steel wire rope tensile strength free sample

Wire rope is also known by many other names, such as: wire, multi-strand wire, flexible wire, cable, cord, steelcord, etc. but it is essentially a collection of small filaments wound around each other in a manner that largely retains its shape when bent, crushed and/or tensioned.

It is a system for significantly increasing the strength and flexibility of steel wire and is used in almost every important application we see around us. For example: suspension bridges, tyres, brake and accelerator cables (in cars), high-pressure flexible pipes, lifting and rigging cables, electrical conductors, etc. and it comes in many different forms. Fig 2 shows just a very small sample of available designs.

With minor variations, the generally accepted method for designating a wire rope construction in the industry is by describing it numerically. For example:

"0.43+6x0.37+6x(0.37+6x0.33) HT" refers to a seven strand construction: a single central strand (one central filament diameter 0.43mm and 6 planetary filaments of diameter 0.37mm) and 6 planetary strands (one central filament of diameter 0.37mm and 6 planetary filaments of diameter 0.33mm) all manufactured from high-tensile steel"

Whilst "IWRC" wire ropes offer a slightly greater tensile capacity (≈7%) than those with fabric or polymer fillers, the additional strength does not come from the tensile capacity of the core filaments but from improved dimensional stability under load. And whilst they are also much more resistant to crushing, they are stiffer than fibre core ropes and therefore not recommended for applications where tension occurs under bending.

Warrington (Fig 1) is a parallel lay construction with an outer layer comprising wires of alternating large and small diameters, each outer layer having twice the number of wires as the layer immediately beneath. The benefit of this design is to increase packing and therefore strength density, however, unless the different diameter filaments are of the same strength (unlikely), this construction is limited by the strength of the weakest filaments.

Seale (Figs 1 & 2 6x36) is also a parallel lay construction but with the same number of wires in each wire layer. All the wires in any layer are the same diameter. This is an alternative to the Warrington construction, with similar benefits and disadvantages.

Regular lay constructions are used much more widely (than Lang lay) because they have excellent structural stability and less tendency to unwrap under tension (see Rotating vs Non-Rotating below). However, because it has a knobbly (undulating) surface it will wear both itself and any surface over which it is run much more quickly than Lang lay wire rope.

Lang lay constructions have a flatter surface than regular lay constructions giving them better resistance to wear and bending fatigue, especially when made from flattened (elliptical) filaments. They are, however, much less structurally stable and subject to birdcaging if the wire rope is over-bent or twisted against its wrapped direction.

"Regular Lay", multi-strand constructions are normally subject to slightly less rotation under tension (than Lang lay) due to the opposite helical direction of the filaments (within the strands) and the strands (within the rope), however, you can improve their rotation characteristics still further by;

Fillers (Fig 2) may be fabric, polymer or even smaller diameter filaments (e.g. 6x36). Whilst they contribute little to the tensile strength of wire rope, they can significantly; improve performance under bending (fabric and polymer cores only), reduce axial growth, reduce rotation in rotation-resistant constructions, improve structural stability and increase fatigue life.

This filler material should not be included in strength (tensile capacity) calculations, but must be included in those for axial stiffness (extension). If it is ignored, your calculations will reveal excessive extension as the wire rope collapses.

Suspension bridges tend to be constructed from densely packed, single strand plain "Wire Rope" constructions using large diameter galvanised filaments. Little heed is paid to rotational resistance as strength is paramount and once tensioned, they should remain in that loading condition for their design life.

Lifting & winching normally require wire ropes of good flexibility and fatigue resistance. Therefore they tend to be similar to 6x36 but with fibre core instead of the IWRC in Fig 2

Hosecord is suitable for HPHT flexible pipes as lateral flexibility is generally considered less important than minimal longitudinal growth or maximum tensile strength (per unit cross-sectional area).

Remote operating cables such as hand-brakes and accelerators on cars normally only work in tension so they need to be strong but not necessarily stiff (as they are fully contained in reinforced outer sheaths). These tend to be manufactured from large diameter "TyreCord" or small diameter single-strand "Wire Rope".

Axial stiffness is the linear relationship between axial strain and force that allows us to predict the condition of any material or structure when exposed to a specified tensile force. However, it works only with materials and structures that obey Hooke"s law.

Wire rope does not obey Hooke"s law. Therefore, you cannot accurately predict how much it will stretch for any specified force. This unpredictability applies to any section removed from the same manufactured length of cord and even between cords produced to the same specification but by different manufacturers.

CalQlata has decided that the accuracy of axial stiffness (EA) of wire rope falls outside its own levels of acceptability and therefore does not include it in the wire rope calculator. The extension calculated in the Wire Rope calculator (δLᵀ) is based upon the effect of axial tension on packing density. It is therefore important that core material is not ignored when using the calculator to evaluate this characteristic.

Wire rope does not obey Hooke"s law. Therefore, you cannot accurately predict how much it will twist for any specified torque. This unpredictability applies to any section removed from the same manufactured length of cord and even between cords produced to the same specification but by different manufacturers.

CalQlata has decided that the accuracy of torsional stiffness (GJ) of wire rope falls outside its own levels of acceptability and therefore does not include it in the wire rope calculator.

1) No wire rope calculator, whether dedicated or generic, will accurately predict the properties of any single construction under a wide range of loading conditions

2) No wire rope calculator, whether dedicated or generic, will accurately predict any single property for a range of constructions under a wide range of loading conditions

The only wire rope that can be reliably analysed is that which is used for suspension bridges, because; it comprises a single strand, is very densely packed, has negligible twist, contains filaments of only one diameter, is never subjected to minimum bending and every filament is individually tensioned.

There is a very good reason why manufacturers do not present calculated performance data for construction or design proposals, because even they cannot accurately predict such properties and quite rightly rely on, and publish, test data.

During his time working in the industry, the wire rope calculator"s creator has seen, created and abandoned numerous mathematical models both simple and complex. He has gradually developed his own simplified calculation principle based upon his own experience that still provides him with consistently reliable results of reasonable accuracy.

The purpose of CalQlata"s wire rope calculator is to provide its user with the ability to obtain a reasonable approximation for a generic construction, after which, accurate test data should be sought from the manufacturer for the user"s preferred construction.

