steel wire rope splicing manufacturer

Manufacturer of aluminum swage sleeves including hour glass, oval, thin wall, combo & fiber rope sleeves. Hour glass sleeves range in rope & sleeve size from 1/32 to 1/2, width from .090 to 1.062, height from .136 to 1.625, hole width from .040 to .562, length from 1/4 to 2. Oval sleeves have a rope & sleeve size of 1/16, width of .172, height of .250, hole width of .078 & length of 3/8. Thin wall sleeves range in rope & sleeve size from 3/32 to 5/32, in width from .226 to .375, height from .372 to .562, hole width from .118 to .200 & length from 1/2 to 11/16. Combo sleeves are available with rope & sleeve size of 1/8 x 1/16, width of .343, height of .500, hole widths of .156 & .078 & length of 5/8 or sleeve size of 3/16 x 1/8, width of .430, height of .656, hole widths of .160 & .320 & length of 1. Fiber rope sleeves range in rope & sleeve size from 1/8 to 7/16, width from .250 to .855, height of .388 to 1.35, hold width from .160 to .525 & length from 1/2 to 1 1/4.

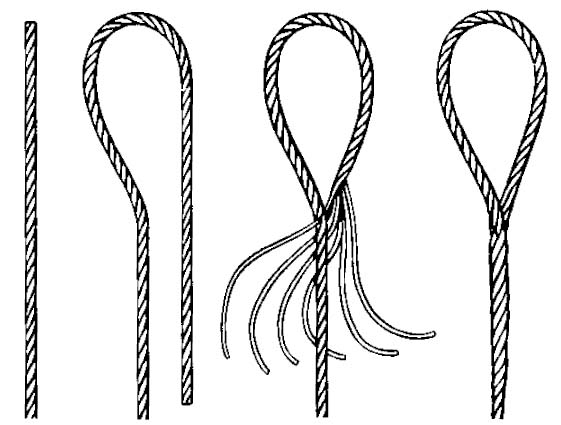

We custom manufacture wire rope assemblies (endless loop) for conveyor lines. Our specialty is the Long splice. The Long splice is used to create a continuous or endless loop of wire rope cable frequently utilized on conveyor systems. The splice is a difficult multi-step labor intensive process in which two wire rope cable ends are joined end to end and the strands are intertwined to merge the two individual wire rope cable ropes ends.

Our proven experience can be viewed first hand in the quality of our wire rope cable splices we perform regularly for diverse clientele in the Unites States and around the world. For assistance with your unique wire rope conveyor cable splicing needs, please complete theor call us directly at

A wire rope is a type of cable that includes several wire strands laced together to form a single wire. Generally, both the terms “wire” and “rope” are used interchangeably with “wire rope”; however, according to the technical definition, to be labeled a wire rope, the cable must have a thickness of at least 9.52 mm. As a versatile, high load capacity alternative to natural fiber ropes such as hemp and manila, wire rope provides motion transmission through nearly all angles, tie down, counterbalance, guidance, control, or lift.

Modern wire rope was invented by Wilhelm Albert, a German mining engineer, between 1831 and 1834. He developed them in order for work in the mines in the Harz Mountains. This rope replaced weaker natural fiber ropes, like hemp rope and manila rope, and weaker metal ropes, like chain rope.

Albert’s rope was constructed of four three-stranded wires. In 1840, a Scot named Robert Stirling Newall improved upon this model. A year later in the United States, American manufacturer John A. Roebling started producing wire rope, aimed at his vision of suspension bridges. From there, other interested Americans, such as Erskine Hazard and Josiah White, used wire rope in railroad and coal mining applications. They also applied their wire rope techniques to provide lift ropes for something called the Ashley Planes project, which allowed for better transportation and increased tourism in the area.

Approximately twenty-five years later, back in Germany in 1874, the engineering firm Adolf Bleichert & Co. was founded. They used wire rope to build bicable aerial tramways for mining the Ruhr Valley. Years later they built tramways for both the Wehrmacht and the German Imperial Army. Their wire rope systems spread all across Europe, and then migrated to the USA, concentrating at Trenton Iron Works in New Jersey.

Over the years, engineers and manufacturers have created materials of all kinds to make wire rope stronger. Such materials include stainless steel, plow steel, bright wire, galvanized steel, wire rope steel, electric wire, and more. Today, wire rope is a staple in most heavy industrial processes. Wherever heavy duty lifting is required, wire rope is there to facilitate.

