what is the difference between strand and wire rope pricelist

Have you ever wondered why aircraft cable is called aircraft cable instead of aircraft strand? Do you use the words cable and wire rope interchangeably when you’re not sure which is correct? The world of manufacturing is chock-full of words to describe wire products, and while it may seem confusing to keep track of them at first, having some background knowledge about cable construction will help you understand each component. Let’s take a moment to differentiate our terms by starting small.

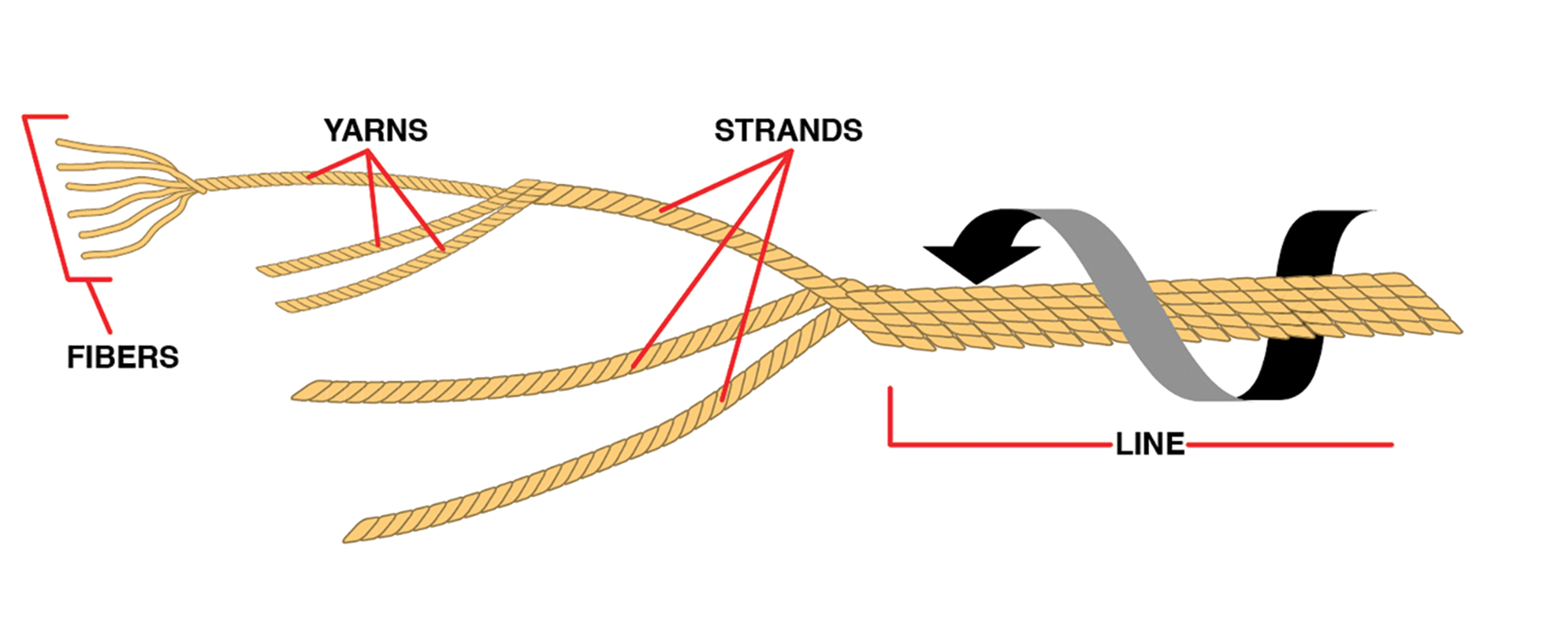

Wire: In its simplest form, wire is a single, flexible, string-like rod. It begins life as a metal such as stainless steel or carbon steel that becomes narrower in diameter as it is drawn through a series of small holes called dies. Used in everything from electrical equipment and coat hangers to art projects and nails, wire is the foundation of many wide and varied items.