The calculation principle in the wire rope calculator is based upon changes in the properties of the wire rope that occur with variations in packing density under tension

Bearing in mind the above limitations CalQlata can provide the following assistance when generating (manipulating) the wire rope calculator"s input data and interpreting its output

Alternatively, for wire rope with multiple filament diameters, you need to find an equivalent diameter with the following proviso; you must enter the minimum filament yield stress (SMYS)

It is expected that apart from fillers, all the material in the wire rope will be identical and therefore have the same density, i.e. using different materials will result in less than "best" performance. However, if such a construction is proposed, you can calculate an equivalent density as follows:

It is expected that apart from fillers, all the material in the wire rope will be identical and therefore have the same tensile modulus, i.e. using different materials will result in less than "best" performance. However, if such a construction is proposed, you should enter the highest tensile modulus.

The wire rope calculator simply adds together the total area of all the filaments and multiplies them by the SMYS entered, which represents a theoretical maximum breaking load that would exist if this load is equally shared across all of the filaments and the lay angles have been arranged to eliminate localised (point) loads between adjacent filaments.

If the wire rope has been properly constructed it is likely that its actual break load will be greater than 80% of this theoretical value. However, given the vagaries of wire rope construction, the actual break load can vary considerably dependent upon a number of factors. CalQlata suggest that the following factors may be used to define the anticipated break load of any given construction:

The axial stiffness and strain under load will be affected by this value, hence the reason why the most reliable (predictable) constructions tend to be minimum [number of] strands and single filament diameter. The Warrington and Seale constructions and combinations thereof tend to provide the highest packing density (but lowest flexibility) and there is little to be gained from using these constructions in more than single stranded wire rope as the benefit of high-packing density will be lost with no gain in flexibility.

The anticipated second moment of area of the wire rope at tension "T" due to deformation but insignificant flattening as it is assumed the wire rope will be bent over a formed (shaped) sheave or roller.

The anticipated tensile modulus of the wire rope at tension "T" due to deformation but insignificant flattening as it is assumed the wire rope will be bent over a formed (shaped) sheave or roller.

It is not advisable to induce this bend radius in operation due to uncertainties associated with wire rope construction, especially for dynamic applications. CalQlata suggests that a similar approach to that used for the break load (Fb) above also be applied here, i.e.:

A change in diameter will occur in all wire rope, irrespective of construction, until packing density has reached a limiting value. The value provided in the wire rope calculator is that which would be expected if the construction remains intact at the applied tension "T"

Unreliability of this value increases with complexity in wire rope due to its longitudinal variability and the increased likelihood of premature failure.

The accuracy of this data will range from about ±1% for wire rope with a single strand and a single filament diameter, up to about ±15% for constructions of similar complexity to OTR cord

A change in length of any wire rope will occur due to the fact that the packing density increases with tension. This is not, however, a linear relationship.

This can be an unreliable value as illustrated by tests carried out (by the author) on two pieces of wire rope supplied by the same well-known manufacturer both of which were cut from the same length, varied in tensile capacity by only 1.5%, but the tensile modulus (and strain at break) varied by 34%. Whilst this was an extreme case, significant variations have been seen in wire rope manufactured by a number of manufacturers.

Whilst the wire rope calculator does not calculate axial stiffness (see Calculation Limitations 9) above), CalQlata can suggest the following rule-of-thumb that will provide reasonable results for most constructions at the applied tension "T":

Whilst the wire rope calculator does not calculate bending stiffness (see Calculation Limitations 8) above), CalQlata can suggest the following rule-of-thumb that will provide reasonable results for most constructions at the applied tension "T":

Low complexity means single strand and single wire diameter. Medium complexity means multi-strand and single wire diameter. High complexity means multi-strand and multiple wire diameters.

In selecting the right steel wire rope, it is important to determine how important the various properties are in relation to the application and then to assign priorities to these. It is also important to be aware of the relevant standards and regulations. If you are in any doubt, please contact our sales consultants or our Technical Department.

The tensile strength of the steel wire rope depends on the rope’s dimensions, the tensile strength of the wires and the construction. The minimum guaranteed tensile strength for the different kinds of rope is shown in the Randers Reb product catalogue.

The design of the steel wire rope does not significantly affect the tensile strength (up to approx. 5%). A change of core from fibre to steel makes slightly more difference (approx. 10%). The greatest change is achieved by changing the dimensions, usage of Compacted steel wire ropes or tensile strength of the wires (see also fig. 28).

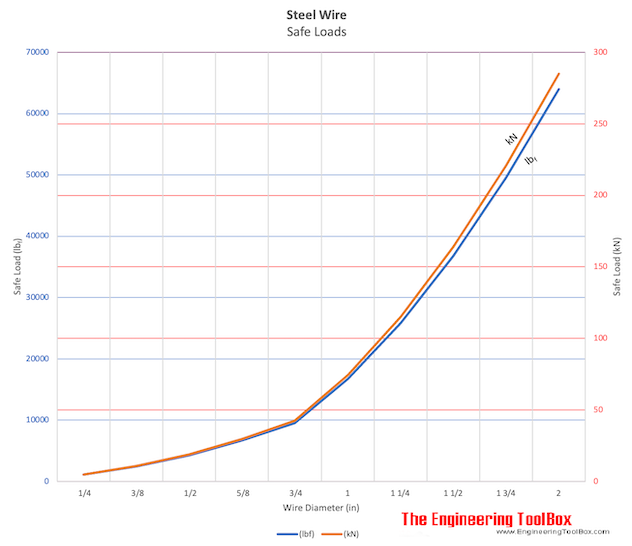

It is often required that the steel wire rope must have a specific SWL value (Safe Working Load), also known as a WLL value (Working Load Limit). This means the steel wire rope’s tensile strength divided by the safety factor required for the relevant application.

Steel wire ropes with thick outer wires (e.g. 6x7 Standard or 6x19 Seale) provide good abrasion resistance. Lang lay ropes provide better abrasion resistance than regular lay steel wire ropes (see also fig. 28). Abrasion resistance can also be increased by using wires with greater tensile strength.

The greater the number of wires in the strand, the greater the bending fatique resistance and flexibility. Lang lay ropes provide better bending fatique resistance than regular lay steel wire ropes. Bending fatique resistance can also be increased by using pre-formed steel wire ropes (see also fig. 28).

Galvanised and rustproof wires provide excellent protection against corrosion. Lubrication with special types of grease or oil will also increase resistance to corrosion. If the steel wire rope is subjected to significant corrosive influences, it is recommended that strands with thick outer wires are used.

