volunteer wire rope knoxville tn made in china

We fabricate wire rope, wire rope slings, chain and chain slings, farm accessories and trailer parts and other materials. Volunteer Wire Rope & Supply is a wholesaler/retailer of a complete line of rigging supplies, as well as synthetic ropes, hose, agricultural tools and safety equipment.

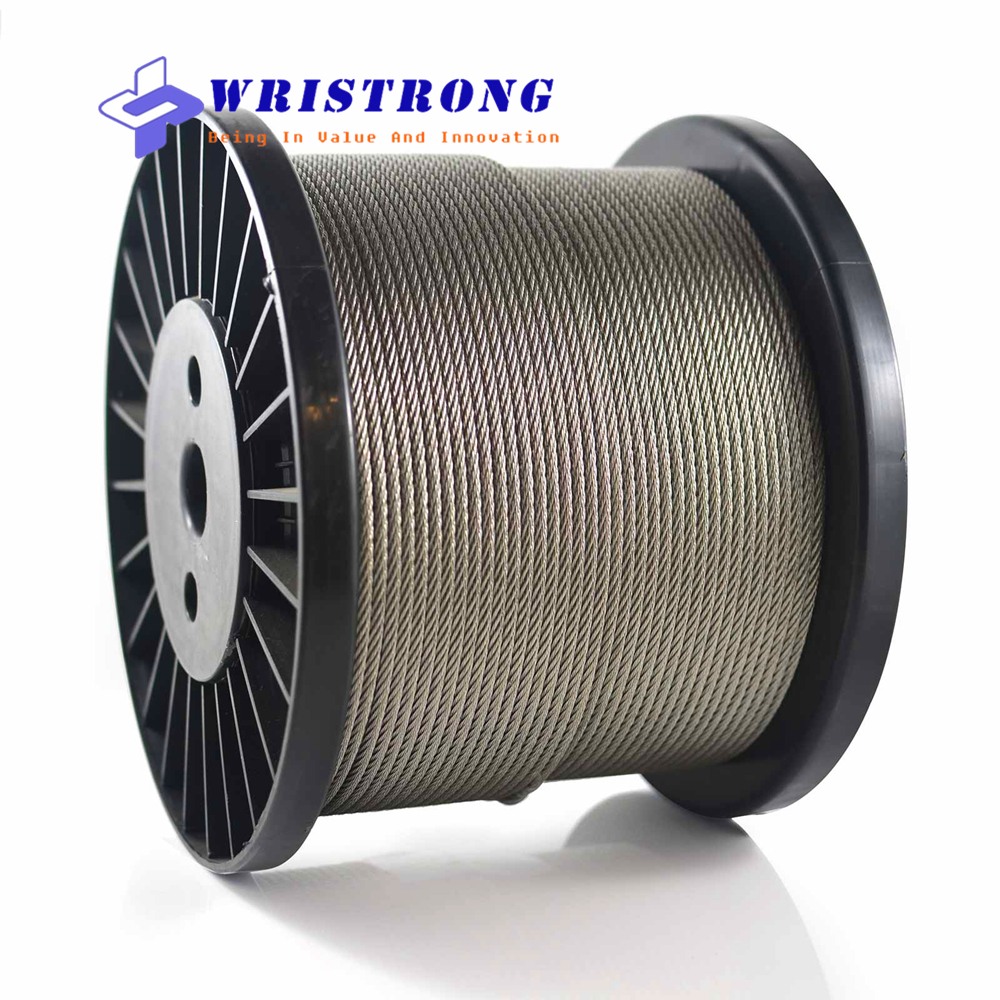

Wire ropes can be seen everywhere around us, they are made of strands or bundles of individual wires constructed around an independent core, suitable for construction, industrial, fitness, commercial, architectural, agricultural, and marine rigging applications.

Wire rod is made from high carbon steel wires(0.35 to 0.85 percent carbon) in a hot rolling process of a required diameter, usually from 5.5mm to 8 mm.

Wire rod is drawn to the required diameter by the 1st drawing machine after descaling dust and rust, adding mechanical properties suitable for application.

Positioning the wires different or the same size lay in multiple layers and same direction, or cross lay and diameter is maintained by one-third of the rope size.

So in theory, it is very simple to manufacture wire ropes. However there are many more details that must be closely monitored and controlled, and this requires time and experienced personnel since it is a super complicated project you cannot imagine.

Many rigs are equipped with winches that are used for a variety of tasks. To properly and efficiently use this tool, rigging is required to connect the winch line to the load (or resistance).

This article offers information about various rigging tools and their proper use, plus inspection. Calculating an accurate line load is fundamental when using rigging gear. No rigging component should ever exceed the manufacturer’s established working load limit (WLL).

Chain begins as a continuous wire. Once testing has verified the required properties are met, the wire is drawn into a specific diameter. From this wire, proper size wire “slugs” are cut into an exact length. These slugs are then formed into a link and welded into a continuous chain sling.

When placing a synthetic sling eye over the pin of a shackle, ensure that the pin diameter is less than one-third the length of the sling eye. Do not open the sling eye any greater than the eye length. The synthetic web slingwidth should be no greater than 75 percentof the shackle width. The diameter of shackle pin should be greater than the wire rope diameter if no thimble is used in the sling eye. A synthetic or wire rope sling eye must not be placed over an object (usually a hook or other collector) that is greater than one-third of the sling eye length. Never replace any part of a hook or shackle with anything other than a part specified by the manufacturer. Don’t use hooks or shackles for lifting personnel unless approved by the manufacturer. Shackle screw pins should be tightened fully when installed.

The capacity of a choker hitch is based on the hitch being formed properly. For full choker hitch capacity, the angle of the choke for all types of slings should be a minimum of a minimum of 120 degrees. According to the Web Sling & Tie Down Association, synthetic slings have a reduction of up to 25 percent at an angle of choke greater than or equal to 120 degrees (75 percent of WLL for a single-leg hitch). If the angle of choke is less than 120 degrees, the sling capacity will decrease even more.

Do not place the sling eye of a synthetic or wire rope over an object (usually a hook or other collector) greater in width than one-third of the eye length.

The general makeup of wire rope includes the core, wire, and strands. There are basically two types of wire rope, steel core and fiber core. Steel-core wire rope has stands of wire wrapped around a steel core. It resists crushing better than fiber core.

Fiber core is wire wrapped around a fiber or a synthetic center. The core forms the center or heart of the wire rope and is the center around which the main wire strands are wrapped. The core supports the wire strands, preventing jamming and compacting of these strands. The core material depends on the specific purpose and conditions for which the wire rope will be used. Fiber core wire rope is adequate for towing and rescue operations because it offers maximum flexibility, elasticity, and is lighter in weight than steel-core wire rope. Fiber core wire rope isn’t as strong as steel-core wire rope of equal size and grade. Fiber core material is usually sisal or manila; however synthetic fibers such as polypropylene may be used.

During manufacturing, wire ropes are lubricated internally and externally. After use, they should be provided special care through proper lubrication. When in use, the wire rope is constantly moving, and proper lubrication offers maximum life of the wire rope. Prior to lubricating the wire rope, it should be thoroughly cleaned with wire brushes, compressed air, steam, or a recommended solvent. Frequent light lubrication is preferred over infrequent heavy lubrication. Follow the wire rope manufacturer’s specific recommendations when lubricating wire rope. Storage should be in a clean dry location that is protected from the elements.

Use cribbing pieces for “padding” when passing a wire rope over a sharp edge to prevent point loading. Remove any kinks or twists from a wire rope before applying force. Keep the wire rope straight.

All wire rope must be inspected periodically as specified by the manufacturer. Stretching, damage, and deterioration of the wire rope occur during use.

