steel wire rope lubrication oil quotation

JET-LUBE"s WLDis highly tenacious, adhesive lubricant containing both molybdenum disulfide (MoS2) and graphite, and is specially formulated for use on wire lines, cable and open roller chains. WLDpenetrates the outer strands of wire rope and cable, displacing moisture, and permeating to the core of the rope or cable, lubricating and protecting each strand.

As the low vapor pressure carrier solvent of WLDevaporates, a thin, flexible film of lubricant is formed. This barrier film prevents the incursion of moisture and dirt between the strands, and contains rust and corrosion inhibitors to prevent both abrasive and corrosive wear, significantly prolonging the life of cable and wire rope. The barrier film of WLDprotects against the formation of rust and prevents "rust binding", which reduces cable flexibility and life; increasing friction and wear. The barrier also offers protection against corrosion, preventing pitting of wire strands that can cause fatigue failure in the cable or rope. WLDalso performs effectively in the presence of high humidity or salt water.

WLDresists being thrown and dripping off the cable or rope even at the highest operating speeds. Because it is a "thin film" lubricant, constant replenishment of the lubricant is not required, thus reducing the cost of lubricant application.

WLDmay be used on crane and dragline hoist and draglines, elevator hoist lines, sprayed directly on sheaves, or winding drum faces, oilfield wire lines, offshore rig anchor cables, chain vises, corrosion barrier for iron surfaces, drilling lines, mast hoisting cables or any wire rope cable that operates at the extremes of operating speeds and loads in harsh environments.

WLDmay also be used on open roller drive chains in both oilfield and industrial applications; on motorcycle or snowmobile drive chains; conveyor drive chains or any open roller chain.

With Alibaba.com, you can rest easy that you will be able to find the exact wholesale wire rope grease for the applications you have in mind. As one of the largest marketplaces for B2B shopping in the world, we have a huge network of wholesalers that have listed all sorts of lubricating jelly products and more.

For personal lube listings, we have a range of safe-to-use wire rope grease products. This includes pre seed lubricant options that are great for couples trying to conceive and mimics the body’s natural lubricants. For older women, we have options for menopause dryness. These vaginal moisturizers are designed specifically to prevent discomfort and add pleasure. For those with sensitive skin, we have specialist lube for sensitive skin products.

wire rope grease are also needed for home appliances and industrial lubricants. For home use, we have products for gun lubrication, sewing machine lubricants and more. These petroleum based lubricants can be used anywhere in the home where moving parts rub together. Squeaky door hinges will be a thing of the past with the options available here.

Proper lubrication of your wire rope, chain and cable can safely extend its operational life regardless of application. Cranes, elevators, shovels, drilling rigs, suspension bridges and draglines are some of the many applications that use wire rope, chain or cable to perform work such as pulling, dragging or hoisting. These applications often are exposed to harsh environmental conditions, including extreme weather. Lubrication Engineers can help your wire rope, chain and cable last longer and operate safely by implementing a lubricant reliability program and recommending the right lubricants for the job.

Most wire ropes are lubricated during the manufacturing process, but this lubricant will not last the entire life of the rope. When looking for a lubricant to relubricate your wire rope, choose one that contains no acids or alkalis, possesses the adhesive strength to stay on the rope, can penetrate between wires and strands, has high fluid film strength, resists oxidation and remains pliable. It is important to remember that most wire ropes fail from the inside out. Corroded rope can be a safety hazard, as there is no way to determine its remaining strength and life. Proper lubrication will help prevent deterioration of wire rope due to rust and corrosion.

Because most wire ropes fail from the inside, it is critical to ensure the center core receives sufficient lubricant. LE recommends a combined regimen in which a penetrating lubricant is used to saturate the core, followed by a coating lubricant to seal and protect the outer surface. LE offers several penetrating and coating type wire rope lubricants to suit your specific needs.

Penetrating lubricants contain an evaporative solvent that facilitates migration of the lubricant into the core of the wire rope, then evaporates, leaving behind a heavy lubricating film that protects and lubricates each strand.

Wirelife Almasol Coating Grease (451-453) is a soft, semifluid calcium-based grease designed to coat wire rope as well as moving chain and cable parts to ensure long life and smooth, quiet operation. Its tacky, water-resistant characteristics enable it to adhere strongly to rapidly moving parts, seal out damaging moisture, protect against premature wear and shield metal against corrosive attack.

