what is the difference between strand and wire rope manufacturer

Have you ever wondered why aircraft cable is called aircraft cable instead of aircraft strand? Do you use the words cable and wire rope interchangeably when you’re not sure which is correct? The world of manufacturing is chock-full of words to describe wire products, and while it may seem confusing to keep track of them at first, having some background knowledge about cable construction will help you understand each component. Let’s take a moment to differentiate our terms by starting small.

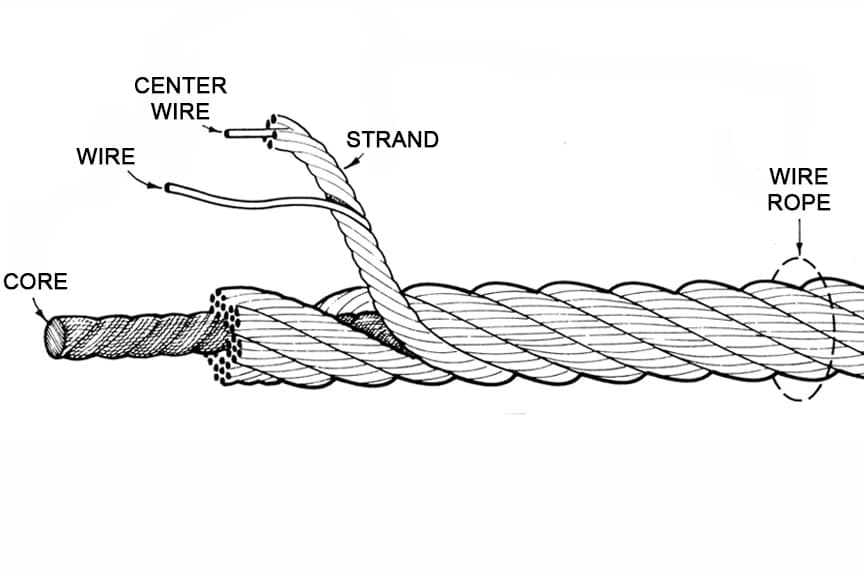

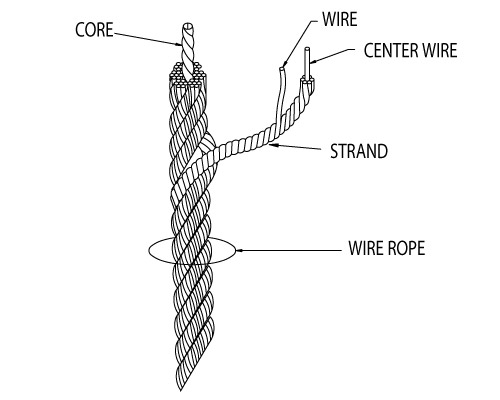

Wire: In its simplest form, wire is a single, flexible, string-like rod. It begins life as a metal such as stainless steel or carbon steel that becomes narrower in diameter as it is drawn through a series of small holes called dies. Used in everything from electrical equipment and coat hangers to art projects and nails, wire is the foundation of many wide and varied items.

Strand: Strand is made of two or more wires laid around a single center wire. In general, “1 by…” products are considered strand, like 1x7 and 1x19, which are two common configurations.

Notice how this 1x7 strand is a unit comprised of individual wires. It is 1 strand of 7 wires.1x19, as another example, is 1 strand of 19 wires. Like wire,strand can exist as its own product, or it can be laid around a core in multiples to become cable or wire rope.

Cable:Cables are made by concentrically wrapping groups of strands. A 7x7 cable, for example, is comprised of seven strands, each made of 7 wires. 7x19 cable, as another example, has seven strands with 19 wires in each one. Wire rope is technically also a group of strands wrapped around a core, which is why the terms cableand wire rope are often used interchangeably. Professions will argue that wire rope is designated for products with a diameter larger than 3/8 inch while cableis designated for all smaller diameters, but in practical application, the terms are somewhat interchageable.

Looking for wire, strand, or cable for your application? Make sure that you specify the size, construction, and material of a product when building your quote on www.strandcore.com. Luckily, Strand Core provides comprehensive data sheets for all our aircraft cable and general purpose wire rope products to help make your selection easier. Visit https://strandcore.com/products/general-purpose-wire-rope/ to start browsing our wire rope products, today.

Wire rope and cable, is there a difference? The terms are often used interchangeably, but are they different? Each is considered a machine. Wire ropes are usually ⅜” in diameter or larger, while cables or cords are smaller. Though this little distinction exists in aircraft and marine cables, wire ropes and cables are synonymous in most other ways.

A strand is made up of two or more wires twisted around a center wire. Each strand is made up of 7, 19, or 37 wires. Cable or wire rope is made when a group of strands is twisted around a center wire or rope. They are named for the numbers of wires and strands. A 7×7 cable has 7 strands with 7 wires in each strand wrapped around a central core. A 7×19 cable would include 7 strands with 19 wires in each cable.