Measure the wire rope’s length when new as supplied by the manufacturer, and record this number. Measure the wire rope’s length during inspection. Consult the manufacturer for an acceptable stretch measurement, and replace as necessary. Severe stretch may indicate overloading or loss of strength.

Measure the wire rope’s diameter when new as supplied by the manufacturer, and record this number. Measure the wire rope’s diameter during inspection. Consult the manufacturer for an acceptable diameter reduction, and replace as necessary.

Visually inspect the entire rope length for any sign of damage, deterioration, distortion, core protrusion, and broken or cut strands or wires. The manufacturer will provide a recommendation regarding replacement depending on the number of broken wires in a rope lay or wires within a strand in a rope lay. A rope lay is the length of wire rope in which one strand makes one complete revolution around the core.

Wire rope may be terminated with various fittings (wedge sockets, clips, swaged, for example). For maximum strength, choose a steel swage termination with a heavy-duty thimble. Wedge sockets are intended for temporary on-the-job applications only. The efficiency of wedge sockets is approximately 80 percent if properly installed. Installing wire rope clips as a permanent fitting is not recommended, as their efficiency is approximately 80 percent of the WLL if properly installed. Wire rope clips should not be used on coated wire rope.

A 5/8-in improved plow steel wire rope has an ultimate load of 20.6 tons. Wire rope clips will be installed as a termination, thus 20.6 × 0.80 = 16.5 tons. To determine the WLL, the figure of 16.5 tons is divided by the design factor of 5 = 3.3 tons.

All manufacturers will provide specific instructions for installing, using, inspecting, and maintaining their fittings. These instructions must be followed precisely, along with applicable federal and state OSHA and other rules and regulations. More than one broken wire at any (within one wire rope diameter of the fitting) termination is cause for removal from service.

These tools are used extensively for rescue rigging operations. It is vitally important that components are never operated beyond their WLL. Proper use and maintenance are fundamental to offer greater safety for all.

Billy Leach Jr. has been actively involved in emergency services since 1976, combining career and volunteer experience. He is the developer of and senior presenter for BIG RIG RESCUE™. Frequently, he conducts training in vehicle rescue and has presented at the International Vehicle Extrication Learning Symposium, Fire Department Instructor’s Conference (FDIC), Fire Rescue Magazine’s First Due Conference, FDNY’s Technical Rescue School, and Los Angeles County Fire Department Special Operations Division. Numerous presentation experiences include national and international audiences. He has co-authored BIG RIG RESCUE© on the topic of heavy truck anatomy and extrication. Also, he is a certified rigger and signal person according to the National Crane Operators Certification Commission. He is a certified Wreckmaster 6/7 and Crosby Rigging Trainer. As a selected committee member, he helped develop the National Fire Protection Association Hybrid and Electric Vehicle program.