Steel wire ropes with fewer wires (e.g. 1x7 Standard and 1x19 Standard) are subject to the least elongation (have the greatest elasticity modulus). This type of steel wire rope is ideally suited for guy ropes, but is not suitable to be run over sheaves/blocks. If only a small degree of elongation when running over sheaves is required, 6x7 or 6x19 steel wire rope should be used, in each case with a steel core or with certain special constructions. For larger dimensions, 6x36 steel wire rope with a steel core can also be used (see also Elongation and Pre-stretching, page 8-28).

Standard 6-lay and 8-lay steel wire ropes will rotate when they hang free and carry a load. Regular lay steel wire rope provides greater resistance to rotation than lang lay steel wire rope. A steel wire rope with a steel core rotates less than a steel wire rope with a fibre core. The type of rope that provides greatest resistance to rotation is, as the name suggests, low-rotation and rotation-resistant steel wire rope (special constructions, see also ”Low-Rotation and Rotation-Resistant Steel Wire Rope”, page 8-10).

A steel core provides better support for the strands than a fibre core, which is why the risk of flattening is less in a steel wire rope with a steel core. Strands with fewer, thicker wires have greater resistance to flattening/crushing. Also, a 6-lay steel wire rope has greater crushing resistance than an 8-lay rope (see also fig. 28).

Vibrations, from wherever they might come, send shock waves through the steel wire rope, which will be absorbed by the steel wire rope at some point, and in some cases they may cause localised destruction of the steel wire rope (not necessarily on the outside). This may, for example, be at places where the steel wire rope comes into contact with a sheaf/block, or enters the drum, and by the end terminals. In general, those steel wire ropes with the greatest flexibility also have the greatest vibration resistance.

Changes in the tension of a steel wire rope, depending on the size and frequency, will reduce the rope’s life expectancy. In general, steel wire ropes with the greatest flexibility can cope better with intermittent loading. Great care should be taken in the use of end terminals or fittings, as their pulsation resistance is equally as important as the selection of the right steel wire rope.

Lang lay steel wire ropes are the ones most suited to running over sheaves and are the most durable, but if they are to be used, three things must be observed:

The reason for Lang lay steel wire ropes’ excellent qualities of abrasion resistance and pliability is that the wires are affected/loaded in a different way and have a larger load-bearing surface than a regular lay steel wire rope (see fig. 29). Note that the largest wearing surface is on the Lang lay steel wire rope.

ASTM A931 is the most efficient testing method; it calculates the measured braking force, yield strength, elongation, and modulus of elasticity. Tension testing should be done on new wire ropes in most cases. Individual wire strengths can be reduced by abrasion and nicking when the wire rope is used in any application, reducing the wire rope’s strength. Damage to the outside wires reduces the maximum tensile strength achievable during tension testing.

ASTM A931 method is based on measuring the actual rope diameter and sample length then zeroing is completed. For this purpose, the maximum rate of loading should be 0.032 in. per minute. Reduction from a full reading occurs when the load is applied. When no more force can be used, the measured breaking force is attained.

Wire rope and cable are each considered a “machine”. The configuration and method of manufacture combined with the proper selection of material when designed for a specific purpose enables a wire rope or cable to transmit forces, motion and energy in some predetermined manner and to some desired end.

Two or more wires concentrically laid around a center wire is called a strand. It may consist of one or more layers. Typically, the number of wires in a strand is 7, 19 or 37. A group of strands laid around a core would be called a cable or wire rope. In terms of product designation, 7 strands with 19 wires in each strand would be a 7×19 cable: 7 strands with 7 wires in each strand would be a 7×7 cable.

Materials Different applications for wire rope present varying demands for strength, abrasion and corrosion resistance. In order to meet these requirements, wire rope is produced in a number of different materials.

Stainless Steel This is used where corrosion is a prime factor and the cost increase warrants its use. The 18% chromium, 8% nickel alloy known as type 302 is the most common grade accepted due to both corrosion resistance and high strength. Other types frequently used in wire rope are 304, 305, 316 and 321, each having its specific advantage over the other. Type 305 is used where non-magnetic properties are required, however, there is a slight loss of strength.

Galvanized Carbon Steel This is used where strength is a prime factor and corrosion resistance is not great enough to require the use of stainless steel. The lower cost is usually a consideration in the selection of galvanized carbon steel. Wires used in these wire ropes are individually coated with a layer of zinc which offers a good measure of protection from corrosive elements.

Cable Construction The greater the number of wires in a strand or cable of a given diameter, the more flexibility it has. A 1×7 or a 1×19 strand, having 7 and 19 wires respectively, is used principally as a fixed member, as a straight linkage, or where flexing is minimal.

Selecting Wire Rope When selecting a wire rope to give the best service, there are four requirements which should be given consideration. A proper choice is made by correctly estimating the relative importance of these requirements and selecting a rope which has the qualities best suited to withstand the effects of continued use. The rope should possess:Strength sufficient to take care of the maximum load that may be applied, with a proper safety factor.

Strength Wire rope in service is subjected to several kinds of stresses. The stresses most frequently encountered are direct tension, stress due to acceleration, stress due to sudden or shock loads, stress due to bending, and stress resulting from several forces acting at one time. For the most part, these stresses can be converted into terms of simple tension, and a rope of approximately the correct strength can be chosen. As the strength of a wire rope is determined by its, size, grade and construction, these three factors should be considered.

Safety Factors The safety factor is the ratio of the strength of the rope to the working load. A wire rope with a strength of 10,000 pounds and a total working load of 2,000 pounds would be operating with a safety factor of five.

It is not possible to set safety factors for the various types of wire rope using equipment, as this factor can vary with conditions on individual units of equipment.

The proper safety factor depends not only on the loads applied, but also on the speed of operation, shock load applied, the type of fittings used for securing the rope ends, the acceleration and deceleration, the length of rope, the number, size and location of sheaves and drums, the factors causing abrasion and corrosion and the facilities for inspection.

Fatigue Fatigue failure of the wires in a wire rope is the result of the propagation of small cracks under repeated applications of bending loads. It occurs when ropes operate over comparatively small sheaves or drums. The repeated bending of the individual wires, as the rope bends when passing over the sheaves or drums, and the straightening of the individual wires, as the rope leaves the sheaves or drums, causing fatigue. The effect of fatigue on wires is illustrated by bending a wire repeatedly back and forth until it breaks.

