steel wire rope lubrication oil in stock

Prolongs the life of wire rope, sheaves, pulleys, drums, guides, pins and rollers in a variety of applications, including cranes, hoists, marine tow and mooring lines, dockside cables, aerial tramways, dredges, draglines, mining, elevators and many other applications in construction, mining, transportation and manufacturing.

Distributor of wire rope and cable lubricants. Lubricants come in multiple forms and are frequently used to reduce friction, prevent thread locking and provide chemical resistance.

Manufacturer of heavy duty lubricants for chain, wire rope and cable applications. Available in 16 oz. capacity and 900 degrees F operating temperature. Protects from corrosion and rust. Provides non-gumming protective film. Serves the marine, heavy equipment repair, mining, power generation, wastewater treatment and chemical industries.

Distributor of wire and cable drawing and pulling lubricants. Value added services include assembly, barcoding, bin stocking, bonded inventory, consignment inventor, consolidated billing, dock-to-stock, drop ship, EDI, electronic funds, JIT, Kanban, kitting, long term pricing, one-stop, quality control, rebates, schedule sharing, vendor inventory, and more.

Manufacturer of wire rope & cable lubricants. Products include coating grease, penetrating lubricants, coating lubricants & synthetic coating lubricants. Services include equipment reliability assessment, oil analysis, lubricant storage, handling & transfer, contamination exclusion, contamination removal, education & training & design, implementation & support.

Almagard, Almaplex, Almasol, Almatek, DEXRON, Duolec, Earthwise, Futura, Low Tox, Lubrication Engineers, Monolec, Monolex, Multilec, PERMA, Pyroshield, Quinplex, Synolec, Synpag, Syntemp

Manufacturer of non-staining and slow-drying foam and synthetic wax wire/cable pulling lubricants. Available in aerosol cans, squeeze bottles and buckets. Working temperature ranges from 20 to 122 degrees F. Suitable for electrical and utility applications. Meets ANSI, ASTM and OSHA standards. CSA approved. cUL listed. Made in the USA.

Manufacturer and distributor of multi-purpose and heavy duty aerosol grease chain/cable lubricants. Available in 16 oz. capacity. Contains molybdenum disulfide. Suitable for chain saw, hinge, hoist, conveyor, wire rope and cable, roller chain and sprocket applications. Meets NFPA standards.

Manufacturer of lubricants including oils and grease for oven, conveyor chains, wire ropes and cables applications. Features include biodegradability, temperature and mechanical stability, non-toxic, resistance to rust or corrosion. Extremely high temperature working grease is also offered. Packaged in pails, drums, cans and tote. Serves the construction, agriculture, energy, government, rail, mining, oil and gas industries. NSF H1 Certified. USDA, FM and FDA approved.

Manufacturer and distributor of wire pulling cable lubricants for industrial applications. Available in pails, bottles and drums with an operating temperature from 30 degrees F to 120 degrees F and 6 pH to 8 pH solution. Various features include cling characteristics, translucent, non-staining, non-toxic and non-corrosive. Lubricant gels are suitable for reducing friction. Meets ASTM-D1693 and IEEE-1210-1996 standards. UL listed. On-time delivery.

ISO 9001:2000 certified woman-owned manufacturer of standard & custom wire drawing, wire pulling, wire rope, cable & chain lubricants including molybdenum disulfide aerosol lubricants. Features include anti-friction & anti-wear properties. Aerosol lubricants range in operating temperatures from -300 degrees F to plus 750 degrees F with molybdenum disulfide concentration of 5 percent . Made in the USA.

Distributor of cable and wire rope lubricants. Features include semi-synthetic and polymer base formulations and high temperature stabilities. Suitable for use with wire or cable insulated with rubber, neoprene, nylon and PVC plastics , hypalon, high density polyethylene and cross linked polyethylene (XLP). Serves the chemical, civil, food, mining, oil, gas, power generation, paper, OEM and wastewater industries.