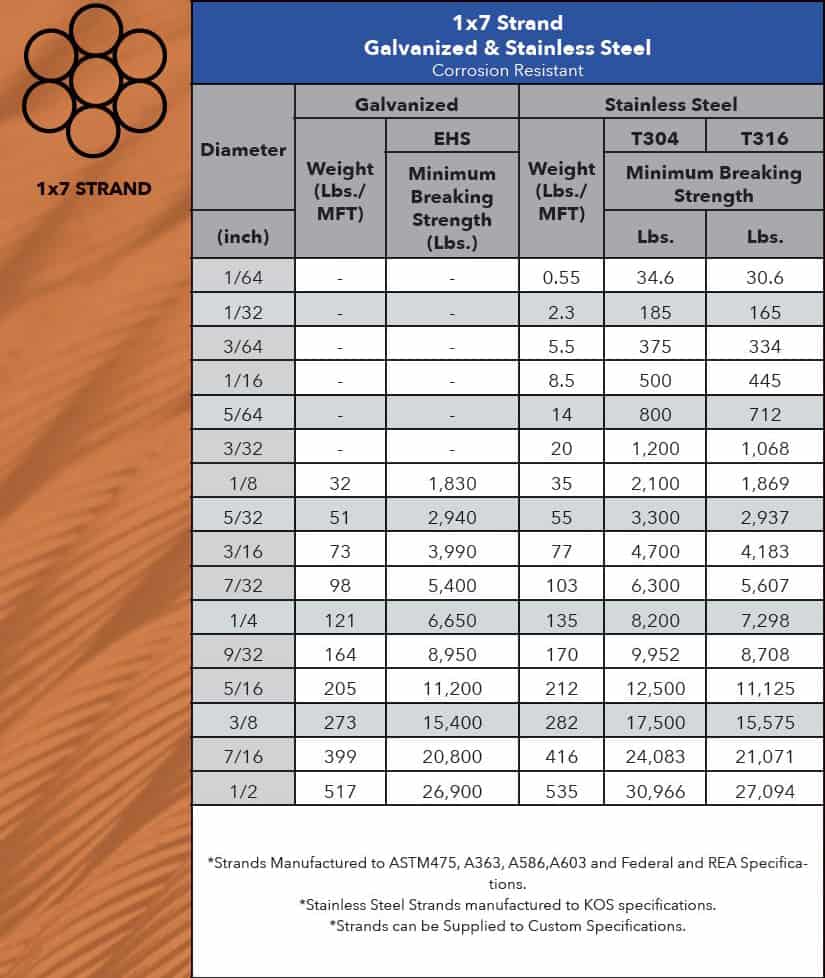

Strand: Strand is made of two or more wires laid around a single center wire. In general, “1 by…” products are considered strand, like 1x7 and 1x19, which are two common configurations.

Notice how this 1x7 strand is a unit comprised of individual wires. It is 1 strand of 7 wires.1x19, as another example, is 1 strand of 19 wires. Like wire,strand can exist as its own product, or it can be laid around a core in multiples to become cable or wire rope.

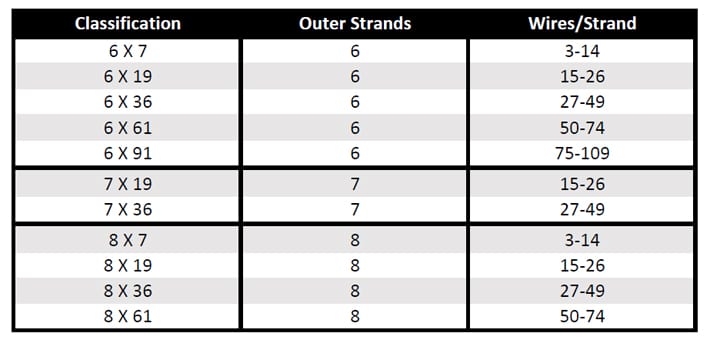

Cable:Cables are made by concentrically wrapping groups of strands. A 7x7 cable, for example, is comprised of seven strands, each made of 7 wires. 7x19 cable, as another example, has seven strands with 19 wires in each one. Wire rope is technically also a group of strands wrapped around a core, which is why the terms cableand wire rope are often used interchangeably. Professions will argue that wire rope is designated for products with a diameter larger than 3/8 inch while cableis designated for all smaller diameters, but in practical application, the terms are somewhat interchageable.

Looking for wire, strand, or cable for your application? Make sure that you specify the size, construction, and material of a product when building your quote on www.strandcore.com. Luckily, Strand Core provides comprehensive data sheets for all our aircraft cable and general purpose wire rope products to help make your selection easier. Visit https://strandcore.com/products/general-purpose-wire-rope/ to start browsing our wire rope products, today.

US Producer Price Index: Metals and Metal Products: Ferrous Wire Rope, Cable, Forms Strand is at a current level of 374.05, up from 373.69 last month and up from 316.95 one year ago. This is a change of 0.09% from last month and 18.02% from one year ago.

Wire rope and cable, is there a difference? The terms are often used interchangeably, but are they different? Each is considered a machine. Wire ropes are usually ⅜” in diameter or larger, while cables or cords are smaller. Though this little distinction exists in aircraft and marine cables, wire ropes and cables are synonymous in most other ways.

A strand is made up of two or more wires twisted around a center wire. Each strand is made up of 7, 19, or 37 wires. Cable or wire rope is made when a group of strands is twisted around a center wire or rope. They are named for the numbers of wires and strands. A 7×7 cable has 7 strands with 7 wires in each strand wrapped around a central core. A 7×19 cable would include 7 strands with 19 wires in each cable.

