steel wire rope net manufacturer

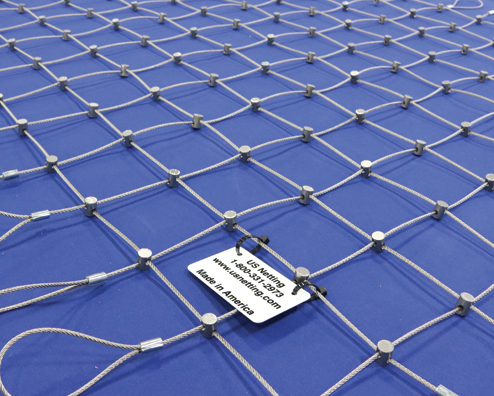

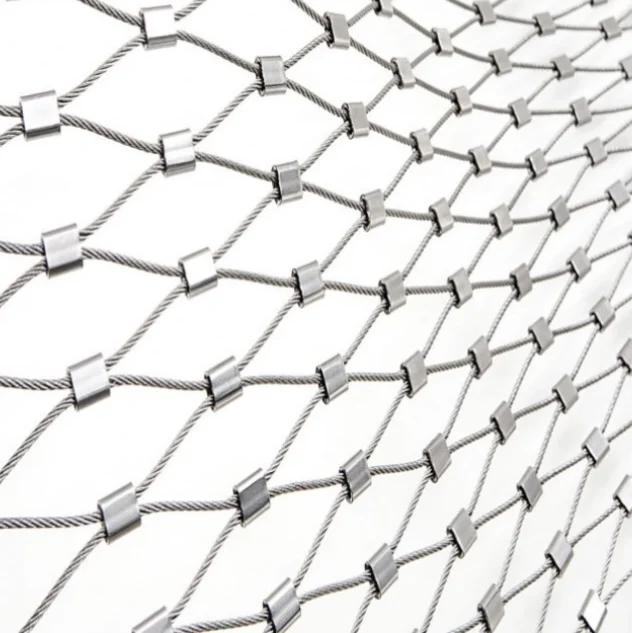

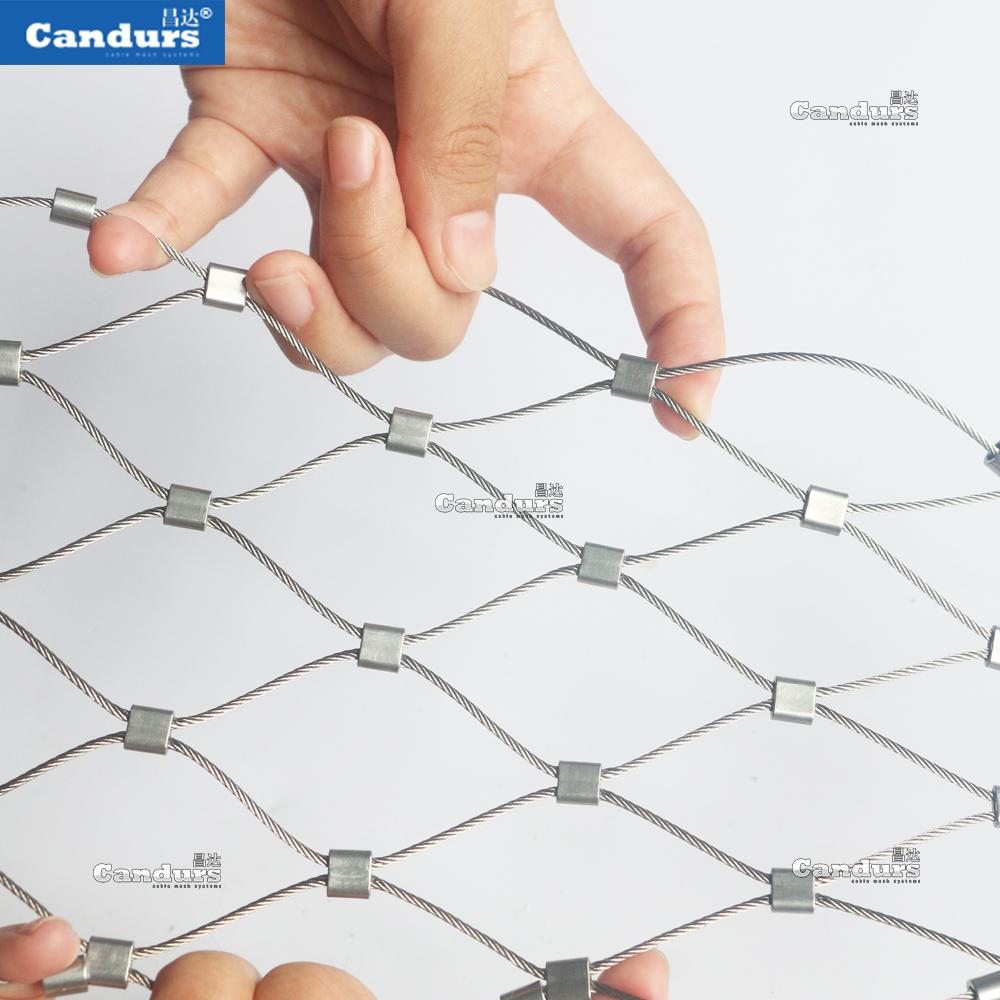

Our wire rope nets consist of individual steel ropes, which are between 1.5 and 8.0 mm thick. The ropes are brought into a net shape and pressed using clamps at the crossing points to achieve a highly resilient connection. At the edge, the characteristic loops are created all around, which serve as an attachment point or to hold a steel cable running all around. We can offer the steel wire nets in various mesh sizes and mesh shapes with a size between 20 and 300 mm.

The maximum width produced by the machines is 5 meters. Wider nets would be made out of connected multiple nets. The length is continuous and is not limited in terms of production technology. Depending on their width and design, the nets can be made up to a total weight of approx. one ton. A continuous adjustment of the mesh size or a special assembly in the edge area is also possible. If you have any further questions, please contact us!

Custom-made steel wire net with high mechanical load capacity for industry, construction sites and the public sector. Enter the desired dimensions in the appropriate fields above. Net area and price will be calculated and displayed automatically.

The ropes are running in vertical and parallel lines and are fixed at the crossing points using aluminium cross clamps. The clamps are pressed to a permanent connection. The rounded shape of the clamps ensures good haptics and minimizes the risk of injury.

The steel wire mesh is highly resilient and weather-resistant, making it suitable for continuous use. Please note, that the steel wire mesh is a rigid network. In contrast to textile nets the energy consumption is more erratic. Depending on the nature of load on the network, the specified slip resistance of the wire connectors is also relevant beside the breaking force of the ropes.

The net size always means the dimension from the inner edge of the loop to the inner edge of the loop on the opposite side (respectively th emeasure between the attachment points).