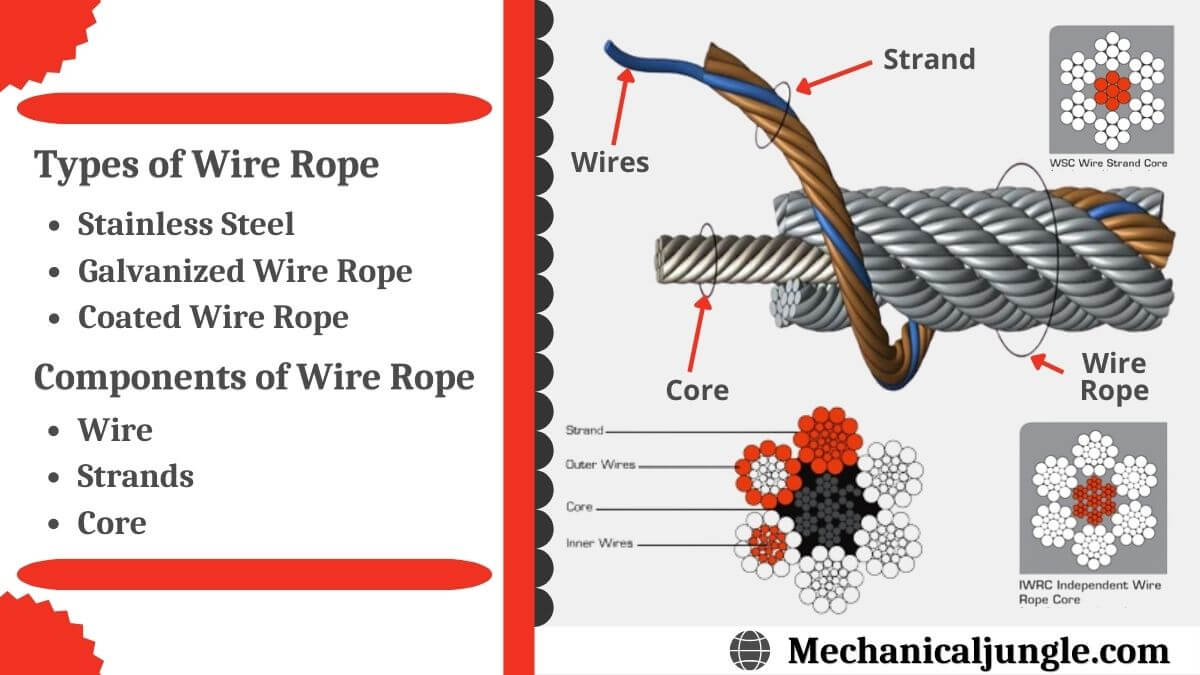

Different wire rope applications require different demands for abrasion, strength, and corrosion resistance. Different materials are used to meet different needs. Sizes under ⅜ “ are considered aircraft cable, sizes over 3/8 “ in diameter are considered wire rope.Stainless Steel – Type 302, made up of 18% chromium and 8% nickel alloy, is the most common grade because of its high strength and resistance to corrosion. When non-magnetic properties are required, type 305 is employed. Other common types used in wire rope are 304, 305, 316, and 321. Each has specific advantages and disadvantages. Stainless steel is the stronger of the two, so its cost is higher but well worth it.

Galvanized Carbon Steel – To protect from the elements, a coating of zinc is applied to wire ropes used in the making of this wire rope. It is the wire rope of choice when strength is necessary, but corrosion resistance is not significant enough to warrant the use of stainless steel. Galvanized carbon steel is the go-to for cost-effectiveness.

If you require flexibility, you need wires that have more strands, more strands equal more flexibility. Look for 3×7, 7×7, and 7×19; these will give you more flexibility. However, as the degrees of flexibility increase, the abrasion resistance decreases. These cables are most useful where you require continuous flexing. Basic cable construction:

1×19 cable – This cable is still reasonably flexible, yet it resists compressive forces. It is smooth on the outside, and sizes above 3/32” diameter are the strongest.

It is essential to correctly estimate the qualities necessary for the work the wire rope will be doing. To decide the importance of the essential attributes to do the job, you need to look for quality and figure out whether it can withstand how it will be used and the length of time it can be used in this capacity. In choosing a wire rope for the job at hand, these four things must be considered:Sufficient strength to lift the load and then some, keeping safety in mind. Always overestimate.

Whether it is a crane, a pulley, or some other machine, be sure to choose the proper size, construction, and grade of wire rope appropriate for the job.

To find the wire rope or cable you need for the job, contact us atSilver State Wire Ropefor all of your wire rope and rigging needs. We have all sizes of cable and wire rope; whether you need it for aircraft, marine, or land use, we have it all!

Wire rope and cable are each considered a “machine”. The configuration and method of manufacture combined with the proper selection of material when designed for a specific purpose enables a wire rope or cable to transmit forces, motion and energy in some predetermined manner and to some desired end.

Two or more wires concentrically laid around a center wire is called a strand. It may consist of one or more layers. Typically, the number of wires in a strand is 7, 19 or 37. A group of strands laid around a core would be called a cable or wire rope. In terms of product designation, 7 strands with 19 wires in each strand would be a 7×19 cable: 7 strands with 7 wires in each strand would be a 7×7 cable.

Materials Different applications for wire rope present varying demands for strength, abrasion and corrosion resistance. In order to meet these requirements, wire rope is produced in a number of different materials.

Stainless Steel This is used where corrosion is a prime factor and the cost increase warrants its use. The 18% chromium, 8% nickel alloy known as type 302 is the most common grade accepted due to both corrosion resistance and high strength. Other types frequently used in wire rope are 304, 305, 316 and 321, each having its specific advantage over the other. Type 305 is used where non-magnetic properties are required, however, there is a slight loss of strength.

Galvanized Carbon Steel This is used where strength is a prime factor and corrosion resistance is not great enough to require the use of stainless steel. The lower cost is usually a consideration in the selection of galvanized carbon steel. Wires used in these wire ropes are individually coated with a layer of zinc which offers a good measure of protection from corrosive elements.

Cable Construction The greater the number of wires in a strand or cable of a given diameter, the more flexibility it has. A 1×7 or a 1×19 strand, having 7 and 19 wires respectively, is used principally as a fixed member, as a straight linkage, or where flexing is minimal.

Cables designed with 3×7, 7×7 and 7×19 construction provide for increasing degrees of flexibility but decreased abrasion resistance. These designs would be incorporated where continuous flexing is a requirement.

Selecting Wire Rope When selecting a wire rope to give the best service, there are four requirements which should be given consideration. A proper choice is made by correctly estimating the relative importance of these requirements and selecting a rope which has the qualities best suited to withstand the effects of continued use. The rope should possess:Strength sufficient to take care of the maximum load that may be applied, with a proper safety factor.

Strength Wire rope in service is subjected to several kinds of stresses. The stresses most frequently encountered are direct tension, stress due to acceleration, stress due to sudden or shock loads, stress due to bending, and stress resulting from several forces acting at one time. For the most part, these stresses can be converted into terms of simple tension, and a rope of approximately the correct strength can be chosen. As the strength of a wire rope is determined by its, size, grade and construction, these three factors should be considered.

Safety Factors The safety factor is the ratio of the strength of the rope to the working load. A wire rope with a strength of 10,000 pounds and a total working load of 2,000 pounds would be operating with a safety factor of five.

It is not possible to set safety factors for the various types of wire rope using equipment, as this factor can vary with conditions on individual units of equipment.

The proper safety factor depends not only on the loads applied, but also on the speed of operation, shock load applied, the type of fittings used for securing the rope ends, the acceleration and deceleration, the length of rope, the number, size and location of sheaves and drums, the factors causing abrasion and corrosion and the facilities for inspection.

Fatigue Fatigue failure of the wires in a wire rope is the result of the propagation of small cracks under repeated applications of bending loads. It occurs when ropes operate over comparatively small sheaves or drums. The repeated bending of the individual wires, as the rope bends when passing over the sheaves or drums, and the straightening of the individual wires, as the rope leaves the sheaves or drums, causing fatigue. The effect of fatigue on wires is illustrated by bending a wire repeatedly back and forth until it breaks.

The best means of preventing early fatigue of wire ropes is to use sheaves and drums of adequate size. To increase the resistance to fatigue, a rope of more flexible construction should be used, as increased flexibility is secured through the use of smaller wires.

Abrasive Wear The ability of a wire rope to withstand abrasion is determined by the size, the carbon and manganese content, the heat treatment of the outer wires and the construction of the rope. The larger outer wires of the less flexible constructions are better able to withstand abrasion than the finer outer wires of the more flexible ropes. The higher carbon and manganese content and the heat treatment used in producing wire for the stronger ropes, make the higher grade ropes better able to withstand abrasive wear than the lower grade ropes.

Effects of Bending All wire ropes, except stationary ropes used as guys or supports, are subjected to bending around sheaves or drums. The service obtained from wire ropes is, to a large extent, dependent upon the proper choice and location of the sheaves and drums about which it operates.