Different wire rope applications require different demands for abrasion, strength, and corrosion resistance. Different materials are used to meet different needs. Sizes under ⅜ “ are considered aircraft cable, sizes over 3/8 “ in diameter are considered wire rope.Stainless Steel – Type 302, made up of 18% chromium and 8% nickel alloy, is the most common grade because of its high strength and resistance to corrosion. When non-magnetic properties are required, type 305 is employed. Other common types used in wire rope are 304, 305, 316, and 321. Each has specific advantages and disadvantages. Stainless steel is the stronger of the two, so its cost is higher but well worth it.

Galvanized Carbon Steel – To protect from the elements, a coating of zinc is applied to wire ropes used in the making of this wire rope. It is the wire rope of choice when strength is necessary, but corrosion resistance is not significant enough to warrant the use of stainless steel. Galvanized carbon steel is the go-to for cost-effectiveness.

If you require flexibility, you need wires that have more strands, more strands equal more flexibility. Look for 3×7, 7×7, and 7×19; these will give you more flexibility. However, as the degrees of flexibility increase, the abrasion resistance decreases. These cables are most useful where you require continuous flexing. Basic cable construction:

1×19 cable – This cable is still reasonably flexible, yet it resists compressive forces. It is smooth on the outside, and sizes above 3/32” diameter are the strongest.

It is essential to correctly estimate the qualities necessary for the work the wire rope will be doing. To decide the importance of the essential attributes to do the job, you need to look for quality and figure out whether it can withstand how it will be used and the length of time it can be used in this capacity. In choosing a wire rope for the job at hand, these four things must be considered:Sufficient strength to lift the load and then some, keeping safety in mind. Always overestimate.

Whether it is a crane, a pulley, or some other machine, be sure to choose the proper size, construction, and grade of wire rope appropriate for the job.

To find the wire rope or cable you need for the job, contact us atSilver State Wire Ropefor all of your wire rope and rigging needs. We have all sizes of cable and wire rope; whether you need it for aircraft, marine, or land use, we have it all!

We sell a lot ofwire rope and fittings through our online shop; and one of the main questions we get asked is, what is the difference between 7x7 and 1x19 wire. The answer is quite simple, but is also important to know, as some fittings will only suit a certain type of wire rope.

While stainless steel wire can be used for a variety of different purposes, we"ll specifially be talking about the differences in relation to wire balustrade.

In simple terms; 7x7 means 7 stands of wire twisted to form 1 strand, which is then combined with 6 more of these; 49 stands in total (ie 7x7=49). Whereras 1x19 is 19 stands of wire that are twisted to form 1 stand. A total of 19 strands in total (ie. 1x19=19). Despite the fact that the 7x7 has more than double the number of strands, the end product is still the same overall thickness.

As 7x7 is made up of thinner strands it is more flexible than the 1x19. This is important if you are using a hand swager combined with a ferrule and thimble, as the 1x19 will not be able to bend around the thimble without kinking. The 7x7 on the other hand is flexible enough to do the job properly.

If using a hydraulic swager with the hydraulically swaged fittings, then either the 7x7 or 1x19 can be used; but most customers tend to use the 1x19, as despite it being fractionally more expensive, it does tend to look and fell nicer than the 7x7.

Wire rope and cable are each considered a “machine”. The configuration and method of manufacture combined with the proper selection of material when designed for a specific purpose enables a wire rope or cable to transmit forces, motion and energy in some predetermined manner and to some desired end.

Two or more wires concentrically laid around a center wire is called a strand. It may consist of one or more layers. Typically, the number of wires in a strand is 7, 19 or 37. A group of strands laid around a core would be called a cable or wire rope. In terms of product designation, 7 strands with 19 wires in each strand would be a 7×19 cable: 7 strands with 7 wires in each strand would be a 7×7 cable.

Materials Different applications for wire rope present varying demands for strength, abrasion and corrosion resistance. In order to meet these requirements, wire rope is produced in a number of different materials.

Stainless Steel This is used where corrosion is a prime factor and the cost increase warrants its use. The 18% chromium, 8% nickel alloy known as type 302 is the most common grade accepted due to both corrosion resistance and high strength. Other types frequently used in wire rope are 304, 305, 316 and 321, each having its specific advantage over the other. Type 305 is used where non-magnetic properties are required, however, there is a slight loss of strength.

Galvanized Carbon Steel This is used where strength is a prime factor and corrosion resistance is not great enough to require the use of stainless steel. The lower cost is usually a consideration in the selection of galvanized carbon steel. Wires used in these wire ropes are individually coated with a layer of zinc which offers a good measure of protection from corrosive elements.