Manufacturer of wire rope and cable lubricants. Contains organic molybdenum and anti-wear additives. Resistant to corrosion, water wash-off, high-temperature sling off and friction. Used in meat and poultry plants. Can withstand temperatures up to 350 degrees F. Offered in 16 oz. aerosol containers and 5 gal. and 55 gal. drums. Markets served include food and beverage, marine, oil and gas, automotive, utility, commercial and institutional. On-time delivery available.

Distributor of lubricants for industrial and commercial applications. Products include greases, engine and compressor oils, transmission fluids, fuels, oil additives, hand and industrial cleaners. Types of lubricants include wire rope/chain, cable, gear, food-grade and industrial spray. Other services such as diagnostic, preventive maintenance, monitoring, testing and evaluation. Serves the heavy construction, mining, manufacturing, marine, transportation, agri-business, concrete, sand and gravel industries.

ISO 9001:2000 certified manufacturer & distributor of lubricant products including chain, wire rope & cable lubricants. Services include analysis & consultation, operation & plant surveys & fuel & oil analysis.

Multi-Purpose Lubricator & Penetrating Oil Made From Refined Non-Solvent Petroleum For Lubricating, Penetrating, Protecting, Cleaning, Dressing, Machining

Manufacturer of a complete line of specialty lubricants, anti-seize, and dry film lubricants available in aerosol & bulk. Lubricant applications used for cable, chain, extreme pressure, friction & wear, high pressure, high temperature, industrial process, low temperature, rope, water repellent, and belting. Contract packaging & custom formulations.

Manufacturer of lubricants for the industrial manufacturing and plastics industries. Available lubricant types include oils, greases, and fluids. Other products include wax, fuels, chemicals, and motor oils. Serves industries such as aviation, commercial vehicle, marine, and automotive.

Private-label & contract packaging manufacturer of custom wire, wire rope & cable pulling lubricants. Types of lubricants include vegetable based lubricants, metal drawing lubricants, stamping lubricants, extrusion lubricants, mold release lubricants & conveyor lubricants. Other products such as degreasers, hand soaps, cleaners, coatings, detergents, automotive cleaning products, food service cleaning products & commercial laundry products are also available. Services include contract packaging & private labeling.

Molybdenum disulfide (moly) & graphite dry lubricants with rust & corrosion inhibitors for outdoor applications & as protective coating for wire rope & cable, crane booms & mine shaft cables.

Distributor of industrial lubricants for wire ropes, gears, and bearings. Available in 20 L pails and 205 L drums with aluminum, lithium, and PTFE thickener, non-melting, and rust and wear protection features. Suitable for high and low temperature and wet applications. Serves the power generation market.

Distributor of lubricants & cleaners for chains, wire ropes & cables. Specifications of lubricants include flash point of more than -17 degrees C temperature, 360 degrees C auto ignition temperature, 60.5 degrees C boiling point, 3.0 vapor density, 47 kPa vapor pressure, 0.74 & 0.76 specific gravity, viscosity more than 14 sq. mm/second & 45 percent VOC content.

Manufacturer of petroleum based lubricants including wire rope & cable lubricants in black color. Lubricants are available with flash point greater than 400 degrees F and 0.91 specific gravity. Custom formulations available.

Using the correct lubricant with the appropriate application method can not only maximise the wire rope life but can also eliminate costly replacements and improve safety.

The fluidity of the lubricants helps to ensure that the rope strands are well lubricated, reducing internal wear caused by the metal-to-metal contact occurring when the wires slide or bend around a drum or sheave.

The Wire Rope Lubricants and Grease range prevent corrosion by displacing moisture and forming a thin barrier of continuous lubricant film protecting against the elements.

Do your wire ropes, cables and draglines become rusted, corroded or frayed? You can protect your wire rope and cable from high stress loading, shock loading, jerking and heavy loads with LE"s full line of penetrating and coating wire rope lubricants. Whether you want lubricant to penetrate to the core or to coat and seal, LE has a full range of protective lubricant solutions, including wire rope lubricant applicators to reduce labor costs and ensure safe, reliable operation.