Steel wire nets should be installed with a slight tension, which reduces the effectiveness of an impact. It should be noted that the loops can distort under load when they are attached at certain points and can therefore change in length. In this case, the dimension of the netting should be reduced accordingly. Manufacturing tolerances are subject to change depending on the design and type of fastening.

The specified mesh size describes the dimension between the inner edges of the wire ropes. The size of the meshes and especially the edge meshes is adjusted so that they match the size ordered and the type of edge design and can therefore vary slightly.

The maximum production width is 500 cm. We can offer you wider networks on request. However, the length is not limited. The nets can be made up to a weight of 1,000 kg per single net. We recommend separating nets weighing over 300 kilograms into several individual nets.

The edges of the net are designed as loops as standard. Due to the meandering course of the ropes, the net has a loop on every second stitch. Depending on the number of individual strands, the start and end point of a rope can be pressed to a loop, converted in the direction or executed as a thimble. Depending on the overall size and aspect ratio, the net can consist of one or more individual steel cables.

The loops on every second mesh serve as an attachment point. For example, they can be mounted directly to a substructure with hooks or eyes. Another option is to mount the net with rigid profiles (profiles or pipes made of steel or aluminium). Alternatively, an additional steel cable can be used, which is threaded and tensioned through the edge meshes.

Attention: The wire rope nets must not be pinched or warped during assembly. Pinched or warped nets have a considerably lower strength due to increased shear forces or additional tension in the edge area.

Attachment made of galvanized steel or stainless steel with an open thread. Different diameters and lengths are possible depending on the rope strength.