The best means of preventing early fatigue of wire ropes is to use sheaves and drums of adequate size. To increase the resistance to fatigue, a rope of more flexible construction should be used, as increased flexibility is secured through the use of smaller wires.

Abrasive Wear The ability of a wire rope to withstand abrasion is determined by the size, the carbon and manganese content, the heat treatment of the outer wires and the construction of the rope. The larger outer wires of the less flexible constructions are better able to withstand abrasion than the finer outer wires of the more flexible ropes. The higher carbon and manganese content and the heat treatment used in producing wire for the stronger ropes, make the higher grade ropes better able to withstand abrasive wear than the lower grade ropes.

Effects of Bending All wire ropes, except stationary ropes used as guys or supports, are subjected to bending around sheaves or drums. The service obtained from wire ropes is, to a large extent, dependent upon the proper choice and location of the sheaves and drums about which it operates.

A wire rope may be considered a machine in which the individual elements (wires and strands) slide upon each other when the rope is bent. Therefore, as a prerequisite to the satisfactory operation of wire rope over sheaves and drums, the rope must be properly lubricated.

Loss of strength due to bending is caused by the inability of the individual strands and wires to adjust themselves to their changed position when the rope is bent. Tests made by the National Institute of Standards and Technology show that the rope strength decreases in a marked degree as the sheave diameter grows smaller with respect to the diameter of the rope. The loss of strength due to bending wire ropes over the sheaves found in common use will not exceed 6% and will usually be about 4%.

The bending of a wire rope is accompanied by readjustment in the positions of the strands and wires and results in actual bending of the wires. Repetitive flexing of the wires develops bending loads which, even though well within the elastic limit of the wires, set up points of stress concentration.

The fatigue effect of bending appears in the form of small cracks in the wires at these over-stressed foci. These cracks propagate under repeated stress cycles, until the remaining sound metal is inadequate to withstand the bending load. This results in broken wires showing no apparent contraction of cross section.

Experience has established the fact that from the service view-point, a very definite relationship exists between the size of the individual outer wires of a wire rope and the size of the sheave or drum about which it operates. Sheaves and drums smaller than 200 times the diameter of the outer wires will cause permanent set in a heavily loaded rope. Good practice requires the use of sheaves and drums with diameters 800 times the diameter of the outer wires in the rope for heavily loaded fast-moving ropes.

It is impossible to give a definite minimum size of sheave or drum about which a wire rope will operate with satisfactory results, because of the other factors affecting the useful life of the rope. If the loads are light or the speed slow, smaller sheaves and drums can be used without causing early fatigue of the wires than if the loads are heavy or the speed is fast. Reverse bends, where a rope is bent in one direction and then in the opposite direction, cause excessive fatigue and should be avoided whenever possible. When a reverse bend is necessary larger sheaves are required than would be the case if the rope were bent in one direction only.

Stretch of Wire Rope The stretch of a wire rope under load is the result of two components: the structural stretch and the elastic stretch. Structural stretch of wire rope is caused by the lengthening of the rope lay, compression of the core and adjustment of the wires and strands to the load placed upon the wire rope. The elastic stretch is caused by elongation of the wires.

The structural stretch varies with the size of core, the lengths of lays and the construction of the rope. This stretch also varies with the loads imposed and the amount of bending to which the rope is subjected. For estimating this stretch the value of one-half percent, or .005 times the length of the rope under load, gives an approximate figure. If loads are light, one-quarter percent or .0025 times the rope length may be used. With heavy loads, this stretch may approach one percent, or .01 times the rope length.

The elastic stretch of a wire rope is directly proportional to the load and the length of rope under load, and inversely proportional to the metallic area and modulus of elasticity. This applies only to loads that do not exceed the elastic limit of a wire rope. The elastic limit of stainless steel wire rope is approximately 60% of its breaking strength and for galvanized ropes it is approximately 50%.

Preformed Wire Ropes Preformed ropes differ from the standard, or non-preformed ropes, in that the individual wires in the strands and the strands in the rope are preformed, or pre-shaped to their proper shape before they are assembled in the finished rope.

This, in turn, results in preformed wire ropes having the following characteristics:They can be cut without the seizings necessary to retain the rope structure of non-preformed ropes.

They are substantially free from liveliness and twisting tendencies. This makes installation and handling easier, and lessens the likelihood of damage to the rope from kinking or fouling. Preforming permits the more general use of Lang lay and wire core constructions.

Removal of internal stresses increase resistance to fatigue from bending. This results in increased service where ability to withstand bending is the important requirement. It also permits the use of ropes with larger outer wires, when increased wear resistance is desired.

Outer wires will wear thinner before breaking, and broken wire ends will not protrude from the rope to injure worker’s hands, to nick and distort adjacent wires, or to wear sheaves and drums. Because of the fact that broken wire ends do not porcupine, they are not as noticeable as they are in non-preformed ropes. This necessitates the use of greater care when inspecting worn preformed ropes, to determine their true condition.

Lifting operations are performed in every area of the iron and steel plant. In these operations, safety is a critical factor, which requires reliable materials. Steel wire ropes are a key element of the lifting operations, since everything depends on their performance.

Steel wire rope is also known as steel cable. It is a type of rope which consists of several strands of steel wire laid (twisted) into a helix. It is a preferred lifting device for several reasons. Its unique design consists of multiple steel wires which form individual strands laid in a helical pattern around a core. This structure provides strength, flexibility, and the ability to handle bending stresses. Different configurations of the material, wire, and strand structure provide different benefits for the specific lifting applications. These benefits include strength, flexibility, abrasion resistance, crushing resistance, fatigue resistance, corrosion resistance, and rotation resistance.

Wires are the basic building blocks of a wire rope. They lay around a ‘centre’ in a specified pattern in one or more layers to form a strand. The strands are helically laid together around a centre, which is typically some type of core, to form a wire rope. The strands provide all the tensile strength to the wire rope. Properties like fatigue resistance and resistance to abrasion are directly affected by the design of strands. Selection of the proper wire rope for a lifting application needs some careful considerations.

Modern wire rope was invented by the German mining engineer Wilhelm Albert in the years between 1831 and 1834 for use in the mining operations. It was quickly accepted because it proved superior to metal chains and ropes made of hemp which were used earlier. Wilhelm Albert’s first ropes consisted of three strands with each strand having four wires. With the change in the needs, the designs of the wire ropes have also undergone major changes with respect to the core, overlay, and the weight requirement etc.

