steel wire rope cad drawings supplier

Wire rope consists of several strands of metal wire laid (twisted) into a helix. The term "cable" is often used interchangeably with "wire rope", but narrower senses exist in which "wire rope" refers to diameter larger than 3/8 inch (9.52 mm), whereas sizes smaller than this are designated cable or cords.wrought iron wires were used, but today steel is the main material used for wire ropes.

Historically wire rope evolved from wrought iron chains, which had a record of mechanical failure. While flaws in chain links or solid steel bars can lead to catastrophic failure, flaws in the wires making up a steel cable are less critical as the other wires easily take up the load. Friction between the individual wires and strands, as a consequence of their twist, further compensates for any flaws.

Wire ropes were developed starting with mining hoist applications in the 1830s. Wire ropes are used dynamically for lifting and hoisting in cranes and elevators, and for transmission of mechanical power. Wire rope is also used to transmit force in mechanisms, such as a Bowden cable or the control surfaces of an airplane connected to levers and pedals in the cockpit. Only aircraft cables have WSC (wire strand core). Also, aircraft cables are available in smaller diameters than wire rope. For example, aircraft cables are available in 3/64 in. diameter while most wire ropes begin at a 1/4 in. diameter.suspension bridges or as guy wires to support towers. An aerial tramway relies on wire rope to support and move cargo overhead.

Modern wire rope was invented by the German mining engineer Wilhelm Albert in the years between 1831 and 1834 for use in mining in the Harz Mountains in Clausthal, Lower Saxony, Germany.chains, such as had been used before.

Wilhelm Albert"s first ropes consisted of three strands consisting of four wires each. In 1840, Scotsman Robert Stirling Newall improved the process further.John A. Roebling, starting in 1841 suspension bridge building. Roebling introduced a number of innovations in the design, materials and manufacture of wire rope. Ever with an ear to technology developments in mining and railroading, Josiah White and Erskine Hazard, principal ownersLehigh Coal & Navigation Company (LC&N Co.) — as they had with the first blast furnaces in the Lehigh Valley — built a Wire Rope factory in Mauch Chunk,Pennsylvania in 1848, which provided lift cables for the Ashley Planes project, then the back track planes of the Summit Hill & Mauch Chunk Railroad, improving its attractiveness as a premier tourism destination, and vastly improving the throughput of the coal capacity since return of cars dropped from nearly four hours to less than 20 minutes. The decades were witness to a burgeoning increase in deep shaft mining in both Europe and North America as surface mineral deposits were exhausted and miner had to chase layers along inclined layers. The era was early in railroad development and steam engines having sufficient tractive effort to climb steep slopes were in the future, so incline plane railways were common, and the mining tunnels along inclined shafts between coal layers were just a which came first variant, but where steam engines could not go. This pushed development of cable hoists rapidly in the United States as surface deposits in the Anthracite Coal Region north and south dove deeper every year, and even the rich deposits in the Panther Creek Valley required LC&N Co. to drive their first shafts into lower slopes beginning Lansford and its Schuylkill County twin-town Coaldale.

The German engineering firm of Adolf Bleichert & Co. was founded in 1874 and began to build bicable aerial tramways for mining in the Ruhr Valley. With important patents, and dozens of working systems in Europe, Bleichert dominated the global industry, later licensing its designs and manufacturing techniques to Trenton Iron Works, New Jersey, USA which built systems across America. Adolf Bleichert & Co. went on to build hundreds of aerial tramways around the world: from Alaska to Argentina, Australia and Spitsbergen. The Bleichert company also built hundreds of aerial tramways for both the Imperial German Army and the Wehrmacht.

In the last half of the 19th century, wire rope systems were used as a means of transmitting mechanical powercable cars. Wire rope systems cost one-tenth as much and had lower friction losses than line shafts. Because of these advantages, wire rope systems were used to transmit power for a distance of a few miles or kilometers.