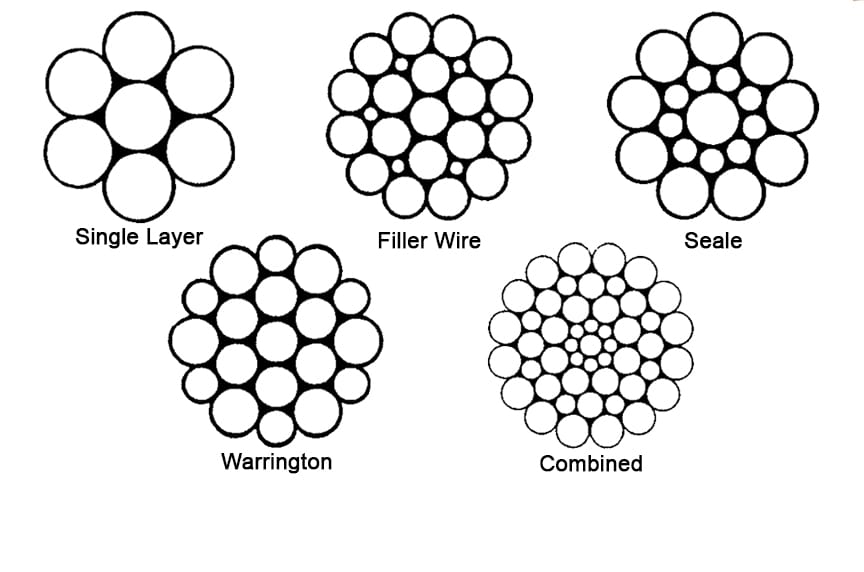

Cable Construction The greater the number of wires in a strand or cable of a given diameter, the more flexibility it has. A 1×7 or a 1×19 strand, having 7 and 19 wires respectively, is used principally as a fixed member, as a straight linkage, or where flexing is minimal.

Cables designed with 3×7, 7×7 and 7×19 construction provide for increasing degrees of flexibility but decreased abrasion resistance. These designs would be incorporated where continuous flexing is a requirement.

Selecting Wire Rope When selecting a wire rope to give the best service, there are four requirements which should be given consideration. A proper choice is made by correctly estimating the relative importance of these requirements and selecting a rope which has the qualities best suited to withstand the effects of continued use. The rope should possess:Strength sufficient to take care of the maximum load that may be applied, with a proper safety factor.

Strength Wire rope in service is subjected to several kinds of stresses. The stresses most frequently encountered are direct tension, stress due to acceleration, stress due to sudden or shock loads, stress due to bending, and stress resulting from several forces acting at one time. For the most part, these stresses can be converted into terms of simple tension, and a rope of approximately the correct strength can be chosen. As the strength of a wire rope is determined by its, size, grade and construction, these three factors should be considered.

Safety Factors The safety factor is the ratio of the strength of the rope to the working load. A wire rope with a strength of 10,000 pounds and a total working load of 2,000 pounds would be operating with a safety factor of five.

It is not possible to set safety factors for the various types of wire rope using equipment, as this factor can vary with conditions on individual units of equipment.

The proper safety factor depends not only on the loads applied, but also on the speed of operation, shock load applied, the type of fittings used for securing the rope ends, the acceleration and deceleration, the length of rope, the number, size and location of sheaves and drums, the factors causing abrasion and corrosion and the facilities for inspection.

Fatigue Fatigue failure of the wires in a wire rope is the result of the propagation of small cracks under repeated applications of bending loads. It occurs when ropes operate over comparatively small sheaves or drums. The repeated bending of the individual wires, as the rope bends when passing over the sheaves or drums, and the straightening of the individual wires, as the rope leaves the sheaves or drums, causing fatigue. The effect of fatigue on wires is illustrated by bending a wire repeatedly back and forth until it breaks.

The best means of preventing early fatigue of wire ropes is to use sheaves and drums of adequate size. To increase the resistance to fatigue, a rope of more flexible construction should be used, as increased flexibility is secured through the use of smaller wires.

Abrasive Wear The ability of a wire rope to withstand abrasion is determined by the size, the carbon and manganese content, the heat treatment of the outer wires and the construction of the rope. The larger outer wires of the less flexible constructions are better able to withstand abrasion than the finer outer wires of the more flexible ropes. The higher carbon and manganese content and the heat treatment used in producing wire for the stronger ropes, make the higher grade ropes better able to withstand abrasive wear than the lower grade ropes.

Effects of Bending All wire ropes, except stationary ropes used as guys or supports, are subjected to bending around sheaves or drums. The service obtained from wire ropes is, to a large extent, dependent upon the proper choice and location of the sheaves and drums about which it operates.

A wire rope may be considered a machine in which the individual elements (wires and strands) slide upon each other when the rope is bent. Therefore, as a prerequisite to the satisfactory operation of wire rope over sheaves and drums, the rope must be properly lubricated.

