vanguard wire rope free sample

Whenever a mast tumbles overboard, the two seemingly obvious offenders are the mast itself — the aluminum extrusion — and the wire stays and shrouds that support the mast. In practice however, these are rarely the culprits. The offenders, in most cases, are the tangs, turnbuckles, and chainplates and the smaller, but no less significant, screws, bolts, terminal fittings, clevis and cotter pins that hold everything together. These can be inspected in a couple of hours or less. All you need for an inspection is a magnifying lens, a mirror, some toilet paper, your fingernails, a boatswain’s chair, and a pair of reasonably good eyes.

Most sailboats rely on swage fittings at the terminals, but these fittings are not necessarily the most reliable, especially in warmer climates where they have a history of failure. Swage fittings are made by compressing a tube onto the wire under great pressure, a process that must be done exactly right to assure a strong bond. If the swage has to be pressed several times (a bad practice) before the wire is secure, there is an increased chance that the swage has been weakened and could crack.

Terminal fittings, especially swage fittings at the deck, are prone to rust where the wire enters the swage. Rust indicates a serious problem and the swage and possibly the wire should be replaced. Some skippers like to use gel or wax to prevent water from entering the swage. While this may be effective for a while, it probably won’t keep water out for long and could very well trap water inside, encouraging corrosion.

A mast that is stepped on deck can cause problems if the load isn’t supported properly down below. This is sometimes a design problem, but most often it is because a bulkhead or support stanchion has failed — shifted, rotted, delaminated, etc. Look down below for indications of movement, including jammed doors, broken bonds, and splitting wood. A sagging cabin top is a strong indication that adequate support isn’t being provided.

Most people have a natural aversion to hanging from a rope at the top of a swaying mast. If possible, inspect your mast while it is unstepped. If you do go aloft, make sure there are experienced hands below to hoist you up. A snap shackle, if one is used on the halyard, can be made safer by taping the lanyard to prevent its accidentally opening. Also, if the boat is in the water, you’ll want to moor it where it won’t get tossed around by a passing boat wake.

First stop is the spreaders. (While you’re working, have the trailer cleat-off the halyard.) Make sure the ends of the spreaders bisect the shrouds at equal angles and are secured properly to prevent slipping. Skewed spreaders have been responsible for many dismastings. Tape or spreader boots, used on the spreader ends to prevent damage to the sails, should be removed temporarily so that the spreader ends can be inspected and the connection tightened as necessary. Some skippers paint the top of the spreaders, even aluminum spreaders, to reduce damage from sunlight. This is a necessity with wooden spreaders, unless you go aloft every month and add a coat of varnish. Remember, you can’t see the tops of the spreaders from down below.

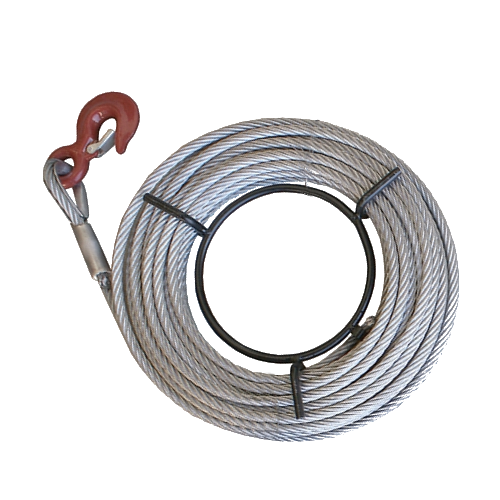

Wire should be inspected for broken strands or “fishhooks” by wrapping some toilet paper around the wire and running it up and down. If the paper shreds, the wire is nearing the end of its useful life and should be replaced. Check the wire where it enters the swage fittings for rust, which also indicates weakened wires that should be replaced.

As a general cost guideline, replacing the standing rigging on a typical 30 footer with 1/4″ wire rigging will cost about $1,200. That price includes turnbuckles but not unstepping the mast. The cost of replacing the standing rigging on a 40-foot cruising boat with 3/8″ wire could be almost twice as much. Incidentally, it pays to get estimates, as prices can vary significantly. Our estimates to replace the standing rigging on a 30-foot boat, for example, were as high as $2,800.

The Vanguard series of flagpoles offers a simple way to keep vandals from cutting your flag rope. This pole is and economical alternative to our Deluxe concealed halyard system. The Vanguard"s wire center halyard runs through a revolving truck and is secured in a cam action cleat located inside the flagpole behind a lockable access door.

VANGUARD SERIES FLAGPOLE ESTIMATED PRICES(Raw material PRICEs change frequently, so please use the "Get a Quote" button and we will contact you promptly with a flagpole PRICE estimate including freight.)

Last year I bought the Emporia Vue whole-house electricity monitoring system.* This past weekend, I finally installed it. The photo below shows my electrical panel with the monitor installed. Yes, it looks like a mess at the moment. The panel itself is a mess from all the changes made over the 61 years my house has existed. And I haven’t tucked all the Vue wires into the panel yet. I’m leaving it open for a bit while I tweak the setup but will close it up soon.