Steel wires for wire ropes are normally made of non-alloy carbon steel with a carbon content of 0.4 to 0.95%. The very high strength of the rope wires enables wire ropes to support large tensile forces and to run over sheaves with relatively small diameters.

In the mostly used parallel lay strands, the lay length of all the wire layers is equal and the wires of any two superimposed layers are parallel, resulting in linear contact. The wire of the outer layer is supported by two wires of the inner layer. These wires are neighbours along the whole length of the strand. Parallel lay strands are made in one operation. The endurance of wire ropes with this kind of strand is always much greater than of those (seldom used) with cross lay strands. Parallel lay strands with two wire layers have the construction Filler, Seale or Warrington.

In principle, spiral ropes are round strands as they have an assembly of layers of wires laid helically over a centre with at least one layer of wires being laid in the opposite direction to that of the outer layer. Spiral ropes can be dimensioned in such a way that they are non-rotating which means that under tension the rope torque is nearly zero.

The open spiral rope consists only of round wires. The half-locked coil rope and the full-locked coil rope always have a centre made of round wires. The locked coil ropes have one or more outer layers of profile wires. They have the advantage that their construction prevents the penetration of dirt and water to a greater extent and it also protects them from loss of lubricant. In addition, they have one further very important advantage as the ends of a broken outer wire cannot leave the rope if it has the proper dimensions.

Stranded ropes are an assembly of several strands laid helically in one or more layers around a core. This core can be one of three types. The first is a fiber core, made up of synthetic material or natural fibers like Sysal. Synthetic fibers are stronger and more uniform but can"t absorb much lubricant. Natural fibers can absorb up to 15% of their weight in lubricant and so protect the inner wires much better from corrosion than synthetic fibers do. Fiber cores are the most flexible and elastic, but have the downside of getting crushed easily. The second type, wire strand core, is made up of one additional strand of wire, and is typically used for suspension. The third type is independent wire rope core (IWRC), which is the most durable in all types of environments.ordinary lay rope if the lay direction of the wires in the outer strands is in the opposite direction to the lay of the outer strands themselves. If both the wires in the outer strands and the outer strands themselves have the same lay direction, the rope is called a lang lay rope (formerly Albert’s lay or Lang’s lay). Regular lay means the individual wires were wrapped around the centers in one direction and the strands were wrapped around the core in the opposite direction.

Multi-strand ropes are all more or less resistant to rotation and have at least two layers of strands laid helically around a centre. The direction of the outer strands is opposite to that of the underlying strand layers. Ropes with three strand layers can be nearly non-rotating. Ropes with two strand layers are mostly only low-rotating.

Stationary ropes, stay ropes (spiral ropes, mostly full-locked) have to carry tensile forces and are therefore mainly loaded by static and fluctuating tensile stresses. Ropes used for suspension are often called cables.

Track ropes (full locked ropes) have to act as rails for the rollers of cabins or other loads in aerial ropeways and cable cranes. In contrast to running ropes, track ropes do not take on the curvature of the rollers. Under the roller force, a so-called free bending radius of the rope occurs. This radius increases (and the bending stresses decrease) with the tensile force and decreases with the roller force.

Wire rope slings (stranded ropes) are used to harness various kinds of goods. These slings are stressed by the tensile forces but first of all by bending stresses when bent over the more or less sharp edges of the goods.

There are technical regulations for the rope drives of cranes, elevators, rope ways and mining installations not exceeding a given tensile force and not falling short of a given diameter ratio D/d of sheave and rope diameters. A general dimensioning method of rope drives (and used besides the technical regulations) calculate the five limits

Donandt force (yielding tensile force for a given bending diameter ratio D/d) - strict limit. The nominal rope tensile force S must be smaller than the Donandt force SD1.