Loss of strength due to bending is caused by the inability of the individual strands and wires to adjust themselves to their changed position when the rope is bent. Tests made by the National Institute of Standards and Technology show that the rope strength decreases in a marked degree as the sheave diameter grows smaller with respect to the diameter of the rope. The loss of strength due to bending wire ropes over the sheaves found in common use will not exceed 6% and will usually be about 4%.

The bending of a wire rope is accompanied by readjustment in the positions of the strands and wires and results in actual bending of the wires. Repetitive flexing of the wires develops bending loads which, even though well within the elastic limit of the wires, set up points of stress concentration.

The fatigue effect of bending appears in the form of small cracks in the wires at these over-stressed foci. These cracks propagate under repeated stress cycles, until the remaining sound metal is inadequate to withstand the bending load. This results in broken wires showing no apparent contraction of cross section.

Experience has established the fact that from the service view-point, a very definite relationship exists between the size of the individual outer wires of a wire rope and the size of the sheave or drum about which it operates. Sheaves and drums smaller than 200 times the diameter of the outer wires will cause permanent set in a heavily loaded rope. Good practice requires the use of sheaves and drums with diameters 800 times the diameter of the outer wires in the rope for heavily loaded fast-moving ropes.

It is impossible to give a definite minimum size of sheave or drum about which a wire rope will operate with satisfactory results, because of the other factors affecting the useful life of the rope. If the loads are light or the speed slow, smaller sheaves and drums can be used without causing early fatigue of the wires than if the loads are heavy or the speed is fast. Reverse bends, where a rope is bent in one direction and then in the opposite direction, cause excessive fatigue and should be avoided whenever possible. When a reverse bend is necessary larger sheaves are required than would be the case if the rope were bent in one direction only.

Stretch of Wire Rope The stretch of a wire rope under load is the result of two components: the structural stretch and the elastic stretch. Structural stretch of wire rope is caused by the lengthening of the rope lay, compression of the core and adjustment of the wires and strands to the load placed upon the wire rope. The elastic stretch is caused by elongation of the wires.

The structural stretch varies with the size of core, the lengths of lays and the construction of the rope. This stretch also varies with the loads imposed and the amount of bending to which the rope is subjected. For estimating this stretch the value of one-half percent, or .005 times the length of the rope under load, gives an approximate figure. If loads are light, one-quarter percent or .0025 times the rope length may be used. With heavy loads, this stretch may approach one percent, or .01 times the rope length.

The elastic stretch of a wire rope is directly proportional to the load and the length of rope under load, and inversely proportional to the metallic area and modulus of elasticity. This applies only to loads that do not exceed the elastic limit of a wire rope. The elastic limit of stainless steel wire rope is approximately 60% of its breaking strength and for galvanized ropes it is approximately 50%.

Preformed Wire Ropes Preformed ropes differ from the standard, or non-preformed ropes, in that the individual wires in the strands and the strands in the rope are preformed, or pre-shaped to their proper shape before they are assembled in the finished rope.

This, in turn, results in preformed wire ropes having the following characteristics:They can be cut without the seizings necessary to retain the rope structure of non-preformed ropes.

They are substantially free from liveliness and twisting tendencies. This makes installation and handling easier, and lessens the likelihood of damage to the rope from kinking or fouling. Preforming permits the more general use of Lang lay and wire core constructions.

Removal of internal stresses increase resistance to fatigue from bending. This results in increased service where ability to withstand bending is the important requirement. It also permits the use of ropes with larger outer wires, when increased wear resistance is desired.

Outer wires will wear thinner before breaking, and broken wire ends will not protrude from the rope to injure worker’s hands, to nick and distort adjacent wires, or to wear sheaves and drums. Because of the fact that broken wire ends do not porcupine, they are not as noticeable as they are in non-preformed ropes. This necessitates the use of greater care when inspecting worn preformed ropes, to determine their true condition.

There are a variety of cables and wires that are used for various purposes. They can either be hidden underground or pass overhead. Crane Cable is one such cable wire rope made out of several strands of metal wires that are twisted together into a helix form to make them into a single rope. Initially, wrought iron was used to make these Crane Cables however, these days steel is the primary material used. Apart from this high carbon steel and galvanized steel are also used in manufacturing these cables. Dents or flaws in the ordinary link chain can lead to severe failure whereas, damage in these EOT Crane Cablecan be easily covered up. Ther are ideally used for lifting elevators, in the transmission of mechanical power, and in cranes.

Crane Lifting Cables are resistant to corrosion and have excellent ductility for optimal fatigue. They have a high breaking strength compared to steel crane wire rope. The radially elastic rope structure absorbs the dynamic force thus giving it high impact resistance. Crane Cable Wires are said to be cost-effective as a strong and durable structure helps in reducing maintenance costs and downtime. They can be coated with bright phosphate or galvanized depending upon the customers’ requirements.