Jakob Rope SystemsJakob Rope Systems is one of the market leaders in the manufacture and supply of top-end, design-forward solutions to industrial and construction-related rope and cable applications in which elegance, simplicity and superlative quality are required.

Now, for more than a century and in over 55 countries, Jakob offers a range of steel rope products to our clients who return time and again seeking a reliable maker and provider of stainless steel wire ropes, rod fasteners, nets and unique fittings, all custom-designed and produced to fit exact specifications. At Jakob, we understand it’s the little details that make the big differences.

Every piece of finished goods leaving our warehouses is put through a stringent testing process to ensure compliance with AISI 316, ISO and DIN standards. Our cable railing, wire mesh, wire ropes, and rods can be used in multiple applications, both indoor and outdoor and at various scales, such as sign stanchions, shelving, as trellises on green walls, safety netting, and even in zoo enclosures.

Jakob and our USA -based team can provide cables and wire netting solutions for any commercial and business application. We take pride in offering custom-made designs to fit our clients’ needs.

In 1984, Yingkaimo Metal Net Co., Ltd. was founded in Anping County Hebei Province, which is the hometown of wire mesh in China. It has Anping Factory, Dezhou Factory and Dubai Office with more than 500 employees. YKM"s annual value of production is about 50 million US dollars, of which 90% of products delivered to more than 70 countries and regions. It is a high-tech enterprise, also a leading company of industrial cluster enterprises in Hebei Province. YKM brand as a famous brand in Hebei Province has been registered in 17 countries around the world for trademark protection. Nowadays, YKM is one of the most competitive metal wire mesh manufacturers in Asia.

Total area of the two factories is about 156000 square meters with more than 400 sets of manufacturing machines, main machines including international advanced technology Japanese-made RGK, German-made Jager and some Chinese-made machines. Annual production capacity for stainless steel mesh is more than 10 million square meters, with range from 1 mesh to 635 mesh of square mesh and highest dutch weave 3600 mesh. The self-designed two epoxy coating production lines are the most advanced epoxy mesh coating equipment in Asia, its annual output is more than 13 million square meters and it makes YKM to be the R&D and supply center for epoxy mesh. YKM"s main products are stainless steel wire mesh,epoxy coated wire mesh,nickel wire mesh, copper wire mesh, low-carbon steel wire mesh and all kinds of mesh further-processing products. Total 6 series, about thousand types of products, widely applied for petrochemical, aeronautics and astronautics, food, pharmacy, environmental protection, new energy, automotive and electronic industry.

Safety is always penetrated through the company development, also a part of YKM"s company culture. As Chairman Mr.Yan Xiangyang emphasized that: Without HSE, what we manufacture will be human"s pains and social loss. The target to carry out HSE is to bring more happiness to human beings and create more value for society, it also reflects the life value and meanings of each YKM staff.

Company Culture Our Mission Building competitive products, devotion to providing competitive products, do best to meet customer demands, become the most influential and valuable wire mesh manufacturing company both home and abroad. Enterprise Core Values Building competitive products, leading the future. Corporate Vision Based on domestic market and world-oriented, We aim to build a harmonious cultural system, enhance core competitiveness, create famous brand & enterprises image, gradually build YKM precise, excellent, strong, large and become leader & the most valuable enterprise in domestic metal mesh industry & rank top in the international metal industry. As our Chairman stated, "the future favors the enterprise which has dream, we believe that as long as our staff share the same goal, YKM"s vision must come true!

Development Milestone 1984, Anping vibrating Screen Factory was founded; 1998, Hebei Yingkaimo Metal Net Company was established; 2003, ISO9001 International Quality System Certification and ISO14001 Environmental System Certification were granted; 2004, Dubai Office in the United Arab Emirates was set up; 2006, Hebei FLD Filter Co., Ltd was established, a joint-venture with South Korean Company; 2007, YKM Dezhou plant was built; 2008, YKM Trademark was registered in 17 countries, such as: The United States, Germany, Britain, France, Italy, Switzerland, Belgium, Australia and Japan and so on. 2009, the first Asia"s largest epoxy coating production line in Asia was completed; 2012, renamed as Yingkaimo Metal Net Co., Ltd 2013, the second Asia"s largest epoxy coating line was successfully developed by YKM Team. 2015, the ISO/TS16949 System Certification was received. 2016, YKM achieved "the high-tech enterprise". 2018, YKM"s R&D was designated as"Enterprise Technology Center in Shandong province"