A wire rope is, in reality, a very complicated machine. It consists of a number of precise moving parts, designed and manufactured to bear a definite relation to one another. In fact, some wire ropes contain more moving parts than many complicated mechanisms. For example, a six strand wire rope laid around and independent wire rope core, each strand and core with 49 wires, contains a total of 343 individual wires. All these wires are to work together and move with respect to one another if the rope is to have the flexibility necessary for successful operation. The wires in a wire rope move independently and together in a very complicated pattern around the core as the rope bends. Clearances between wires and strands are balanced when a rope is designed so that proper bearing clearances exist to permit internal movement and adjustment of wires and strands when the rope has to bend. These clearances vary as bending occurs, but are of the same range as the clearances found in the automobile engine bearings.

The primary factor in wire rope performance is selecting a wire rope with the best combination of properties for the job. The service life of that rope can be greatly extended by following a planned program of installation, operation, maintenance, and inspection to avoid its failure. The appropriate time to replace a wire rope in service is frequently determined by counting the number of broken wires in the length of one rope lay.

The terms which help to define the construction and properties of the wire rope are length, size, pre-formed or non pre-formed, direction and type of lay, finish of wires, grade of rope, and type of core. The length of the wire rope is the total number of meters (cut to size) when wrapped around the spool and the size is the specified nominal diameter of the wire rope and is specified in millimeters.

There are three basic components which make up the design of a steel wire rope. These are (i) wires made from steel which form a singular strand, (ii) multi- wire strands laid around a core in a helical pattern, and (iii) the core.

Wires– Wires are the basic and smallest component of the wire rope and they make up the individual strands in the rope. Wires can be made from a variety of metal materials including steel, iron, stainless steel, Monel, and bronze but in the steel wire rope they are made from steel. The wires can be manufactured to predetermined physical properties and sizes and in a variety of grades which relate to the strength, resistance to wear, fatigue resistance, corrosion resistance, and curve of the wire. A pre-determined number of finished wires are helically laid together in a uniform geometric pattern to form a strand. The process is carried out with precision and exactness to form a strand of correct size and characteristics. The wires themselves can be coated but are most commonly available in a ‘bright’ or uncoated finish.

Strands – Strands of the wire rope consist of two or more wires arranged and twisted in a specific arrangement. The individual strands are then laid in a helical pattern around the core of the wire rope. Strands made of larger diameter wires are more resistant to abrasion, while strands made of smaller diameter wires are more flexible. Strands are designed with various combinations of wires and wire sizes to produce the desired resistance to fatigue and abrasion. Normally, a small number of large wires are more abrasion resistant and less fatigue resistant than a large number of small wires. The required numbers of suitably fabricated strands are laid symmetrical with a definite length of lay around a core to form the finished wire rope.

The core – The core of a wire rope is the foundation of a wire rope. It runs through the centre of the rope. Its primary function is to support the wire strands in the rope and to maintain them in their correct relative positions during the operating life of the wire rope. The core supports the strands and helps to maintain their relative position under loading and bending stresses. Cores can be made from a number of different materials including natural or synthetic fibres and steel but in the steel wire rope, the core is made from steel. Steel core provides more support than the fibre core. Steel cores resist crushing, are more resistant to heat, reduce the amount of stretch, and increase the strength of the wire rope.

Steel cores are normally of two types. The first type is wire strand core (WSC). This type of the core is used in case of small diameter ropes and in some rotation resistant wire ropes. The second type of steel core is independent wire rope core (IWRC). The IWRC can be made in a separate operation or during the closing operation of the wire rope. IWRC normally provides increased strength to the rope, greater resistance to crushing, and resistance to excessive heat. IWRC increases the strength of the wire rope by 7 %, increases its weight by 10 %, and decreases the flexibility slightly. These ropes are recommended for use on installations where severe loads are placed on ropes running over sheaves or wound on drums. The wire core can also have a plastic coating.

Cores made of compacted strands have the additional designation (K). An independent wire core made of compacted strands is hence called IWRC (K). A rope closed in a single operation and made out of compacted strands both in the core and the outer strands is called PWRC (K).

Wire ropes and their free rope end rotate to a greater or lesser extent around its longitudinal axis under the influence of tension. Wire ropes having a core lay direction opposite to the lay direction of the outer strands and 3-strand or 4-strand regular lay wire ropes rotate considerably less than wire ropes with the same lay direction of the wire core and the outer strands and wire ropes with fibre cores.

According to VDI 2358, a wire rope is semi rotation-resistant when ‘the wire rope which turns around its longitudinal axis when subjected to unguided load and / or hardly transmits a torque to the attachment at the end in the event of guided rope ends’. According to ISO 21669 and DIN EN 12385-3 ‘a rope is considered to be semi rotation resistant if it rotates at least once and at most four times around its axis at a length of 1,000 x d under a load of 20 % of the minimum breaking force. In terms of rotation angle, the defined limits are between 360 deg and 1,440 deg’.

According to the regulation of VDI 2358, a wire rope is rotation-resistant, when ‘the wire rope, which hardly turns around its longitudinal axis when subjected to unguided load and / or hardly transmits a torque to the attachment at the end in the event of guided rope ends’. According to ISO 21669 and DIN EN 12385-3 ‘a rope is considered to be rotation resistant if it rotates around its axis at most once at a length of 1,000 x d under a load of 20 % of the minimum breaking force. The rotation can be exhibited here in rope closing or rope opening sense. For the rotation angle, this implies between -360 deg and 360 deg’.

A distinction is made between the nominal rope diameter and the actual rope diameter. The nominal wire rope diameter is an agreed theoretical value for the diameter of the smallest circle enclosing the outer strands. The effective diameter of the wire rope, also called actual rope diameter, is the diameter of the smallest circle enclosing all outer strands, as measured on the rope itself. The tolerance range for the effective rope diameter is specified in related national and international standards. In order to define the correct effective rope diameter, the correct measuring device has to be used. The measurement is to be strictly done over the round ends (circumscribed circle of the rope). If the measurement is done in the strand valleys, the result is inaccurate. For ropes with an uneven number of outer strands, it is important that the measuring surface covers several strands. Fig 1 shows components of a wire rope and measurement of its diameter.

