stainless steel wire rope woven mesh factory

High security and fast lead time. We are a reliable supplier and factory of stainless steel wire rope mesh. If you need the ferrule mesh or woven mesh for the new zoo enclosure project, please contact us directly at sales@ecozoomesh.com.

About stainless steel rope mesh for zoo animal cage protection field, liulin stainless steel rope factory for its animal cage mesh product specifications, advantages, characteristics, application areas, etc. to make the following description.Stainless steel rope mesh is liulin company made from 304

The stainless steel wire rope mesh have two types material, said AISI 304, and AISI 316. There is no difference on the surface, but if to test ingredients, you will find the difference. The Ni in AISI 316 is much more than AISI 304 material. The material AISI 316 are more resistant to corrosion and

Liulin stainless steel rope mesh factory on the zoo built large monkey cage protection netting, monkey fence, stainless steel monkey enclosure mesh and other protective net related introduction. In general, we only in the zoo, circus, performance venues and other places can see the monkeys, because

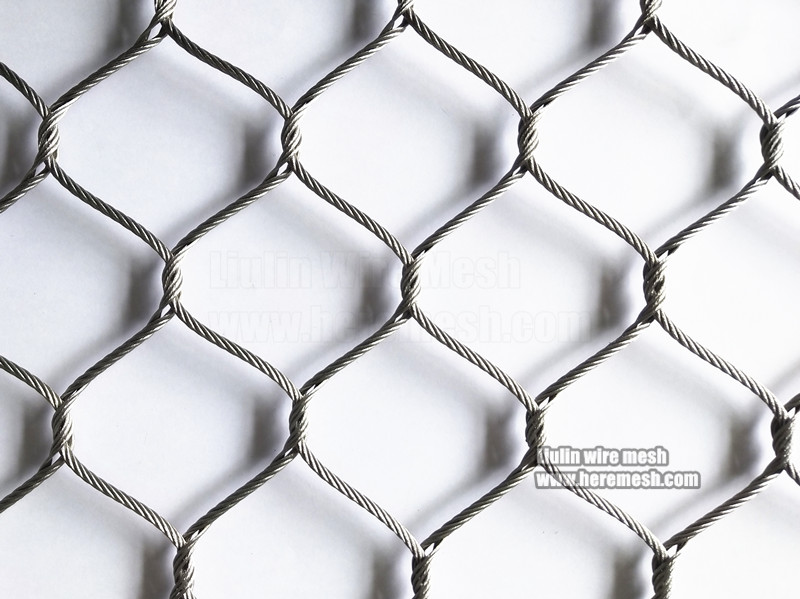

Stainless steel wire rope mesh also can be called: stainless steel cable netting, wire rope netting, wire cable netting mesh.Stainless steel wire rope mesh 100% hand woven by Multi-stranded (7 x 7 or 7 x 19 group) and Flexible AISI 304 or 316 s s wire cables material. The knots of stainless steel wi

Liulin Factory direct supply Low-cost 304 stainless steel braided rope netting, liulin stainless steel cable braid mesh factory set up more than 20 years, mainly to do the export of stainless steel rope mesh products, liulin manufacturers custom production of wire rope braid netting, stainless steel

hand woven stainless steel wire rope mesh is a kind of flexible netting for animal cage, as known as animal enclosure netting, animal fencing, zoo animal fence mesh, ect. liulin zoo enclosure fence netting mesh manufacturer & supplier.About flexible netting for animal cage, animal enclosure netting,

The AISI 304 or 316 wire rope netting is a ideal leopard barrier mesh, leopard cage netting in zoo, wildlife park, safari parks, protective center, museum and so on.1. Wire rope netting is impact resistance, not easy to destroy, to prevent leopard escape and hurt tourists.2. Leopard zoo mesh is good

Lions enclosures mesh are one of the world"s best-selling stainless steel wire rope hand-woven products. Applicable to all kinds of lion cages in the field of protection, such as: lion fence, Lion cage enclosures for stainless steel wire mesh, hand woven netting, lion fence protection mesh, African lion cage enclosures, lion safety isolation mesh, lion pavilion fence, large cat enclosures fence

Liulin metal fabric co.,ltd.. the hand woven stainless steel rope mesh manufacturers.Products include: stainless steel metal braided rope net, hand woven steel wire rope mesh for animal cage mesh, zoo fence mesh, stainless steel wire rope mesh, Hand woven stainless steel wire mesh, metal braided rop

About liulin stainless steel Golden Pheasant fence net, turkey cage fence mesh, guinea fowl fence mesh and other poultry fence netting Introduction: Pheasant, pheasant, turtle, guinea fowl, golden pheasant, frog, long tail chicken, blue pheasant, element Baoji, wolf pheasant, Chinese partridge, gold

Jakob Rope SystemsJakob Rope Systems is one of the market leaders in the manufacture and supply of top-end, design-forward solutions to industrial and construction-related rope and cable applications in which elegance, simplicity and superlative quality are required.