Wire rope is strong, durable, and versatile. Even the heaviest industrial loads may be lifted with a well-made wire rope because the weight is distributed evenly among constituent strands.

There are three basic elements of which wire ropes are composed: wire filaments, strands, and cores. Manufacturers make wire rope by taking the filaments, twisting or braiding them together into strands, and then helically winding them around a core. Because of this multiple strand configuration, wire rope is also often referred to as stranded wire.

The first component, the filaments, are cold drawn rods of metal materials of varying, but relatively small diameter. The second component, the strands, can individually consist of as few as two or as many as several dozen filaments. The last component, the core, is the central element around which strands are wrapped; wire rope cores maintain a considerable amount of flexibility, while increasing strength by at least 7.5% over the strength of fiber core wire ropes.

The helical winding of the strands around the core is known as the lay. Ropes may be right hand lay, twisting strands clockwise, or they may be left hand lay, twisting strands counter-clockwise. In an ordinary lay, the individual strands are twisted in the opposite direction of the lay of the entire rope of strands to increase tension and to prevent the rope from coming unwound. Though this is most common Lang"s lay has both the strands and the rope twisted in the same direction while alternate lays, as the name suggests alternate between ordinary and Lang style lays. While alternative rope designs are available, the helical core design is often favored, as it allows a wire cable to hold a lot of weight while remaining ductile.

There are many design aspects that wire rope manufacturers consider when they are creating custom wire rope assemblies. These include: strand gauge (varies based on application strength, flexibility, and wear resistance requirements), wire rope fittings (for connecting other cables), lay, splices, and special coatings. Specially treated steel cable and plastic coated cables, for instance, are common to many application specific variations of wire rope such as push pull cable assemblies used in transferring motion between two points.

Suppliers typically identify wire cable by listing both the number of strands and the amount of wires per strand respectively, though stranded cable may alternatively be measured by their lay and length or pitch. For example, a door-retaining lanyard wire rope is identified by its 7 x 7 construction, and wire rope used for guying purposes is identified by its 1 x 19 construction. The most common types are 6 x 19, 6 x 25, 19 x 7, 7 x 7, 7 x 19, 6 x 26, and 6 x 36.

An ungalvanized steel wire rope variety. This uncoated wire rope can also be designed to resist spinning or rotating while holding a load; this is known as rotation resistant bright wire rope.

Also called a coiled wire rope, a coiled cable is a rope made from bundles of small metal wires, which are then twisted into a coil. Wire rope and cable can come in a huge variety of forms, but coiled cables specifically provide the benefits of easy storage and tidiness. Unlike other wire ropes, coiled cables do not require a spool for storage. Because it has been coiled, the cable will automatically retract into its spring-like shape when it is not in use, making it incredibly easy to handle.

A type of high strength rope, made of several individual filaments. These filaments are twisted into strands and helically wrapped around a core. One of the most common types of wire rope cable is steel cable.

Wire rope made not as one solid piece, but as a piece made up of a series of metal links. Wire rope chain is flexible and strong, but it is more prone to mechanical failure than wire rope.

Push pull cables and controls are a particular type of control cable designed for the positive and precise transmission of mechanical motion within a given system. Unlike their counterpart pull-pull cables, these wire rope assemblies offer multidirectional control. Additionally, their flexibility allows for easy routing, making them popular in a number of industrial and commercial applications.

Iron and steel are the two most common materials used in producing wire ropes. A steel wire is normally made from non-alloy carbon steel that offers a very high strength and can support extreme stretchable forces. For even more strength and durability, manufacturers can make stainless steel wire rope or galvanized steel wire rope. The latter two are good for applications like rigging and hoisting.

Technically, spiral ropes are curved or round strands with an assemblage of wires. This gathering of wires has at least one cord situated in the opposite direction of the wire in the outer layer of the rope. The most important trait of this rope is that all the wires included are round. The biggest benefit of this category of rope is that it does not allow the entrance of pollutants, water, or moisture.

Contain an assemblage of strands placed spirally around a core. Stranded rope steel wire patterns have different layers that cross each other to form an even stronger cable or rope. Stranded ropes contain one of three types of core: a fiber core, a wire strand core, or a wire rope core.

Provide an added level of security to a manufacturing production application. Wire rope slings are made from improved plow steel wire ropes that, apart from offering added security, also provide superior return loop slings. Plow steel wire ropes improve the life of a mechanism by shielding the rope at its connection points. The key objective of wire rope slings is to enhance the safety of an application while increasing its capacity and performance. Rope slings are also available in various sling termination options, such as hook type, chokers, and thimbles.