Typical Applications: Wire rope, chain links, pins, bushings, cable sheave bushings, cables, open and closed silent and roller chains, and small, slow-turning gearboxes that require a semifluid lubricant

Wirelife Almasol Coating Lubricant (2002) is a fluid wire rope lubricant that provides a tough outer coating to seal and protect against fretting corrosion, wear and rust – even under extreme load and moisture. It seals and protects better than any product available. When used in conjunction with Wirelife Monolec Penetrating Lubricant, maximum protection and wear reduction is achieved.

Wirelife Almasol Syn Coating Lubricant (2022) is an extremely tacky, nonasphaltic synthetic lubricant with exceptionally high film strength. Perfect for extreme environments and conditions, it is the ultimate outer surface protector for wire rope and cable and comes from the same advanced technology that LE developed to protect large open gears in the mining and quarry industries. It derives its high load-carrying capacity from its synergistic blend of an extreme pressure additive and Almasol, LE’s exclusive wear-reducing additive.

Wirelife Monolec Penetrating Lubricant (2001) has excellent corrosion resistance and high load-carrying (EP) properties. It penetrates to the core of wire ropes, whether they are running or stationary. It is also excellent as a penetrating lubricant for chains of all sizes and works well in a variety of other industrial applications. When used in conjunction with Wirelife Almasol Coating Lubricant, maximum protection and wear reduction is achieved.

It contains a petroleum solvent to enhance its ability to penetrate. The solvent evaporates, leaving behind a film of heavy-bodied lubricant that protects and lubricates each strand and resists leakage from the wire rope core. Available in bulk sizes or in an aerosol version.

Typical Applications: All stationary or moving wire ropes or cables under heavy loads; chains of all sizes; mining and construction applications such as standing and running lines, draglines, cranes and derricks; marine applications such as cranes, hoists and drilling rigs; any other application that requires excellent rust protection for steel parts.

Designed for marine environments and other applications where environmental concerns require the use of a very low toxicity wire rope and chain lubricant, LE’s Wirelife Low Tox Penetrating Lubricant (2011) has excellent load-carrying capability and provides outstanding protection against rust, while having the lowest possible toxic effect on the environment.

Earthwise EAL Wire Rope Grease (3353) is recommended for use in applications on or near the waterways. It is an EAL and meets the specifications required by the EPA’s Vessel General Permit (VGP). It is readily biodegradable, exhibits minimal aquatic toxicity and will not accumulate in the cells of fish and other aquatic life forms. It is a soft, semifluid formulation designed to coat wire rope as well as moving chain and cable parts to ensure long life and smooth, quiet operation. Its semi-tacky, water-resistant characteristics enable it to adhere to the application and seal out damaging moisture and protect against rust formation.

Typical Applications: Applications near or around waterways including: Wire rope; chain links, pins and bushings; cable sheave bushings, bearings and strands; open and closed silent and roller chains. Ideal for use in automatic lubrication systems.

LE is happy to offer industrial lubricant and reliability recommendations for a variety of applications, and to provide product-specific data on all of our items to help you make the right decision. To learn more about our wire rope lubricants, wire rope lubricators as well as our other enhanced lubricants and lubricant reliability products, please

A HISTORY OF EXCELLENCE ROCOL® has been providing engineers with high performance lubrication solutions for more than 100 years. During that time we have worked with some of the world’s leading companies in many diverse industries and applications, developing products with one common goal: to deliver optimum performance. ROCOL operates to internationally recognised standards for quality, environment and safety. ROCOL is proud of its commitment to the continual engagement and development of staff and holds Investors In People accreditation. BENEFITS OF WIRE ROPE LUBRICATION Although simple...

KEY REQUIREMENTS OF WIRE ROPE LUBRICANTS Whilst it may be clear that good lubrication is a key part of maximising rope life, delivering the correct balance of properties in a single product is a significant challenge. A good wire rope lubricant must: Be easy, pleasant and safe to apply Achieve maximum penetration to ensure lubrication and protection of the rope core Resist wash-off and ing-off Have excellent corrosion protection Reduce friction and wear Allow easy inspection of the rope ROCOL® WIRE ROPE LUBRICANTS ROCOL have manufactured wire rope lubricants for many years. This has allowed...