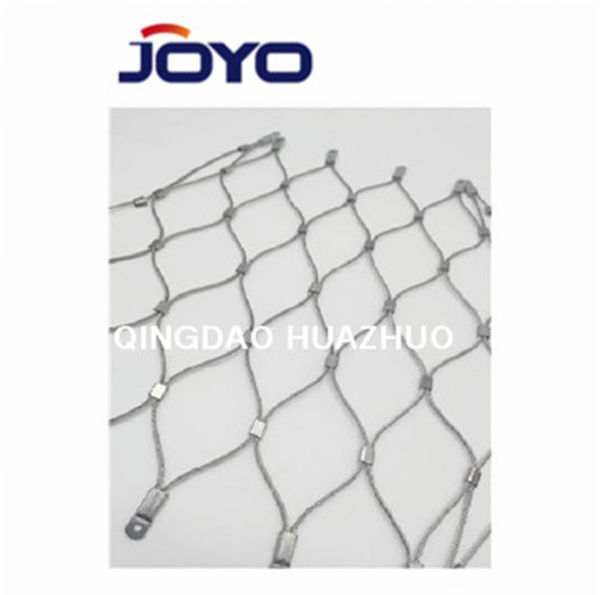

Galvanized wire rope net is the most common used rockfall barrier type. It is made of hot dipped galvanized steel wire rope. The wire ropes are intersected and fixed by the clips. The steel wire rope has higher tensile strength than the steel wires.

The galvanized wire rope net can be used individually or it can be used with chain link fence or hexagonal wire meshes. When it is used individually, it is commonly used in the mountains which the stones is large and the impact is huge. When it is used combined with chain link fence or hexagonal wire mesh, the mountain or the slope is loose and have several small stones. The chain link fence or the hexagonal wire mesh can block the small stones.

Galvanized wire rope net. The main component of steel wire rope rockfall barrier system. It is made of 8 mm steel wire rope and then woven into steel wire rope net with diamond shapes. Steel wire rope has high tensile strength and load capacity.

Chain link fence. Chain link fence is another important component. It is used with galvanized wire rope net to make up the disadvantages of galvanized wire rope net. Place the chain link fence in the wire rope net to block and prevent the smaller stones from falling down. The chain link meshes are made of hot dipped galvanized materials for corrosion and rust resistance.

Wire rope anchor. Made of steel wire rope, the wire rope anchor is mainly used for fastening the galvanized wire rope net and chain link meshes on the mountain firmly. The wire rope anchor has higher tensile strength and better flexible performance than the concrete anchor.

Supporting rope. Supporting rope is placed along the galvanized wire rope net, it is used for share the loading and pressure of the wire rope net. Support rope is also made of 8 mm steel wire rope, which has high loading capacity and tensile strength.

Sewing rope. Sewing rope is mainly used for connecting the neighbor steel wire rope net and form a whole protection for the mountain. Sewing rope is very important, 8 mm steel wire rope can supply high loading capacity to prevent the stones from leakage in the joint.

Galvanized wire rope net has the same applications with PVC coated wire rope net. It is widely used in the mountains and slopes to prevent stones from falling down.

Find and filter through a wide variety of wholesale steel wire rope cargo net. Enjoy the wonders of the outdoors while being a door"s opening away from the cozy comfort of the indoors with the canvas awnings and porch awnings. Metal awnings, metal canopies, and metal patio covers are also available for a more straightforward and robust installation.

Browse through a rich selection of RV awnings, camper awnings, and car awnings that are available. These steel wire rope cargo net are perfect for camper vans, RV buses, motor homes, and even cars. These are perfect for providing shade for a day at the beach, taking in the sights and sounds of nature at your local park, or jamming with family and friends at a music festival.

steel wire rope cargo net for homes or buildings are available as a temporary, retractable awning structure that folds away when not in use. Some examples of these are the retractable patio awning and the retractable awning for the deck. These are generally lighter, easier to install and use, and pose lesser potential issues with the building rules due to their light and temporary nature. They are perfect for providing temporary extra space and shade for parties and small gatherings with friends and extended family.

8613371530291

8613371530291