The eye in this rope sling is made using the Flemish Splice method. Just like a typical sling, a Permaloc rope sling improves safety and provides reverse strength meaning that the uprightness of the eye does not depend on the sleeves of the metal or alloy. Additionally, permaloc rope slings offer an abrasion resistance feature that makes them long lasting.

These slings have all the features that most other slings offer. However, compared to their counterparts, Permaloc bridle slings provide better load control, wire rope resistant crushing, robust hooks and links that work for a longer duration, and help save on maintenance requirements.

Manufacturers produce wire rope for many different reasons; from cranes to playground swings, wire ropes have something for everyone. Among the many applications of wire rope are hoisting, hauling, tie down, cargo control, baling, rigging, anchoring, mooring, and towing. They can also serve as fencing, guardrails, and cable railing, among other products.

Some of the industries that make use of wire rope include industrial manufacturing, construction, marine, gas and oil, mining, healthcare, consumer goods, and transportation. Others include the fitness industry, which uses plastic coated cable products in weight machines, the theater industry, which uses black powder coated cables for stage rigging, the recreation industry, which uses plastic coated cables for outdoor playground equipment, and the electronics industry, which uses miniature wire rope for many types of electronic equipment and communications devices.

Wire ropes are typically made from cold drawn steel wire, stainless steel wire, or galvanized wire. They may also be made from a wide variety of less popular metals, including aluminum, nickel alloy, bronze, copper, and titanium. However, nearly all wire ropes, including control cables, are made from strands of cold drawn carbon steel wires. Stainless steel rope and cables are subbed in for highly corrosive environments. Galvanized cables and galvanized wire rope are popular for their increased strength and durability; these qualities are important to specialized ropes like galvanized aircraft cable.

A core may be composed of metal, fiber or impregnated fiber materials depending on the intended application. Cores may also be another strand of wire called an independent wire rope core (IWRC).

Wire rope, depending on its application, is subject to many standard requirements. Among the most common of these are the standards detailed by OSHA, ASTM International, and ISO. Per your application and industry, you’ll likely have others you need to consider. To get a full list, talk to your service provider.

To determine the safety factor, which is a margin of security against risks, the first step involves knowing the type of load that the rope will be subjected to. The load must consider the shock loads and blowing wind effects. The safety factor is characterized in ratios; typical are 4:1 and 5:1. If a ratio is 5:1, then the tensile strength of a wire rope must be five times of the load it will be subjected to. In some applications, the ratios can go up to 10:1.

By weighing all these factors carefully, the wire rope that you will buy will be safe to use and last considerably. For the best advice and guidance, though, don’t go it alone! Find a great wire rope supplier that you can trust. You’ll know you’ve found the right supplier for you when you talk to one that can not only fulfill your requirements, but shows that they are excited to go the extra mile for you. For a company like this, browse the list near the top of the page.

As the cables play an integral role in the safety of many operations and structures, careful analysis of a wire rope and all of its capabilities and features is vital. Important qualities and physical specifications you must consider include wire rope diameter, breaking strength, resistance to corrosion, difficulty of flattening or crushing, bendability, and average lifespan.

Each of the aforementioned considerations should be compatible with the specific application for which the rope is intended as well as the environment in which such operations are undertaken. Temperature and corrosive environments often require specially coated wire ropes with increased durability.

When you use your industrial wire rope, the first thing to remember is to not exceed your rope’s rated load and breaking strength. If you do not stay within these parameters, you risk causing your rope to weaken or even break.

Rust, kinks, fraying and even carefully performed splicing will all have an impact on the performance of wire ropes. To maintain the integrity of your wire rope assembly, you need to inspect them regularly and clean and lubricate them as needed. In addition, you need to store them out of the wet and cold as much as possible. Also wrap them up properly, so they are not kinked.

Steel that is designed for applications, which require greater safety features with no increase in diameter size and the highest resistance to abrasive wear. This steel is fifteen percent stronger than Improved Plow Steel, and the tensile strength of this grade ranges from 280,000 to 340,000 psi.

A high-carbon steel having a tensile strength of approximately 260,000 psi that is roughly fifteen percent stronger than Plow Steel. Most commercial wires are made from IPS.

