacturers. We sell the highest-quality domestic and non-domestic rigging products because product quality and operating safety go hand-in-hand. We have one of the largest and most complete inventories of both domestic and non-domestic rigging and lifting products to suit your lifting needs.

In addition to the standard range, SWR supply high quality wire rope fittings for various uses including architectural, marine, yacht rigging and structural applications. SWR"s fittings are sourced from approved factories worldwide and fully supported by test certificates where applicable.

The most popular splicing method. Its safety relies mainly on the craftsmanship of the correct splicing method. The sleeve’s function is to secure the strand ends around the rope body. Steel sleeves are very rugged and withstand a lot of abuse. The flemish eye splice is the preferred method in the construction industry and for most industrial sling applications.

Loop end terminations for rotation resistant- and non-rotating ropes, and for ropes having more than 6 strands, require either aluminum- or loop-back steel sleeves.

Note: Stainless steel slings which have sleeves made from regular carbon or aluminum metal may experience accelerated deterioration due to an electro-chemical reaction between the two metals. Particularly if the slings are used in saltwater or corrosive environments.

8613371530291

8613371530291