Crane Electrical Cable is available in rotating, rotation, compact, or non-compact structures. Most of the wire ropes have the tendency of developing torque and are thus prone to rotation. However, non-rotation wires are designed in a way that their outer rotation naturally counteracts the inner strands rotation. Crane Hoist Cable can be used in tower crane ropes or offshore crane ropes.

Overhead Crane Cable reel should be capable of winding it automatically. The drive torque of the crane cable should not be less than the max winding torque of the winding crane cable. The cable conductor should be as small as possible when the Crane Rope laying acts on the traction force.

The Crane Wire Rope does not have a reinforcement core, the maximum tension allowed on the copper conductor cross-section is 20N/mm2. We at Bhuwal Insulation Cable Pvt. Ltd. not only provide you the best quality Tower Crane Cable but also the parts required to assemble them. Our long-standing reputation in providing the best quality product at a competent price has made us one of the leading Crane Cable manufacturers in India.

Looking Crane Cable manufacturers to lifting and hoisting heavy materials? Manufacturer of Crane Electrical Cable as per ISO 4309:2011, VDE0482, IEC60332 -1, EN50265-2-1 and CE standards.

Colombia, Iraq, MOZAMBIQUE, South Africa, Israel, Malaysia, Australia, Kuwait, Italy, Oman, Kenya, Singapore, UNITED ARAB EMIRATES (UAE), Saudi arabia, Zambia, Sri lanka, Chile, Kuwait, Netherlands, Cuba, Bangladesh, Indonesia, South Africa, Brazil, Qatar, Austria, Srilanka, Russia, Dubai, United Arab Emirates, United kingdom, Qatar, Sudan, Howrah, Ankara, Melbourne, Montreal, Caracas, Ahvaz, Bengaluru, Argentina

Cables or cords are the wire ropes which have diameters smaller than 3/8 inches, While wire ropes have diameters greater than 3/8 inches. if there are two or more wire concentrically laid then it is known as strand

Warrington: Two layers of wires around a center with one diameter of wire in the inner layer and two diameters of wire alternating large and small in the outer later

6 by 19 is a type of wire rope which can withstand fatigue resistance, abrasion and prevents crushing on drums. it is available in diatmeter range of 3mm to 6 mm. While 7 by 19 are wire rope which has diameters ranging between 3 mm to 16 mm which can be use in different applications.

Rope Services Direct supplies a variety of anti-spin non rotating wire rope (also called rotation resistant wire-rope). All standard rope wirehas a tendency to develop torque and therefore prone to rotation, whereas non-rotating wire ropes are designed so that the wire-rope outer rotational force naturally counteracts the inner strands rotational force. This is in the event that a rope is subjected to a load.

Rope elongation and rotation occurs on standard ropes when loaded, which can therefore spin the load, quite possibly out of control, which can be dangerous. When the rope rotates in this way the strands will begin to unravel. This causes the rope to lose strength and will undoubtedly fail, which could be catastrophic. It is for these reasons that non rotating wire rope is commonly used for many types of lifting applications including main hoist rope, whip rope,crane rope, off-shore and deck rope and more.

Non rotating wire rope or rotation resistant wire rope has a different construction to standard. as wires and strands are not laid in the same direction like they would be on standard rope. Inner and outer strands of wires are laid in opposite directions. For example the inner may be constructed in left hand lay whilst the outer layer is in right hand lay. The nature of this construction means that torsional forces on the inner and outer wires/strands will counteract each other and therefore minimising the risk of unraveling.

It is worth noting that the number of strand layers will have an effect of the resistance of rotation. A 2 layer rope has less resistance than a 3 layer rope. Therefore the more layers the rope has the greater rotation resistance it will have.

These types of ropes can be classified as spin resistant, rotation resistant or non rotation resistant. Classed on the basis of the number of rotations a certain length of rope does when a force of 20% of the MBF is applied; with 1 turn or less the rope will be classified as non rotating; with rotations between 1 & 4 the rope is classed as low rotation and for rotations between 4 & 10 the rope will be classified as spin resistant, any higher and the rope is NOT rotation resistant at all.

Correct usage and care with handling will prolong the working life. This is due to the friction on the inner wires caused by the strand crossover’s which will eventually cause the inner wires to break up. This is more apparent on non rotating wire rope with two layers. Ropes with 3 or more strand layers will distribute the radial pressures more evenly. Which will reduce friction and stress on the inner wires.

Regular,thorough inspectionsof non rotating rope are essential due to the fact that it is the inner strands that often break first and broken internal wires often go unnoticed as they are difficult to see.Rope Services Direct offer inspectionson all rope with certification issued on completion.

Holding both ends of the rope will prevent unraveling. Correctly fitted terminations will help to prevent damage. Kinking and unraveling may occur and they can also have an effect on the rotational balance if not fitted correctly.