Rope safety factor = minimum breaking force Fmin / nominal rope tensile force S. (ability to resist extreme impact forces) - Fmin/S ≥ 2,5 for simple lifting appliance

Discarding number of wire breaks (detection to need rope replacement) Minimum number of wire breaks on a reference rope length of 30d should be BA30 ≥ 8 for lifting appliance

Optimal rope diameter with the max. rope endurance for a given sheave diameter D and tensile rope force S - For economic reasons the rope diameter should be near to but smaller than the optimal rope diameter d ≤ dopt.

The wire ropes are stressed by fluctuating forces, by wear, by corrosion and in seldom cases by extreme forces. The rope life is finite and the safety is only ensured by inspection for the detection of wire breaks on a reference rope length, of cross-section loss, as well as other failures so that the wire rope can be replaced before a dangerous situation occurs. Installations should be designed to facilitate the inspection of the wire ropes.

Lifting installations for passenger transportation require that a combination of several methods should be used to prevent a car from plunging downwards. Elevators must have redundant bearing ropes and a safety gear. Ropeways and mine hoistings must be permanently supervised by a responsible manager and the rope must be inspected by a magnetic method capable of detecting inner wire breaks.

The end of a wire rope tends to fray readily, and cannot be easily connected to plant and equipment. There are different ways of securing the ends of wire ropes to prevent fraying. The most common and useful type of end fitting for a wire rope is to turn the end back to form a loop. The loose end is then fixed back on the wire rope. Termination efficiencies vary from about 70% for a Flemish eye alone; to nearly 90% for a Flemish eye and splice; to 100% for potted ends and swagings.

When the wire rope is terminated with a loop, there is a risk that it will bend too tightly, especially when the loop is connected to a device that concentrates the load on a relatively small area. A thimble can be installed inside the loop to preserve the natural shape of the loop, and protect the cable from pinching and abrading on the inside of the loop. The use of thimbles in loops is industry best practice. The thimble prevents the load from coming into direct contact with the wires.

A wire rope clamp, also called a clip, is used to fix the loose end of the loop back to the wire rope. It usually consists of a U-shaped bolt, a forged saddle, and two nuts. The two layers of wire rope are placed in the U-bolt. The saddle is then fitted over the ropes on to the bolt (the saddle includes two holes to fit to the u-bolt). The nuts secure the arrangement in place. Three or more clamps are usually used to terminate a wire rope. As many as eight may be needed for a 2 in (50.8 mm) diameter rope.

There is an old adage; be sure not to "saddle a dead horse." This means that when installing clamps, the saddle portion of the clamp assembly is placed on the load-bearing or "live" side, not on the non-load-bearing or "dead" side of the cable. According to the US Navy Manual S9086-UU-STM-010, Chapter 613R3, Wire and Fiber rope and Rigging, "This is to protect the live or stress-bearing end of the rope against crushing and abuse. The flat bearing seat and extended prongs of the body (saddle) are designed to protect the rope and are always placed against the live end."

An eye splice may be used to terminate the loose end of a wire rope when forming a loop. The strands of the end of a wire rope are unwound a certain distance, and plaited back into the wire rope, forming the loop, or an eye, called an eye splice. When this type of rope splice is used specifically on wire rope, it is called a "Molly Hogan", and, by some, a "Dutch" eye instead of a "Flemish" eye.