Wire ropes are identified by a nomenclature which is referenced to (i) the number of strands in the rope, (ii) the number (nominal or exact) and arrangement of wires in each strand and (iii) a descriptive word or letter indicating the type of construction i.e. the geometric arrangement of wires.

In the stranding process, initially straight wires are forced into a helical or double-helical form. Hence, the wires in a rope are always under tension, even in an unloaded rope. Such a rope is to be sealed very tightly left and right of the joint before cutting the rope since otherwise the free ends of the wires spring open.

By using a ‘pre-forming tool’, the wires and strands can be heavily plastically deformed during the stranding, so they are laying nearly without tension in the rope, the rope now is pre-formed. The rope producers consider such ropes to be ‘dead’. Pre-formed ropes can be cut much easier, also secured by seizings of course, than non pre-formed ropes.

The wire rope lay is the helix or spiral of the wires and strands. The word ‘lay’ has got three meanings in the rope design. The first two meanings are descriptive of the wire and strand position in the rope. The first meaning describes the direction in which strands rotate around in the wire rope i.e. right lay or left lay. If the strands rotate around the wire rope in a clock wise direction, the rope is said to be right lay. When the strands rotate in the counter-clockwise direction, the wire rope is left lay. The second meaning shows the relationship between the direction strands lay in the wire rope and the direction wire lay in the strands. The third meaning is a length measurement used in manufacturing and inspection. In the third meaning it is the linear length along the rope that a strand makes one complete spiral around the rope core. Lay length is measured in straight line parallel to the centre line of the rope, not by following the path of the strand.

Direction and type of lay refer to the way the wires are laid to form a strand (either right or left) and how the strands are laid around the core (regular lay, lang lay, or alternate lay). Fig 2 shows direction and types of wire rope lay.

Regular lay in the wire rope denotes that the wires are twisted in one direction, and the strand in opposite direction to form the rope. The wires in regular lay line up with the axis of the rope. The direction of the wire lay in the strand is opposite to the direction of the strand lay. Regular lay wire ropes are distinguished between right hand ordinary lay (RHOL) and left hand ordinary lay (LHOL). Due to the difference in direction between the wires and strand, regular lay ropes are less likely to untwist or kink. Regular lay roes are also less subject to failure from crushing and distortion because of shorter length of exposed outer wires. Regular lay ropes are naturally more rotation-resistant, and also spool better in a drum than lang lay ropes. The advantages of regular lay ropes are (i) better structural stability, (ii) higher number of broken wires is allowed, and (iii) identification of broken wires is easier.

Lang lay in the wire rope is the opposite. The wires form an angle with the axis of the rope. The wire lay and strand lay around the core in the same direction. The wires and strands appear to run at a diagonal to the centre line of the rope. Lang lay wire ropes are distinguished between left hand lang lay (LHLL) and right hand lang lay (RHLL). Due to the longer length of the exposed outer wires, lang lay ropes have greater flexibility. These ropes are more likely to twist, kink, and crush. Lang lay ropes have a greater fatigue-resistance and are more resistant to abrasion. The advantages of lang lay ropes are (i) better contact in the groove of the sheaves, (ii) superior resistance to wear, (iii) longer lifetime in case of high dead loads, and (iv) considerably better spooling behaviour on a multi-layer drum

As regards lay direction of a wire rope, a distinction is made between right hand and left hand lay ropes. The lay direction is left hand, when the strands (moving away from the beholder) are rotated counter-clockwise. The lay direction of a rope is right hand, when its strands (moving away from the beholder) are rotated clockwise. The lay direction of a rope is frequently given by a capital S for the left hand lay rope and by a capital Z for the right hand lay rope. Others frequently use abbreviations are RH for right hand lay ropes and LH for left hand lay ropes.

One strand is normally made up of seven to several tens of wires with similar, or differing, diameters in single or multi-layers. In the method where the wires are positioned to form more than two layers, there is the cross lay where the wires of each layer are in the same lay angle, and the parallel lay where one process is used to lay the wires so that the wires of each layer are of the same pitch. For strands of the same diameter, the more is the number of wires, the smaller is the diameter of each wire and the greater is the flexibility of the strand. However, conversely, the rope becomes inferior in its wear resistance nature and its shape deformation nature.

Cross lay – The cross lay is referred to as the point contact lay, as each wire is in contact with each other. The laying of the wires is carried out in such a way that the lay angle is almost equal for each layer of wire of the same diameter. The length of the wires in each layer is also to be the same and the wires of each layer are in contact with each other. Hence, the tension stress which works on the wire becomes uniform, but the bending stress due to the contact points is added and so the fatigue resistance is not as great.

Parallel lay – Parallel lay is also referred to as equal lay. It is also called one operation lay from the number of stranding processes and also as linear contact lay as each wire is in contact with each other. In the parallel lay, the wires of each layer are positioned in such a way that there is no space between them so that the upper layer wires fit neatly into the groove of the lower wires of the strand. For this, wires of differing diameters are positioned at the same time so that each wire layer has the same pitch and is in contact with each other. Hence, parallel lay rope differs from the cross lay rope, although the lay angle of each wire layer and the length of the wires are not uniform, as each wire is in contact with each other, it is superior in its fatigue resistance nature.

The fill factor of a rope is defined as the ratio of the metallic cross section of the rope (or a simplified calculation of the sum of the single wire cross sections) related to the nominal rope diameter. The fill factor specifies the amount of space the wires and strands take in the rope. The fill factors of the most common ropes are between 0.46 and 0.75. This means, that the amount of steel in the rope volume is around 46 % to 75 %. Wire ropes with a wire rope steel core have higher fill factors than ropes with a fibre core. The fill factor of the strand is the proportion of the metallic cross sections at the metal cross section area of the minimum circumscribed circle. Wire ropes which are made of compacted strands have higher fill factors than ropes of un-compacted strands. By compacting and rotary swaging of the rope itself the fill factor can further be increased.

The basic parallel lay are basically of five types namely (i) single layer type, (ii) Seale type, (iii) Warrington type, (iv) filler type with filler wire, and (v) combined pattern type. Fig 3 shows types of basic parallel lay wire rope.

The single layer type wire rope has the basic strand construction of having wires of the same size wound around a centre. The most common example of the single layer construction is a 7 wire strand. It has a single-wire centre with six wires of the same diameter around it.