A wire rope may be considered a machine in which the individual elements (wires and strands) slide upon each other when the rope is bent. Therefore, as a prerequisite to the satisfactory operation of wire rope over sheaves and drums, the rope must be properly lubricated.

Loss of strength due to bending is caused by the inability of the individual strands and wires to adjust themselves to their changed position when the rope is bent. Tests made by the National Institute of Standards and Technology show that the rope strength decreases in a marked degree as the sheave diameter grows smaller with respect to the diameter of the rope. The loss of strength due to bending wire ropes over the sheaves found in common use will not exceed 6% and will usually be about 4%.

The bending of a wire rope is accompanied by readjustment in the positions of the strands and wires and results in actual bending of the wires. Repetitive flexing of the wires develops bending loads which, even though well within the elastic limit of the wires, set up points of stress concentration.

The fatigue effect of bending appears in the form of small cracks in the wires at these over-stressed foci. These cracks propagate under repeated stress cycles, until the remaining sound metal is inadequate to withstand the bending load. This results in broken wires showing no apparent contraction of cross section.

Experience has established the fact that from the service view-point, a very definite relationship exists between the size of the individual outer wires of a wire rope and the size of the sheave or drum about which it operates. Sheaves and drums smaller than 200 times the diameter of the outer wires will cause permanent set in a heavily loaded rope. Good practice requires the use of sheaves and drums with diameters 800 times the diameter of the outer wires in the rope for heavily loaded fast-moving ropes.

It is impossible to give a definite minimum size of sheave or drum about which a wire rope will operate with satisfactory results, because of the other factors affecting the useful life of the rope. If the loads are light or the speed slow, smaller sheaves and drums can be used without causing early fatigue of the wires than if the loads are heavy or the speed is fast. Reverse bends, where a rope is bent in one direction and then in the opposite direction, cause excessive fatigue and should be avoided whenever possible. When a reverse bend is necessary larger sheaves are required than would be the case if the rope were bent in one direction only.

Stretch of Wire Rope The stretch of a wire rope under load is the result of two components: the structural stretch and the elastic stretch. Structural stretch of wire rope is caused by the lengthening of the rope lay, compression of the core and adjustment of the wires and strands to the load placed upon the wire rope. The elastic stretch is caused by elongation of the wires.

The structural stretch varies with the size of core, the lengths of lays and the construction of the rope. This stretch also varies with the loads imposed and the amount of bending to which the rope is subjected. For estimating this stretch the value of one-half percent, or .005 times the length of the rope under load, gives an approximate figure. If loads are light, one-quarter percent or .0025 times the rope length may be used. With heavy loads, this stretch may approach one percent, or .01 times the rope length.

The elastic stretch of a wire rope is directly proportional to the load and the length of rope under load, and inversely proportional to the metallic area and modulus of elasticity. This applies only to loads that do not exceed the elastic limit of a wire rope. The elastic limit of stainless steel wire rope is approximately 60% of its breaking strength and for galvanized ropes it is approximately 50%.

Preformed Wire Ropes Preformed ropes differ from the standard, or non-preformed ropes, in that the individual wires in the strands and the strands in the rope are preformed, or pre-shaped to their proper shape before they are assembled in the finished rope.

This, in turn, results in preformed wire ropes having the following characteristics:They can be cut without the seizings necessary to retain the rope structure of non-preformed ropes.

They are substantially free from liveliness and twisting tendencies. This makes installation and handling easier, and lessens the likelihood of damage to the rope from kinking or fouling. Preforming permits the more general use of Lang lay and wire core constructions.

Removal of internal stresses increase resistance to fatigue from bending. This results in increased service where ability to withstand bending is the important requirement. It also permits the use of ropes with larger outer wires, when increased wear resistance is desired.

Outer wires will wear thinner before breaking, and broken wire ends will not protrude from the rope to injure worker’s hands, to nick and distort adjacent wires, or to wear sheaves and drums. Because of the fact that broken wire ends do not porcupine, they are not as noticeable as they are in non-preformed ropes. This necessitates the use of greater care when inspecting worn preformed ropes, to determine their true condition.

Wire rope is a complex mechanical device that has many moving parts all working in tandem to help support and move an object or load. In the lifting and rigging industries, wire rope is attached to a crane or hoist and fitted with swivels, shackles or hooks to attach to a load and move it in a controlled matter. It can also be used to lift and lower elevators, or as a means of support for suspension bridges or towers.

Wire rope is a preferred lifting device for many reasons. Its unique design consists of multiple steel wires that form individual strands laid in a helical pattern around a core. This structure provides strength, flexibility, and the ability to handle bending stresses. Different configurations of the material, wire, and strand structure will provide different benefits for the specific lifting application, including:Strength

However, selecting the proper wire rope for your lifting application requires some careful thought. Our goal is to help you understand the components of a wire rope, the construction of wire rope, and the different types of wire rope and what they might be used for. This will allow you to select the best performing and longest-lasting wire rope for the job at hand.

From childhood, many of us have been conditioned to think of a machine as some device with gears, shafts, belts, cams, and assorted whirring parts. Yet, by the rules of physics, an ordinary pry bar is a simple machine, even though it has only one part.

A wire rope is, in reality, a very complicated machine. A typical 6 x 25 rope has 150 wires in its outer strands, all of which move independently and together in a very complicated pattern around the core as the rope bends. Clearances between wires and strands are balanced when a rope is designed so that proper bearing clearances will exist to permit internal movement and adjustment of wires and strands when the rope has to bend. These clearances will vary as bending occurs, but are of the same range as the clearances found in automobile engine bearings.

Understanding and accepting the “machine idea” gives a rope user a greater respect for rope, and enables them to obtain better performance and longer useful life from rope applications. Anyone who uses a rope can use it more efficiently and effectively when they fully understand the machine concept.

Wires are the smallest component of wire rope and they make up the individual strands in the rope. Wires can be made from a variety of metal materials including steel, iron, stainless steel, monel, and bronze. The wires can be manufactured in a variety of grades that relate to the strength, resistance to wear, fatigue resistance, corrosion resistance, and curve of the wire rope.

Strands of wire rope consist of two or more wires arranged and twisted in a specific arrangement. The individual strands are then laid in a helical pattern around the core of the rope.

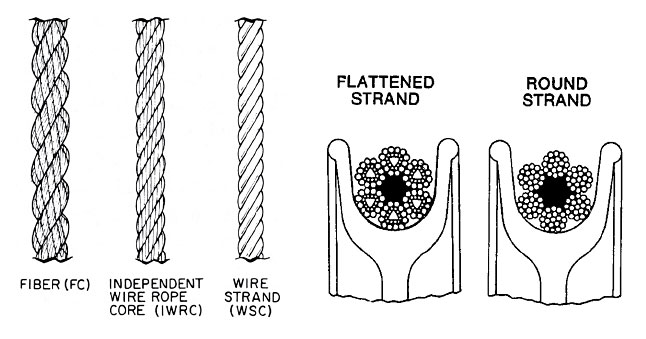

The core of a wire rope runs through the center of the rope and supports the strands and helps to maintain their relative position under loading and bending stresses. Cores can be made from a number of different materials including natural or synthetic fibers and steel.