Now, for more than a century and in over 55 countries, Jakob offers a range of steel rope products to our clients who return time and again seeking a reliable maker and provider of stainless steel wire ropes, rod fasteners, nets and unique fittings, all custom-designed and produced to fit exact specifications. At Jakob, we understand it’s the little details that make the big differences.

Every piece of finished goods leaving our warehouses is put through a stringent testing process to ensure compliance with AISI 316, ISO and DIN standards. Our cable railing, wire mesh, wire ropes, and rods can be used in multiple applications, both indoor and outdoor and at various scales, such as sign stanchions, shelving, as trellises on green walls, safety netting, and even in zoo enclosures.

Jakob and our USA -based team can provide cables and wire netting solutions for any commercial and business application. We take pride in offering custom-made designs to fit our clients’ needs.

Stainless Steel Wire Rope Woven Mesh is hand-woven using Stainless Steel Wire Ropes. The rope construction is either 7 x 7 or 7 x 19 with a standard mesh angle of 90°.

The components are made from AISI 304 or AISI 316 material group. Originally intended and widely applied in Zoos for the construction of animal enclosure, animal cage, and aviary. It is also known as “ZOOMESH”. Meanwhile, it could be also applied in architecture structure.

With the aesthetics of Stainless Steel Wire Rope Woven Mesh, a natural and secure environment can be created. Replacing unsightly chicken wire or non-metal mesh which require constant maintenance as they have a relatively short lifespan. On the other hand, ZOOMESH’s physical properties are well suited for the above-mentioned applications as it is strong and able to withstand harsh environmental conditions eg. salt water and UV exposure. More importantly, ZOOMESH requires low maintenance and has a lifespan of more than 30 years which will be more cost effective in the long run.

Looking for cable mesh netting? Go online and check out for cable mesh netting at Raffles Wire Mesh Pte. Ltd. Explore http://www.rafflesmesh.com for more info. #cablemeshnetting

Hand woven mesh is a kind of plain weave, each warp wire rope crosses alternately above and below each weft wire rope, warp and weft wire ropes generally have the same diameter.

Ferrule mesh is of the same physical properties with the handwoven mesh, the only difference is in the combination style, the stainless wire rope are combined by the ferrules which are made of the same grade stainless steel, the ferrule is divided into open ferrule and closed ferrule.

2. Adaptable- inox cable mesh has multiple applications including balustrades, safety netting, zoo enclosure mesh, aviary mesh, green wall mesh, helicopter mesh, deck mesh etc.

3. Tensile strength - designers can implement creative ideas over large distances due to the extremely high load capacity and low relative weight of stainless steel material, AISI 304 and 316 are the conmonly material

4. Unique - each net is designed and manufactured to meet your specific project requirements, the rope diameter, opening size and mesh size also can be customized.

5. Reduced maintenance cost - made from stainless steel, it"s remarkably strong, provide high performance under severe environmental conditions, protect against corrosion and rust and require very little maintenance over the life of the product.

Stainless steel knotted rope zoo mesh has diamond-shaped openings and high strength, which can protect visitors from being damaged. Therefore, visitors can enjoy the animals at a close distance free of danger. What"s more, the mesh surface is very smooth, it can protect animals from being hurt.

The mesh size and opening size of stainless steel rope mesh can be modified. So it can provide enough space and create a natural environment for birds to make them live comfortably.

Stainless steel rope mesh is resistant to corrosion and rust even though it is exposed to sun directly. And it can make the green wall with green plants. Green wall can regulate the temperature of the building and it can protect the building wall.

The diamond-shaped holes make the stainless steel rope mesh have aesthetic appearance, so rope mesh can be used for decoration of building, such as ceiling and curtain wall.

Stainless steel rope mesh can ensure the safety of helicopters and passengers when it is used as the helideck mesh. It is installed around the helicopter landing deck.

Stainless steel rope mesh is also mainly used in the suspension bridge railing. It can increase the safety performance of suspension bridges and ensure the safety of passers.

Hand woven mesh is a kind of plain weave, each warp wire rope crosses alternately above and below each weft wire rope, warp and weft wire ropes generally have the same diameter.

Ferrule mesh is of the same physical properties with the handwoven mesh, the only difference is in the combination style, the stainless wire rope are combined by the ferrules which are made of the same grade stainless steel, the ferrule is divided into open ferrule and closed ferrule.