WASHINGtON A. ROEblING, tHE CIvIl WAR & tHE bROOklyN bRIdGEUNItEX lEvERAGES SyNERGySUCCESS, A FAmIly tRAdItION FOR CERtIFIEd SlING & SUPPly 8-1/4Trim8-7/16Bleed7 Live10-7/8 Trim11-1/16 Bleed10 LiveATTN: Rick ColvinPH: 707.748.1700 FAX: 707.446.2033rickc@landmannwire.comPlease fax back approvalK ApprovedClient SignatureK Please make noted changesand fax back for my approval4736ad01r WRNPub: WRNews511 Colonia Blvd.Colonia, New Jersey 07067-14021-908-486-3221Edward Bluvias, III (Publisher)vsent@aol.comwww.wireropenews.comClient: Rick ColvinLandmann Wire Rope Products2051 Cessna Dr #200Vacaville CA 95688800-331-0794/ph707-446-2033/faxDesign: Garson Design Services239 Concord AvenueFairfield, CA 94533707 428-1743/phone707 428-3652/faxmail@garsondesign.comSize: FULL PAGE - 8-1/4 (.25) x 10-7/8 (.875)Specs: 4/c RRED 133LColors: CyanMagentaYellowBlackSEND:Program: Hi-res PDF13Issue1: Dec(&Jan) of Each YearDeadl: 11/20/13Issue2: Feb(&Mar) of Each YearDeadl: 01/20/14Issue3: Apr(&May) of Each YearDeadl: 03/20/14Issue4: Jun(&Jul) of Each YearDeadl: 05/20/13Issue5: Aug(&Sep) of Each YearDeadl: 07/20/13Issue6: Oct(&Nov) of Each YearDeadl: 09/20/13Time: 05/06/13-3:45amFile: 4736LDMad01r13-17WRN.qxdK OPTION 1.1Run File: 4736LDMad01r13_043013.pdfWHATDoes Landmann Wire RopeProducts, Inc. Provide For You?WHATDoes Landmann Wire RopeProducts, Inc. Provide For You? Customized and ProfessionalClient Service Widest range of quality productsin the industry Largest stocking distributor onthe West Coast Overseas sourcing through ourInternational partnerships Fulfilling the needs of companiesbig & small alike With over 60 years of combinedexperience, and 150 years ofsolid history from our parentcompany, Grebruder Thiele,Landmann is the source for yourwire rope and rigging equipment.Pacific Northwest4301B Industry Dr. EastFife, WA 98424Phone: 877-926-3500Fax: 253-926-2510Northern California2051 Cessna Dr #200Vacaville, CA 95688Phone: 800-331-0794Fax: 707-446-2033Southern California12941 Sunnyside PlaceSanta Fe Springs, CA 90670Phone: 800-344-6751Fax: 562-946-1600w w w . l a n d m a n n w i r e . c o mMidwest3551 Country Road FTekamah, NE 68061Phone: 800-331-0794Fax 707-748-1701W A R E H O U S E L O C A T I O N SCable Service Five Yarbrough locations to serve your rigging needsPrecision Fabricated Heavy Lift Rigging www.yarcable.comYarbrough Cable precision fabricates single- and multi-part braided wire rope slings up to 4 in. diameter. Yarbroughs unique fabrication process allows us to achieve overall sling length tolerance of plus or minus inch. We maintain this length tolerance between multiple slings of the same size, for slings made today and additional slings made in the future, and for all slings, including multi-part braids, in all wire rope diameters up to 4 inches. An essential part of Yarbroughs sling fabrication process is testing. The load test machine at our Memphis, TN head office has a 1500 ton capacity at 200 feet of length and a 500 ton capacity at 500 feet of length. Test beds of 50 and 175 tons are also available in Memphis, and each Yarbrough branch office is equipped with small capacity load test machinesproviding local verification testing for rigging of all types.When your lift weighs hundreds or thousands of tons and is worth millions of dollars, you need slings you can depend onslings that you know will lift the load, lift it level, and lift it safe. In short, you need Yarbrough slings.Little Rock, AR3000 West 65th Street800 . 749 . 3690Pascagoula, MS5615 Telephone Road228 . 712 . 2933Fort Smith, AR5300 Wheeler Avenue855.200.4558Memphis, TN - Head Ofce950 Stage Road 800 . 395 . 5438Muscle Shoals, AL1904 Webster Street256 . 383 . 32122 SEPTEMBER-OCTOBER 2013 WIRE ROPE EXCHANGE[EDITORS NOTE]As summer ends and fall kicks into gear, its birthday and anniversary season in our family. Te calendar is littered with celebrations, one right after the other. Celebrating anniversaries and birthdays remind us of how far weve come and, more importantly, how far we still want to go. As Im writing this, my father is celebrating his 65th birthday. Whenever we talk about his age, he likes to make a joke about how much he has left in the tank and what the fuel gauge might look like for him with the red needle making the inevitable march toward the big E. We have to laugh, and he guesses hes got about a quarter-tank left. On the other hand, my six-year-old son counts the days until his next birthday. He eagerly anticipates when he can get a bit of independence, make a decent sale with his alien stuf (think lemonade stand but with alien drawings) and his mom can stop getting in the way. Tere are extreme diferences between the two one who cant wait to grow up and the other who cant seem to slow the days down enough. Where we come together is celebrating the big days, the glories and sharing in a year mixed with good times and hard work. In the spirit of celebrating milestones, Cliford Zink, writer and historian, gives us an in-depth look at the remarkable life of Washington A. Roebling and the history of the Brooklyn Bridge. We also learn more about Unitex, who is making a strong footprint in the U.S. in recent years. Finally, we celebrate Certifed Sling & Supply for making the OBJ list of the Fastest 50 growing companies in Central Florida, as well as celebrate three decades of service by industry and J. Henry Holland veteran, Larry Lusk.Each day comes and goes similar to the one before, and often it can be challenging to notice the change of time without these milestones. Te celebrations allow us to hit the pause button for just a moment, and relish in the steps that got us there, and the ones were about to endure.Im always interested in your stories; please email me with your news. As always, thank you for being a part of Wire Rope Exchange!Melissa Hood, Editor | Wire Rope ExchangeP.O. Box 159323, Nashville, TN, 37215Email: mhood@wireropeexchange.com Upcoming Events 2013ICUEE 2013October 1-3, 2013 Louisville, KY www.icuee.comInternational Workboat ShowOctober 9-11, 2013 New Orleans, LA www.workboatshow.comWSTDA 2013 Fall MeetingOctober 15-17, 2013 Chicago, IL www.wstda.comAWRF Fall General MeetingOctober 20-23, 2013 Los Angeles, CA www.awrf.orgCRC CanadaOctober 22-23, 2013 Edmonton, Canada www.craneandriggingconference.comNational Industrial Fastener & Mill Supply ExpoOctober 23 25, 2013 Las Vegas, NV www.fastenershows.comPower Generation Lifting WorkshopNovember 6 8, 2013 New York, NY www.powergenlifting.comSTAFDA 2013 Convention and Trade ShowNovember 11-13, 2013 Las Vegas, NV www.stafda.orgLiftex 2013November 14 15 Bolten Arena, UK www.liftex.orgCHECK IT OUT: www.wireropeexchange.com14th & 15th November | USN Bolton ArenaACDCAJTA.P LiftingArbilAstro ManufacturingBridon InternationalBrindley ChainsCaldwell GroupCarl Stahl EvitaCheckmateCodiproColumbus McKinnonCore RFIDCrosbyEnglish BraidsFisher OffshoreGAP GroupGeorge TaylorGunnebo IndustriesHarrison FabricationHendrik Veder GroupHoffmannHolland 1916InfochipIntegrated Inspection SystemsKito EuropeLHILift-texLift Turn MoveLifting Gear UKLift-RiteLoad Systems UKMetreelModuliftMotion SoftwareNikoPetersen Stainless RiggingPfeifer Drako LtdProbstRedplantRed RoosterReid LiftingRope AssembliesRUD ChainsSafetrakSafety-Lifting.comSeaexSpeedyStraightpointSumnerT AllenTalurit (UK)TractelUnispliceVanBeestWater WeightsWilliam Hackett ChainsWinch SystemsWorliftsCurrent list of exhibitors:BOOK NOW! Guarantee your place by registering at www.liftex.org/registerThe leading lifting exhibition where suppliers to the industry present their latest lifting products and services to an audience of end-users from the UK and beyond - all under one roof over 2 days.the 9th edition of LiftEx DONT MISS Power Generation Logistics Shipping Rail Maintenance Heath & Safety Training Construction Oil & Gas Metal Production Heavy Engineering Civil Engineering Utilities If you are a user or adviser of lifting equipment in any of the following industries, this is the perfect event for you to visit:REASONS TO VISIT LIFTEX 2013: Be part of the UKs only dedicated lifting equipment exhibition Network with over 600 industry professionals over 2 full days See demos from over 70 exhibiting companies Discover new industry products and services in the Innovation Theatre Get the latest advice and training from the industry experts in the LEEA teamINNOVATION THEATRELast years highly successful Innovation Theatre will return to the show oor at LiftEx 2013. Come to the theatre and see presentations and demos of the very latest lifting products and innovations, and nd out which companies will win the coveted LEEA Awards. Keep checking the website at www.liftex.org/innovationtheatre for updates to the theatre programme. Last few exhibition stands and sponsorship still available! If you want to promote your brand to a targeted audience, please email the team at events@leea.co.uk or call +44 7795 110646.For more information, visit www.liftex.orgPlatinum Sponsor Bag sponsor Ofcial Publication Media Sponsors Brought to you byliftex2013_Americanad.indd 1 15/07/2013 15:14RETRACTIONIn our Innovations department of the July-August 2013 issue, photos with the Miller Lifting Products logo were placed on Raktag samples; however, Miller Lifting Products is not a purchaser or endorser of the Raktag product. Paul Jowsey, owner of Jtagz, explained the tags were prepared as marketing samples and were not meant as an endorsement. y LETTER TO THE EDITORMs. Hood: I enjoyed your comments and then read the articles referenced. Of particular interest was the article about Manchester Sling and their cooperation with Mammoet. Your comments about the roads in Western North Carolina are familiar to most of us who live at the other end of Interstate 40 - Havelock, NC, almost to the Atlantic Ocean. There is a company that may be of interest to you (a subscriber who loaned me the magazine!) named TANDEMLOC, Inc. They design, produce, proof-test and provide lifting, securing and mobilizing devices for worldwide use by the transportation and construction industries. They specialize in the design and production of a wide range of hardware for below the hook.Im sure that many of your readers are familiar with TANDEMLOC, Inc. because of their industry unique policy of proof-testing every single lifter they produce, Id like to see them proled like Mr. Nolan did with Manchester Sling.William S. Fiske, COL, US Army (Retired)Dear Colonel Fiske, Thank you so much for your note and Im glad you enjoyed our July August issue. We were excited to highlight the innovative partnership between Manchester Sling and Mammoet. I also agree, Tandemloc would make for a great feature article. Weve touched base with them from your suggestion and we look forward to featuring them soon in an upcoming issue. 