Lubrication is applied during the manufacturing process and penetrates all the way to the core. Wire rope lubrication has two primary benefits:Reduces friction as the individual wires and strands move over each other

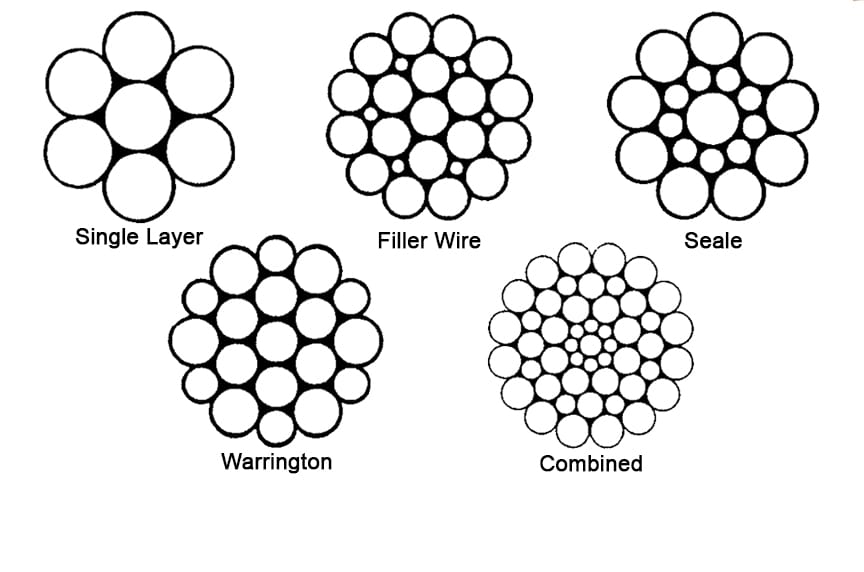

The number of layers of wires, the number of wires per layer, and the size of the wires per layer all affect the strand pattern type. Wire rope can be constructed using one of the following patterns, or can be constructed using two or more of the patterns below.Single Layer – The most common example is a 7 wire strand with a single-wire center and six wires of the same diameter around it.

Filler Wire – Two layers of uniform-size wire around a center with the inner layer having half the number of wires as the outer layer. Small filler wires, equal to the number in the inner layer, are laid in valleys of the inner wire.

Seale – Two layers of wires around a center with the same number of wires in each layer. All wires in each layer are the same diameter. The large outer wires rest in the valleys between the smaller inner wires.

Warrington – Two layers of wires around a center with one diameter of wire in the inner layer, and two diameters of wire alternating large and small in the outer later. The larger outer-layer wires rest in the valleys, and the smaller ones on the crowns of the inner layer.

On a preformed wire rope, the strands and wires are formed during the manufacturing process to the helical shape that they will take in a finished wire rope.

Preformed rope can be advantageous in certain applications where it needs to spool more uniformly on a drum, needs greater flexibility, or requires more fatigue-resistance when bending.

Direction and type of lay refer to the way the wires are laid to form a strand (either right or left) and how the strands are laid around the core (regular lay, lang lay, or alternate lay).Regular Lay – The wires line up with the axis of the rope. The direction of the wire lay in the strand is opposite to the direction of the strand lay. Regular lay ropes are more resistant to crushing forces, are more naturally rotation-resistant, and also spool better in a drum than lang lay ropes.

Lang Lay– The wires form an angle with the axis of the rope. The wire lay and strand lay around the core in the same direction. Lang Lay ropes have a greater fatigue-resistance and are more resistant to abrasion.

A fiber core can be made of natural or synthetic polypropylene fibers. Fiber cores offer greater elasticity than a steel core but are more susceptible to crushing and not recommended for high heat environments.

A steel core can be an independent wire rope or an individual strand. Steel cores are best suited for applications where a fiber core may not provide adequate support, or in an operating environment where temperatures could exceed 180° F.

The classifications of wire rope provide the total number of strands, as well as a nominal or exact number of wires in each strand. These are general classifications and may or may not reflect the actual construction of the strands. However, all wire ropes of the same size and wire grade in each classification will have the SAME strength and weight ratings and usually the same pricing.

Besides the general classifications of wire rope, there are other types of wire rope that are special construction and designed for special lifting applications.

Some types of wire rope, especially lang lay wire rope, are more susceptible to rotation when under load. Rotation resistant wire rope is designed to resist twisting, spinning, or rotating and can be used in a single line or multi-part system.

Special care must be taken when handling, unreeling, and installing rotation resistant wire rope. Improper handling or spooling can introduce twist into the rope which can cause uncontrolled rotation.

Compacted strand wire rope is manufactured using strands that have been compacted, reducing the outer diameter of the entire strand, by means of passing through a die or rollers. This process occurs prior to closing of the rope.

This process flattens the surface of the outer wires in the strand, but also increases the density of the strand. This results in a smoother outer surface and increases the strength compared to comparable round wire rope (comparing same diameter and classification), while also helping to extend the surface life due to increased wear resistance.

A swaged wire rope differs from a compacted strand wire rope, in that a swaged wire rope’s diameter is compacted, or reduced, by a rotary swager machine after the wire rope has been closed. A swaged wire rope can be manufactured using round or compacted strands.

The advantages of a swaged wire rope are that they are more resistant to wear, have better crushing resistance, and high strength compared to a round strand wire rope of equal diameter and classification. However, a swaged wire rope may have less bending fatigue resistance.

A plastic coating can be applied to the exterior surface of a wire rope to provide protection against abrasion, wear, and other environmental factors that may cause corrosion. However, because you can’t see the individual strands and wires underneath the plastic coating, they can be difficult to inspect.

Plastic filled wire ropes are impregnated with a matrix of plastic where the internal spaces between the strands and wires are filled. Plastic filling helps to improve bending fatigue by reducing the wear internally and externally. Plastic filled wire ropes are used for demanding lifting applications.

This type of wire rope uses an Independent Wire Rope Core (IWRC) that is either filled with plastic or coated in plastic to reduce internal wear and increase bending fatigue life.

Remember, wire rope is a complex piece of mechanical machinery. There are a number of different specifications and properties that can affect the performance and service life of wire rope. Consider the following when specifying the best type of wire rope for your lifting application:Strength

When you select a piece of rope that is resistant to one property, you will most likely have a trade-off that affects another property. For example, a fiber core rope will be more flexible, but may have less crushing resistance. A rope with larger diameter wires will be more abrasion resistant, but will offer less fatigue resistance.

At Mazzella Companies, we offer all different kinds of wire rope from all of the leading manufacturers. We sell the highest-quality domestic and non-domestic rigging products because product quality and operating safety go hand-in-hand. We have one of the largest and most complete inventories of both domestic and non-domestic rigging and lifting products to suit your lifting needs.

