steel wire rope for cranes brands

The cable on a crane moves through a series of motorized pulleys that are controlled by the crane operator to raise and lower items. For safety reasons, a crane usually has several wire rope cables that are attached to the object being lifted. This helps to prevent putting too much strain on a single cable.

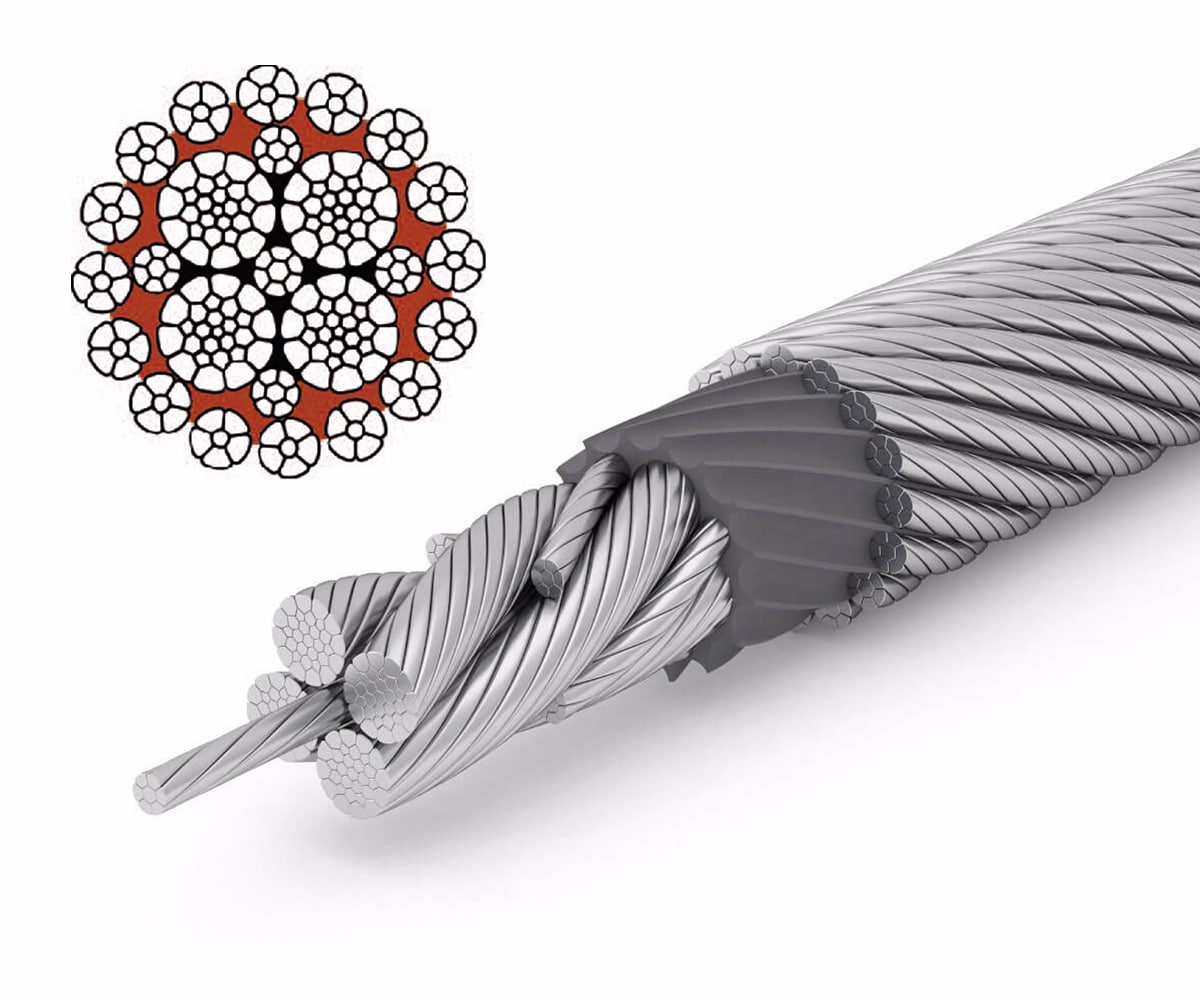

To create wire rope cable, manufacturers begin with long strips of high tensile strength metal that are tightly woven together into strands. A large majority of wire rope cables are constructed using steel due to its durability and strength. Several strands are then spun and pressed tightly together into a helix using a machine.