14th & 15th November | USN Bolton ArenaACDCAJTA.P LiftingArbilAstro ManufacturingBridon InternationalBrindley ChainsCaldwell GroupCarl Stahl EvitaCheckmateCodiproColumbus McKinnonCore RFIDCrosbyEnglish BraidsFisher OffshoreGAP GroupGeorge TaylorGunnebo IndustriesHarrison FabricationHendrik Veder GroupHoffmannHolland 1916InfochipIntegrated Inspection SystemsKito EuropeLHILift-texLift Turn MoveLifting Gear UKLift-RiteLoad Systems UKMetreelModuliftMotion SoftwareNikoPetersen Stainless RiggingPfeifer Drako LtdProbstRedplantRed RoosterReid LiftingRope AssembliesRUD ChainsSafetrakSafety-Lifting.comSeaexSpeedyStraightpointSumnerT AllenTalurit (UK)TractelUnispliceVanBeestWater WeightsWilliam Hackett ChainsWinch SystemsWorliftsCurrent list of exhibitors:BOOK NOW! Guarantee your place by registering at www.liftex.org/registerThe leading lifting exhibition where suppliers to the industry present their latest lifting products and services to an audience of end-users from the UK and beyond - all under one roof over 2 days.the 9th edition of LiftEx DONT MISS Power Generation Logistics Shipping Rail Maintenance Heath & Safety Training Construction Oil & Gas Metal Production Heavy Engineering Civil Engineering Utilities If you are a user or adviser of lifting equipment in any of the following industries, this is the perfect event for you to visit:REASONS TO VISIT LIFTEX 2013: Be part of the UKs only dedicated lifting equipment exhibition Network with over 600 industry professionals over 2 full days See demos from over 70 exhibiting companies Discover new industry products and services in the Innovation Theatre Get the latest advice and training from the industry experts in the LEEA teamINNOVATION THEATRELast years highly successful Innovation Theatre will return to the show oor at LiftEx 2013. Come to the theatre and see presentations and demos of the very latest lifting products and innovations, and nd out which companies will win the coveted LEEA Awards. Keep checking the website at www.liftex.org/innovationtheatre for updates to the theatre programme. Last few exhibition stands and sponsorship still available! If you want to promote your brand to a targeted audience, please email the team at events@leea.co.uk or call +44 7795 110646.For more information, visit www.liftex.orgPlatinum Sponsor Bag sponsor Ofcial Publication Media Sponsors Brought to you byliftex2013_Americanad.indd 1 15/07/2013 15:14Register by Phone800.727.6355Event Partners: World-Class Instruction FromAn interactive training workshop addressing the rigging and lifting challenges faced by organizations in power generation and distributionRegister Today at powergenlifting.com $795ITI Workshops: Improving Lifting Operations by Educating Organizational LeadersPowerGenerationNovember 6-8, 2013 New York, NYFirst 50 students to register with Promo Code ITI-NYC receive a FREE ITI hat![CONTENTS]WIRE ROPE EXCHANGE SEPTEMBER-OCTOBER 2013 5WIREROPEEXCHANGE.COM | 800.643.5189SEPTEMBER/OCTOBER 2013VOLUME 28 | ISSUE 531 | WHATS NEWModulift unveils the CMOD Spreader Frame; Columbus McKinnon launches the CM Bandit Ratchet Lever Hoist in Canada; Miller Lifting Products Announces the introduction of DIN Hook Latches and much more.33 | WRE CATALOG GUIDEView the latest product oerings and updated listings. WRE CATALOG GUIDEFEATURES 2 | EDITORS NOTE 7 | INDUSTRY NEWS 19 | WRE SPOTLIGHT 76 | WRE UPDATE | BUSINESS 79 | ADVERTISERS INDEX 80 | RIGGERS CORNERON THE COVER: BROOKLYN BRIDGE CONSTRUCTION, MAY 1877. As the frst cable wires were readied for running across the towers, bridge company directors gathered ceremoniously on the Brooklyn Tower footbridge. Washington A. Roeblings sign admonished footbridge users, Do not walk close together, nor run, jump or trot. Break step! The eyebars in the foreground were used to connect the cables to large plates at the bottom of the anchorage. Collection of Robert M. VogelIN THIS ISSUE20 | WASHINGTON A. ROEBLING, THE CIVIL WAR & BUILDING BROOKLYN BRIDGETe Roebling family played a pivotal role in many iconic structures throughout the United States. Renowned writer and historian, Cliford Zink, discusses the remarkable life of Washington A. Roebling and the Brooklyn Bridge as we celebrate the 130th anniversary.26 | UNITEX LEVERAGES SUPERIOR SYNERGYPart of a large, multi-national manufacturing company specializing in synthetic slings and tie-down products, Unitex has made a strong footprint in the U.S. in the past few years to complement a growing trend in its other locations worldwide. Citing success from strategic coordination of many companies under one roof; Unitex is uniquely positioned to continue this pattern of manufacturing growth and product innovation.Wire Rope Exchange September/October 2013, Vol. 28, Issue 5Wire Rope Exchange is published bimonthly by Wire Rope Exchange, P.O. Box 159323, Nashville, TN 37215. Periodical postage pending at Nashville, TN and additional mailing o ces. U.S. and International Annual Subscription rate: $124. Complimentary subscriptions are given on a controlled circulation basis. 76 20Strategic coordination weaves Unitex togetherCelebrating 130 years of historyCertifed Sling & Supply relies on a tradition of core values26WIRE ROPE EXCHANGE SEPTEMBER-OCTOBER 2013 7[INDUSTRY NEWS]I&I Sling Celebrates 50 Years> In September, members of I&I Slings management, sales and fabrication teams came together to celebrate the companys semi-centennial near its headquarters in Aston, PA.I&I Slings founder, and keynote speaker for the evenings festivities, Dennis St. Germain Sr., provided plenty of laughs for everyone in attendance. As only he can do, Dennis delivered a detailed slideshow and added little known facts about previous and current employees, customers and products. Dennis went on to say, Im overwhelmed to see how far this company has grown from its humble beginnings. Since my retirement 6 years ago, my sons have continued this growth and Im excited to see how far they will take it.I&I Sling Inc. was founded on September 25th, 1963 by Dennis St. Germain Sr. Five decades later, the company has grown to 100 employees with 6 full service rigging shops positioned from Massachusetts to Florida. The company is proud to be an original Slingmax Dealer and holds the distinction of being the first sling manufacturer in the world to produce High Performance Fiber Roundslings. I&I Sling is also one of 10 Learning Centers for the Rigging Institute LLC, a rigging training company headquartered in Knoxville, TN.In 2008 Dennis retired from his day to day activities and named Scott St. Germain as I&I Slings new President/CEO and Dennis St. Germain, Jr. as COO. I&I Slings other top management includes Robert Capone (CFO) and Tom DeSoo (Director of Sales). yDeakins Appointed President of Bishop Lifting Products, Inc. > Derrick Deakins has been appointed President of Bishop Lifting Products, Inc., effective August 1, 2013.Derrick joined Bishop Lifting Products as Chief Financial Officer in 2007 and was appointed Chief Operating Officer earlier this year. He has been instrumental in the development and execution of both our tactical as well as our strategic plans and is a valuable part of our executive management team, said Otis Dufrene, CEO of SBP Holdings, Bishops parent company where Mr. Deakins is also a member of the Board of Directors.Prior to joining Bishop Lifting Products Mr. Deakins held senior finance and engineering positions with Shell Oil Company and Hewlett Packard. He holds a mechanical engineering degree from Texas A&M University and an MBA from the University of Chicago.Founded in 1984, Bishop Lifting Products is one of the nations premier industrial distributors specializing in the fabrication and sale of lifting, rigging, and load securement products and services. Bishop Lifting Products and Singer Equities, Inc., a group of value added industrial rubber distributors, are wholly owned subsidiaries of SBP Holdings and together service a wide range of diversified industries throughout North America. More information can be obtained at www.sbpholdings.com. yCargotec Appoints New President for MacGregor Division> Cargotec has appointed Eric Nielsen as president of its maritime and offshore division MacGregor, succeeding Mikael Mkinen. As a member of the executive board he will report to Cargotec chief executive Mika Vehvilinen.Nielsen was previously vice president corporate development for mining equipment supplier Joy Global, where he was responsible for the companys mergers and acquisitions as well as strategic planning activities. Before Joy Global, Nielsen held different senior executive positions at Terex and Volvo Construction Equipment. Cargotec chief executive Mika Vehvilinen said: MacGregor is heading towards new challenges, and it is time to bring in new executive management to accelerate the growth and renewal. Nielsen has a strong track record within global machinery and engineering as well as in enhancing performance and growing business. His international background and experience in Scandinavian and Asian business world demonstrate his excellent capabilities to respond to changing customer demands.On the resignation of former president, Vehvilinen added: Mkinen has headed the preparations to list MacGregor to the Singapore stock exchange and to drive the consolidation of the industry, and he has succeeded well in executing these plans. As per his own decision not to move to Singapore, as the listing would require, Mkinen will leave his current position as president of MacGregor on 15th September. He will report to the new president during the transition period. yAEM Elects New Director> Tiffany Sewell-Howard, Chief Executive Officer of Charles Machine Works, Perry, Oklahoma, has been elected as a Director of the CE Sector Board of the Association of Equipment Manufacturers (AEM).AEM is the North American-based international trade group for companies that manufacture equipment, products and services used worldwide in the agricultural, construction, forestry, mining and utility sectors.AEM board members and officers work on behalf of all AEM member companies to provide strategic direction and guidance for Association services, activities and programs, in areas including public policy, equipment statistics and market information, trade shows, technical and product safety support, global business development