If you’re looking for a standard or custom specified wire rope for your lifting project, contact a Lifting Specialist at a Mazzella Companies location near you.

We stock well over 2,000,000 feet of wire rope in our various locations … ready for immediate delivery! We provide wire rope assemblies, and manufacture bridge cables, crane cables, steel mill cables, and thousands of OEM assemblies.

We can also manufacture assemblies with standard or custom end fittings. Special testing and tolerance requirements are also available.In sizes from 1/4″ to 3″ diameter and 9 mm to 52 mm diameter

As an operations manager in need of new ropes, your machines require a specific manufacturer of wire ropes. However, when you walk into a supplier’s warehouse, you don’t know how to identify one wire rope manufacturer’s product from another.

With domestic wire rope brands, the way to identify the color strand is by looking at it. This is for general purpose wire rope only, which includes the 6×19 and 6×36 classes.

General purpose wire rope is used in the manufacture of wire rope slings, on overhead cranes, and mobile cranes. It differs from high-performance crane rope. General purpose wire rope isn’t 19-strand or 35×7.

Beginning in the 1980s, U.S. companies used color-coding systems as a form of identification to differentiate from international products. This was done to establish traceability as non-domestic manufacturers became more prominent in the wire rope industry.

The core marker is different than a strand identifier. The core marker is an internal plastic mono filament film that would help identify:Country of origin

Generally, you have to cut into the rope to find the core marker. In the event of a rope failure, the core marker will make it easier to identify the manufacturer. Core markers run throughout the entire wire rope. If you took a cross section of the rope, and deconstructed it, you’d find the film used to identify the manufacturer and country of origin.

Predominantly, domestic wire rope suppliers brought this to market. However, today, most manufacturers, including high quality non-domestic wire rope suppliers, also use internal core markers to identify themselves.

When it comes to the three major domestic wire rope suppliers and the color strand that identifies them, the markings unique to the brand include:Bridon-Bekaert is one blue strand that is going on its general purpose rope

There are no standards from the American Society of Mechanical Engineers (ASME) or Occupational Safety and Health Administration (OSHA) mandating the use of color strand identifiers.

Also, it’s not a hard and fast rule that every run of domestic rope has a color strand. There may be a specific reason that a run of rope doesn’t have a color. Colors are solely based on the manufacturers of the wire rope, and it’s traceability.

This is all about marketing, so customers can identify the manufacturers quickly. The color-coding system was designed so anyone with knowledge of the colors can walk into a warehouse and figure out which suppliers that distributor offers.

By reading this article, you now know the history and reasoning behind the domestic wire rope color-coding system. Also, you understand which colors represent what domestic wire rope manufacturers.

Having this knowledge should clear up confusion the next time you need wire rope. Hopefully, it will make your buying experience more efficient and user-friendly.

Remember, the color strands are simply identifiers. They are not indications of working load limits. For that information, refer to the manufacturer’s standards, or tags required by ASME.

Did you know wire ropes were used as far back as the 1830s for mining hoist applications? Nowadays, we can use steel ropes for many different applications such as lifting and hoisting in elevators and cranes, and for mechanical power transmission. US Cargo Control’s wire rope slings are an excellent choice for heavy-duty jobs as their fabrication offers excellent abrasion resistance and heat resistance for extreme conditions.

Although these slings are beneficial for the lifting and rigging industry, there are a few specifications to know before purchasing them. Continue reading what is wire rope, what are important specifications to look for, and how it’s different from cable rope.

These slings carry different properties that can determine their performance. Wire rope is constructed where a strand consists of two or more wires arranged and twisted in a specific arrangement. The individual strands are then laid in a helical pattern around the core of the rope. Once the wires are formed, they all come together to create greater strength and flexibility.

These slings work well for lifting, hoisting, towing, or anchoring loads. They’re manufactured in a variety of configurations, with 6×19 and 6×36 being the most common. When you see 6×19 or 6×36 from our website, these numbers represent the number of wires making up the strand and the number of strands wrapped around the core.

For example, a 6×19 indicates that there are 19 wires making up a strand, and 6 strands wrapping around the core. To learn more about our 6×19 wire ropes, look into our bestselling 1/2″ Galvanized Wire Rope EIPS IWRC, 1/2″ Stainless Steel Wire Rope IWRC T304, and 1/2″ Bright Wire Rope EIPS FC.

The configurations will offer different benefits for certain applications. In general, a smaller number of large outer wires offers better wear and corrosion resistance, while a larger number of small wires provides a better level of flexibility and fatigue resistance. Continue reading to learn which wire rope fits your job.

There are different versions of wire rope slings, ranging from single leg to 4 legs, as well as braided wire rope and domestic wire rope slings (manufactured in the U.S. with Crosby® hardware). When looking at the types of slings we offer at US Cargo Control, be sure to consider how much versatility and capability you need.

For example, a braided wire rope has increased flexibility and friction to grip loads over a regular wire rope. Adding an additional leg to the sling can add additional versatility and strength.

This is the measurement of the rope’s diameter and can be displayed in inches or millimeters. These sizes commonly display different strand patterns where the number of layers, wires per layer, and size of the wires per layer all affect the strand pattern. Wire rope can be constructed using one of the following patterns below or using two or more patterns.

Warrington – this construction has two layers of wires around a center with one diamter of wire in the inner layer, and two diameteres of wire alternating large and small in the outer layer.

The type of lay refers to the way the wires are laid to form a strand. They’re how the strands are laid around the core which can be regular lay, long lay, or alternate lay.

The wires line up with the axis of the rope. This is where the wires are twisting in one direction, and the strands in the opposite direction create the rope. Regular lay is less likely to untwist and less likely to crush.

This is the opposite of regular lay where the wires form an angle with the axis of the rope. The wires and strands spiral in the same direction and run at a diagonal to the centerline of the rope. Lang lay is more flexible and resistant to abrasion than regular lay wire ropes. The only con is this type of lay will be more likely to twist and crush than the regular lay.

Sometimes known as reverse lay, this type of lay consists of alternating regular lay and long lay strands. This unites the best features of both types, and it’s using relatively large outer wires to provide an increase of abrasion resistance.

This refers to the protective coating that’s applied to the wire rope. There are three types of finishes which are galvanized (zinc-coated), stainless steel, and bright (unfinished steel).

The grade of the rope means the grade of steel being used. The plow steel strength calculates the strengths of most steel wire ropes. Some classifications include Improved Plow Steel (IPS), Extra Improved Plow Steel (EIPS), Extra Extra Improved Plow Steel (EEIPS), Galvanized Improved Plowed Steel (GIPS), and Drawn Galvanized Imrpoved Plow Steel (DGEIP).

EIPS is 15% stronger than IPS, and EEIPS is 10% stronger than EIPS. Along with that, GIPS and DGEIP wires can add corrosion resistance to your application, but DGEIP wires have a higher break load than GIPS.

The type of core is what makes up the center of the wire rope. There are three types of core: Fiber Core (FC), Independent Wire Rope Core (IWRC), and Wire Strand Core (WSC).