PSEUDOPLASTIC WIRE ROPE DRESSING One of the most difficult problems encountered in formulating wire rope lubricants is finding the optimum balance between good penetration properties and resistance to water wash-off. Good penetration is achieved by low viscosity products such as oils but these have poor resistance Good wash-off resistance is achieved by highly adhesive grease-like products but these have poor penetration properties Until now there has been a trade off between these competing requirements. However, thanks to its pseudoplastic rheology, WIRESHIELD achieves maximum penetration...

THE DIFFERENCE IS CLEAR The key safety check for wire rope users is a visual inspection of the condition of the rope. Traditional wire rope lubricants contain black solid lubricants such as graphite and molybdenum disulphide. These materials make the lubricant unpleasant to handle and impossible to see through. WIRESHIELD™ uses an advanced load carrying system based on sub-micron white solids. The result is a nished product that is both clean to handle and translucent in use - without compromising the load carrying or anti-wear properties. Below is an illustration of the translucency of the...

COMPREHENSIVE RANGE ROCOL manufacture a comprehensive range of wire rope lubricants. ROCOL products have been proven over many years of service to: Reduce wear on wires and strands, maximising service life Provide outstanding corrosion protection Resist water wash-off, extending re-lubrication intervals WIRE ROPE Dressing WIRE ROPE Spray Multi-purpose rope lubricant Convenient aerosol pack Semi-uid grease based on highly rened mineral oil and an organically modied clay thickener. The unique blend of lubricating solids contained in the product reduces the internal friction and wear often...

WIRE ROPE LUBRICATION Methods of rope lubrication range from traditional, unsophisticated techniques such as brushes and swabs to dedicated, high performance equipment. ROCOL wire rope lubricants are designed to be as easy to apply as possible by whichever method is most convenient. While there is no single method that is “right” and works in all situations, the modern trend is to move away from manual application, to automated systems which: Maximise efciency of lubricant delivery on to the rope Improve health and safety by reducing operator contact with the rope and lubricant To make the...

CASE HISTORIES CLIENT: P&O FERRIES Product: WIRESHIELD™ Location: Dover, UK Application Details: The Pride of Kent crosses the channel to Calais up to 10 times a day. The vessel is moored using steel wire ropes which can be immersed in sea water up to 20 times a day and are exposed to extreme coastal weather conditions. In order to lubricate the wire ropes, sh oil was applied to them on a regular basis. Although easy to apply and offering reasonable penetration to the rope core the sh oil produced unsatisfactory results, including poor wash-off resistance, leading to increased lubrication...

CLIENT: MARMAGOA PORT TRUST CLIENT: BAE SYSTEMS – SHIPLIFT ROPES Product: WIRE ROPE Dressing Product: WIRE ROPE Dressing Application Details: The wire ropes on the bulk iron ore unloaders suffered from a high degree of wear due to a combination of the large amount of abrasive iron ore dust in the atmosphere and the heavy duty nature of the unloading operation. As a result the ropes were replaced every three to four weeks costing both time and money. Required Specication: Good penetration properties to ensure that the rope core received effective lubrication Increase the operational life of...

ADDITIONAL PRODUCTS PRODUCT NAME FEATURES & BENEFITS SAPPHIRE Hi-Torque Range A range of high performance, thermally stable, semi-synthetic EP gear oils, incorporating SUPs to provide maximum protection in all types of gearboxes. SUP’s – A unique protection for gear teeth on start up and in use (start up protection) Incorporates blue dye for high visibility Long life reduces the need for frequent draining Superior EP load carrying performance Excellent corrosion protection Very low foaming in operation ISO VG 100, 220, 320, 460 & 680 grades available Temperature range –20°C to +120°C...

PRODUCT NAME CORROSION PROTECTION FEATURES & BENEFITS Waxy lm for long term outdoor corrosion protection. Ideal for long term protection of machinery, elevators, forklift trucks, underground installations and offshore platforms. Temperature range -20°C to +110°C Heavy duty, waxy lm for long term corrosion protection Excellent corrosion protection outdoors for up to 2 years Good de-watering properties Good penetration Can provide a light lubricating lm in some applications Ideal for outdoor corrosion protection of exposed metal parts Does not contain silicones or chlorinated solvents...