and education/training. yHouston Structures Announces Dowen Raynor as New Engineering Sales Manager> The Ulven Companies are pleased to announce the hiring of Dowen Raynor as an Engineering Sales Manager within their Houston Structures business. In this position at Houston Structures, Raynors main accountability is for global field sales activities.Tammy Sievers, Director of Human Resources at Ulven said, We were looking for a skilled technical sales professional who could help our company continue to attain our growth goals and establish our product acceptance in the marketplace. We feel we have found this person in Dowen.8 SEPTEMBER-OCTOBER 2013 WIRE ROPE EXCHANGE[INDUSTRY NEWS]Dowen has an MBA from George Fox University, a M.S. in Metallurgical Engineering from University of Idaho, and a B.S. in Civil Engineering from Boise State University. He is also Six Sigma Green Belt certified. Dowen has over 15 years of sales, engineering and manufacturing experience in areas such as commercial casting design, blueprint-to-production activities and leading a global product team.Houston Structures supplies the cast, forged, machined, and fabricated structural support products the world depends on for Hydroelectric, Bridge, Structural, and Mining Industry projects.The Ulven Companies have been in the forging industry for over 40 years starting with the founding of Ulven Forging, Inc. in 1971. The Ulven Companies now comprise a group of four different American companies and are privately held. Each company has its unique set of process capabilities in different areas of the industry and is known for bringing high quality, cost-effective products to its customers with reliability and integrity. yTNT Promotes Lunsford to President; Acquires TSD and Greenergy Crane & Rigging> TNT Crane & Rigging, Inc. (TNT) is pleased to announce the promotion of Kregg Lunsford to President. Kregg has served as the Executive Vice President and Chief Development Officer since joining TNT last year and has led the strategic growth initiatives of the company including the acquisitions of Southway Crane & Rigging, TSD Crane & Rigging (TSD) and Greenergy Construction & Maintenance LLC. Mike Appling, Chief Executive Officer of TNT said, I am excited for the Company as Kregg moves into his new role as President. He has successfully executed our growth initiatives since joining the TNT team and has been an invaluable partner during the process. I am continuing as CEO and we will work closely together building our business. His past experience as a public company CFO and EVP of international operations brings a broad and deep skill set to the TNT management team and his leadership will drive our success into the future. TNT also announced today their acquisition of the assets of both TSD and Greenergy. This transaction extends TNTs footprint into the Permian, Panhandle and Kansas regions with new branches in Odessa and Canadian, Texas. These new operations will position TNT to partner with its oilfield and refinery customers as they grow their respective businesses in these strategic markets. Kregg Lunsford said, We are very optimistic about the growth opportunities that TSD and Greenergy bring. Were not only picking up additional crane assets in targeted locations but these companies also bring an abundance of young talented managers and key seasoned veterans that will lead our expansion in these high growth markets. yLifting Gear Hire Adds New Representative for North Dakota Market> Lifting Gear Hire (LGH) recently hired Bryen Birkholz as a new Rental Representative for the North Dakota market.Bryen comes to LGH with over 25 years of outside sales and direct marketing experience and has almost 5 years experience in the rental industry. Bryen has a proven track record of proficiency in customer relations and this made him the ideal candidate for our start-up venture in the North Dakota territory. Bryen is eager to demonstrate who LGH is and how LGH can help with equipment needs. In turn he is ready to help build and develop his territory. ySims Crane Names Mark Hollister Vice President of Business Development> Mark Hollister has been named Vice President of Business Development at Tampa-based Sims Crane & Equipment, a leader in the crane and heavy transport industry.A veteran of the construction equipment and crane industry with more than 35 years of experience, Hollisters expertise includes sales, management and operations. Hollister has excelled at building and managing high-performance teams, while running efficient operations and growing market share. Mark has a proven track record of training and motivating sales teams in our industry, and we are confident he will bring his enthusiasm and successful strategies to our organization, said Dean Sims II, Vice President of Marketing for Sims Crane. This strategic hire is in line with our growth objectives for the next five years.Sims Crane & Equipment, which continues to grow its business nationwide, has led the crane and rigging industry in Florida for over 50 years with innovative safety practices and education, sophisticated technology and financial stability.A proven leader with a successful history, Hollister has a great depth of knowledge in the construction equipment and crane industry.Hollister was previously Senior Vice President of Sales and Marketing at Norco LLC, a manufacturer of construction attachments and mobile biomass processing equipment.He also previously served as vice president/general manager of the Southeast for Nortrax, Inc., a John Deere Company and distributor of heavy construction equipment.Hollister holds a B.A. in marketing from Drake University. His continuing education includes being Sales Certified by the Deere Signature Sales Process and certified in the Dimensions of Professional Selling (DPS), as well as participating in the Leadership Process Motivating Achievement (LPMA) program and many other classes in management and leadership. ySpider Hires New District Sales Representative for Las Vegas> Spider, a division of SafeWorks, LLC, announces Bronson Faher has joined its Las Vegas operation center as District Sales Representative. In this role, Faher is responsible for solving the suspended scaffolding and fall protection challenges of contractors and facility owners throughout Nevada, Arizona & southern California.Faher brings seventeen years of experience in the Las Vegas scaffolding industry, holding operational management positions with WACO Scaffolding & Equipment, Inc., Nevada Scaffold & Equipment, and C.O.B. Scaffolding. Most recently, he served as Commercial Construction Supervisor for BRAND Energy Services.With his entire career in the Las Vegas area, Bronson has built outstanding rapport with sub and general contractors in the area and has refined his knowledge of local safety codes, comments John Sotiroff, Vice President Spider Sales and Distribution. This combines with his extensive scaffolding experience and track record of successfully meeting project goals (45Yrs)(QxP2xS2)+K+E =Q=QualityP=People & ProductsS=Safety & ServiceK=KnowledgeE=ExperienceAlps is the Answer!Headquarters2530 Production DriveSt. Charles, IL 60174phone: (630) 893-3888fax: (630) 893-8164Branch LocationsOhio: (614) 294-0600California: (626) 458-0055Florida: (904) 741-6121www.alpswirerope.comALPS WIRE ROPE CORPORATION The Pinnacle of Quality10 SEPTEMBER-OCTOBER 2013 WIRE ROPE EXCHANGE[INDUSTRY NEWS]to ensure Spider customers in Bronsons territory will receive the expert service and reliable solutions they have come to expect from the suspended scaffolding market leader since 1947. yRed Rooster Announces New Depot in Poland> As part of its continuous expansion plans, Red Rooster Industrial (UK) Limited have officially announced the opening of a new center located on the outskirts of Krakow, Poland.The new center, opened to better serve central and eastern European countries, will eventually offer most products and services currently available from Red Rooster within the UK and Norway. The Red Rooster product range consists of air hoists (standard and ATEX), powered winches, manual winches, load cells, load shackles, wire rope hoists, snatch blocks and wire rope spoolers. It has recently been extended since the company became an official Kito distributor within the UK. The Kito range of products consists of electric chain hoists, manual chain hoists, lever hoists, trolleys and beam clamps. The products were an ideal addition due to their high quality, durability and value for money.Red Rooster sells, hires, repairs and services its range of products, most of which may be supplied in standard or ATEX configuration. Manual chain hoists up to 50t capacity are available with optional ATEX Zone 1 or offshore configurations. Within its rental fleet, Red Rooster also holds 20t, 30t and 40t-capacity hand chain hoists.After years of continued growth, Red Rooster Industrial is fully committed to a strategic plan that ensures continued customer satisfaction, product reliability and competitive pricing. Its new center in Poland is an integral part of this plan and will further improve the overall success of the company in the future. yDelta Rigging & Tools Named Exclusive Redaelli Distributor> Delta Rigging & Tools, Inc., one of the largest providers of lifting and rigging products and related services in the United States, recently announced that they have reached an agreement with Redaelli to be the exclusive Redaelli distributor for both onshore and offshore in the U. S. Gulf of Mexico region. The agreement gives Delta Rigging & Tools sales and marketing exclusivity in the Gulf of Mexico region for Redaelli specialty compacted, non-rotating and multi-strand Steel Wire Ropes.Based in Milan, Italy, Redaelli is one of the global leaders in the production of steel wire ropes leveraging almost 200 years of experience. Redaelli wire ropes are found in numerous onshore and offshore sectors. Some Redaelli wire rope applications include; steel wire rope for offshore cranes, abandoning and recovery Winch systems, A-Frames, ROV and diving bell systems, anchoring and towing systems, as well as deployment winches, ect.Redaelli is best known for their World Record breaking state-of-the-art product, Flexpack. Flexpack wire rope represents the ultimate answer to subsea applications where high non-rotating characteristics, combined with easy handling and long lifetime, are required. The specific design, based on a modular strand concept, together with the compaction of all strands provides the perfect combination C. DREW