A fiber core can be made of synthetic polypropylene fibers. The fiber cores offer greater elasticity than a steel core, but are more susceptible to crushing. This isn’t recommended for high heat environments.

A steel core can either be an independent wire rope or individual strand. The steel cores can provide adequate support, or in an operating environment where temperatures can exceed very high heat.

Wire and cable ropes are terms that are often interchangeable but do have one varying difference. Wire rope refers to the diameters that are larger than 3/8 inch. Sizes smaller than this are classified as cable rope or even cords. Regardless of the size difference, cable and wire rope are still classified as a “machine.” Even a group of strands laid around a core would still be called a cable or wire rope.

We know the importance of quality when it comes to lifting supplies. We carry a variety of rigging hardware, as well as lifting beams and spreader bars that are designed to lift heavy loads safely and efficiently. If you’re interested in other lifting slings, check the other types of slings we carry like nylon slings and chain slings.

Contact our sales team at US Cargo Control today at 866-444-9990. Our team of product experts is here to answer any questions about rigging hardware, lifting slings, and more.

The difference between wire rope and industrial cable is important to understand. Both are renowned for their incredible strength and durability. While smaller cables and wires are used in everything from swing sets and exercise equipment, more robust models are used in suspension bridges and skyscrapers.

While wire ropes and cables are used all the time in today’s world, they have only been around for less than 200 years. Thewas created in Germany by a mining engineer with wrought iron. However, today’s cables and wire ropes are made nearly exclusively from steel.

But this is not the only detail that both wire ropes and industrial cables share. This is often why these pieces of hardware are confused and their terms are used interchangeably. So, what is the difference between wire rope and industrial cable?

As the name implies, a wire rope is constructed similarly to ropes made from fabric like hemp, but in this case, it is made with thin metal strands. These are woven together to form a strong yet flexible material that is used for support, overhead lifting, and securement. Wire ropes are used in industrial applications commonly with cranes, hoists, swivels, shackles, or hooks for attachments.

The demand for durable wire ropes has been steadily increasing since it is extensively used in massive industries like oil and gas, construction, marine fishing, and mining. While COVID-19 slowed down production in 2020 and 2021, the market size isthrough 2026 and will exceed $17.5 billion.

There are various mechanics which attribute to the strength and recommended use of wire ropes. For instance, a wire rope constructed with more strands will be more flexible than one with fewer. The diameter of the wires also contributes to flexibility and strength.

Wire ropes come in bright, galvanized, or stainless-steel finishes. Bright wire ropes may only be used for applications where the rope will not come into contact with moisture, as the material will corrode. Galvanized and stainless-steel ropes are corrosion resistant, and stainless steel is the strongest material available.

Other factors to be aware of when purchasing wire ropes are the core and pattern or lay. Wire ropes may have a fiber, independent wire, or wire strand core to support either flexibility or strength. The lay or direction in which the wires are woven also impacts the rotation resistance.

Although cable shares many of the same properties as wire rope, it is most easily classified based on size. The key difference between industrial cable and wire rope is the diameter of the strands. The smallest diameter of strands for a wire rope is typically 3/8”, while cables can have wires.

Since industrial cable wires are smaller, they are far more flexible and a bit more versatile. Like wire ropes, cables are used in construction, engineering, and machinery. But industrial cable is also commonly used in

Another slight difference between industrial cables and wire ropes. Industrial cable is not offered in a bright finish, only galvanized and stainless steel. This is because the increased flexibility naturally decreases abrasion resistance. Galvanized and stainless steel are better at resisting fatigue and abrasion than bright steel.

Industrial cables do have the same core offerings as wire rope: fiber, independent wire, or wire strand. However, another difference is the strand groupings. Industrial cables are most commonly offered in either 7×7 or 7×19 construction, while wire ropes have far more groupings.

While the differences between industrial cable and wire ropes may appear subtle, it is critical to select the correct hardware depending on the application. Weight load limits are generally the first indication of whether a wire rope or industrial cable will be used. Since wire ropes have a larger wire diameter, they can withstand heavier loads.

The required range of flexibility is also an important factor. For applications such as pulley systems, industrial cables are often recommended. Their construction is more flexible and abrasion-resistant, and it even offers a bit of stretch to combat cable fatigue.

No matter what, safety and overall construction quality need to be of top priority when selecting this type of hardware. If you are unsure of which to use, consult a knowledgeable wire rope and industrial cable wholesaler for assistance.

If you have further questions regarding the construction and use of either wire ropes or industrial cable, you can. We’ve built a reputation as a trustworthy and experienced wire rope and industrial cable supplier – and our team is here to help you out.

We believe that purchasinghigh-quality wire ropes and cable is the best way to ensure its strength and performance. That’s why we only offer the best-rated hardware on the market. Get in touch today to place an order.

Here you will find everything you need to know about ropes and cables. What is the difference between a wire, strand and a rope? Which rope constructions do exist? What is meant by lay directions? What is the effect of stretching? What materials are available? What is a coated rope and what is it required for? These and other questions we, from Carl Stahl Technocables would like to answer here.

Strands are made of single high tensile wires. These are placed helically around an insert * (heart wire) in the steel cable factory. This is the basic model for the further rope prodution.

The lay direction indicates the direction in which the outer wires (outer strands) of the strand (cable) are laid around the center wire (core strand).

Furthermore, a distinction is made between ordinary/regular lay and langs in the stranding (see figure). As standard, Carl Stahl Technocables delivers the steel cables in right hand ordinary lay (sZ).

For example, in the case of cable systems that run over pulleys, we recommend using coated cables in order to achieve a high bending cycle and a long service life. With higher bending cycles a longer service life could be achieved.

Carl Stahl Technocables uses polyamide as the standard coating material. Polyamide is an optimum cable coating, distinguished by its high wear resistance and high bending cycle capability. A further advantage of the coated cables: The coating protects the rope from dirt.

Furthermore, the coating keeps the manufacturing lubricant within the rope. This film of oil functions as a lubricant between the individual wires and strands, thereby reducing wear on the cable.

Are high temperatures or good sliding properties required of your steel wire rope? Then we use special materials for coating of the steel wire rope. For example, we recommend FEP/PTFE for temperatures of between -190°C and + 205° C.

We can also offer PA6. PA6 is stiffer than PA12 and is therefore not suitable for pulleys. However, PA6 has better sliding properties and is therefore highly suitable as a guide cable for example.

Depending on the application, the appropriate coating material is used. Don’t you know which wire rope coating is the right for your rope application? - We"re glad to help you finding the right material. Contact us directly

After the manufacturing process of the ropes and strands, small gaps remain between each wire within the strand and between each strand in the rope. When the rope is tensioned, the wires and the strand move closer to each other, and reach their optimum position. A result of this process is, that the rope elongates to a certain extent. This constructional elongation is not the same in every rope construction. It depends on lay, lay length, rope construction and other factors.