Byculla, Mumbai No. 2/14, Pais Street, Byculla West, Opposite Kinjal Towers Near Veena Killedar Industrial Estate, Byculla, Mumbai - 400011, Dist. Mumbai, Maharashtra

We Pearl Overseas Have Stainless Steel Wire Rope In Ready Stock, We are specialist in Stainless Steel Wire Rope, Stainless Steel Wire Rope available in 304, 304l,read more...

Bhuleshwar, Mumbai Bhagirathi Bhavan, Ground Floor, Shop No. 5 1st Panjrapole, Near Gulalwadi Circle, Bhuleshwar, Mumbai - 400004, Dist. Mumbai, Maharashtra

Kalasipalya, Bengaluru No. 1/2, No. 3rd Cross, N. R. Road Nazz Complex, Below Vijaya Bank, Kalasipalya, Bengaluru - 560002, Dist. Bengaluru, Karnataka

We make it easy to find the information you need when you need it. Browse through our different Industry specific Product Catalogs and download straight to your mobile device. Its the fastest way to look up Cable Strengths and Capacities for your upcoming Wire Rope projects.

The actual diameter of a wire rope is the diameter of a circumscribed circle that will enclose all the strands. It’s the largest cross-sectional measurement as shown here. You should make the measurement carefully with calipers.

The rope diameter should be measured on receipt for conformity with the specification. British Standard (B.S. 302:1987, standard steel wire rope, Part 1. Clause 5.1) allow for a tolerance of - 1% to 4 % of the nominal rope diameter.

The generally accepted method of measuring rope diameter for compliance with the standard is to use a caliper with jaws broad enough to cover not less than two adjacent stands. The measurement must be taken on a straight portion of rope at two points at least 1 meter apart. At each point two diameters at right angles should be measured. The average of the four measurement is the actual diameter.

After the rope has made the first few cycles under low load, the rope diameter should be measured at several points. The average value of all the measurements at each point must be recorded and will form the basis of comparison for all future measurements.

The measurements of the rope diameter an essential part of all inspections and examinations. It ensures the maximum diameter reduction does not exceed the recommended figure. As stated in 5.2 British standard 6570 recommends that a wire rope should be discarded when the diameter of the rope is reduced to 90% of the nominal diameter.

A comparison of the measured data with the recorded previous values can detect an abnormal rate of reduction in diameter. Coupled with assessment of previous rope examination data, the probable date of rope renewal can be predicted.

If we examine the cross-section of a six-stand wire rope, we will find that measuring the thickness of the rope over the crowns (Fig-a) will produce a higher value than measuring it over the valleys (Fig-b). The actual diameter of the rope is defined as the diameter of the circumscribing circle.

When using a conventional caliper, wire rope with an even number of outer strands (four-, six, eight-, and multi strand) ropes must be measured from crown to crown. The advantage of a proper wire rope caliper with measuring plates is that even if the measurement is carried out "incorrectly", adjacent crowns are always included, so that the actual diameter is determined at any section. (Fig-c)

Measuring the diameter of wire rope with an uneven number of outer strands (three, five, seven, or nine-strand ropes) is more complicated: a crown on the one side of the wire rope always has a valley as a counterpart on the other side of the wire rope. A conventional caliper, therefore, has to be applied diagonally to the axis of the rope, so that at any time a crown adjacent to a valley is covered. Again a wire rope caliper with measuring plate is definitely to be preferred as it always includes strands crowns.

In all cases during periodic examinations where the measurements are to be recorded, the rope should be measured as already described. Where the roundness is being checked to detect potential faults, two diameters, one at right angles to the other can be taken and noted in the records. The entry into the records might read rope diameter : 20.4/20.5mm.

After a rope has been fitted to the appliance, its length cannot be measured again accurately, with out a great deal of trouble. The purpose of measuring the length of lay is to detect any increase in the rope length which may have been caused by corrosion, core deterioration or rope rotation (unlaying). With n new rope the wire and strands should be allowed to settle into their permanent position. Six or seven lifting cycles with a light to medium load are recommended before measuring error, the measurement should be made over four lays and the length divided by four lays and the length divided by four to find the average lay length.

On eight strand ropes the eight, sixteen, twenty-four and thirty-second strands must be marked. Using a straight length of the rope and with the rope under no load, first mark any strand on the crown with a piece of chalk; this strand now become"" crown zero"". Excluding this strands, count the next eight strands and mark the eight strand with chalk. Exclude the eight strand and repeat the procedures further two times. The measured length between the outer chalk marks is then divided by four to give the lay length.

As a rough check on the overall accuracy of the chalk marking, the length of lay for eight strand ropes is approximately between 6.25 and 6.5 x the diameter of the rope e.g. using a lay length of 6.5 x rope diameter, four lay length of a 32mm diameter rope will be 32mm x 6.5 x 4=832mm.