Wire rope lubrication is critical to extending the life of a cable (often referred to as the “lift cable”). How significant is it? Failure to complete this simple maintenance can reduce wire rope life by up to 50%.

A wire rope consists of wire strands wound around a central core, then again wound around themselves to form a wire rope. The center may consist of steel or even plastics. Here are just some of the MANY different configurations for a wire rope.

The use of a small strand size is better suited to bending around small sheaves (pulleys). Taken to an extreme, a wire made of one thick “strand” would not be able to go around a pulley.

Many small strands allow the wire rope to bend easily around the pulleys. In doing so, the strands “rub” against each other, causing friction. Over time, friction rubs any external coatings off the wire rope.

The cable strands get a coating of zinc for rust protection (called galvanizing). The steel strands travel through a hot zinc bath to coat the surface with rust protection. The “con” to galvanized cables – the surface does not regenerate when damaged.

In simplest terms, when molten high carbon steel mixes with chromium, it forms stainless steel. When in contact with air, the chrome restores the anti-rust properties. The “con” side – it gives up small amounts of strength.

There are different types of wire rope lubricants – penetrating and coating. Solvents in penetrating oils carry a lubricant into the core of the wire rope. When the solvent evaporates, it leaves behind a lubricating film to protect the strands.

Most wire ropes fail on the inside first. It is vital to ensure that the center core receives enough lubrication. Repeated applications over a day are a good idea.

It is best to apply short bursts of spray lubricant on the top cables wound around the drum. Spray across the top of the wires to get the best penetration and protection. The rope strands tend to separate slightly due to bending around the winch drum. This separation allows the lubricant better access to the core of the wire rope.

PWS attributes the increase in the life cycle to the use of penetrating oil to displace water and decrease friction. The oil reduces the wear and corrosion occurring inside the rope. Spraying with a penetrating lubricant acts like an oil change for cars. You’d never allow your vehicle to run out of oil. Right?

In a previous post, we explained the danger to boat lift cables if the waves hit the bottom of your boat. We also demonstrated what defective wires look.

Warning – It is possible to break strands inside a cable without any exterior signs of damage. This situation is especially true on stainless steel cables which do not rust. If you see “rust” on a stainless steel cable, it is from the winch drum depositing rust in the winding process.

Wire ropes are integral components for many buildings, machines, and structures. This material is comprised of contiguous wire strands that are wrapped around a centralized core. It is important to lubricate wire ropes in order to limit friction and prevent corrosion.

There are two main types of wire rope lubricants: penetrating and coating. A penetrating lubricant contains a solvent that transports the lubricant into the core of the wire. Once on the core, it evaporates and leaves behind a heavy, lubricating film that is capable of protecting each strand. A coating lubricant penetrates the wire slightly, and protects the outside of the cable from moisture, wear, fretting and corrosion.

Both of these lubrications are used on wire ropes, but since most failures come from the inside of the wire rope, it is most important to thoroughly saturate the core with lubrication.

Most lubricators are a made up of a mixture between petroleum and other compounds. The petroleum provides excellent corrosion and water resistance, which helps to extend the life of the wire. In addition to petroleum lubricants, grease and vegetable oils are also uses to coat the wires. These mixtures penetrate the core and are easily applied. Most cables are lubricated before they are used, but it is important to re-lubricated wires habitually.

ASV RL1 is a highly adhesive,semi fluid extreme pressure grease for lubrication and corrosion protection of wire ropes and steel cables operating under adverse conditions of load,temperatures or environment.It penetrates rapidly through wire rope strands to leave a completely water resistant heavy duty lubricating film which provides both internal as well as external lubrication & corrosion protection.The solid lubricants prevent wearing and premature damage of internal strands and increase the life of the wire ropes.ASV RL 1 forms a protective and lubricating water proof film over the surface which does not emulsify even if submerged in water.