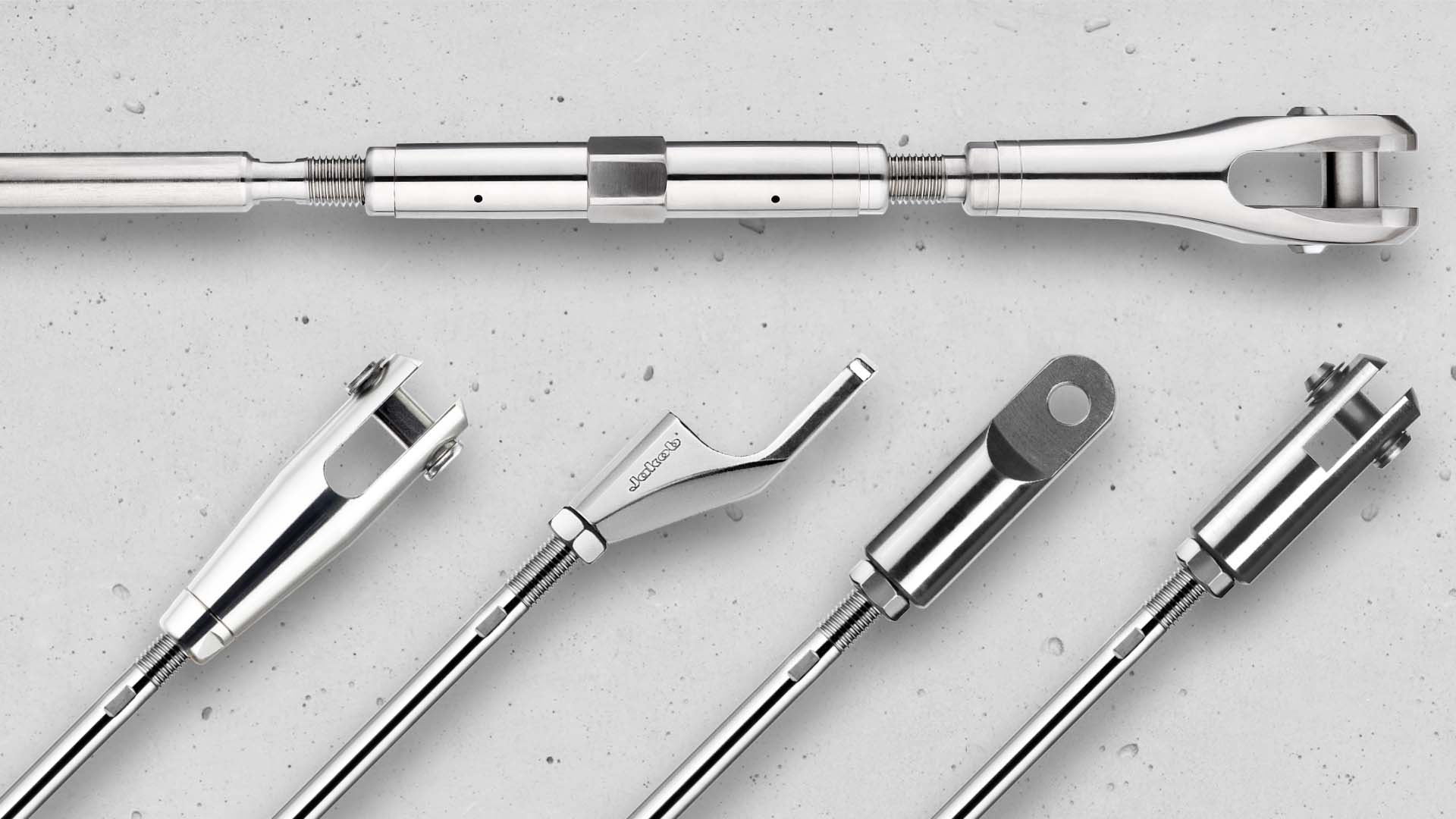

Swaging is a method of wire rope termination that refers to the installation technique. The purpose of swaging wire rope fittings is to connect two wire rope ends together, or to otherwise terminate one end of wire rope to something else. A mechanical or hydraulic swager is used to compress and deform the fitting, creating a permanent connection. There are many types of swaged fittings. Threaded Studs, Ferrules, Sockets, and Sleeves are a few examples.