2. Adaptable- inox cable mesh has multiple applications including balustrades, safety netting, zoo enclosure mesh, aviary mesh, green wall mesh, helicopter mesh, deck mesh etc.

3. Tensile strength - designers can implement creative ideas over large distances due to the extremely high load capacity and low relative weight of stainless steel material, AISI 304 and 316 are the conmonly material

4. Unique - each net is designed and manufactured to meet your specific project requirements, the rope diameter, opening size and mesh size also can be customized.

5. Reduced maintenance cost - made from stainless steel, it"s remarkably strong, provide high performance under severe environmental conditions, protect against corrosion and rust and require very little maintenance over the life of the product.

Stainless steel knotted rope zoo mesh has diamond-shaped openings and high strength, which can protect visitors from being damaged. Therefore, visitors can enjoy the animals at a close distance free of danger. What"s more, the mesh surface is very smooth, it can protect animals from being hurt.

The mesh size and opening size of stainless steel rope mesh can be modified. So it can provide enough space and create a natural environment for birds to make them live comfortably.

Stainless steel rope mesh is resistant to corrosion and rust even though it is exposed to sun directly. And it can make the green wall with green plants. Green wall can regulate the temperature of the building and it can protect the building wall.

The diamond-shaped holes make the stainless steel rope mesh have aesthetic appearance, so rope mesh can be used for decoration of building, such as ceiling and curtain wall.

Stainless steel rope mesh can ensure the safety of helicopters and passengers when it is used as the helideck mesh. It is installed around the helicopter landing deck.

Stainless steel rope mesh is also mainly used in the suspension bridge railing. It can increase the safety performance of suspension bridges and ensure the safety of passers.

Boss Metal has been stainless steel cable mesh supplier and one of the leading wire rope mesh manufacturers since 2006; we supply high-quality cable mesh at the lowest price

Stainless steel wire rope mesh (alternate names: stainless steel cable mesh, flexible wire mesh, stainless steel wire woven mesh, stainless steel wire rope ferrule mesh, hand-woven stainless steel mesh, stainless steel wire cable mesh). A premium wire fabric with strength and flexibility, hand-woven from stainless steel wire ropes by knotting and twisting.

BOSS METAL is a professional research, development, production and sales of stainless steel wire mesh supplier, its characteristic products are stainless steel wire rope mesh, we call it ZOOMESH and Railing mesh and bridge cable mesh was founded in 2006, located in Hengshui City, covers an area of 22600 square meters

Stainless steel wire cable knotted many colors: natural color stainless steel wire rope mesh, black stainless steel wire rope mesh, bronze stainless steel wire rope mesh.

Boss Metal Stainless steel Wire rope mesh Factory is China’s most professional and extensive stainless steel cable mesh suppliers. It produces stainless steel 2163,000 square meters of rope mesh annually, trusted by more than 2535 users. Since its inception, the company has continued to invest in research & development to improve stainless steel wire rope woven mesh products.Zoo stainless steel meshmanufacturer, complete specifications, sales nationwide, exported to all over the world, Marine park, stadiums architectural decoration industry, etc.

As one of the elder wire rope mesh manufacturers, We have always regarded our customers as the most commendable and valuable customers. We believe that we can provide you with authentic products that meet your requirements through our reliable materials and quality assurance. If you are interested in any of our products or looking for a reliable and stable supplier to complete your project, please contact us to discuss your requirements. We sincerely welcome the establishment and development of business cooperation between domestic and foreign customers.

Due to the high-quality characteristics of stainless steel, stainless steel wire rope mesh has the following advantages. High strength, flexibility, lightweight, UV resistance and weather resistance, no rust, no corrosion, simple structure, durability and service life of more than 30 years. Good transparency, almost invisible from a distance, rope net fence can provide perfect interaction conditions for tourists.

Safely accommodate any species on land, in the air, indoors or outdoors. Customers can customize the mesh aperture to meet the precise specifications of the exhibits. If you buy, x-tend stainless steel cable mesh can customize oversized stainless steel rope mesh panels. Usually used as the roof of a birdhouse. Factory manufacturing, high quality, high ex-factory price, customized products and the best after-sales service. Whether zoo, design company or individual users, we are your best choice.

Stainless steel wire cable mesh of AISI304/316 material wire mesh, meet international standards, free from rust and corrosion prevention. 100% hand woven wire rope, flexible, soft, no deformation, no shift free and available for over 30 years.

As one of the reputation wire rope mesh manufacturers, We supply stainless steel rope mesh Complete quality management system, equipped with the spectral detector, component tester, tensile test machine and other test equipment.