A low carbon steel wire of approximately 10,000 psi, which is pliable and capable of repeated stresses from bending around small sheaves. This grade is effective for tillers, guys and sash ropes.

The manner in which the wires are helically wound to form rope. Lay refers specifically to the direction of the helical path of the strands in a wire rope; for example, if the helix of the strands are like the threads of a right-hand screw, the lay is known as a right lay, or right-hand, but if the strands go to the left, it is a left lay, or left-hand.

A classification of wire rope according to its breaking strength. The rank of grades according to increasing breaking strengths is as follows: Iron, Traction, Mild Plow Steel, Plow Steel, Improved Steel, Extra Improved Steel.

The act of fastening a termination to a wire rope through physical deformation of the termination about the rope via a hydraulic press or hammering. The strength is one hundred percent of the wire rope rating.

A grade of rope material that has a tensile strength range of 180,000 to 190,000 psi. Traction steel has great resistance to bending fatigue with a minimum of abrasive force on sheaves and drums, which contributes to its long use in elevators, from which the steel gets its name.

It is composed of wire strands that are braided together. Wire braid is similar to stranded wire. The difference between the two is the fact that stranded wire features strands that are bundled together, rather than braided.

Essential parts of cable assemblies, wire rope assemblies and wire rope slings that assist spliced or swaged rope ends in connecting to other cables and keeping cables and rope from unraveling.

A wire rope cable assembly is a metallic rope consisting of bundles of twisted, spiraled, or bonded wires. While the terms wire rope and cable are often used interchangeably, cables are typically designated as smaller diameter wire ropes, specifically wire ropes with a diameter less than 3/8 inch. Therefore, wire rope cable assemblies are typically utilized for lighter duty applications.

Or cable assemblies, are cables which are composed of many spiraled bundles of wire. These cables are used to support hanging objects, connect objects, pull or lift objects, secure items, and much more.

Wire rope wholesalers can sell an extensive range of wire rope and wire rope accessories at a very affordable rate as well as in bulk. Many of the additional wire rope equipment that wire rope wholesalers provide include: swivel eye pulleys, eye nuts, eye bolts, slip hooks, spring hooks, heavy duty clips, clevis hooks, turnbuckle hooks, anchor shackle pins, s hooks, rigging blocks, and much more. Wire rope fittings will generally improve the versatility of the wire and also prevent fraying.

We were established in 1961 and since then Sahm-Seilklemmen has produced and distributed products complementing the mechanical splicing of wire ropes. Today we are a leading supplier for wire rope end terminations to the rigging industry and in addition to ferrules, we can supply appropriate accessories and the most diverse services.

Our product range includes ferrules made from aluminium, copper, steel and stainless steel, all manufactured exclusively by us in Germany and USA. As a system supplier, we can provide you not only with the correct ferrule for your application, but also a large range of swaging machines, test beds, cutting & annealing machines and differenttools.

Alibaba.com offers a classic collection of steel wire rope splicing machine machines that are powerful, sturdy, and loaded with unique sets of features for more enhanced performances. These modernized machines can contribute to all types of heavy-duty lathe requirements involving metal, leather, etc. These technically-advanced steel wire rope splicing machine are equipped with a broad spectrum of fascinating features that offer superior precision and consistent performance level. Leading steel wire rope splicing machine suppliers and wholesalers on the site offer these premium machines for competitive prices and intriguing deals.

The incredibly powerful steel wire rope splicing machine are not only made up of sturdy materials such as metal and FRP but also very sustainable against all kinds of usages. These machines are ideal for use in the manufacturing industry due to the wide variety of purposes that they cater to. The steel wire rope splicing machine on the site are available in both semi-automatic and automatic versions depending on your requirements. Coming with distinct capacities and max spindle speeds, these steel wire rope splicing machine are well efficient in processing distinct workpieces such as shafts, discs, and rings.

Alibaba.com boasts of multiple steel wire rope splicing machine available in various designs, shapes, colors, and sizes depending on your specific requirements and the models are chosen. These superior-quality steel wire rope splicing machine are ideally used for distinct purposes such as drilling, reaming, tapping, and knurling in accordance with your preferences. The products available here are provided with a centralized automatic lubrication guide to reduce heat distortion and offers better stability. These steel wire rope splicing machine are also equipped with low noise generating technology for soundless performance.

At Alibaba.com, you get to select among distinct steel wire rope splicing machine depending on your specific budget and requirements to purchase these products without having to spend excessive money. These products are ISO, CE certified and are available as OEM orders. Customizing is also an option when you are buying these machines in bulk.