Bio-E.P.™ Wire Rope Lubricants are ultimately biodegradable vegetable oils formulated with antiwear, extreme pressure (EP), antirust, oxidation inhibitors, and a tackifier. They provide a light waxy-tacky coating, and are recommended for lubricating multi-strand cables and wire rope wound around central cores of steel or fiber, which are subject to heavy loading and/or shock loading. These biobased products provide improved fire resistance over equal viscosity petroleum products and contain no chlorine, zinc, or heavy metals. Performance is enhanced by use of the Stabilized HOBS’s natural vegetable oil composition, which provides an oily boundary film. In addition, this oily film has a natural polarity to metal surfaces and helps clean and then penetrates deep into the inner core of the cable preventing rust and wear. The super high viscosity index of the Stabilized HOBS adds additional lubrication qualities to this high performance lubricant. Laboratory and field tests have shown that the products provide exceptional protection with excellent low temperature pumpability.View More Products

Whether you are working with manufacturing equipment, automotive equipment, or any other industrial equipment, you need products you can count on to reduce friction and wear. Kimball Midwest carries the right chain and rope lubricants for your operation. Our

Wire rope forms an important part of many machines and structures. There are many kinds of wire rope designed for different applications. The wire rope’s performance is influenced by several factors, including type of operation and environment which can accelerate corrosion, oxidation, and wear. Hence, proper, and adequate lubricant application in the field is paramount. Essentially, wire rope lubricants have three principal functions, and it is to reduce friction, provide wear protection and corrosion protection.

The Chain and Wire Rope Lubricant is a heavy duty high temperature and pressure lubricant that penetrates chains, cables, and wire rope to deposit a wear resistant coating. The foam spray clings to the surface penetrates and coats leaving a Molybdenum and extreme pressure lubricant on the inner surfaces. This two in one lubricant both penetrates into the core of the wire rope , evaporates and leaves behind a heavy lubricating film to protect and lubricate each strand and with a second coating penetrates slightly and seals the outside from moisture reducing wear and corrosion.

The Chain and Wire Rope Lubricant can be used on conveyors, hoist chains, link and roller assemblies, rail equipment, mining equipment, road and construction machinery, cutter bars, material handling equipment, chain saws, etc.

Distributor of wire rope and cable lubricants. Lubricants come in multiple forms and are frequently used to reduce friction, prevent thread locking and provide chemical resistance.

Manufacturer of heavy duty lubricants for chain, wire rope and cable applications. Available in 16 oz. capacity and 900 degrees F operating temperature. Protects from corrosion and rust. Provides non-gumming protective film. Serves the marine, heavy equipment repair, mining, power generation, wastewater treatment and chemical industries.

Distributor of wire and cable drawing and pulling lubricants. Value added services include assembly, barcoding, bin stocking, bonded inventory, consignment inventor, consolidated billing, dock-to-stock, drop ship, EDI, electronic funds, JIT, Kanban, kitting, long term pricing, one-stop, quality control, rebates, schedule sharing, vendor inventory, and more.

Manufacturer of wire rope & cable lubricants. Products include coating grease, penetrating lubricants, coating lubricants & synthetic coating lubricants. Services include equipment reliability assessment, oil analysis, lubricant storage, handling & transfer, contamination exclusion, contamination removal, education & training & design, implementation & support.

Almagard, Almaplex, Almasol, Almatek, DEXRON, Duolec, Earthwise, Futura, Low Tox, Lubrication Engineers, Monolec, Monolex, Multilec, PERMA, Pyroshield, Quinplex, Synolec, Synpag, Syntemp

Manufacturer of non-staining and slow-drying foam and synthetic wax wire/cable pulling lubricants. Available in aerosol cans, squeeze bottles and buckets. Working temperature ranges from 20 to 122 degrees F. Suitable for electrical and utility applications. Meets ANSI, ASTM and OSHA standards. CSA approved. cUL listed. Made in the USA.

Manufacturer and distributor of multi-purpose and heavy duty aerosol grease chain/cable lubricants. Available in 16 oz. capacity. Contains molybdenum disulfide. Suitable for chain saw, hinge, hoist, conveyor, wire rope and cable, roller chain and sprocket applications. Meets NFPA standards.

Manufacturer of lubricants including oils and grease for oven, conveyor chains, wire ropes and cables applications. Features include biodegradability, temperature and mechanical stability, non-toxic, resistance to rust or corrosion. Extremely high temperature working grease is also offered. Packaged in pails, drums, cans and tote. Serves the construction, agriculture, energy, government, rail, mining, oil and gas industries. NSF H1 Certified. USDA, FM and FDA approved.