Buy SS wire rope mesh from Direct factory price is the best, very competitive, good quality and reasonable price. We have advanced technologies that can guarantee each knot is interwoven, firmly and durably. The knots never get detached, and meshes never deform. We have molds with precision at the millimeter level.

The wire rope zoo net is woven in custom sizes and can only make rectangles. Raw materials, specifications, dimensions, and shipping methods can be customized. Excellent processing technology ensures the production of more than 2 000 square feet of single mesh panels and, under certain specifications, more than 3000 square feet!

We are a professional zoo mesh manufacturer integrating R & D, production, sales and after-sales service. It is transformed from BM stainless steel wire mesh factory. Since the manual production of stainless steel wire mesh began in 2006, we are proud of our long history. We are committed to improving the living environment of animals and the ecological construction of zoos.

After years of development, the company covers an area of 30000 square meters and has 230 employees, including 22 technicians and senior engineers. The company has perfect organizational structure, advanced production technology, excellent production equipment and scientific quality management system. The rich experience in the production of zoo mesh enables us to provide customized services for customers.

Stainless steel wire rope mesh Zoo mesh is the customer’s abbreviation for stainless steel wire rope net (alternative name: stainless steel cable net, cable ferrule net, webnet, hand-woven stainless steel net). It is commonly used in zoo fences. We ensure that our product quality meets international and industrial standards, service life exceeds ten years and delivered on time. 100% of the products meet the ASTM and industrial inspection AS/NZS standards.

With new technologies and innovative talents, we have upgraded product materials and production processes as one of the advanced wire rope mesh manufacturers. In addition to ordinary stainless steel wire mesh, we have also developed a new particular ecological network for zoos, including dozens of varieties, such as an animal fence, birdcage net, zoo net, birdcage net, phantom net, parrot birdcage net, large birdcage panel, Zoo monkey cage net, zoo tiger cage net, tiger cage net, deer fence net, etc.

BMP is one of the leading wire rope mesh manufacturers; we strongly recommend the following specifications, which contain most of the cases you may be needed

Handwoven Stainless Steel Netting is hand-woven from Material 304 or 316 stainless steel ropes by molds. It is a creative product that perfectly replaces the fences and bars used in zoological gardens, so it is called zoo mesh by clients. Stainless steel wire rope mesh for enclosure fences (alternate names: stainless steel cable mesh, flexible metal mesh, stainless steel wire rope woven mesh, stainless steel knotted rope mesh, stainless steel wire mesh, hand-woven stainless steel netting, stainless steel rope mesh).

HEBMETALMESH is a stainless steel wire mesh manufacturer from China, being a professional Handwoven Stainless Steel Mesh supplier. We are the zoo fence, enclosure factory supplier. Our products are widely used in zoos and therefore referred to by our customers as Zoo mesh. Our products are known as zoo fence, enclosure fence & birds aviary mesh, and so on.

Stainless Steel wire rope mesh enclosures zoo fencing produced by Hebmetalmesh is safety-certified, simple in structure, easy to install. Beautiful in appearance, highly durable, and maintenance-free (alternate names: hand-woven stainless steel netting, stainless steel wire mesh, flexible metal mesh, stainless steel cable mesh, stainless steel knotted rope mesh, handwoven multiple wire mesh).

Zoo mesh’s reliable strength, flexible shape, and long service life. It has been recognized by more and more zoo enclosure designers, and there are many successful experiences for later reference.

Wire is one of the generic types of metallurgical products, together with plates, sheets, bars, tubes. Encyclopaediae generally define metallic wire as a “ single strand or rod of metal, usually cylindrical “. The history of wire making goes way back in Antiquity .

The first known writing relating to wire appears in the Bible (Ex.39:3): “ And they did beat the gold into thin plates, and cut it into wires...) However, archeological discoveries date the art of wire making to much earlier times, probably as far back as 4000 BC : a necklace containing gold wire was found in the tomb of an Egyptian Pharaoh who reigned about 2750 BC and there are wire-containing jewelry and ornaments made by Assyrians in the 1700"s BC.

The manufacturing of wire was for a long time limited to jewelry and similar decorative items using “soft” materials such as gold or bronze. Utilitarian uses started to appear in the latter years of BC, as shown by 3 bronze wires twisted into a cable found in Pompei. For many centuries, wire was manufactured by hammering the ductile metals gold & bronze into thin sheets. Then hammers and files were used to transform the thin strips into short round pieces , which could eventually be brazed into longer wires . There is however evidence that even in the antique Egypt some wire were actually drawn through tapered holes , the crude predecessors of “dies”.