Whether you are looking for waterproof salon capes, salon chemical capes, ordinary hair cutting capes, or even special salon gowns such as customised barber capes, you can likely find them on Alibaba.com! Look out for amazing deals for these haircut hair catches and barber gowns and sell them to the many salons in the market! The beauty industry is constantly growing, and even in the worst of economic times, simple beauty tools, cosmetics, and treatments have continued to retain their market size and even growth. The lucrative market draws many barber and hairdresser salons to open at any one time, and you can in turn cater to this market with wholesale equipment and simple wares such as eye splice wire rope!

If you want to gain a competitive edge, you can even sell cute salon capes or cool barber capes with different colours or logo and design customisations. Some wholesalers that are also OEM manufacturers will allow you to do simple printing and customisations. This is especially if you order in large bulk quantities. You can also cater to the upmarket salons with high end salon capes that may be more sleek, made of more durable or slightly better materials. Look out for these eye splice wire rope wholesale or discuss with suppliers when making your purchases to check!

Steel wire rope splicing machine manufacturer in Mumbai, Steel wire rope splicing machine manufacturer, steel wire rope splicing machine manufacturer in Bhandup, hydraulic cylinder, mumbai hydraulic cylinder manufacturer,hydraulic cylinder manufacturer mumbai, bhandup hydraulic cylinder manufacturer, hydraulic cylinder manufacturer, hydraulic cylinder, hydraulic cylinder manufacturer in Bhandup, hydraulic cylinder manufacturer in Mumbai,

Wire rope tensile testing manufacturer, Wire rope tensile testing manufacturer in Mumbai, wire rope splicing machine manufacturers in Bhandup, Hydraulic Press manufacturer, Hydraulic Presses manufacturer,Hydraulic Presses manufacturer mumbai,Hydraulic Presses manufacturer bhandup,

The above shown 500tonnes 4 tie rods compact wire rope splicing press which can splice up to 30mm wire rope in single bite. This is our new indigenous design for wire rope splicing. The machine is working with satisfactory result in Indian market. This machine is available in two options

This press is fabricated in mid steel of IS 226, 2026 or 449 grade. Duly tested chemically as well as physically before manufacturing. The hydraulic cylinder is manufactured of solid bars and duly packed with high pressure chevron packing seals and dust cover seal. The press is provided with the 10H.P. power pack with & without dual pump system as per client’s requirement.

From our KISWIRE ALUMAR wires rope we offer Bridles, Trawl Warps, markings, hand-splicing and swaging with copper and steel ferrules. We can also offer SS wire rope and dyneema rope options for warps, bridles, stays, just name it.

Located in northwest New Jersey, Jersey Strand and Cable, Inc. has been the most diversified fine diameter strand and cable manufacturer of its magnitude in the world for over 30 years. Our highly skilled and experienced staff provides our customers with the highest-quality standard and custom cable and stranded wire products available, including wire rope. Our innovative product development and unique custom cable manufacturing techniques allow us to provide micro-miniature, miniature, and small diameter wire sizes up to 1/8-inch finished product diameter.

With two state-of-the-art facilities in New Jersey that total over 100,000 square feet, Jersey Strand and Cable, Inc. is fulfilling a need in the industry for specialty cable and wire strand made to exact customer requirements. Our modern testing and development laboratory, along with other peripheral equipment and 200+ production machines, helps ensure that each customer’s product is manufactured and delivered to meet their precise specifications. Spearheaded by a former IBM systems engineer, we have developed a computerized, fully integrated management control system that controls and records all details of the manufacturing process, from RFQs to shipping and invoicing, to ensure that our products are adhering to customer and Jersey Strand and Cable, Inc. specifications. This system is efficient and streamlined and has been a huge factor in our success as the leading manufacturer of strand and cables.

Welcome to AAA Wire Rope & Splicing! If you are looking for high quality lifting and rigging products and first class customer service, you"ve come to the

right place. Since 1962, AAA Wire Rope & Splicing has been serving Southeast Michigan and beyond. Our committment to customer service combined with our daily delivery routes get

Dec. 5, 1967 P. R. BAGBY IRE ROPE LONG SPLICE AND METHOD OF MAKING Filed May 7, 1965 Fxcer-4 l A VEN TOR. PERCY Q. SAC-15V ATTORNEYS United States Patent Ofiice 3,356,397 WIRE ROPE LONG SPLICE AND METHOD OF MAKING Percy R. Bagby, 27844 Conestoga Drive, Rolling Hills, Calif. 90274 Filed May 7, 1965, Ser. No. 453,950 2 Claims. (Cl. 287--78) The present invention relates to a wire rope pressed sleeve splice and to a method of making such a splice.