Manufacturer and distributor of wire pulling cable lubricants for industrial applications. Available in pails, bottles and drums with an operating temperature from 30 degrees F to 120 degrees F and 6 pH to 8 pH solution. Various features include cling characteristics, translucent, non-staining, non-toxic and non-corrosive. Lubricant gels are suitable for reducing friction. Meets ASTM-D1693 and IEEE-1210-1996 standards. UL listed. On-time delivery.

ISO 9001:2000 certified woman-owned manufacturer of standard & custom wire drawing, wire pulling, wire rope, cable & chain lubricants including molybdenum disulfide aerosol lubricants. Features include anti-friction & anti-wear properties. Aerosol lubricants range in operating temperatures from -300 degrees F to plus 750 degrees F with molybdenum disulfide concentration of 5 percent . Made in the USA.

Distributor of cable and wire rope lubricants. Features include semi-synthetic and polymer base formulations and high temperature stabilities. Suitable for use with wire or cable insulated with rubber, neoprene, nylon and PVC plastics , hypalon, high density polyethylene and cross linked polyethylene (XLP). Serves the chemical, civil, food, mining, oil, gas, power generation, paper, OEM and wastewater industries.

Manufacturer of wire rope and cable lubricants. Contains organic molybdenum and anti-wear additives. Resistant to corrosion, water wash-off, high-temperature sling off and friction. Used in meat and poultry plants. Can withstand temperatures up to 350 degrees F. Offered in 16 oz. aerosol containers and 5 gal. and 55 gal. drums. Markets served include food and beverage, marine, oil and gas, automotive, utility, commercial and institutional. On-time delivery available.

Distributor of lubricants for industrial and commercial applications. Products include greases, engine and compressor oils, transmission fluids, fuels, oil additives, hand and industrial cleaners. Types of lubricants include wire rope/chain, cable, gear, food-grade and industrial spray. Other services such as diagnostic, preventive maintenance, monitoring, testing and evaluation. Serves the heavy construction, mining, manufacturing, marine, transportation, agri-business, concrete, sand and gravel industries.

ISO 9001:2000 certified manufacturer & distributor of lubricant products including chain, wire rope & cable lubricants. Services include analysis & consultation, operation & plant surveys & fuel & oil analysis.

Multi-Purpose Lubricator & Penetrating Oil Made From Refined Non-Solvent Petroleum For Lubricating, Penetrating, Protecting, Cleaning, Dressing, Machining

Manufacturer of a complete line of specialty lubricants, anti-seize, and dry film lubricants available in aerosol & bulk. Lubricant applications used for cable, chain, extreme pressure, friction & wear, high pressure, high temperature, industrial process, low temperature, rope, water repellent, and belting. Contract packaging & custom formulations.

Manufacturer of lubricants for the industrial manufacturing and plastics industries. Available lubricant types include oils, greases, and fluids. Other products include wax, fuels, chemicals, and motor oils. Serves industries such as aviation, commercial vehicle, marine, and automotive.

Private-label & contract packaging manufacturer of custom wire, wire rope & cable pulling lubricants. Types of lubricants include vegetable based lubricants, metal drawing lubricants, stamping lubricants, extrusion lubricants, mold release lubricants & conveyor lubricants. Other products such as degreasers, hand soaps, cleaners, coatings, detergents, automotive cleaning products, food service cleaning products & commercial laundry products are also available. Services include contract packaging & private labeling.

Molybdenum disulfide (moly) & graphite dry lubricants with rust & corrosion inhibitors for outdoor applications & as protective coating for wire rope & cable, crane booms & mine shaft cables.

Distributor of industrial lubricants for wire ropes, gears, and bearings. Available in 20 L pails and 205 L drums with aluminum, lithium, and PTFE thickener, non-melting, and rust and wear protection features. Suitable for high and low temperature and wet applications. Serves the power generation market.

Distributor of lubricants & cleaners for chains, wire ropes & cables. Specifications of lubricants include flash point of more than -17 degrees C temperature, 360 degrees C auto ignition temperature, 60.5 degrees C boiling point, 3.0 vapor density, 47 kPa vapor pressure, 0.74 & 0.76 specific gravity, viscosity more than 14 sq. mm/second & 45 percent VOC content.

Manufacturer of petroleum based lubricants including wire rope & cable lubricants in black color. Lubricants are available with flash point greater than 400 degrees F and 0.91 specific gravity. Custom formulations available.