Modern wire manufacturing done by drawing through dies can be traced to the 300 AD to 700 AD period. Wire manufacturing by drawing through dies became common in the 12th to 14th centuries, in France, England and Germany: in those times, wire was drawn by hand. German wire manufacturers started to use waterpower to replace hand operation in the Middle Age. Also, German manufacturers of the Düsseldorf area discovered about 1650 the advantage of using lubricants (such as stale beer!) to draw hard steel.

Thus, the basic method of wire manufacturing, i.e. drawing a soft metal through a hard, incompressible die has remained unchanged for centuries. Obviously, modern industrial wire manufacturing has developed for productivity and quality a number of sophisticated technologies pertaining to:

The above narrative obviously only pertains to the “metallic wire” and not to the increasingly important glass wire involved in the “fiber optics” industry.2 - STAINLESS STEEL: History & Production

Stainless Steel (also commonly referred to as “inox” or “rostfrei”) is now a very common feature of 21st Century living. However, this material is the most modern type of steels: basically, its invention dates only to the early days of the 20th Century when it was discovered that a certain amount of Chromium as alloying element (minimum about 11%) added to ordinary steel made it shiny and highly resistant to tarnishing and rusting. This rust-resisting property translates into “corrosion resistance “which sets stainless steel apart from all other steels. Though the true “discovery” of stainless steel occurred in the 1900 to 1915 time period, several earlier contributions can be traced back to:

Frenchman Léon Guillet, who published in 1904 research on steels with close to current grades 410, 420 compositions and 1906 a detailed study of an alloy iron-nickel-chromium with the basic metallurgical structure of the 300 series stainless steel. These findings were completed by Frenchman Portevin who published in 1909 studies on an alloy close to current 430 stainless steel

At the same time, Englishman Harry Brearley, Chief of the research lab of Thomas Firth & Sons in Sheffield conducted research which led to the first industrial cast of a stainless steel in 1912. Beardley called the new material “rustless steel”. Shortly therafter, the manufacturer Ernest Stuart coined the name “stainless steel”.

Later on, W. Hatfield, successor of H. Brearley at Thomas Firth patented the 18% Chromium and 8% Ni austenitic stainless steel which became the most widespread used stainless steel known as grade 304. On a parallel time frame, Société d’Electrométallurgie d’Ugine has to be credited for the metallurgical research and industrialization of the ferritic grades such as 430, with 17% Chromium and no Nickel. Also, German metallurgists of Krupp Research Institute have to be recognized for their work in the 1915 to 1930 time frame.

The large development of industrial production of stainless steels is only fairly recent: It has exhibited a spectacular growth from 2 Million Tons in 1950 to 48 million Tons in 2017, with 3 modern metallurgical processes playing a key role in this development:

Like every type of steel wire, stainless steel wire is an established and widely used basic metallurgical product. Made of a modern specialty steel “discovered “in the 1910’s, it is also manufactured by the “drawing process” dating back to Antiquity and extensively developed in Europe in the 12th to 16th Centuries. The wire drawing process is simple in concept: it reduces the cross-section of the wire by pulling it through a single or a series of drawing dies typically made of Tungsten carbide or polycrystalline diamond (in the case of fine stainless-steel wire sizes).

The raw material/ feedwire for drawing stainless steel wire is stainless steel “wire rod” produced on modern hot rolling mills from billets issued of the “Electric furnace + AOD converter + continuous casting” process. The wire rod comes in sizes 5.5 to 30 mm with 5.5 mm (0.218”) being the prevalent size; the wire rod is annealed + pickled or simply pickled if the rod is controlled-cooled.

For wire sizes > 0.8mm, the drawing process is known as “dry drawing”. In this case, the wire rod is subjected to a phosphate pre-coat which will provide a suitable substrate for wire drawing lubricants, typically Na or Ca-containing soaps. The stainless steel wire is then drawn through a series of dies boxes containing the lubricant in powder form + the tungsten carbide die, often on so-called multi-holes or multiple-die machines (up to 12 in some of the most modern machines). Depending on the finish size and the grade, it may be necessary to do intermediate operations of in-line cleaning followed by in-line annealing in N2/H2 reducing atmosphere and eventual re-coating for finish drawing. Depending on the range of tensile strength and the surface condition specified, a final anneal and a “skin-pass” light draw might be performed. Also, single block drawing is sometimes used with grease as lubricant, to obtain bright surface finish.