This elongation concerns the material that the single wires are made of. It occurs, when the wire is tensioned. The material elongation is proportional to the applied load. Under normal circumstances the rope will almost regain its original length as soon as the load is removed.

Contact us directly for your individual cable solution. We can recommend suitable steel cables for your purposes. The service life of strands and cables depends on many factors:

The diverse properties and possibilities of wire ropes and strands are attracting more and more attention when it comes to implementing mechanical applications flexibly and safely. The result is high-quality solutions for a wide range of applications, in a wide variety of industries. The possible applications of wire ropes are almost endless. Wire ropes with larger diameters up to 8.00 mm are used in mechanical engineering or in the sun protection sector. Fine wire ropes with smaller diameters from 0.09 mm are used in the medical, furniture or lighting industries, among others. Optical aspects also often play a role.

The selection of the right wire rope for the respective application is of great importance. This is done according to various criteria, which are selected on the basis of the respectivearea of application. Properties and conditions such as tensile strength, environment, corrosion resistance, form, function, surface and structureare taken into account.

Standard wire ropes and strands are made of galvanized steel, or stainless steel. Stainless steel ropes, for example, offer very high corrosion protection, are solidand have a very long service life. Wire ropes made of galvanized wire, are in many cases the most economical option and offer sufficient corrosion protection for various applications.

Carl Stahl Technocables GmbH is your competent partner from the initial consultation, through the development of technical specifications, to the manufacture of assembled ropes, Bowden cables, wire ropes and strands. We supply our products to a wide variety of industries and markets worldwide.

Ropes made of stainless steel are rustproof. They score high on durabilitydue to low abrasion, are solidand have low ductility. Stainless steel ropes offer high tensile strength for mechanical applications and are temperature resistant.

Stainless steel is a corrosion-resistant alloy of iron, chromium-nickel and other elements, containing not less than 10.5% chromium, and its specific ratios vary depending on the alloy. The higher the chromium content in stainless steel, the higher the corrosion resistance. There are different types of stainless steel cables. We mainly use AISI 316 / 1.4401 or AISI 304 / 1.4301. The most common stainless steel is 1.4401. We also offer other stainless steels on request.

1.4301 is the standard material for austenitic chromium-nickel steels. It is characterized above all by its good workability and also has a high corrosion resistance. AISI 304 / 1.4301, for example, has about 10 percent more tensile strength than equivalent materials.

Although the differences between stainless steel specifications are small, they affect their effectiveness in various applications. For example, the additional molybdenum content in 316 stainless steel helps make it even more corrosion resistant than 304.

AISI 304 / 1.4301 is widely used in medical applications due to its strength, malleability, precision in manufacturing and reliability. In addition, it is recyclable, heat resistant.

Stainless steel wire rope is the right choice for applications where the rope needs to be protected from corrosion. Applications that are likely to be used outdoors, underwater or in an area where the wire rope would be exposed to the elements. In particular, it is highly resistant to corrosion by acids and bases.

In the case of steel cables made of galvanized steel, the steel has undergone a galvanizing process called hot-dip galvanizing or HDP. HDP is the process of immersing the steel in molten zinc, which forms a coated zinc layer around the steel that protects the material from corrosion. While it is not as corrosion resistant as stainless steel cable, it is sufficient for an outdoor application in some cases.

The low cost-to-benefit ratio of galvanized steel wire rope makes this the preferred material for many mechanical applications intended for indoor use such as hanging heavy signage or suspending, lifting or balancing large objects.

The standard wires for steel wire strands and cables are made of galvanised steel or stainless steel 1.4401/ AISI 316. Galvanised wire offers sufficient corrosion protection for many areas of use. If the steel wire cables and strands are to be used in highly corrosive media, we recommend stainless steels.

In order to meet your special cable requirements, we also produce cables using other materials. In addition to the standard materials, stainless steel and galvanised steel special materials are also used, such as the following for example:

Here you will find everything you need to know about ropes and cables. What is the difference between a wire, strand and a rope? Which rope constructions do exist? What is meant by lay directions? What is the effect of stretching? What materials are available? What is a coated rope and what is it required for? These and other questions we, from Carl Stahl Technocables would like to answer here.

Strands are made of single high tensile wires. These are placed helically around an insert * (heart wire) in the steel cable factory. This is the basic model for the further rope prodution.

The lay direction indicates the direction in which the outer wires (outer strands) of the strand (cable) are laid around the center wire (core strand).

Furthermore, a distinction is made between ordinary/regular lay and langs in the stranding (see figure). As standard, Carl Stahl Technocables delivers the steel cables in right hand ordinary lay (sZ).

For example, in the case of cable systems that run over pulleys, we recommend using coated cables in order to achieve a high bending cycle and a long service life. With higher bending cycles a longer service life could be achieved.

Carl Stahl Technocables uses polyamide as the standard coating material. Polyamide is an optimum cable coating, distinguished by its high wear resistance and high bending cycle capability. A further advantage of the coated cables: The coating protects the rope from dirt.

Furthermore, the coating keeps the manufacturing lubricant within the rope. This film of oil functions as a lubricant between the individual wires and strands, thereby reducing wear on the cable.

Are high temperatures or good sliding properties required of your steel wire rope? Then we use special materials for coating of the steel wire rope. For example, we recommend FEP/PTFE for temperatures of between -190°C and + 205° C.

We can also offer PA6. PA6 is stiffer than PA12 and is therefore not suitable for pulleys. However, PA6 has better sliding properties and is therefore highly suitable as a guide cable for example.

Depending on the application, the appropriate coating material is used. Don’t you know which wire rope coating is the right for your rope application? - We"re glad to help you finding the right material. Contact us directly

After the manufacturing process of the ropes and strands, small gaps remain between each wire within the strand and between each strand in the rope. When the rope is tensioned, the wires and the strand move closer to each other, and reach their optimum position. A result of this process is, that the rope elongates to a certain extent. This constructional elongation is not the same in every rope construction. It depends on lay, lay length, rope construction and other factors.

This elongation concerns the material that the single wires are made of. It occurs, when the wire is tensioned. The material elongation is proportional to the applied load. Under normal circumstances the rope will almost regain its original length as soon as the load is removed.

Contact us directly for your individual cable solution. We can recommend suitable steel cables for your purposes. The service life of strands and cables depends on many factors:

The diverse properties and possibilities of wire ropes and strands are attracting more and more attention when it comes to implementing mechanical applications flexibly and safely. The result is high-quality solutions for a wide range of applications, in a wide variety of industries. The possible applications of wire ropes are almost endless. Wire ropes with larger diameters up to 8.00 mm are used in mechanical engineering or in the sun protection sector. Fine wire ropes with smaller diameters from 0.09 mm are used in the medical, furniture or lighting industries, among others. Optical aspects also often play a role.

The selection of the right wire rope for the respective application is of great importance. This is done according to various criteria, which are selected on the basis of the respectivearea of application. Properties and conditions such as tensile strength, environment, corrosion resistance, form, function, surface and structureare taken into account.