MARLIN SPIKESWe pay shipping on ordersof six or more spikes within the U.S.Quantity discounts are available.WINDY RIDGE CORPORATIONP.O. Box 32Tamworth, NH 03886800-639-2021603-323-2323 FAX 603-323-2322sales@windyridgecorp.com[INDUSTRY NEWS]WIRE ROPE EXCHANGE SEPTEMBER-OCTOBER 2013 11to achieve top performance. Redaelli has been awarded by Guinness World Records for two consecutive years for the heaviest wire rope ever manufactured in the world.Delta Rigging & Tools looks to partner with top suppliers around the world and with Redaellis technological and industrial success and capability in designing and manufacturing hi-tech steel wire ropes for the most severe conditions the decision to become an exclusive Distributor agent was easy.Carrying the Redaelli line was a good fit since we have the ability to stock the large diameter ropes and deliver conveniently out of our facility in Hurst, Texas, said Mitch Hausman, President and CEO for Delta Rigging & Tools. We were honored to receive the offer to enter into the Distributor agreement, and are eager to start delivering this high quality product to our customers continued Hausman.Willi Carzolio, Wire Ropes Division Manager, of Redaelli added, Our management team is delighted to have appointed Delta Rigging & Tools as the exclusive distributor agent for the Gulf Coast region. It is great to have such a well-respected company and market leader representing our brand and product in North America.As of August 1, 2013, Delta Rigging & Tools is stocking a wide range of Redaelli products including large diameter crane wire ropes. To request more information please email info@deltarigging.com. yDelta Rigging and Tools Acquires Holloway Wire Rope> In addition, Delta Rigging & Tools also announced it has completed the acquisition of Holloway Wire Rope, supplier of wire rope, below-the-hook lifting devices and rigging supplies headquartered in Tulsa, OK, with a second location in Wichita, KS. The acquisition of Holloway Wire Rope expands Delta Rigging & Tools footprint into the Oklahoma oil & gas fields, along with broadening its reach into the Midwest markets.Holloway Wire Rope, celebrating its 72nd year in the industry, is proud to be one of the earliest established wire rope and rigging companies in the United States. Through the efforts of its experienced and long-term management team, they have become an internationally recognized supplier specializing in Wire Rope Slings, Rigging, Fall Protection, Nylon Slings, Wire Rope, Chain, Chain Slings, Rope, Hoists, Shackles, Turnbuckles, Eye Bolts, Sheaves, Snatch Blocks, Tie Downs and Cargo Control, Load Binders, Crane Blocks, Winches, Swivels, Pull Testing Safety Belts, Chokers, Round Slings, Rigging Hardware, and Suspended Personnel Platforms.We had been looking for a way to expand our footprint deeper into the Oklahoma oil fields and Midwest markets for some time, said Mitch Hausman, President & CEO of Delta Rigging & Tools. After a careful review of the Holloway Wire Rope operations, it became clear that taking a well- established business with great customer and vendor relationships was a strong strategic move for us, and the best way to serve our existing and new customers working in the Midwest.Curt Tuggle Owner of Holloway Wire Rope will be joining the Delta Rigging & Tools management team and continue as General Manager of the Tulsa and Wichita operations. We are very pleased that a company with Delta Rigging & Tools national stature and reputation for quality and value is acquiring Holloway Wire Rope said Curt. Holloway Wire Rope is recognized for the high quality products we offer, customer satisfaction and safety. We believe that joining Delta Rigging & Tools will help us continue to grow by bringing us access to tremendous purchasing power and distribution of some of the best brands in our industry.Over the past several years, working closely with Austin Ventures, Delta Rigging & Tools has successfully executed a strategy of acquiring and integrating a number of high-performing regional market leaders to create a scalable, industry-leading platform across the United States. Delta Rigging & Tools is well positioned to pursue further growth initiatives through strategic acquisitions, geographic expansion, the expansion of existing and new customer relationships, and additional product and service offerings both in the US and abroad. According to Mr. Hausman, Delta Rigging & Tools will continue to seek additional acquisition opportunities of companies offering sales and rental of rigging, lifting and specialty products serving energy and industrial customers around the country. yNorthern Crane Acquires Scorpion> Canadian crane rental company Northern Crane has changed its name to NC Services Group or NCSG and has agreed the acquisition of S.S. Pevach Ventures which trades as Scorpion Industries.Edmonton based NCSG will acquire all outstanding shares in the Bonnyville, Alberta company from founders Shawn and Sonia Pevach who set the business up in 2001. Scorpion is a leading supplier of fully operated boom trucks up to 45 tons, and oilfield services in the shale and 877-LIFT AMHallmaterialhandling.comHOISTSOne STOp SHOpRIGGInG HARDWAReSLInGS12 SEPTEMBER-OCTOBER 2013 WIRE ROPE EXCHANGE[INDUSTRY NEWS]heavy oil regions of Alberta, such as Bonnyville/Cold Lake, Wabasca and Conklin. Shawn Pevach will remain with the company as regional director responsible for all operations in the Bonnyville/Cold Lake and Wabasca areas.NCSG chief executive Ted Redmond said: We are thrilled to be partnering with Scorpion Industries to help service the fast growing Bonnyville/Cold Lake, Wabasca and Conklin markets. There are numerous SAGD and Heavy Oil sites both under construction and in need of reoccurring maintenance services in this region and Scorpion is a major supplier to those sites with an outstanding reputation for safety and customer service.Shawn Pevach added: We will continue to provide our clients with all our existing services and enhance these with additional equipment from NCSGs crane and heavy haul operations. Our locally based employees will continue to provide outstanding service to our many loyal customers. With access to the NCSG safety and engineering team and a combined fleet of over 280 cranes/boom trucks, 200 lines of specialized heavy haul tractor and trailer fleet servicing the oil sands, traditional oil and gas, mining, infrastructure and the wind industries. yCortland Companys Quick Turnaround Ensures Safety of Battleship TEXAS> Cortland, the global designer and manufacturer of engineered synthetic ropes, heavy lift slings, electro-optical-mechanical cables, and umbilicals has delivered a three-part Plasma 1212 mooring line configuration hydraulic platform trailers, 190 conventional trailers and 65 tractors we will be able to meet all of our customers project, turnaround, and maintenance crane rental, hauling and other oilfield services needs.Northern Crane Services was founded in 1987 and purchased by Northwest Capital Appreciation in 2006. Since that time, it has done six follow-on acquisitions including A-1, Mullen and Parkland- and grown at a compound annual growth rate of over 30 percent.Today it claims to be the largest Canadian owned crane and heavy haul company and the 10th largest in North America. It operates from locations in Edmonton, Fort McMurray, Grand Prairie, Wabasca, Bonnyville, Tumbler Ridge, Regina, Terrace/Kitimat, Fort St John in Canada and Soda Springs Idaho, Billings and Sidney in Montana, Williston and Dickinson in North Dakota, and Odessa, Texas covering the western half of North America.It runs a diverse fleet of over 280 cranes ranging from eight to 1,350 tons along with a filtec precise inc.engineered yarns engineered yarnsfiltecWhen Performance Matters!EHP Engineered Hybrid Power