WRL™ coats the internal strands of the wire ropes to prevent friction and wear. This results in longer life, less downtime for rope changes and more production. Wire ropes contain numerous moving parts that require lubrication. Each time the rope bends or flexes, the internal strands rub together. Jet-Lube"s wire rope and chain lubricant quickly penetrates to the cores. This ensures that the rope is lubricated throughout while providing a nondrying, non-tacky film on the outside of the rope that protects outer strands from corrosion, as well as lubricating the wire rope drums and sheaves. WRL is pumpable at temperatures down to -25 deg F (-32 deg C) its nondrying film remains flexible in most extreme weather conditions, which eliminates flaking and peeling.Lead-free

Applications:Easily pumpable at low-temperatures, used to lubricate all sizes of wire rope as well as chains, leaf springs and other applications where a penetrating oil is needed

Lubricating with the aid of brushes, rags, gloves, or by other means is costly, risky, and ineffective. The lubricant forms a film on the surface which water vapour can penetrate, thus becoming trapped. Temperature changes cause condensation and rust then begins to form from the inside. A wire rope can appear to be in good condition, when in fact corrosion and friction are destroying it from the inside. Its useful life is shortened and it becomes potentially dangerous. Even factory lubricated wire rope requires regular relubrication.

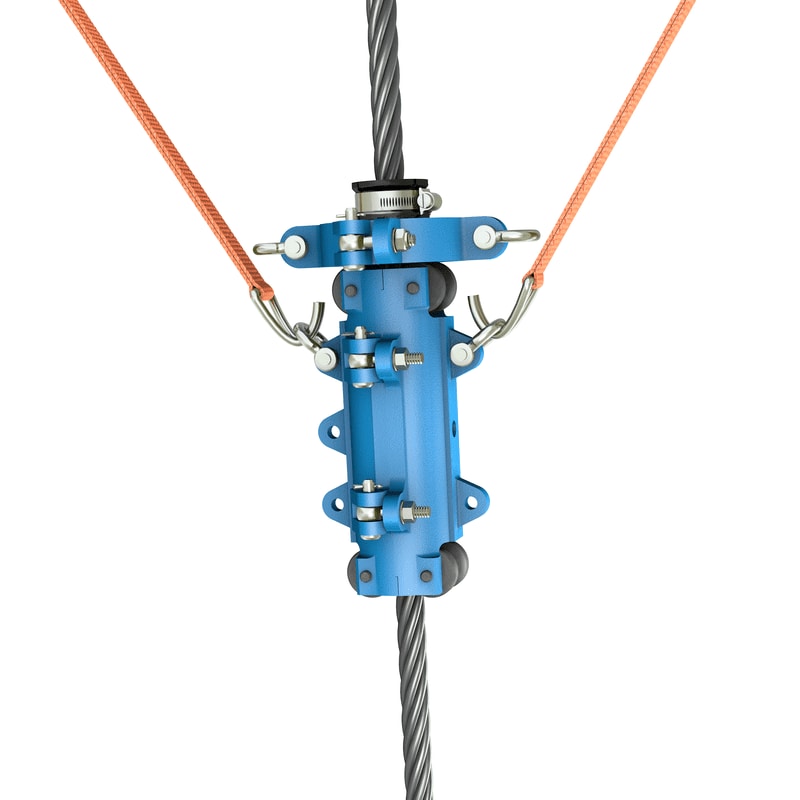

Only the Masto Lubricator penetrates under high pressure all types of wire rope, such as Non-rotating, Dyform, and Locked Coil with heavy grade lubricant. NB. To obtain total penetration through a compact rope the pressure must be minimum 20 bar (285 PSI) in the chamber. Even wire rope subjected to severe surface wear will have a longer life when lubricated with the Masto. Stainless steel, galvanized, and other special types of wire rope require just as much lubrication since friction is the same and corrosion can also occur.

If you start using the MASTO Lubricator, the best results are obtained with the highest quality Wire Rope Grease. If you use SWEPCO 150 Wire Rope Grease your wire ropes will be protected in an optimum way.

An impressive load wear index of greater than 75 and 4-ball weld load of 800 kg demonstrate the superiority of SWEPCO 150’s industry leading extreme pressure and anti-wear protection. The result is significantly longer service life for wire rope and wire rope system components.

8613371530291

8613371530291