A common method of splicing wire rope is the long splice in which the two rope ends to be spliced are overlapped a predetermined length and the complemental strands of the rope ends are severed at longitudinallyspaced points. The conventional wire rope includes a core, and this core must be removed in the area adjacent the abutting ends of each pair of complemental strands in order to make the long splice. Each one of the severed ends is secured in position by tucking it into one of the open spaces formed by the removal of the fiber core. As many strand splices are formed as there are strands, and all of these splices constitute the long splice for the wire rope proper.

The prior art procedure for forming the long splice is a tedious and time-consuming operation, particularly that part of the operation in which the rope core is removed and replaced by the tucked ends of each complemental pair of strands in the rope. In addition, the procedure requires highly-skilled, experienced workmen, who may not readily be available when a wire rope unexpectedly parts. Nevertheless, this method of repairing wire rope has been used for many years because of certain advantages. That is, the strength of the wire rope is largely retained, losing only perhaps twenty percent because of the splice. This is apparently due to the appreciable length of the splice area which in a one-inch diameter rope may be 33 feet, with a 33-inch tuck for each of the strands. This length of splice provides a relatively large area of interengagement between the tucked strands and the adjacent strands so that the latter can exert a powerful clamping action and prevent the spliced ends from parting. In addition, the long splice is advantageous because the diameter of the wire rope in the splicearea is not appreciably increased. This in an important consideration in situations where the wire rope is, for example, formed into an endless loop for passage about sheaves and the like.

Accordingly, it is an object of the present invention to provide a method of long splicing the ends of a wire rope without the use of tucks while yet providing substantially the same tensile strength as the conventional, tucked long splice.

Another object of the invention is to provide a method of long splicing which can be quickly and easily accomplished by workmen having only a relatively rudimentary background in wire rope splicing techniques.

Another object of the invention is to provide a method of splicing the ends of a wire rope and which utilizes a plurality of pressed sleeves disposed about the rope. Each sleeve is applied to a strand splice and, by virtue of the number of such strand splices, the diameter and length of each sleeve can be reduced sufiiciently so as not to interfere with movement of the wire rope about sheaves or similar structure.

Another object of the invention is to provide a method of splicing or repairing a single damaged strand of a wire rope by pressing a sleeve about the damaged area.

Still another object of the invention is to provide a method of splicing a wire rope of that type having only circumferentially-arranged strands and no central core.

The present method is not limited to use with any particular length, diameter, number of strands, number 3,356,397 Patented Dec. 5, 1967 of wires per strand, wire arrangement, lay direction, lay type, type of core, or the like, and is applicable to the splicing or repair of wire ropes in general, as will be seen.

FIG. 1 is an elevational view of an exemplary short section of wire rope having six circumferentially arranged strands and a central fiber core, the rope section being shown parted in the middle;

FIG. 3 is a diagrammatic showing of the six strands of the wire rope of FIG. 1, illustrating the longitudinally spaced arrangement of the six splices over the splice length, the proximity of the splices being exaggerated so as to fit the drawing area;

FIG. 4 is an elevational view of a wire rope having six sleeves pressed about the rope to provide six splices longitudinally spaced along the splice length, the proximity of the splices being exaggerated to conform to the showing in FIG. 3;

FIG. 5 is an enlarged longitudinal cross-sectional view of one of the sleeves of FIG. 4, the sleeve being illustraed after it is pressed in position upon the wire rope; an

Referring now to the drawings, there is illustrated a conventional type of wire rope 10 having six outer strands 12, 14, 16, 18, 20 and 22 which are circumferentially arranged about a central fiber core 24. To facilitate the description which follows, the strands 12 through 20 of the rope end located to the left are designated a, while those in the rope end located to the right are designated b, as best viewed in FIGS. 1 and 3.

The wire rope 10 is merely exemplary and it will be understood that various other types of wire rope are equally suited for repair by use of the method and splice of the present invention.