FiberFiltec Precise 218 HWY 701 North Bypass Tabor City, NC 28463 USA Telephone: (910) 653-5200 Email: info@ltec-precise.comWIRE ROPE EXCHANGE SEPTEMBER-OCTOBER 2013 13for the Battleship TEXAS, the state historic site. Cortland received the quote, visited the site, supplied a quote and delivered the solution in less than a week.TEXAS is the last battleship to participate in the first and second world wars, and was the first battleship to become a memorial museum in the U.S in 1948. TEXAS has been under the stewardship of the Texas Park & Wildlife Department since 1983, and is permanently anchored in La Porte on the busy Houston Ship Channel.Andy Smith, Ship Manager at the Texas Park & Wildlife Department initially contacted Cortland to determine if they could provide an additional mooring support system.TEXAS has 4 mooring monopiles to which she is currently and permanently chained, but portions of this system have been compromised over the last year. Plans to retro-fit and repair the system are currently projected to be complete by mid-September, but this left TEXAS vulnerable during the heart of hurricane season.Cortland was consulted, and within a week, the battleship was secured using a three-part mooring line configuration using Cortlands 1212 Plasma rope.I was very impressed by the service we received, said Andy Smith. Time was of the utmost importance in this instance and Cortland delivered a practical and workable solution in an impressive timeframe.Brooks Nunley, Gulf of Mexico Technical Sales Professional for Cortland Company commented, The TEXAS is the last of the battleships that participated in World Wars I and II, and is a great source of pride throughout Texas and the rest of the United States. After a site-analysis, we recommended Plasma back-up mooring lines in a specific configuration, for added safety and security. We were able to deliver a custom-solution in less than 48 hours to preserve this monumental landmark.Cortlands Plasma 1212 is a 12-strand single braided rope in which each of the 12 strands is, in turn, a 12-strand rope. This patented construction addresses the most critical properties of the fibers, to provide very high strength translation efficiency for larger ropes.The design allows for long lay lengths, making the rope more flexible for bending applications and rope that is easy to inspect and can be quickly spliced using standard 12 strand splicing techniques. yRenewed DNV Type Approval Certifcate for Van Beest> Van Beest has been audited by DNV (Det Norske Veritas) for the renewal of our Type Approval certificate for the Green Pin Standard and Green Pin Polar shackles. They achieved positive results with a certificate renewal for another 4 years. Shackles provided by Van Beest are found to comply with:DNV 2.7-1 Offshore Containers EN 12079-2 Offshore containers and associated lifting sets EN 13889 Forged steel shackles for general lifting purposes IMO/MSC Circular 860 US Federal Specification RR-C-271D DNV Standard for Certification No. 2.7-3 Portable Offshore UnitsThe new certificate S-7593 confirms continued compliance of the above mentioned types of shackles with the latest DNV standards. The approval of both the design and the production process make individual testing unnecessary, so it saves you a lot of time and money.VAN BEEST B.V. is a manufacturer and supplier of wire rope and chain fittings. Reg. trade marks include Green Pin and Excel. y[INDUSTRY NEWS]14 SEPTEMBER-OCTOBER 2013 WIRE ROPE EXCHANGE[INDUSTRY NEWS]Muncy Industries Contest Winner Glenn Richard of Certex Makes Skydive> Glenn Richard of Certex Lifting Products Lafayette branch, made use of a skydive he won at Muncy Industries 2nd annual crawfish boil. Glenn made the tandem skydive at Westside Skydivers just outside of Houston, Texas. Glenn jumped with tandem instructor Bob Hunter while videographer Nate Wernig shot video and took still photographs. Muncy Industries Lafayette branch manager, John Leisenring, joined in the fun as well.After climbing to 14,000 feet in a Cessna Caravan, Glenn and John jumped, free falling at speeds up to 120 miles per hour. John was able to link up in free fall with Glenn making the skydive truly memorable. Glenn deployed his own parachute around 5,000 feet and glided to a soft landing. When asked what his favorite part was, he answered, the exit. What a rush! Cant wait to go again. was Johns reaction to the skydive.For your chance to win prizes such as this once in a lifetime opportunity, be sure to attend the annual crawfish boil festivities hosted by Muncy Industries, LLC, in the month of March at their Lafayette, Louisiana location. You will also have a chance to see Muncys new product lines such as Stainless Steel 1 Piece Duplex Sleeves, Casing and Slip through thimbles, Wedge Buttons, and Twist-on Buttons. yCASAR Turboplast Ropes Help Lift Jacques Chaban-Delmas Bridge> The Jacques Chaban-Delmas Bridge, a new vertical lift bridge crossing the Garonne River, is the largest lift bridge in Europe, boasting a central span of 117 meters long, 2600 tons and rises to a staggering height of 53 meters in order to allow passenger liners and large sailboats to pass underneath.Hardesty & Hanover provided conceptual design, detailed final design construction support and supervision documents working in conjunction with the Vinci Group, the Design-Build Contractor, and the Design Consortium of EGIS Jean Muller International; Michel Virlogeux; and Lavigne-Cheron Architects. The lift span has a symmetric cross section and carry four traffic lanestwo monorail tracks and two outboard sidewalk/bikeways. Four, independent pylon towers one at each corner of the lift span will allow a counterweight (a quarter of the total lift span weight) to travel vertically inside each pylon.Operation of the lift span is achieved via high strength wire ropes passing over sheaves that connect the lift span to the counterweights. A wire rope winch drive operating system with electric motor and flux vector regenerative drives haul in and payout the counterweights, thereby raising and lowering the lift span.WireCo WorldGroups wire rope facility in Kirkel-Limbach, Germany produced over 4,600 meters (nearly three miles) of CASAR Turboplast ropes to help complete the project. Dedicated on March 16th, 2013 by the President of France, Francois Hollande, the bridge will handle 43,000 vehicles daily. yCrosby Product Specifed in Panama Canal Enlargement> Through an Authorized Crosby Distributor in Europe, Crosby is pleased to supply several, 64.37in./1635mm diameter, roll-forged sheaves for a project concerning the Panama Canal Enlargement, known as The Third Set of Locks Project, commissioned by the Panama Canal Authority.Six (6) chambers will each be equipped with 2 horizontal sliding gates. Each gate is powered by electric winches capable of opening the lock in 3 to 4 minutes. It is within these sliding gates that, 226 Crosby sheaves, 64.37in./1635mm in diameter with a 1.81in./46mm wireline, will be used.McKissick Roll-Forged sheaves were chosen for this contract for a number of reasons. They are lighter, stronger and more wear-resistant due to our roll-forged process. Sheaves produced under this roll-forged method are more economical because less welding and machining are involved compared to conventional methods. These sheaves can be made lighter because the rolling process incorporates upsetting the sheave. The upsetting operation allows material to be gathered where needed, in order to support the rope, as opposed to starting with a thicker blank. Our sheaves are manufactured out of different materials in order to meet demanding requirements such as Charpy Impact Testing and rigorous hardness requirements in the groove. Crosby is the only company who can manufacture a superior roll-forged sheave by the use of our proprietary upset roll-forged process.Crosby McKissick Products began manufacturing sheaves and blocks for the oilfield industry in the 1920s and is now the largest supplier of aftermarket replacement Caldwell quality. Guaranteed.Our expanded INSTOCK* program has many items available for same dayshipment. Call us at 800-628-4263 to place your order now. Orders placedafter 12:00 PM (CST) ship the next business day. *Not all sizes are available for same day shipment. The Caldwell Group 5055 26th Ave. Rockford, IL 61109 800.628.4263 caldwellinc.comORDER BY NOONSHIPS THE SAME DAYDesigned and manufactured to ASME B30.20 and BTH-1.CW_AD_WRN_051313_Layout 1 5/13/13 2:56 PM Page 1COMMERCIAL MARINE NEW ENGLAND ROPESNEW ENGLAND ROPES848 AIRPORT ROADFALL RIVER, MA 02720800-333-6679NEROPES@NEROPES.COM WWW.NEROPES.COMGIVE YOUR BUSINESS A LIFT BY ADDING SYNTHETICS!NEW ENGLAND ROPES ARE MADEUSING THE FINEST FIRST-CLASS FIBER,WORLD-CLASS MANUFACTURING, ANDINNOVATIVE DESIGN AND ENGINEERING.DRIVEN BY EXCELLENCE, OUR PRODUCTSPROVIDE THE STRENGTH AND DURABILITYNECESSARY FOR YOUR APPLICATION.CHOOSE THE ROPE THAT IS SYNONYMOUS WITH QUALITY AND PERFORMANCE.CHOOSE NEW ENGLAND ROPES.16 SEPTEMBER-OCTOBER 2013 WIRE ROPE EXCHANGE[INDUSTRY NEWS]sheaves for both land-based and offshore drilling companies. The McKissick brand is recognized worldwide as a quality product that is designed specifically to withstand harsh applications.To find out more about our McKissick Roll-Forged Sheaves visit www.thecrosbygroup.com. ySpider Provides Expert Suspended Scaolding Solution> Spider, a division of SafeWorks, LLC, provides the suspended access solution, including swing stages, fall protection and training, for installation of panels on the faade of the 400-ft tall Colorado State Bank Building in downtown Denver, CO. Under the direction of general contractor Swinerton Builders, Spider supplied subcontractor GEN3 with nine u-shaped swing stages powered by Zmac/1000 traction hoists to access the columns of the structure. In addition, seven standard modular platforms ranging in length from 15 ft to 45 ft and also powered by the workhorse Zmac/1000s are increasing efficiency by feeding materials to the u-shaped stages. Safety line, rope grabs and termination plates from Spiders trusted line of fall protection solutions are also in place throughout the project.Spider provided Competent Person Training for all of the equipment operators from GEN3 and Swinerton Builders and is making regular site visits to ensure safety compliance.Spiders cooperation and knowledge is second to none, and as the superintendent for the 27-story re-clad of the Colorado State Bank building, that makes them first in line when its time for staging and safety, says Doug Schnorr, Senior Superintendent for Swinerton Builders.Spider was the only local swing stage company that could provide the high volume of rental equipment for the projects 7-month duration along with the training support and expertise. Since the work began in April, there have been no incidents or injuries, and the goal is for that trend to continue until the projects October completion. yBridon Incorporates Energy Saving Technology at Wire Mill> Intelligent, energy-saving blower technology has been installed by Thorite to agitate the rinse tanks at Bridon Internationals Doncaster wire mill more efficiently. Working closely with Bridon Internationals Environmental Manager Lucy Smith, Thorites engineering team developed a system which slashes energy requirements to such an extent that it will pay for itself in well under 12 months.Blown air is piped to agitate the water in rinse tanks which wash away residual acids and coatings on steel wire rod after dipping. Bridon International, the global technology leader in the manufacture of steel wire and fibre rope solutions, previously used compressed air at 6bar to carry out this process, but the new system requires only 0.2bar to achieve the same results.The system comprises a Becker variable speed side channel blower and control panel, Bonomi piloted, actuated, PVC ball valves with marine coatings to protect against the corrosive environment, plus all necessary pipework and electrical installations.Lucy Smith, Bridon Internationals Environmental Manager said: In order to produce the worlds most innovative ropes, Bridon requires the very best in advanced and efficient technology. The installation of the energy-saving systems that Thorite has provided to enhance this step in the production line will play a role in helping Bridon maintain and develop its technology leadership position across its key markets. yP.O. BOX 2423, ASTON, PA 19014-2423 USATEL: 800-874-3539 610-485-8500 FAX: 610-494-5835 www.slingmax.comSLINGS TO THE MAX