A wedge socket termination is useful when the fitting needs to be replaced frequently. For example, if the end of a wire rope is in a high-wear region, the rope may be periodically trimmed, requiring the termination hardware to be removed and reapplied. An example of this is on the ends of the drag ropes on a dragline. The end loop of the wire rope enters a tapered opening in the socket, wrapped around a separate component called the wedge. The arrangement is knocked in place, and load gradually eased onto the rope. As the load increases on the wire rope, the wedge become more secure, gripping the rope tighter.

Poured sockets are used to make a high strength, permanent termination; they are created by inserting the wire rope into the narrow end of a conical cavity which is oriented in-line with the intended direction of strain. The individual wires are splayed out inside the cone or "capel", and the cone is then filled with molten lead-antimony-tin (Pb80Sb15Sn5) solder or "white metal capping",zincpolyester resin compound.

Proprietary Rights. Crosby retains all ownership right, title, and interest in and to all programs, procedures, information, and documentation associated with the Materials. The Crosby name and all names, logos, and icons identifying Crosby and its products and services are proprietary trademarks of Crosby, and any use of such marks without the express written permission of Crosby is strictly prohibited. Except as expressly provided herein, Crosby does not grant any express or implied right to You or any other person under any intellectual or proprietary rights. Accordingly, unauthorized use of the Materials may violate intellectual property or other proprietary rights laws as well as other domestic and international laws, regulations, and statutes, including, but not limited to, United States copyright, trade secret, patent, and trademark law.

Term and Termination. This License Agreement and Your right to use the Materials will take effect upon the earliest of: (i) delivery of the Materials to You, (ii) at the moment You choose “I ACCEPT” or (iii) You install, download, access, or use the Materials, whichever occurs first, and is effective for a period of forty-eight (48) months unless earlier terminated as set forth below. This License Agreement will terminate automatically if You choose “I REJECT” or if You fail to comply with any of the terms and conditions described herein, including by exceeding the scope of the License. Termination or expiration of this License Agreement will be effective without notice. You may also terminate at any time by ceasing to use the Materials, but all applicable provisions of this Agreement will survive termination, as outlined below. Upon termination or expiration, You must return, destroy, or delete from Your system all copies (including electronic copies) of PowerPoint files and training materials in Your possession. The provisions concerning proprietary and intellectual property rights, submissions, confidentiality, indemnity, disclaimers of warranty and liability, termination, and governing law will survive the termination or expiration of the License Agreement for any reason.

The Cable Connection was established in 1991. Its principals have been in the wire rope business for over thirty years and are specialists in manufacturing cable assemblies and fittings for up to 3/8 in. diameter cable. Since 1998, Ultra-tec® Cable Railing Infill has been a favorite of architects, specifiers, and builders. With its signature Invisiware® fittings that are concealed inside the end post and sleekly designed outside-the-post fittings, Ultra-tec® Cable Railing Infill provides an attractive alternative to conventional barrier rail systems and can be found in projects throughout North America.

IAM Design is an Italian brand, leading in the design and the production of railing systems, stairs and canopies made in stainless steel, carbon steel, aluminum and glass. The materials used are ecologically sustainable and they represent the raw materials of the collection. Designing metal is IAM Design purpose in life.

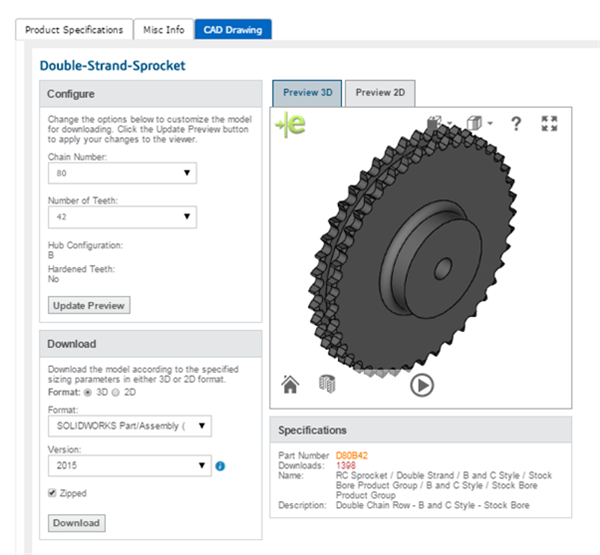

We want it to be easy for you as a customer to use our products, in all perspectives. Therefore, we have made sure that selected parts of our range are available as CAD models, which you can easily download in the format you want and integrate into your design.