The newly created wire rope cable is then rolled up onto a spool and shipped out, or it is rolled up onto a pulley to be used with a brand new piece of heavy equipment.

Stationary ropes bear tensile forces and are loaded with fluctuating levels of stress. These are the types of cables that would be found on a suspension bridge.

Finally, wire rope slings (also called stranded ropes) are used to harness all kinds of goods. These are bent over sharp edges of goods to hold them in place.

We have been dealers of steel wire rope products since 1969 and we have built up a large network of suppliers around the world, so whether you need galvanized 1×19, 7×7, 6×19, 7×19, 6×36, 8×19 , 8×36, 19×7, 35×7 steel wire rope or stainless steel wire rope in the 1×19, 7×7, 7×19, 6×36 - or a special construction - then we are always ready to help.

Steel wire rope from WDI - WDI Ropes is part of the German group Westfälische Drahtindustrie GmbH, whose history dates back to the founding of the first factory in 1856. Since 1890, the company has been known under its current name: WDI. The group produces steel wire rope for many applications, for example steel wire rope for industry and building constructions, etc. We supply the, for us, most interesting part of the program - their program of steel wire rope for eg. industry, construction cranes, maritime cranes and the offshore sectors. These steel wire ropes are known under the brandname PYTHON and you will with garanty find them among our selection here on the page. If we draw parallels to the automotive industry, you can compare PYTHON steel wire rope with brands such as Audi, BMW and Mercedes.

Steel wire rope from CASAR - The company CASAR Drahtseilwerk Saar was founded in 1948. CASAR is the abbreviation for the French outline "Câbleie Sarroise". The company develops or produces special steel wire ropes for cranes and other lifting equipment - steel wire rope produced by CASAR are often preferred by many mobile crane manufacturers as well as other manufacturers of different types of cranes.

Although the type of steel wire rope you choose to buy may not be from one of the well-known brands - our purchasing department ensures that you still get the best possible quality for the price. Steel wire rope purchased from us, is one of the basic elements of a safe lifting operation.

In addition to the sale of steel wire rope, we have over 25 driving services units that can carry out inspection of steel wire rope. In addition, we have workshops in Aalborg, Esbjerg, Odense and Copenhagen - where we can make repairs, carry out casting of sockets or make special solutions in steel wire rope.

Bridon-Bekaert steel wire rope specialists for many years have worked globally together with the major crane manufacturers (OEM) to develop a range of cost-effective ropes for the demanding environments in which today"s construction cranes operate. Our specialists are available to assist users in obtaining maximum performance and reliability from a wide range of globally available Bridon-Bekaert crane ropes.

Numerous industries require lifting equipment to facilitate their operations. Out of those hundreds of sectors, the construction industry is the one whose operations rely the most on a diverse range of rigging solutions that have to be able to hoist light to heavy loads. All lifting operations, especially the heaviest ones, must be done with dependable and safe wire ropes. At Kennedy Wire Rope & Sling, we source our wire rope from manufacturers whose products meet, or exceed, industry standards. Our mission is to provide clients with a product that is nothing less than exceptional.

Wire rope is the best product for doing the heavy lifting for crane operations. Wire rope is made from multiple steel wires that are put together around a core. Steel wire offers strength, flexibility, the ability to handle stress, and works well for bearing heavy loads, which is the whole purpose of crane operations. Wire rope is also extremely resistant to corrosion, rotation, fatigue, crushing, and abrasion. Kennedy Wire Rope & Sling Company offers many different types of wire rope for your crane needs. Many industries, such as the construction, manufacturing, and oil and gas industry, rely on our crane products to meet their needs.

Flex-X 9: Features compacted strands and swaging for increased stability and extra drum crushing resistance. It’s designed for boom hoist applications and tubing line applications where drum crushing is a challenge.