Although ship building involves some unique processes, component manufacturing is not dissimilar to other manufacturing industries. The difficulty in marine lubrication comes with maintenance procedures. In such a busy industry most ships don’t get much time to rest, and maintenance is done mid-voyage, with machinery operating.

New Extended Warranty: Documented use of LE452, LE453 Wirelife™ Almasol Wire Rope Lubricant or Earthwise™ EAL Wire Rope Lubricant will double the Viper warranty period to 24 months.

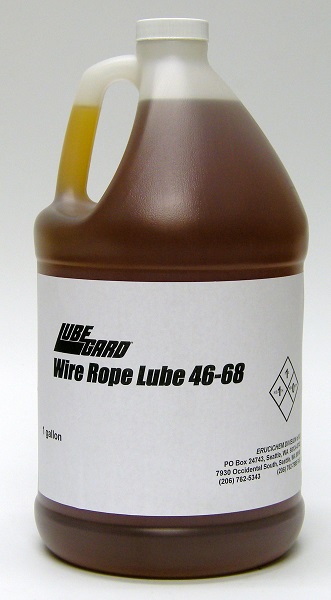

LUBEGARD Wire Rope Lubricants are patented, aquatically non-toxic & biodegradable. They contain a unique blend of corrosion inhibitors, thickeners and wear reducers. Both are ideal for all types of wire ropes and chains in a variety of services and environments.

There are two main methods of wire rope lubricant, oil and grease. Regular maintenance tasks should include lubricating your wire rope. Both oils and grease work in the essential task of lubricating wire rope. This is necessary for corrosion resistance and preventing damaging friction which causes excess “wear and tear”.

The product we recommend is this spray lubricant which can be used on wire rope as well as chains. Applying this wire rope lubricant on a regular basis will greatly extend the working life of your wire ropes. The lubricant penetrates deep into the wires for lasting lubrication. Corrosion protection comes from the thin film left on the rope’s surface. The brown foaming spray is resistant to fling off and highly resistant to washing off. This can be extremely beneficial if used outdoors or in damp environments.

If you need help in advice on how to use lubricant with wire rope then call us on 01384 78004. One of our experts will be able to advise and also take your order.

During the manufacturing process of wire rope many different chemicals are used. Purposefully for keeping the rope well lubricated and also corrosion inhibitors etc. Many wire ropes will have oil, wax, bitumen, resin, gelling agent, corrosion inhibitors and other chemicals present. It is for this reason that care must be taken. Whether handling or working with wire rope to minimize potential problems.

At normal temperatures most of these chemicals will produce minimal hazards. However working with heated rope can cause extra hazards. The minor hazards are usually skin irritations. But this can be easily minimised by wearing the correct protective clothing whilst handling the wire rope. In particular oil impermeable gloves and aprons; good hand washing after handling will also help.

When working with heated rope fumes given off from the heated lubricants can cause quite nasty problems. Heated lubricants which come into contact with the skin can cause severe skin burns. Prolonged or repeated usage may cause longer term skin disorders such as dermatitis.

Inhaling fumes from lubricants that have been subject to heat can cause dizziness, headaches or irritation of the respiratory tract. For these reason concentrations of oil mists, vapours and fumes must be kept as low as possible. Eye contact may also produce mild irritation to some users.

In conclusion the main area of hazard is through inhalation fumes generated by heat, e.g. where disc cutters are used. So always handle rope in a well ventilated area, especially when cutting, and always wear the correct protective clothing.

Phillips 66® Cable Lube is a heavy-duty lubricant developed for the lubrication and preservation of wire ropes and cables. It is formulated with a heavy residual base oil along with special rust and corrosion inhibitors and is cut back with a volatile, non-chlorinated solvent for ease of application without heating. Its low viscosity and special wetting properties permit penetration to the core of the wire rope or cable. The solvent then evaporates, leaving a tough, semi-fluid lubricant in the core and on each wire strand.