Standard wire ropes and strands are made of galvanized steel, or stainless steel. Stainless steel ropes, for example, offer very high corrosion protection, are solidand have a very long service life. Wire ropes made of galvanized wire, are in many cases the most economical option and offer sufficient corrosion protection for various applications.

Carl Stahl Technocables GmbH is your competent partner from the initial consultation, through the development of technical specifications, to the manufacture of assembled ropes, Bowden cables, wire ropes and strands. We supply our products to a wide variety of industries and markets worldwide.

Ropes made of stainless steel are rustproof. They score high on durabilitydue to low abrasion, are solidand have low ductility. Stainless steel ropes offer high tensile strength for mechanical applications and are temperature resistant.

Stainless steel is a corrosion-resistant alloy of iron, chromium-nickel and other elements, containing not less than 10.5% chromium, and its specific ratios vary depending on the alloy. The higher the chromium content in stainless steel, the higher the corrosion resistance. There are different types of stainless steel cables. We mainly use AISI 316 / 1.4401 or AISI 304 / 1.4301. The most common stainless steel is 1.4401. We also offer other stainless steels on request.

1.4301 is the standard material for austenitic chromium-nickel steels. It is characterized above all by its good workability and also has a high corrosion resistance. AISI 304 / 1.4301, for example, has about 10 percent more tensile strength than equivalent materials.

Although the differences between stainless steel specifications are small, they affect their effectiveness in various applications. For example, the additional molybdenum content in 316 stainless steel helps make it even more corrosion resistant than 304.

AISI 304 / 1.4301 is widely used in medical applications due to its strength, malleability, precision in manufacturing and reliability. In addition, it is recyclable, heat resistant.

Stainless steel wire rope is the right choice for applications where the rope needs to be protected from corrosion. Applications that are likely to be used outdoors, underwater or in an area where the wire rope would be exposed to the elements. In particular, it is highly resistant to corrosion by acids and bases.

In the case of steel cables made of galvanized steel, the steel has undergone a galvanizing process called hot-dip galvanizing or HDP. HDP is the process of immersing the steel in molten zinc, which forms a coated zinc layer around the steel that protects the material from corrosion. While it is not as corrosion resistant as stainless steel cable, it is sufficient for an outdoor application in some cases.

The low cost-to-benefit ratio of galvanized steel wire rope makes this the preferred material for many mechanical applications intended for indoor use such as hanging heavy signage or suspending, lifting or balancing large objects.

The standard wires for steel wire strands and cables are made of galvanised steel or stainless steel 1.4401/ AISI 316. Galvanised wire offers sufficient corrosion protection for many areas of use. If the steel wire cables and strands are to be used in highly corrosive media, we recommend stainless steels.

In order to meet your special cable requirements, we also produce cables using other materials. In addition to the standard materials, stainless steel and galvanised steel special materials are also used, such as the following for example:

We advise you on the selection of the suitable wire rope or the right strand for your application. Thanks to the wide range of options, we can offer steel wire ropes for a wide variety of applications. All TechnoCables are manufactured from wires of high tensile strength. Years of experience and a continuous quality assurance chain from incoming goods to dispatch are a guarantee for the highest level of reliability and quality. This makes us your reliable partner for all rope applications.

We offer ropes in the range under 1 mm to 8 mm. Fine ropes with a small diameter are used in medical technology for example. Wire ropes with a larger diameter in mechanical engineering or in the field of sun protection.strands 0.09 mm - 5.0 mm

The selection of the suitable material depends on the area of application. Steel wire ropes are in many cases the most economical option. For many areas of application, ropes made of galvanized steel have adequate corrosion protection. We recommend the use of stainless steel cables for applications with a high corrosion potential.Galvanized steel ropes and strands

Strands are made by stranding wires and are the basic for further rope manufacturing. 3 to 37-wire strands are stranded here. As the number of wires increases, the flexibility of the rope and thus the fatigue strength increases. A strand, rope or fiber insert can be used as the insert.Steel wire ropes

Surface treatments can be individually tailored to the respective demands and customer application. Functional coatings can also be implemented on request.Galvanized steel cable coated, stainless steel cable coated

In stricter senses, the term wire rope refers to a diameter larger than 9.5 mm (3⁄8 in), with smaller gauges designated cable or cords.wrought iron wires were used, but today steel is the main material used for wire ropes.

Historically, wire rope evolved from wrought iron chains, which had a record of mechanical failure. While flaws in chain links or solid steel bars can lead to catastrophic failure, flaws in the wires making up a steel cable are less critical as the other wires easily take up the load. While friction between the individual wires and strands causes wear over the life of the rope, it also helps to compensate for minor failures in the short run.

Wire ropes were developed starting with mining hoist applications in the 1830s. Wire ropes are used dynamically for lifting and hoisting in cranes and elevators, and for transmission of mechanical power. Wire rope is also used to transmit force in mechanisms, such as a Bowden cable or the control surfaces of an airplane connected to levers and pedals in the cockpit. Only aircraft cables have WSC (wire strand core). Also, aircraft cables are available in smaller diameters than wire rope. For example, aircraft cables are available in 1.2 mm (3⁄64 in) diameter while most wire ropes begin at a 6.4 mm (1⁄4 in) diameter.suspension bridges or as guy wires to support towers. An aerial tramway relies on wire rope to support and move cargo overhead.

Modern wire rope was invented by the German mining engineer Wilhelm Albert in the years between 1831 and 1834 for use in mining in the Harz Mountains in Clausthal, Lower Saxony, Germany.chains, such as had been used before.

Wilhelm Albert"s first ropes consisted of three strands consisting of four wires each. In 1840, Scotsman Robert Stirling Newall improved the process further.John A. Roebling, starting in 1841suspension bridge building. Roebling introduced a number of innovations in the design, materials and manufacture of wire rope. Ever with an ear to technology developments in mining and railroading, Josiah White and Erskine Hazard, principal ownersLehigh Coal & Navigation Company (LC&N Co.) — as they had with the first blast furnaces in the Lehigh Valley — built a Wire Rope factory in Mauch Chunk,Pennsylvania in 1848, which provided lift cables for the Ashley Planes project, then the back track planes of the Summit Hill & Mauch Chunk Railroad, improving its attractiveness as a premier tourism destination, and vastly improving the throughput of the coal capacity since return of cars dropped from nearly four hours to less than 20 minutes. The decades were witness to a burgeoning increase in deep shaft mining in both Europe and North America as surface mineral deposits were exhausted and miners had to chase layers along inclined layers. The era was early in railroad development and steam engines lacked sufficient tractive effort to climb steep slopes, so incline plane railways were common. This pushed development of cable hoists rapidly in the United States as surface deposits in the Anthracite Coal Region north and south dove deeper every year, and even the rich deposits in the Panther Creek Valley required LC&N Co. to drive their first shafts into lower slopes beginning Lansford and its Schuylkill County twin-town Coaldale.

The German engineering firm of Adolf Bleichert & Co. was founded in 1874 and beg

8613371530291

8613371530291