Some secondary market whole-house electricity monitors also can do disaggregation. The big name in this category is the Sense energy monitor.* It installs inside the electrical panel like the Emporia Vue but measures only the electricity going through the main wires bringing power into the panel.

Looking at the photo of my panel above, you may be a little intimidated by the confusion of wiring. It’s actually simpler than it looks, though. There really are only four things to do, and they all center around the energy monitor box. It’s the little rectangular box hanging below my panel with a bunch of wires connected to it.

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and writes the Energy Vanguard Blog. He also has a book on building science coming out in the fall of 2022. You can follow him on Twitter at @EnergyVanguard.

* This is an Amazon Associate link. You pay the same price you would pay normally, but Energy Vanguard may make a small commission if you buy after using the link.

To further highlight the challenges, spills of hazardous waste always pose a significant threat to employees and adverse impact to the environment. Hazardous waste is a serious safety and health problem that continues to endanger people, animal life and environmental quality. Hazardous waste – discarded chemicals that are toxic, flammable, or corrosive – can cause injury, illness, fires, explosions and environmental pollution. Unless hazardous waste is properly treated, stored, or disposed of, it will continue to do great harm to all living things that come into contact with it now or in the future. It is because of the seriousness of safety and health hazards related to hazardous waste operations that OSHA issued its HAZWOPER Standard, specifically developed to protect employees in the workplace and to help them handle hazardous wastes safely and effectively.

OSHA has determined that 44 specific chemical hazards are so adverse to employees in the workplace, that stand-alone standards (the term for OSHA laws) have been enacted to protect employees through preventative exposure strategies, including analyses, written programs and employee training. Through its Compliance Gap Analysis, Vanguard screens for these specific hazards, along with virtually all other workplace hazards. OSHA “44” chemical hazards are also screened within a facility’s Indoor Air Quality testing and monitoring to follow.

OSHA decided as a policy matter that the action level, which triggers the measurement requirements, be set below the PEL to better protect employees from overexposure. OSHA reasoned that this method was the most reasonable approach to a recurring problem, that is, how to provide the maximum employee protection necessary with the minimum burden to the employer. It has been determined, therefore, that three key duties should be triggered when an action level is reached: 1. exposure measurement; 2. medical surveillance; 3. employee training. All three actions are considered necessary by OSHA before employee exposure reaches the PEL. It is important to initiate measurement procedures periodically (generally assumed to be annual updating) to monitor whether levels are approaching the PEL. One must do so to ensure that employee exposure does not exceed it. Similarly, employees should be screened for preexisting medical conditions and trained in suitable precautions against dangerous properties of the substance when there is some chance that their exposure will become significant.

This regulation and mandated training has proven to save lives, prevent property damage and prevent accidents and injury involving drivers and other employees in the workplace. Many states require that drivers undergo rigorous driver testing and be issued a license upon successful completion of the course and driver exam.

Gasoline, diesel, electric, or other power plants for proper operation. -Motion-limit devices that interrupt power or cause a warning to be activated.

Wire Rope Inspections. Properly inspecting the rope – keeping an eye out for changes its integrity – is important to maintaining a safe work environment.

A basket, or lantern, deformation, also known as a birdcage, develops when the outer layer of strands in the wire rope becomes longer than the inner layer(s).

A core protrusion is a special type of basket or lantern deformation. In this case the rope imbalance is indicated by a protrusion of the core of the wire rope.

Personal fall restraint systems are used to prevent falling. They consist of an anchorage, connectors, and a body harness or body belt. They may also include a lanyard, lifeline, and rope grab.

OSHA requires very specific training in the proper use of respirators in the workplace, as changing conditions and chemically-oriented atmospheres may have an adverse effect on the safety and health of employees. Therefore, Respirator Training becomes an integral part of a company"s overall OSHA compliance program.

All personal protective equipment should be safely designed and constructed, and should be maintained in a clean and reliable fashion. It should fit comfortably, encouraging worker use. If the personal protective equipment does not fit properly, it can make the difference between being safely covered or dangerously exposed. When engineering, work practice, and administrative controls are not feasible or do not provide sufficient protection, employers must provide personal protective equipment to their workers and ensure its proper use. Employers are also required to train each worker required to use personal protective equipment to know:

Provides references that may aid in recognizing the need for personal protective equipment (PPE) and provides information about proper PPE selection and usage.

Vanguard is pleased to provide this OSHA-mandated necessity to its clientele, the “Computer-Assisted New-Hire Orientation” Program (CAN-Hire). The purpose of this program is to provide a convenient and flexible, ongoing method for clients to host their OSHA-required “New-Hire Orientation” through the advent of the digital technologies and computer-assisted learning with the most simplistic access possible: registration number, username and password.

HazMat Transportation Act (HMTA - 181). DOT has strict guidelines in requiring that all chemically-oriented products be properly labeled and placarded prior to and during shipment.

8613371530291

8613371530291