Die CAD-Dateien (Computer-Aided Design) und alle zugehörigen Inhalte, die auf dieser Website veröffentlicht wurden, wurden von Dritten erstellt und hochgeladen, werden von diesen verwaltet und sind deren Eigentum. Alle CAD-Dateien und sämtliche zugehörigen Texte, Bilder und Daten sind in keiner Weise gesponsort von oder verbunden mit Unternehmen, Organisationen oder realen Objekten, Produkten oder Waren, die sie vorgeblich nachbilden.

3D CAD browser is the online 3D models exchange systems now offered by the LAPP. With this tool, the design is not only made much easier, but even the selection of the correct components is simplified.

Custom manufacturer of stainless steel wire for the automotive, medical, orthodontics, jewelry, oil and gas, temperature control, electronics, spring making, aerospace and fishing industries. Cables, guidewires, thermocouples, retainer wire and safety lock wires are also available.

Manufacturer and distributor of wire rope cable assemblies. Coated, aircraft, independent or fiber core, bridge, rotation resistant, compacted or swaged, cable laid, strand and galvanized cables are also offered. Serves the transportation, mining, railroad, construction, architectural, fitness, automotive, marine, OEM, military, display, signage, lighting, security and recreation industries.

Custom manufacturer of cable assemblies for the automotive, medical, electrical, electronics, power generation and computer and electronics industries. Capabilities include wire harnesses, automotive parts, consumer electronics, customized cables, home appliance, medical device, miniature, stainless steel wire rope, power controls and signals. Additional services such as reverse engineering, CAD/CAM design, drafting, label printing, quality inspection, kitting, 3D printing, scanning and prototype design provided. Low to high volume production offered. Blanket orders accepted. RoHS and REACH compliant. UL listed.

Custom manufacturer of cable assemblies made from alloy steel, stainless steel, aluminum, brass, nylon and PVC materials. Stainless or galvanized, nylon and PVC jacketed, miniature diameter, rotation resistant, tin over zinc, stranded and aircraft cables are available. Serves the aerospace, defense, medical, marine, electronics, power generation and transportation industries. ITAR registered.

Manufacturer and distributor of standard and custom 304 or 316 stainless steel wire rope cable assemblies. Medium-to-high tensile strength cable has seven strands made up of nineteen wires in each strand. Stock items available.

ISO 13485 & AS 9100 certified manufacturer of standard & custom cable assemblies including stainless steel wire rope cable assemblies. Capabilities include automated electro-cutting & shearing, swaging, coiling, welding, engraving, passivation & ultrasonic cleaning, packaging, bar-coding & labeling. Wire rope cable assemblies are used in applications including aircraft, aerospace, truck/automotive, medical & lift. Services include design engineering, machining, testing, assembling & inventory management. JIT delivery available.

Manufacturer of standard and custom wire rope assemblies for the agricultural, automotive, construction, lighting, marine, medical, military, railroad and security industries. Dia. ranges up to 1/2 in. Capabilities include CNC machining, cutting, hydroforming, swaging and zinc die casting. ASTM tensile testing services are also provided. Most items available in stock.

Distributor of stainless steel products including beakers, bumpers, castings, hinges, mirrors, mouldings, washers, sinks and cable assemblies. Products such as flats, angles, channels, bar stock, rounds, squares, hexes, tubing, expanded metal, shafts & grating are also available. Capabilities include saw cutting, shearing, deburring & cutting-to-length.