The Seale type wire rope construction has two layers of wires around a centre with the same number of wires in each layer. All wires in each layer are of the same diameter. The strand is designed so that the large outer wires rest in the valleys between the smaller inner wires. In Seale type, the number of wires of each layer is shown as 1+n+n and the number of wires of the inner and outer layers is the same. The wires of the outer layer fit completely into the grooves of the inner layer wires. The outer layer wires of the Seale type rope is thicker when compared to other parallel lays and so it is superior, particular in its wear resistance and is mainly used for elevators.

The Warrington type wire rope construction has two layers of wires around a centre with one diameter of wire in the inner layer, and two diameters of wire alternating large and small in the outer layer. The larger outer-layer wires rest in the valleys, and the smaller ones on the crowns, of the inner layer. In the Warrington type, the number of wires of each layer is shown as 1+n+(n+n) and there are two types of wires for the outer layers, one being large and the other being small. The number of wires of the outer layer is double that of the inner layer and through a combination of the inner and outer layers the spaces between the wires are kept small. The Warrington type rope is not being used to a great extent these days.

The filler wire type wire rope construction has two layers of uniform-size wire around a centre with the inner layer having half the number of wires as the outer layer. Small filler wires, equal in number to the inner layer, are laid in valleys of the inner layer. In the filler type (with filler wire), the number of wires of each layer is shown as 1+n+(n)+2n and the number of wires of the outer layers is double that of the inner layer. The inner wires and the same number of thin filler wires are used to fill the spaces in the inner and outer layers. This filler type rope has a good balance between the flexibility, fatigue resistance, and wear resistance and has the widest range of use among parallel lay ropes.

The combined patterns type wire rope construction has strand which is formed in a single operation using two or more of the above constructions. As an example, the wire rope can have a Seale construction in its first two layers and a Warrington construction in the third layer, and a Seale construction in the outer layer. The combined pattern type of wire rope construction is very superior in its fatigue resistance nature. It also has high flexibility and is superior in its wear resistance and hence has a wide range of uses.

Flat type – In flat type wire rope, the strands are combined in such a way that the outer circumference of the rope is flat in shape. This rope has a smooth surface and hence the surface pressure due to coming into contact with the groove of the drum and the sheave is smaller than that of ordinary ropes. It is also superior in its wear resistance nature. In general, the triangular strand and the shell strand are used the most. The flat strand is also being used at certain places.

Lubrication is applied during the manufacturing process of the steel wire rope and penetrates all the way to the core. Wire rope lubrication has two primary benefits namely (i) it reduces friction as the individual wires and strands move over each other, and (ii) it provides corrosion protection and lubrication in the core, inside wires, and outside surface.

Lubrication of wire ropes is a difficult proposition, regardless of the construction and composition. Wire rope lubricants have two principal functions namely (i) to reduce friction as the individual wires move over each other, and (ii) to provide corrosion protection and lubrication in the core and inside wires and on the exterior surfaces.

There are two types of wire rope lubricants namely (i) penetrating and (ii) coating. Penetrating lubricants contain a petroleum solvent which carries the lubricant into the core of the wire rope then evaporates, leaving behind a heavy lubricating film to protect and lubricate each strand. Coating lubricants penetrate slightly, sealing the outside of the cable from moisture and reducing wear and fretting corrosion from contact with external bodies. Both types of wire rope lubricants are used. But because most wire ropes fail from the inside, it is important to make sure that the centre core receives sufficient lubricant.

A combination approach in which a penetrating lubricant is used to saturate the core, followed with a coating to seal and protect the outer surface, is normally recommended. Wire rope lubricants can be petrolatum, asphaltic, grease, petroleum oils or vegetable oil-based. Petrolatum compounds, with the proper additives, provide excellent corrosion and water resistance. In addition, petrolatum compounds are translucent, allowing the technician to perform visible inspection. Petrolatum lubricants can drip-off at higher temperatures but maintain their consistency well under cold temperature conditions. Asphaltic compounds normally dry to a very dark hardened surface, which makes inspection difficult. They adhere well for extended long-term storage but crack and become brittle in cold climates. Asphaltic compounds are of coating type.

Various types of greases are used for wire rope lubrication. These are the coating types which penetrate partially but normally do not saturate the rope core. Common grease thickeners include sodium, lithium, lithium complex, and aluminum complex soaps. Greases used for this application normally have a soft semi-fluid consistency. They coat and achieve partial penetration if applied with pressure lubricators. Petroleum and vegetable oils penetrate best and are the easiest to apply since proper additive design of these penetrating types gives them excellent wear and corrosion resistance. The fluid property of oil type lubricants helps to wash the rope to remove abrasive external contaminants.

Wire ropes are lubricated during the manufacturing process. In case of wire rope with a steel core, the lubricant (both oil and grease type) is pumped in a stream just ahead of the die which twists the wires into a strand. This allows complete coverage of all the wires.

After the cable is put into service, re-lubrication is required due to loss of the original lubricant from loading, bending, and stretching of the cable. Field re-lubrication is necessary to minimize corrosion, and to protect and preserve the rope core and wires, and thus extend the service life of the wire rope.

The term ‘bright’ refers to a wire rope manufactured with no protective coating or finish other than lubricant can provide. These wire ropes are normally manufactured from high carbon steel. The chemistry of the steel used and the practice employed in drawing the wire are varied to achieve the ultimate combination of tensile strength, fatigue resistance, and wear resistance in the finished wire rope.

Bright finish is suitable for most of the applications. Galvanized finish is done for corrosive environments. Galvanized finished wire ropes have improved corrosion resistance. These wire ropes are produced from the drawn wires which have been galvanized. Wire ropes are normally produced in three grades as given below.Improved plow steel (IPS) -This steel is strong, tough, durable steel which combines good strength with high resistance to fatigue. Its minimum tensile strength varies from 154 kg/sq mm to 178 kg/sq mm depending upon wire diameter.

Extra-extra improved plow steel (EEIP) – It is a grade where a high breaking strength is needed. This grade typically provides a breaking strength which is a minimum of 10 % higher than the EIP grade.

Breaking strength – The calculated breaking strength of a steel wire rope is defined as the metallic cross-section of a steel wire rope (the sum of the individual cross sections of all the wires making up the rope) multiplied by the nominal tensile strength of the steel wire rope. The minimum breaking strength of the steel wire rope is the calculated breaking strength of the rope multiplied by the spin factor. The actual breaking strength of a steel wire rope is the breaking strength of the rope as determined in a breaking test. A new steel wire rope is required to achieve an actual breaking strength equal to or higher than the minimum breaking strength.