Developed as a service tool, the Lincoln Wire Rope Lubricator is attached periodically to equipment on a monthly, quarterly or other cycle to lubricate wire ropes. Lubrication intervals should be determined according to rope manufacturer specifications. The life cycle of a steel wire rope that has been periodically lubricated is approximately six to eight times longer than a wire rope that has not been lubricated. Specifically for Wire Rope Lubricator applications a biodegradable grease LGTE 2 is available. The grease is environmentally acceptable and certified with Ecolabel.

Also, lubricating a wire rope while in service helps to prevent corrosion of the wires. Corrosion can be internal and external, and it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive and industrial environments in general.

Wire ropes are integral components for many buildings, machines, and structures. This material is comprised of contiguous wire strands that are wrapped around a centralized core. It is important to lubricate wire ropes in order to limit friction and prevent corrosion.

There are two main types of wire rope lubricants: penetrating and coating. A penetrating lubricant contains a solvent that transports the lubricant into the core of the wire. Once on the core, it evaporates and leaves behind a heavy, lubricating film that is capable of protecting each strand. A coating lubricant penetrates the wire slightly, and protects the outside of the cable from moisture, wear, fretting and corrosion.

Both of these lubrications are used on wire ropes, but since most failures come from the inside of the wire rope, it is most important to thoroughly saturate the core with lubrication.

Most lubricators are a made up of a mixture between petroleum and other compounds. The petroleum provides excellent corrosion and water resistance, which helps to extend the life of the wire. In addition to petroleum lubricants, grease and vegetable oils are also uses to coat the wires. These mixtures penetrate the core and are easily applied. Most cables are lubricated before they are used, but it is important to re-lubricated wires habitually.

![]()

Castrol Molub-Alloy 902 SF Wire Rope Lubricant may be applied manually. However, application by automatic spray equipment is recommended. For best coverage and penetration, wire rope should be sprayed on all sides, which requires a minimum of two nozzles opposing each other.

Castrol Molub-Alloy 902 SF Wire Rope Lubricant is intended to provide safe operation through longer service life of wire ropes while reducing total lubrication and maintenance costs. The naturally flexible and adhesive film provides the required persistence to assure also protection of sheaves and drums without excessive application.

Whether you are working with manufacturing equipment, automotive equipment, or any other industrial equipment, you need products you can count on to reduce friction and wear. Kimball Midwest carries the right chain and rope lubricants for your operation. Our

JET-LUBE"s WLDis highly tenacious, adhesive lubricant containing both molybdenum disulfide (MoS2) and graphite, and is specially formulated for use on wire lines, cable and open roller chains. WLDpenetrates the outer strands of wire rope and cable, displacing moisture, and permeating to the core of the rope or cable, lubricating and protecting each strand.

As the low vapor pressure carrier solvent of WLDevaporates, a thin, flexible film of lubricant is formed. This barrier film prevents the incursion of moisture and dirt between the strands, and contains rust and corrosion inhibitors to prevent both abrasive and corrosive wear, significantly prolonging the life of cable and wire rope. The barrier film of WLDprotects against the formation of rust and prevents "rust binding", which reduces cable flexibility and life; increasing friction and wear. The barrier also offers protection against corrosion, preventing pitting of wire strands that can cause fatigue failure in the cable or rope. WLDalso performs effectively in the presence of high humidity or salt water.

WLDresists being thrown and dripping off the cable or rope even at the highest operating speeds. Because it is a "thin film" lubricant, constant replenishment of the lubricant is not required, thus reducing the cost of lubricant application.

WLDmay be used on crane and dragline hoist and draglines, elevator hoist lines, sprayed directly on sheaves, or winding drum faces, oilfield wire lines, offshore rig anchor cables, chain vises, corrosion barrier for iron surfaces, drilling lines, mast hoisting cables or any wire rope cable that operates at the extremes of operating speeds and loads in harsh environments.

WLDmay also be used on open roller drive chains in both oilfield and industrial applications; on motorcycle or snowmobile drive chains; conveyor drive chains or any open roller chain.

8613371530291

8613371530291