19×19 Compacted: A very flexible rope with excellent resistance to rotation and high tensile strength. Best for use with choker ropes, trolley lines, winch lines, hoist ropes and boom lines. Applications include cranes, excavating, dredging, marine, oil and logging.

35×7 Class: Features a high strength-to-diameter ratio. Its unique design minimizes rotation and torque of the rope at normal load ranges of 0 to 20% of the rope’s minimum breaking force. Excellent when load control is vital.

8 x 19 Class: Is resistant to crush and built within ISO 9001 specifications. It has one of the most stringent testing processes of any rope. From creation to deployment, industry experts know what this rope can take.

Let our experienced on-site services team help you with your next wire rope slings installation, inspection, and maintenance procedure. This will ensure that you will get the most out of your equipment, with minimal downtime.

At Kennedy Wire Rope, our teams are dedicated to being and remaining the industry’s leading supplier of hardware used in rigging, construction, and oil and gas operations. We also have the licenses and insurances that our customers’ depend on. Call us today at 800-289-1445 and speak with a friendly representative. We welcome any questions concerning any of our products and rigging services.

Steel Wire rope is a very complex machinery element which primary function is the transmission of tensile forces. Its basic constructional design allows repeated changes in the direction of pull through reeving systems incorporating drums and sheaves. General purpose wire ropeshave been developed and standardized in national and international standards . However the increasing demand for higher breaking strength, greater flexibility, better rotation resistance , and extended rope life cannot be met by such general purpose steel wire ropeconstructions. Horizon Cable is a stocking distributor for Python Wire Rope, which through research, development and engineering over many years has developed rope constructions that have significantly improved operating life. There are vast array of applications that Python Wire Rope can be installed by Horizon Cable Service in Oklahoma, Texas, Wyoming, Kansas, North Dakota and New Mexico to improve service life. Below are a few of the proven applications for our high performance wire ropes:

One benefit to High Performance Wire Rope is the increased breaking strength over standard wire ropes. This is achieved in the manufacturing process by compaction processes. Standard ropes are drawn which create a round outer circumference, but compacted ropes have flat outer service. The two types of compaction are STRAND COMPACTION and SWAGE COMPACTION. Strand compaction is the most popular, in this process the compaction is applied to the individual wires, where the swage compaction is applied to the entire wire rope itself. Both have their advantages for particular applications.

Rotation resistant ropes can fall under three different classes Spin Resistant, Rotation Resistant, and Non Rotating. In all of these types of wire ropes the outer layer is twisted opposite for the inner layers. Rotation resistant and spin resistant ropes will have one inner layer, while non-rotating lines will have multiple inner strands rotating a different direction from the outers.

6 strand high strength swage compacted rope that is perfect for applications that require a crush resistant rope to be used in multi-layer winding systems; e.g. boom hoist on lattice boom mobile and tower cranes

Python Compac 18 is recommended for bot multipart load and single part applications where medium rotational stability is needed. Use as main and auxiliary hoist line on Grove, link belt, Manitowoc, Terex and other us made mobile and truck cranes. Also used very successfully as a pulling rope on underground cable pulling winches.

Main and auxiliary hoist line for European type mobile and for all types of construction tower cranes which require a high strength rotation resistant rope construction. Excellent rotation resistant properties make this rope the preferred choice for all single and multiple line reeving systems.

Years of continuously setting incredible standards in the manufacturing of rotation resistant and non-rotation crane ropes in various construction and engineering sectors has given SWR & Teufelberger a real cutting edge when providing customers with solutions to their steel wire rope requirements.

With over 130 years’ experience in the manufacturing of steel wire ropes Teufelberger strive to continuously maintain and improve quality by using only the highest quality of raw materials, professional quality inspections and modern state of the art manufacturing facilities when producing their SUPERFILL® and PLASTFILL® multi-strand steel wire ropes.

Each single strand of wire that is used in the manufacturing process of Teufelbergers ropes is used with purpose. From the core out to the exterior of all wire ropes they are designed with sophisticated engineering by professional bodies to provide innovative and tailor-made solutions.