An alternate method of measuring the rope lay is to secure the free end of the roll of adding machine paper to the rope with adhesive tape. The paper is rolled out over the rope and simultaneously the wax pencil is drawn over the paper, providing a clear print of the outer wires of the rope. The finished print can be field for comparison with later measurements.

A third method is to wrap typing carbon papers round the rope under the roll of paper. By rubbing along the paper with a piece of cardboard, the carbon marking on the underside of the paper can be confined to the tops of the strand crowns.

Type 304 stainless steel is the standard alloy for use in wire rope and cable. It has about the same strength as galvanized wire rope or cable but is much more corrosion resistant. It can be used in most industrial atmospheres and has acceptable corrosion resistance when used in marine and salt water.

316 grade stainless steel is the standard high-corrosion-resistant steel for wire rope and cable. It is resistant to many chemicals in the pulp and paper, photographic, food processing, and textile industries. Type 316 stainless steel wire rope has the best pitting resistance in marine and salt water, and can be used in temperatures up to 900 degrees Fahrenheit.

The vast majority of wire rope specifications are designated with 316 or 304 (and sometimes 302 grade). The basic difference is in the elements that comprise the alloy itself—and 316 stainless wire rope is known to be more corrosion-resistant than 304.

Commonly used in aircraft controls, sailboat rigging, winches, and garage doors, a 7x19 stainless steel wire rope is made up of seven strands with 19 wires in each strand—approximately twice as flexible as a 7x7 construction. Also available in USA-made.

United States - Producer Price Index by Commodity: Metals and Metal Products: Ferrous Wire Rope, Cable, Forms and Strand was 377.74800 Index Jun 1982=100 in March of 2022, according to the United States Federal Reserve. Historically, United States - Producer Price Index by Commodity: Metals and Metal Products: Ferrous Wire Rope, Cable, Forms and Strand reached a record high of 377.74800 in March of 2022 and a record low of 87.60000 in September of 1983. Trading Economics provides the current actual value, an historical data chart and related indicators for United States - Producer Price Index by Commodity: Metals and Metal Products: Ferrous Wire Rope, Cable, Forms and Strand - last updated from the United States Federal Reserve on December of 2022.

Earlier, for example in the Baroqueperiod, fruit was espaliered on copper wires. Stranded stainless steel wire ("wire-rope" or "cable") is used today, primarily because it is still flexible even with thicker diameters. There do exist gigantic cable systems with 16 mm cables, but FassadenGrün works with stainless steel cables of 2, 3 and 4 mms, which are more than sufficient in nearly all cases. The advantage of wire rope is its discreetness and ability to showcase the plant itself. Cables provide surprising aesthetic effects with their sleak, delicate lines... climbing plants like to hold on tightly to the corrugated surface. Wire cables are unbeatably flexible because, unlike premade lattice frameworks, they are adaptable and for every situation you can find an arrangement! Attachment is not limited to predefined grid points but can be chosen as best fits your unique facade. Wire ropes are also a clean solution! Dirt, algae and moss- build up are no significant problem here.

FassadenGrün also offers stainless steel 1.2 mm single-strand wire (DR 01220) Why? Although today wire rope is preferable to single strand wire in almost all cases, using wire can be an inexpensive solution in minor or lower-lying locations, e.g., with the spanning of small wall fields where the wire ends are then "latched" directly into staples, eyelets, etc.., thus eliminating the need for cable clamps.

Aren"t simple, inexpensive galvanised cables and wall supports just as suitable as high-grade stainless steel? Yes- as a very short-term cheap solution. Such small parts are usually made of steel with a thin layer of zinc applied by electro-zinc plating (as opposed to hot-dip galvanising which creates a thicker layer of zinc). Used in the context of "greening," the metal is subjected to high levels of humidity and evaporation is slow... electrolytic corrosion and organic secretions become inevitable. Soon, the zinc coating is dissolved and rust streaks form.

We sometimes hear that stainless steel wire is "cold," and can therefore be harmful to climbing plants. But, for the millions of vines that easily survive winter after winter on the metal wires, this phenomenon has never been verified and essentially holds no weight. At a temperature of -10°C, plant and metal are equally as cold, because the plant has no intrinsic heat. It protects its cells from freezing by storing sugar molecules. A "heating up" isn"t possible in summer either because the glistening steel cables reflect the light and heat.

With over 25 years of manufacturing, technical and lifting experience, Absolute Wire Rope Solutions is an established strategic safety partner with reputable global manufacturers.

With efficiency and client centric focus, Absolute Wire Rope Solutions ensures a wide range of readily available stock at competitive prices. To this end, the following types of wire rope are available through us:

8613371530291

8613371530291