For fine stainless steel wire production, typically < 0.80mm, the process is quite different and known as “wet drawing”. The feed wire is a so-called “redraw wire” in sizes smaller than 1.2mm and fully annealed. The drawing process is performed through a series of diamond dies (up to 30 in some machines) fully immersed in an oil-type lubricant. This delicate process is followed, for soft wire, by in-line cleaning, annealing in N2/H2 atmosphere and precision spooling on special take-ups adapted to the various types of spools. Ultra fine stainless steel wires, down to about 0.010 mm, are thus produced by a few highly specialized stainless steel wire producers.4 - STAINLESS STEEL WIRE MESH

Stainless Steel Wire Mesh is one of the most widespread uses of stainless steel wire. Over the years, the terminology in the industry has evolved concerning the three following terms “wire mesh”, “wire cloth” and “wire fabric”. In today’s market place, these three wordings are used interchangeably and refer to the same product, with “wire mesh” or even “mesh” as the most prevalent from the purchasing and usage standpoints. Meshs made of stainless steel wire may be woven, knitted, welded depending on the applications and the wire size. Woven stainless steel is the most prevalent mesh. Woven wire products cover a wide variety of weaving patterns depending on the final end-use. Main patterns:

“Dutch” weave, similar to plain weave, with warp wires thicker and closer to each other: this type of mesh is used in industrial filters and separation apparatus

Thus woven stainless steel wire mesh encompasses a large range of wire sizes from 0.04 mm for the finest woven “wire cloth” to 3 to 4 mm for the industrial meshs. End uses cover a very large array from separation, sizing, conveyors, very diverse types of filtration, fencings, screenings, interior/exterior architectural decoration, etc.…

Knitted stainless steel wire mesh is another very common type of mesh, obviously mostly with finer wire sizes. The loop structure gives knitted mesh springiness or two-dimensional flexibility, allowing it to be crimped or compressed to alter characteristics for specific applications, for instance using the high mechanical damping properties of such mesh. Stainless steel knitted mesh can be processed into compressed, pleated or pad forms to allow liquid or gas flowing through. Knitted stainless wire mesh are widely used in auto parts and engineering applications such as filters, mufflers, catalytic converters blanket mesh. Another large area is the field of demisters and separation engineering.

Of course, the stainless steel wire meshs of all types capitalize on the corrosion resistance of stainless steel. Main grades are austenitic 304/304L and 316/316L depending on the corrosion specificities of the usage; also occasionally ferritic 430 (demisters, decoration).5 -STAINLESS STEEL WIRE IN HOUSEHOLD USES

Stainless steel is now the most commonly used material of choice for household appliances and utensils due to its “food compatibility” and more generally to its resistance to various types of corrosion. Leaving aside the important segment of interior decoration, stainless steel wire finds its place in a very wide array of household applications, either in straightened cut lengths, formed or shaped parts or as wire mesh. We will segment here the household uses as follows:

In view of the very diverse household uses, a wide variety of stainless steel grades are encountered : austenitic grades 304, sometimes 316 are the most used, but a substantial proportion of simple utensils use ferritic grade 430 (mixer whips, mesh strainers, etc.. ), all the more so in view of the cost difference with Ni-containing grades. Aerosol spray spring wires sometimes require high corrosion resistance necessitating the use of super-stainless grades such as 904L6 - STAINLESS STEEL WIRE IN INTERIOR DECORATION

The use of stainless steel in interior decoration is a fairly recent phenomenon, quite coherent with the modernity of this material and its widespread production increasing at a yearly rate of over 5% since the 1950’s. Not surprisingly, stainless steel wire has found a broad array of such uses due to its good formability and also its ability to be put in mesh form (via weaving, knitting, crimping) and wire rope/cable form through stranding. The many applications of stainless wire in interior decoration are usually segmented as follows:

- General decoration of interiors of buildings: these applications cover interior decoration of office buildings, shopping malls, museums, theaters, etc. They are a natural component of decorative uses of stainless steels in overall architecture . Stainless steel wire is thus found as wire ropes connecting posts in stairways to complement hand rails made of stainless tubes, in balustrade applications of similar type : such applications combine decorative and structural functionalities. Stainless steel wire in a wide variety of meshes can be found as metallic fabric and drapery for wall cladding decoration. Ring mesh curtains with single wire or wire ropes are often found in shopping malls as dividers. Modern designers can propose and realize very elegant combinations of stainless steel tubes, wire ropes and wood in staircases for building interiors.

- Restaurants and upscale shops: there too, stainless steel wire is in demand for purely decorative reasons as well as functional, in keeping with the luster and cleanliness image of stainless steel . Thus stainless steel wire meshes can be found as: functional partitions, mesh drapery curtains and intercrimp wire meshs for decorative purposes. Also, certain lounge seats and bar stools of “trendy” designs can combine elegantly stainless steel wire mesh and cushions.