Offering worldwide availability for both parts and wire rope along with the latest SUPERFILL® and PLASTFILL® rope technologies Teufelberger guarantee the highest of safety for your daily operations along with extremely high breaking forces and high resistance to challenging conditions.

All materials are fully certified and have full traceability in line with our ISO9001 procedures. All ropes are manufactured to the European standard EN 10204 3.1/LR

Years of continuously setting incredible standards in the manufacturing of rotation resistant and non-rotation crane ropes in various construction and engineering sectors has given SWR & Teufelberger a real cutting edge when providing customers with solutions to their steel wire rope requirements.

With over 130 years’ experience in the manufacturing of steel wire ropes Teufelberger strive to continuously maintain and improve quality by using only the highest quality of raw materials, professional quality inspections and modern state of the art manufacturing facilities when producing their SUPERFILL® and PLASTFILL® multi-strand steel wire ropes.

Each single strand of wire that is used in the manufacturing process of Teufelbergers ropes is used with purpose. From the core out to the exterior of all wire ropes they are designed with sophisticated engineering by professional bodies to provide innovative and tailor-made solutions.

Offering worldwide availability for both parts and wire rope along with the latest SUPERFILL® and PLASTFILL® rope technologies Teufelberger guarantee the highest of safety for your daily operations along with extremely high breaking forces and high resistance to challenging conditions.

All materials are fully certified and have full traceability in line with our ISO9001 procedures. All ropes are manufactured to the European standard EN 10204 3.1/LR

Fulfilling the technical parameters when producing a high performance steel wire rope is only the first step on the road to success. Our knowledge about the professional use of a steel wire rope on site collected over many years is the key to the economic efficiency of a port crane. Crane wire-ropes from Teufelberger-Redaelli, provide a substantially reduction of overall expenses because we know what’s important: safety and a long service life due to flexibility, , high bending fatigue resistance, perfect spooling characteristics, constant quality and reliability. .

The Teufelberger-Redaellirope experts provide competent advise and in case of any question we are always available for you via a network of competent field engineers and a 24-hour hotline. We make sure that your downtimes and total costs of ownership are kept at a minimum.

Designing a high performance steel-wire rope requires detailed technological and production-related know-how. The PLASTFILL® technology developed by Teufelberger-Redaelli consists of covering the lubricated steel-core in a compact synthetic coating. The SUPERFILL® compaction technology uses a special process to compact the individual strands of the steel wire-rope. Galvanized wires and special lubrication provide additional protection against corrosion. The high quality of the individual wires used is the result of long standing cooperation with our suppliers. We rely on the best only.

Teufelberger-Redaelli offers a wide range of rotation resistant and non-rotation resistant high performance steel-wire ropes for port cranes excelling equally as boom hoist rope, hoist rope, trolley rope, or dragline. The various applications include mobile harbor cranes, container cranes, pontoon cranes, ship unloader and shiplifter.

The global success of Usha Martin’s crane rope is based on an uncompromising commitment to quality. Our wire rope for cranes are designed to provide longer life, less downtime, and superior resistance to bending fatigue for lifting applications under adverse working conditions. The company’s quality management system is certified per standard ISO 9001: 2015, along with manufacturing assessment certifications from ABS, DNV-GL, and Lloyds. Crane ropes supplied by Usha Martin and its group companies are supported by an extensive global network, offering expert advice to both crane manufacturers and end users.

With six decades of excellence in manufacturing specialty steel wire ropes for cranes, we have developed next-generation crane ropes for different applications to meet the specific needs of customers. These cover all types of wire rope for cranes, including specially designed compacted ropes with plastic-impregnated cores and rotation-resistant ropes. All steel wire ropes undergo stringent quality testing procedures. We offer a wide variety of hoist ropes to suit the needs of different industrial applications.

verope® AG is a Joint Venture company between Pierre Verreet, head and founder of verope®, and Kiswire Ltd. from South Korea. By using the extraordinary expertise of verope® in the special wire rope market and the long experience of Kiswire Ltd. in efficient production, verope® is a partner you can rely on.