According to the present method, the parted wire rope 10 is spliced by overlapping the rope ends a predetermined length sufficient to closely approach or equal the rated strength of the rope. In a one-inch rope this distance would be aproxirnately 33 feet. This overlap constitutes the splice area, and the individual strands are next severed, unlaid, and relaid in a particular manner toform the long splice. More particularly, ferrules or sleeves 26 are slid or threaded over the rope end to the left, out of the way of the splice area. Next, the strand 12a is unlaid from its rope end approximately the full length of the overlapped portion or splice length and severed. The corresponding strand 12b is then unlaid from its rope end and laid in the open groove formed in the first rope end by the removal of the strand 12a. The strands 12a and 1217 are then in end-abutting relation to define a splice joint. The fiber core 24 is preferably then severed the length of the strand 12a and the remaining core ends are abutted.

One of the sleeves 26 is next arranged about the adjacent pair of strands 12a and 12b and swaged or compressed over these strands. This also compresses the remaining strands of the rope end located on the left, as best seen in FIG. 3, and also compresses the core ends.

The tubular ferrules or sleeves 26 are made of any suitable high-strength material capable of cold flow under pressure into the wire and strand interstices of the rope ends. A sleeve of such material thus becomes an integral part of the rope and is capable of great holding power. Stainless steel is a preferred material because of its high strength and resistance to corrosion. High strength is desirable because it enables the use of relatively short, thin wall sleeves which facilitate movement of the rope about sheaves and the like. Preferably, the sleeve is kept below approximately twice the rope diameter, the sleeve lengthening somewhat during swaging. In this regard, it is noted that the swaging action compresses the wire rope, reducing its diameter somewhat, and also desirably reduces the thickness of the sleeve wall. In the example of the one-inch wire rope, the sleeve thickness is initially on the order of one-quarter inch when using stanless steel, that is, one-fourth the diameter of the wire rope. The finished diameter of the sleeve and rope would therefore be about one and one-eighth inches. Of course, the sleeve length and wall thickness will vary according to the wire rope diameter and type and the particular application for the wire rope.

After the strands 12a and 12b are sleeve-swaged together, the strand 14a is then severed at a point longitudinally spaced from the first splice but within the overlap or splice length. The strand 14b is then unlaid from its rope end and laid in the open groove formed by the removal of the strand 14a from the other rope end. The strand 14b is next severed to locate its severed end adjacent and in abutting relationship to the severed end of the strand 14a.

The operation is repeated with the strands 18a and 18b, the"strands 20a and 20b, and the strands 22a and 22b to provide the six splices illustrated in FIGS. 3 and 4. The six splices are illustrated in rather close proximity to enable their illustration in the space available. In actual practice the splices are located over a relatively long splice length, the length being approximately 33 feet for a one-inch wire rope, for example. Each splice is approximately six lays from the next splice.

The six splices constitute a long splice capable of carrying a load approaching or equaling the full rated strength of the wire rope, each of the sleeves developing approximately one-sixth of the load. Because the strength of the long splice is distributed over the six splice points, the cross section and length of each sleeve 26 can be reduced to a minimum. The use of the sleeves 26 thus provides a relatively quick and inexpensive means for long splicing wire rope. Tucks are completely eliminated. As a matter of fact, the present method can be used for splicing wire rope having no core, whereas the luck of a core greatly complicates present splicing practices since there is then no central core void within which to make tucks.

1. A long splice for the severed strands of a wire rope and adapted for passage about a sheave or the like, said long splice comprising: complemental pairs of the severed strands of the rope ends arranged in abutting relation to define splice joints, the abutting ends of each of said pairs being axially spaced from the abutting ends of the others of said pairs whereby said splice joints are axially spaced along said wire rope;

and a plurality of sleeves pressed upon said rope and about all of said strands, said sleeves being axially spaced to locate a separate one of said sleeves about each of said splice joints, the length of each said sleeve being approximately twice the diameter of said Wire rope, the wall thickness of each said sleeve being not more than approximately one-fourth the diameter of said wire rope, and the axial spacing between adjacent ones of said splice joints being such that, upon passage of said long splice portion of said wire rope about a usual sheave, the section of said wire rope between adjacent said sleeves engages upon the periphery of the sheave.

We are a leading UK midland based Family run manufacturing Company and stockist of Lifting Equipment, Chain slings, Wire Rope Rigging of all ropes including Anti spin and Crane ropes, Hand splicing of all ropes, and 316 quality Marine equipment, including Architectural, industrial applications.... Read More

8613371530291

8613371530291