Manufacturer and designer of standard and custom wire rope cable assemblies. Various configurations, cable constructions, materials and cable coatings are available, including steel and stainless steel material with coatings including PVC, nylon, PTFE, and more. Industries served include transportation, material handling, military and defense, aerospace, automation and medical. ISO 9001 Certified.

Manufacturer of standard and custom stainless steel wire rope cable assemblies including lanyards. Available with 6 in. to 12 in. length with 0.047 in. wire dia. Features include coiled wire, stop balls, hooks and yokes. Capabilities include CNC Swiss machining, light assembly and molding. Secondary services include drilling, tapping, shaving, pointing, bagging, pad printing, hot stamping, private labeling and retail packaging. Stock items and 24 hour services available.

Custom manufacturer of stainless steel wire rope cable assemblies. Stainless steel wire rope cable assemblies include bronze bushings, aluminum sleeves, threaded studs & plugs, molded & stamped eyes, nylon balls, thimbles & ball shanks.

Lean manufacturing capable custom manufacturer of molded cable assemblies including stainless steel wire rope cable assemblies. Types include coaxial wire, discrete wire, flat ribbon, power cord, patch cord and GPT/UL/PTFE cable assemblies. Types of coaxial cable assemblies such as semi-rigid, conformable, R.F., video cable assemblies are available. Capabilities including butt splicing, hot stamp marking, automatic and manual cutting, CAD designing, in-house tooling and E.D.M tooling. Products are UL listed. JIT delivery and Kanban services available.

Custom manufacturer of cable adapters. Types include DB25, DB15, DB9, RJ45, RJ12, RJ11 and centronic adapters. Various industries served include government, electronics, construction, education, manufacturing, medical, OEM, wireless, military, transportation and retail. RoHS compliant.

Distributor of wire rope products and assemblies. Product include cables, rope, fittings, reels, and assembly hardware. Serves the architectural, drilling, elevator, marine rigging, mining, agriculture, railroad, and oil and gas industries, as well as crane, winching, rigging, and general engineering applications.

Manufacturer of standard & custom application wire rope assemblies including stainless steel wire rope cable assemblies. Up to 3 in. diameter including bright ropes, galvanized, stainless, nylon or plastic coated. Standard special high strength alloy & stainless terminations from .062 in. to 3.5 in. From inventory or manufactured in-house on CNC equipment. For OEMs in mining, trucking, marine, construction, farm, crane & hoist, aircraft, guard rail, cable railings, conveyor & industrial markets.

Custom manufacturer & distributor of wire rope cable & cable assemblies made from stainless steel. Specifications of wire rope cables include 1/4 in. to 1/2 in. dia., 2.94 tons to 11.50 tons strength & 0.460 lbs. weight. Wire rope cable assemblies are available with internal lubrication & high carbon steel wire. Wire rope cable assemblies are suitable for general purpose applications.

ISO 9001:2008/HUBZone certified custom manufacturer of wire rope cable assemblies made from stainless steel. Other products include control panels, power & battery cables, wire harnesses & subassemblies. Various applications include telecommunication & network infrastructure, transportation, recreational vehicles, motion & control manufacturing, heating/cooling (HVAC), electronics, energy & healthcare & medical, food service & pharmaceutical automation equipment. Kan Ban/JIT manufacturing. CSA approved. RoHS compliant. UL listed.

Custom fabricator & stocking distributor of wire rope cable assemblies made from stainless steel. Cable assemblies are available with turnbuckles, hooks, swivels, snap hooks, stake eyes, clevises, ball shanks, threaded studs, sleeves & stops, thimbles, loops, custom & ball fittings, links, wire rope clips & shackles. Cables assemblies are suitable for aerospace, petrochemical, building & construction, mining, recreational goods, automotive, consumer goods & marine industries.