We strive to create premium products in a class all their own, but we believe our global impact is so much bigger than that. Press play to learn what makes WireCo a world ahead of other companies.

Crane wire ropes play an important role in ensuring a smooth conduct of work processes in harbors, off-shore platforms or various other applications where cranes are needed. Whether you need tower crane ropes or offshore crane ropes, galvanized or stainless steel ropes, you will find the optimal solution in our company.

When you are picking up crane wire ropes, make sure that the breaking strength of new wire ropes is five times the sizes of the largest load for lifting applications and three times for pulling applications.

The following guidelines are principally directed towards crane operators who need to periodically replace steel wire ropes and to crane designers who are required to specify ropes for new build projects.

When replacing a steel wire rope on any crane or appliance reference should be made to the relevant original equipment manufacturers manual, the wire rope manufacturers test certificate originally supplied with the crane or appliance and to any other relevant documentation.

In order to ensure safe and efficient operation, Brunton Shaw UK recommends that any replacement wire rope should conform with the specified nominal diameter and at least equal the required strength originally specified by the manufacturer of the machine or appliance.

Additionally, the wire rope construction selected should provide an equal or greater resistance to rotation, bend fatigue, crushing, abrasive wear, and corrosion.

Looking for wire rope? Trinity Sling has been known as the go-to supplier for overhead lifting supplies and rigging for decades. Since its inception, Trinity has produced rigging and lifting solutions for many different industries, like construction, manufacturing, oilfield and fracing, transportation, and architectural railing. Today, the company continues to expand its reach, supplying across North America while calling North Texas home.

Trinity Sling distributes the highest quality wire rope both from domestic and European manufacturers. Trinity’s domestic supplier, Washington Wire Rope, manufactures general purpose and oilfield ropes in the USA to industry standards. Among their products that Trinity carries are crane ropes, drill lines, sand lines and tubing lines for construction and oilfield applications. Trinity also carries Verope-branded crane ropes, European-engineered specialty ropes for all types of cranes used in construction and manufacturing.

Trinity Sling has built strong vendor relationships with Washington Wire Rope and Verope in order to be a great supplier both to our new and existing customers. Our staff understands deadlines and RFQs and works diligently to partner with our customers to provide products of high quality that they can count on.

Wire rope is a complex mechanical device that has many moving parts all working in tandem to help support and move an object or load. Wire ropes are attached to a crane or hoist and are fitted with swivels, shackles or hooks. These are suitable for lifting or lowering elevators and are also used for supporting suspension bridges or towers.

In this article, we"ll cover details on the top U.S. providers of wire ropes, along with our featured list of top wire rope suppliers on Thomasnet.com.

Below is a list of featured suppliers of wire rope from our platform. Included with these companies is their location, year established and the number of employees.

Below we have assembled information on the top suppliers of wire rope in the U.S. based on currently available public sales data. The table also includes the company name, location and the number of employees.

With the help of the provided details on the wire rope suppliers in the United States in the above tables and descriptions, we hope you can use this data to further aid your sourcing decisions.

ISO 9001 & AS 9120 certified 8(m)WOSB certified custom manufacturer of corrossion resistant galvanized aircraft stainless steel metal safety cable and wire braid materials include braided cords with wire center for aeronautical, aerospace, halyard, helicopter lead line, sailboat, rigging, hoisting, automotive applications and more. Wire rope products are available in 1x7 strand through 6x36 strand for aircraft cable, non rotating and non flexible applications. Custom coatings and finishes available for aerospace, automotive, safety applications. Also offers custom braids in specialty colors, finishes, and materials such as aramid, ceramic, Dyneema®, fiberglass, Kevlar®, linen, Nomex®, plasma, Spectra®, tarred, marlin, Technora™, Twaron®, and Vectran™. Galvanized aircraft wire ropes and cables available in 302/304, 305, and 316 stainless steel and zinc-coated carbon steel materials. Offers non-flexible types in 1 x 7 and 1 x 19 strand models. Suitable for aeronautical, logging, hoisting, aircraft control, and winching applications.

In this Crane Rope Products brochure, you’ll find valuable product information and specifications to help you choose the right rope for your application.