The breaking strength of a steel wire rope can be increased by increasing the metallic area of the rope (e.g. by using strands with higher fill factors, by compacting the strands or by swaging the rope), by increasing the tensile strengths of the individual wires, or by increasing the spin factor of the rope. This can also be achieved by improving the contact conditions between the rope elements by using a plastic infill.

Bending fatigue resistance – The bending fatigue resistance of steel wire rope is defined as the number of bending cycles a rope can achieve in a bending fatigue test under defined parameters (e.g. running over sheaves with a defined diameter and a pre-determined line pull corresponding to the minimum braking load of the steel wire rope). The bending fatigue resistance of the steel wire rope increases with increasing D/d ratio (sheave diameter (D) / nominal rope diameter (d)), and by reducing the line pull.

The bending fatigue resistance of a steel wire rope can be increased by increasing the contact area between the steel wire rope and the sheave and by increasing the contact conditions between the rope elements, by adding a plastic layer between the IWRC, and the outer strands. Due to the larger contact area between the ropes and the sheaves and due to the increased flexibility, 8- strand wire ropes are more resistant to bending fatigue than 6- strand wire ropes of a similar design.

Flexibility – The flexibility of a wire rope is a measure of how easily the rope allows itself to bend around a given diameter. The flexibility of the wire rope is among other things dependent on the line pull. The flexibility of an unloaded rope can be measured by the sag of a rope under its own weight.

The flexibility of a steel wire rope typically increases with an increasing number of strands and wires in the rope. The flexibility is also influenced by the lay lengths of the strands, of the rope core and the rope, as well as by the gaps between wires and strands.

If a rope is not flexible enough, it is forced to bend around a sheave of a given diameter, which reduces the bending fatigue life of the rope. It also forced to bend around a drum of a given diameter. Spooling problems can be a consequence.

Efficiency factor – When running over a sheave, a wire rope has to be converted from a straight condition into a bent condition at the point when the rope runs onto the sheave and has to be converted again from the bent into the straight condition when it runs off the sheave. Also the bearing has to be turned. In doing so, the friction forces in the rope as well as the friction forces in the bearing have to be overcome. This leads to a change of the rope force.

One describes the relationship of the rope force on both sides of the sheave as the efficiency factor and accepts that this numerical value also takes into account the friction losses of the bearing. When measuring the efficiency factor of a wire rope, the loss of the line pull while the rope is running over the sheave is measured. An efficiency factor of 0.98, or alternatively a strength loss of 2 %, is normally assumed for wire ropes.

Wear resistance – Changes in line pull cause changes in the rope length. Rope sections lying on a sheave or on the first wraps of a drum can only adapt to the changing line pull by sliding over the groove surface of the sheave or the drum when the length change occurs. This relative motion causes abrasion (both in the grooves and on the special wire rope). Using less and hence larger outer wires can increase the wear resistance of the rope. The pressure between the sheave and the rope can be minimized due to the optimized contact areas and hence also the wear of the rope can be minimized. The wear resistance can also be influenced by the metallurgy of the outer strands.

Modulus of elasticity – The modulus of elasticity of a material is defined as the proportional factor between load and elongation. The modulus of elasticity is a material property. Besides the elastic properties of the wire material used, the modulus of elasticity of wire ropes is dependent on the rope geometry and the load history of the rope. Since this is not a material property, ISO 12076 recommends calling this factor as the ‘rope modulus’. Fig 4 shows the deformation behaviour of wire rope.

Fig 4(a) shows a load-elongation diagram of a wire. Here the modulus of elasticity can be determined as the gradient of the curve in the linear area. Fig 4(b) shows a load-elongation diagram of a strand. As the strand consists of several wires of different lengths and different lay lengths or different lay angles, here the shorter and less elastic elements get loaded first. For this reason the curve is not linear in the lower area. The graph only gets linear, when all the wires in the strand bear the load together.

Fig 4(c) shows the load-elongation diagram of a rope. Here also a non-linear correlation is found in the lower area between load and elongation. Here again the non-linearity can be explained by the overload of the shorter and the less elastic rope elements. The load-elongation diagram is linear in the area in which all elements share the load and plastically deform. As a result of settling effects, the modulus of elasticity of wire ropes increases over the life time. The biggest part of this change happens with the first loading of the rope. Later the modulus of elasticity varies only very slightly. For this reason a new wire rope is always to be loaded and relived multiple times before measuring the modulus of elasticity. The determination of the modulus of elasticity is described in ISO 12076.

Radial stability – The radial stability of a wire rope is a function of the rope geometry and the line pull. The radial stability of a steel wire rope typically reduces with an increasing number of rope elements. It also increases with the increase of the line pull. Ropes with insufficient radial stability are not suitable for multi-layer spooling.

Structural stability – It is necessary that a rope maintains its structure during its working life. Adding a plastic layer between the IWRC and the outer strands can increase the stability of the rope structure. The plastic fixes the position of the rope elements relative to each other.

Diameter reduction of a special wire rope – With increasing line pull, a special wire rope not only gets longer, but it also reduces in diameter. A great part of that diameter reduction is reversible which means that the rope diameter increases again after unloading. Part of the diameter reduction, however, is permanent. If the diameter reduction of a steel wire rope under load is too high, in multi-layer spooling the rope can pull into deeper layers of the drum. Hence, the diameter reduction of steel wire ropes is to be considered when designing ropes for multi-layer applications as shown in Fig 4(d).

Kinking – It results in the permanent rope deformation and localized wear. It is normally caused by allowing a loop to form in a slack line and then pulling the loop down to a tight permanent set.

Steel wire ropes are widely used in many applications such as crane, tower crane, surface and underground mining, excavation, logging of any type of terrain, tramway, elevator, oil and gas, drilling, marine and electrical constructions. They are used dynamically for lifting and hoisting in cranes and elevators, and for transmission of mechanical power. Wire rope is also used to transmit force in mechanisms, such as a Bowden cable or the control surfaces of an automobile or an airplane connected to levers and pedals. Wire ropes have to fulfill different requirements depending on where they are used. Some of the uses of the wire ropes are as follows.

Running ropes – They are also called stranded ropes. These wire ropes

8613371530291

8613371530291