- Home decoration & furnishing: mixing functionality and beauty, stainless steel wire mesh was recently used in the renovation of a large luxury apartment complex in Chicago: elegant wall panels offered distinctive decoration while concealing mechanical equipment and complex home control systems. Stainless steel as a modern trendsetter is often combined with glass in dining room and sitting room furniture such as dining room table and chairs, coffee tables, bar stools, lamp stands with intertwined wire, modern design chandeliers, etc. Stainless steel wire is also widely used for art work either in free standing structures or framed with a background of velvet for wall hanging. Finally, stainless steel wire mesh are found in partition screens and also draperies in bathrooms.

In view of the low level of corrosion resistance required for interior decoration, stainless steel grades used are mostly austenitic 304 with its elegant gray luster and also ferritic 430 where bright and shiny appearance is needed.7 - STAINLESS STEEL WIRE IN FOOD PROCESSING

Stainless Steel Wires , as one of the generic stainless steel products, find numerous applications in food processing . Indeed, stainless steels have long ago established themselves as the materials of choice for almost all food processing and storage equipment. What attributes make stainless steels so eminently suitable ? First and foremost, it is their corrosion resistance which makes them ideal for food contact, provided that the proper grades are used in view of the possible aggressive content of some foods, mostly salt presence. If home cooking is included, food processing is estimated to encompass close to 50 % of all stainless steel wire usages.

“Industrial” food processing : this large domain of applications goes from the upstream crop processing to the booming industrial areas of meat, dairy, cheese and cooked edible products, whether for animal feeds or, more or less extensively processed , food products for human consumption. On the upstream , wire mesh grids are used to screen agricultural raw products from grain to vegetables and fruit where calibration is a must and finer wire mesh are used for filtering primary juices such as olive oil, fruit juices. In the downstream, many uses of stainless wire baskets, trays, racks are found in meat and cheese processing, as well as hooks made of formed stainless steel wire. Also, wires woven, crimped or straight & cut , are the choice in many conveyor belt systems used for food processing and transfer. Grade selection is obviously a must with prevalence of the austenitic grades 304, 316 (if presence of salty mixtures or brine, etc.) and sometimes 314 (heat resistant grade). Cable trays made of stainless wire baskets are also a common use all through the “food chain” of industrial processing.

“Professional" food processing: though the limit between industrial and professional is not clear cut, “ professional” correspond to food processors in direct contact with end consumers, such as bakeries, butcheries, delicatessen shops , fish markets, restaurants (regular , fast food ). As to be expected, one will find there the same types of usages as in industrial, but on smaller scale and different product mix: for instance, prevalence of racks for display to customers and cold storage, formed wire in mid-size mixers, cooking racks for ovens, wire baskets for strainers and also specific applications such as formed wire for transfer trolleys. Fast food outlets have generated a large use of frying baskets for French fries, most often electropolished 304 formed wire of so-called “EPQ” quality. Also, the wineries use routinely stainless wire mesh for filtering purpose, all through the wine making process.

In summary, food processing is a key area of use of stainless wire or mesh. Beyond the prime aspect of resistance to corrosion and well established “food compatibility”, austenitic stainless steel wire also brings its unique mechanical properties : easy conformation and strain induced high strength.8 - STAINLESS STEEL WIRE FOR AUTOMOBILE APPLICATIONS

Stainless Steel , a modern material in view of its attractive combination of mechanical and corrosion resistance properties, has found a large array of usages in the Automobile Industry, as to be expected in spite of its cost higher than regular steels. Stainless steel wire is used in very diverse applications, notably as follows:

--Automobile fasteners: fasteners is a generic wording for a range of parts used to link or fasten in place several components of a vehicle: this covers bolts, nuts,washers and rivets usually cold headed from stainless steel wire rod or drawn wire. There is a large variety of grades used in automotive fasteners generally per ASTM A193 . Most prevalent are 302HQ, 304L, 316L, 410, 409Cb . Also 17-4 (grade 630) for restraint systems and for brakes. Noteworthy the substantial use of high temperature “super stainless” A286 (grade 660) for exhaust manifold safety bolts : this very same grade is a common use in Aerospace applications. Also 409Cb bolts in exhaust line.

--Exhaust line: the development of use of stainless steel in car exhaust systems started in the USA and Germany in the 1980"s with the catalytic converters, then spread out in all the Automotive Industries , with also usage in all components of the exhaust line from manifolds to tail pipes. The prevalent grade for pipes and converters shell is the low-grade 409 Ti; this has brought a large usage of grade 409Cb welding wire for the components of the exhaust line, as well as use of 409Cb large size wire for exhaust systems hangers. Some exhaust lines use ferritic grade 439 and hence the welding wire 439 Cb. There are significant other usages such as:

Thus, stainless steel wire is indeed a widely used material essential to Automobile safety, durability and performance.9 - STAINLESS STEEL WIRE IN AEROSPACE APPLICATIONS