Twisted hoist lines can bring a construction project to a sudden halt, resulting in downtime. But the good news is that you can minimize block rotation through proper installation, handling and corrective measures. In this reference document, you will better understand torque and gain tips on how to reduce block rotation.

No single rope can do it all. In this reference document, you will learn how the characteristics of specific ropes should greatly influence your rope choice including: strength, fatigue resistance, crushing resistance, resistance to metal loss and deformation, and resistance to rotation.

In this Product Bulletin, you will learn about the various causes of crushing, the effects of crushing and how to properly evaluate the crushing. Additionally, observations about drum crushing from WireCo WorldGroup engineers are included.

In this product bulletin, you will learn why Category 1 Ropes are special wire ropes that must be handled differently than other wire ropes. Understand why WireCo WorldGroup recommends not removing the welded ends. And, learn the proper step-by-step recommended procedure for cutting and preparing Category 1 Ropes.

In this product bulletin, you will learn WireCo WorldGroup’s preferred technique for installing a hoist rope onto a crane. Learn tips on relieving twist during installation.

In this reference document, you will learn WireCo WorldGroup’s preferred technique for installing rope onto a crane. Additionally, you will learn tips on breaking in your new wire rope, relieving twist, rigging in tight quarters, and cleaning and lubricating ropes.

Despite their durability and strength, wire ropes used on cranes will wear out and need to be retired from service. This reference document will better explain why regular inspection is so crucial to your long-term success.

Learn how to properly install wire rope on mobile cranes. Two factors are key to proper installation no matter what type of equipment, or which wire rope is being used: making sure the rope is free of twist and assuring that the rope is tightly spooled on the drum.

When a load is placed on a rope, torques are created within the rope as wires and strands try to straighten out. Ropes are designed to operate with these load-created torques within them. In this product bulletin, learn four methods of making a lift that is within the capacity of a single-part line. And finally, you will understand the removal criteria of rotation resistant rope.

Using an active, in-line, anti-friction swivel with the majority of types and classes of wire ropes is detrimental to their service life and can lead to unpredictable conditions during operation. This product bulletin provides the basic reasoning behind why swivels aren"t recommended for use with wire ropes except for those that exhibit a similar torque characteristic to that of a category 1 rotation-resistant rope.

XLT4 is designed to be used with a design factor as low as 3.5 on mobile cranes. In this product bulletin, you will learn more about the ASME B30.5 design factor requirements.

XLT4 was designed and engineered to be compatible with a full complement of end terminations including wire rope clips, wedges and swaged crane buttons. In this product bulletin, learn how Union’s 4-strand crane rope delivers more strength than premium 6-strand, and equal or greater stability under load than Category 1 35x7 style rotation-resistance ropes.

XLT4 is truly the four strand mobile crane hoist rope that is unequaled. After reading this product bulletin, you will understand why. You will learn how XLT4 was designed specifically to meet the special wire rope requirements of mobile crane operations and how XLT4 offers a unique combination of characteristics.

More area equals less wear. In this product bulletin, learn why this is important for our XLT4 rope product. After reading this product bulletin, you will understand why XLT4 Crane Rope provides a greater rope footprint when in contact with drums and sheaves and what this means for your application performance. Additionally, you will learn why XLT4 offers less scrubbing and abrasion and why this reduces contact pressure on ropes.

Our company is well known in the market for the export of a superior range of Platform Steel Wire Ropes which are high on demand all over the globe and these products have been supplied and manufactured using a superior range of raw materials which have been priced at very reasonable rates in the market. These products are made using the latest technology available in the market and they are very durable in their performance. These products can be got customized by the clients as per their specifications.

Certex offers a full solution for lifting products and services. Certex provides steel wire rope, lifting equipment and services to customers in the industrial, oil & gas, renewable and elevator markets.Certex has a notable reputation for providing innovative solutions to lifting problems and has a proven record of saving our customers money through product selection and tailored written schemes of examination. Further we can provide our customers application know how through accredited training, statutory examination and maintenance services.

8613371530291

8613371530291