technology for consistentlystrong slingsIRepairable at over 40 locations worldwideSlingmax Rigging Solutions is a technology and marketingcompany, associated with the best companies in the riggingbusiness inside and outside the USA.The Slingmax family of products includes the Twin-Pathbrand in synthetic slings and the CornerMax brands forcut protection for synthetic slings. Our Gator-sling brandsare well-known multi-part wire rope slings.Our technology results in a competitively priced productline that is far ahead of any competition. Our built-insling inspection and safety features are not availableanywhere else. And this technology is backed up by themost extensive testing program in the sling industry. Ourpolicy of continuous improvement is well documented.Here are some important features of our products.The Power of... SLINGMAX

Our most popular Gantry Style Take-up MachineCumberland Sales Company offers their GS series ranging from 5,000 lbs to 60,000 lbs.Forward & Reverse Operation Variable Speeds Arbor Cones Standard With Optional Coiling HeadReliable. DuRable. unpaRalleleD.Cumberland SaleS Company 615.833.7884 800.643.5189 FaX: 615.333.9879 CSCi nFo@edge.netCSC_Ad_2013FULL_2.indd 1 3/4/13 2:40 PMWIRE ROPE EXCHANGE SEPTEMBER-OCTOBER 2013 19[WRE | SPOTLIGHT]dedicated character, lusk celebrates milestone with J. henry hollandIts a notable accomplishment. Its also one Lusk can hardly believe has come due as time truly does fy by when everything has been, as hes well known for saying, all good.Its hard to believe its been so long, he observes. My life has been enriched in so many positive ways, both personally and professionally, thanks to my af liation with this company and with this industry as a whole. In the late 1970s, fresh out of high school, Lusk never imagined hed be where he is today. In reality, as a young man, he yearned for adventure and was more interested in making extra money so that he might purchase a boat. He initially took on two jobs to satisfy the latter goal working at a local gas station and at Virginias Newport News Shipyard as a welder and ship ftter. Eventually, he became an ofshore commercial fsherman, which fulflled his desire for excitement. After fve years at sea, Lusk wanted back on solid land and a newspaper advertisement led the way. I saw an ad for an opening for a salesperson experienced with wire rope, cordage, and marine hardware. It was a small, family-run start-up Hampton Roads Trading Company. I was thrilled! It was a perfect ft, he recalls. Interestingly, it was this job which would actually lead him to JHH. I competed against the JHHs salesman at that time, Rick Sawin. We were friendly and, at one point, he told me they were hiring. Lusk applied and the rest, as the adage goes, is history. Te year after Lusk joined the frm, in 1984, Baltimore, Maryland-based Indusco Group purchased JHH. It was a move which was, according to Lusk, the best thing that could have ever happened. Tey invested heavily in us, both from an inventory perspectiv

8613371530291

8613371530291