It is no surprise that Stainless Steel, a modern material with an attractive combination of mechanical and corrosion resistance properties, would indeed find many usages in Aeronautics/Aerospace domains. Stainless steel in wire form is understandably on the forefront of these usages, in view of the weight savings considerations, in spite of the increasing competition from the more expensive Titanium alloys. Thus stainless steel wire, wire rope and wire mesh are found in many critical parts of aircrafts and primarily in the areas of fasteners (via cold heading) and aircraft cables, as follows:

-- Aerospace fasteners: fasteners is a generic wording for a wide range of parts used to link together several components together such as stringers, flanges, skins,ribs, stiffners in the aircraft airframe and the engine mostly. Such fasteners are cold headed from wire rod or drawn wire into screws, bolts,washers,nuts and rivets. In view of the stringency of the applications, the wire rod or wire is frequently “shaved” to minimize the occurrence of surface cracks. Though regular grades such as 302HQ and 316L are used, specific grades are prevalent in Aerospace, primarily A286 – grade 660 / ASTM A453. This high end austenitic Ni/25-Cr/15 is age hardenable and combines good corrosion resistance with excellent creep resistance up to 700°C. It is therefore widely used, particularly for jet engine components. Another set of precipitation hardening grades 13-8Mo and 15-7Mo, have found a large use as stems of blind rivets (Allfast technology).

-- Aircraft cables: aircraft cables are obviously of primary importance to safely provide the essential functions of controls in aircrafts for wing flaps, landing gear, as well as adjustable head-back on passenger seats, etc. Note also other applications such as helicopter hoists for cargo loads or rescue .These cables are made of wire ropes stranded from 304 and preferably 316 wires.

-- Miscellaneous applications: a specific application of particular relevance to safety of aircraft assemblies is the “safety lock wire”. This wire is a physical locking device which holds nuts, bolts or other fasteners in place to counteract forces due to vibrations. Safety lock wire is often an annealed 316 stainless wire, size ranging from 0.5 to 1mm packed in small canisters. Also more traditional uses of stainless wires : springs for switches, flexible metal hoses, emphasizing the large use of stainless wire in Aerospace applications.10 - STAINLESS STEEL WIRE IN MEDICAL APPLICATIONS

Stainless steel wires are increasingly present in medical applications which rely on their attractive combination of corrosion resistance, durability and mechanical properties. The main domains of applications are primarily the increasingly sophisticated field of “medical devices" used in diagnosis, investigations and innovative surgical techniques such as laparoscopy, and the more traditional areas of implants as well as surgical miscellaneous parts. Stainless steel wire can be in various presentations (round, flat or shaped wire) and forms (mesh, braided, straightened cut lengths, cables). Main grades used are 302, 304, 316L most often as the ESR-remelted grades 302 V, 304V, 316 LVM. Also used are grades 630 (17-4 PH) and 440C . Wire sizes are mostly in the smaller dimensions.

-- Vascular therapy: continuous improvements of medicine allow minimally invasive intervention through arteries and veins. Stainless steel wires are found in intra-arteria stents, angioplasty catheters, guide wires and diagnostic catheters, aneurysm clips, etc.

-- Orthopaedics applications: this broad field covers trauma,reconstructive, spinal & sports medicine. Stainless wires can be found in fracture fixations, spinal devices, nails, bone pins and screws, cerclage cables, suture wire.

-- Endoscopic medical devices: this fast growing field targets efficiency, comfort through minimally invasive procedures. Strands and cables made of fine stainless steel wires are used for : biopsies, gallstone removal, support of colonoscopy, retrieval of foreign objects in airways, laparoscopic surgery...

-- Orthodontics: this specific field of applications often uses shaped stainless steel wires for arch wire, self-litigating brackets , springs. Both the aesthetic and the mechanical properties of stainless steel are at work there. Related field of “implant dentistry” also makes use of stainless steel wire.

– Surgical and diverse applications: Stainless steel wire is often used for post-surgery staples, suture wire and needles , stylets. Another important field of use of stainless steel spring wire are the spring mechanisms of syringes , medical or self-injection systems for diabetes, allergic reactions.

Stainless steel wire is thus an important item in the increasingly diversified and fast growing medical field, in surgery, implants and sophisticated devices.

We also provide various parts, including stainless steel wire rope, buckle, sleeve, cable eye ends, suspension rope clamps, thread ends, rod articulation and wall mount. As shown in the following figure:

Stainless steel turnbuckle is ideal for areas requiring a great deal of tension, whether it be in gardens, fence or large structural elements in buildings.

Wall mount is an smart stainless steel device for mounting cable meshes to the wall conveniently and quickly to form a green facade for climbing plants.

8613371530291

8613371530291