ISO/TS 16949 registered manufacturer of stainless steel wire rope cable assemblies including control & O.E.M. mechanical cable assemblies up to 3/8 in. dia., miniature cable assemblies, remote actuation systems with a wide range of actuators, operators & custom cable controls, light & medium duty standard & custom push-pull/pull-pull controls. Complete design, tooling, molding & testing services available.

Distributor of stainless steel angles, bars, balls, bearings, cables, carts, circles, discs, doors, extrusions, forgings, grilles, mesh, pipe, tubes, shapes, tanks, tubing, turnbuckles, valves, walkways, & wire

Manufacturer & distributor of cable assemblies including stainless steel wire rope available in 1/4 in. to 2 in. dia. Types include galvanized mooring lines & fiber core & aircraft cables. Cable assemblies are suitable for rigging & marine applications.

Distributor of industrial rigging hardware & supplies including wire rope cable assemblies & stainless steel wire rope cable assemblies. Architectural railings & sail boat life lines & standing rigging.

Manufacturer of stainless steel wire rope assemblies & galvanized wire rope cable assemblies 1/8 in. to 1 in. Stainless steel tie rods 1/4 in. to 1.5 in. Wire rope cable assembly terminations.

Manufacturer & distributor of rigging equipment & supplies including domestic & imported wire rope, blocks, tackle, cable, sleeves, wire rope slings, rigging & logging hardware, chain & wire rope slings in stainless & galvanized steel.

Brewer Titchener, Bridon-American, CM, CM, Continental Western, Crosby, Esco, Johnson, Laclede, Letellier, MSI, MacWhyte, Miller, Morse Starrett, Muncy, Newco, Ropemaster Skookum, Samson, Thern, Ulven, WRCA, Weissenfels, Wolf

Jakob Rope SystemsJakob Rope Systems is one of the market leaders in the manufacture and supply of top-end, design-forward solutions to industrial and construction-related rope and cable applications in which elegance, simplicity and superlative quality are required.

Now, for more than a century and in over 55 countries, Jakob offers a range of steel rope products to our clients who return time and again seeking a reliable maker and provider of stainless steel wire ropes, rod fasteners, nets and unique fittings, all custom-designed and produced to fit exact specifications. At Jakob, we understand it’s the little details that make the big differences.

Every piece of finished goods leaving our warehouses is put through a stringent testing process to ensure compliance with AISI 316, ISO and DIN standards. Our cable railing, wire mesh, wire ropes, and rods can be used in multiple applications, both indoor and outdoor and at various scales, such as sign stanchions, shelving, as trellises on green walls, safety netting, and even in zoo enclosures.

Jakob and our USA -based team can provide cables and wire netting solutions for any commercial and business application. We take pride in offering custom-made designs to fit our clients’ needs.

We offer hundreds of thousands of CAD models to support your design and product needs. We offer 3-D and 2-D models in file formats compatible with most CAD applications.

Free CAD and BIM blocks library - content for AutoCAD, AutoCAD LT, Revit, Inventor, Fusion 360 and other 2D and 3D CAD applications by Autodesk. CAD blocks and files can be downloaded in the formats popular blocks and top brands.

CAD blocks: libraries dwg blocks bloques blocos blocchi blocco blocs bl�cke family families symbols details parts models modellen geometry elements entourage cell cells drawing bibliotheque theme category collections content kostenlos insert scale landscaping

Nous appr�cions tous vos commentaires et suggestions sur la fonctionnalit� du catalogue CAO, sur l"arborescence des cat�gories, etc ainsi que sur les bogues �ventuellement rencontr�s. Merci de transmettre vos remarques a webmaster@cadstudio.cz.

See the add-on application Block Catalog for AutoCAD 2013 and higher and the add-on application BIM-Families (now in Revit Tools) for Revit 2015 and higher.

CAD blocks can be downloaded and used for your own personal or company design use only. Any distribution of the Catalog content (to other catalogs, web download, CD/DVD media, etc.) is prohibited - see Terms of use.

8613371530291

8613371530291