what is the most abrasion resistant wire rope made in china

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Rotation rope and non-rotation rope or rotation resistant rope. Round strand rope, compacted rope, swaged rope. Wire rope with fiber core, wire rope with IWRC(Independent Wire Rope Core). Galvanized wire rope, ungalvanized wire rope or bright wire rope. Wire rope with plastic insert, Wire rope without plastic insert. Wire rope covered with plastic.

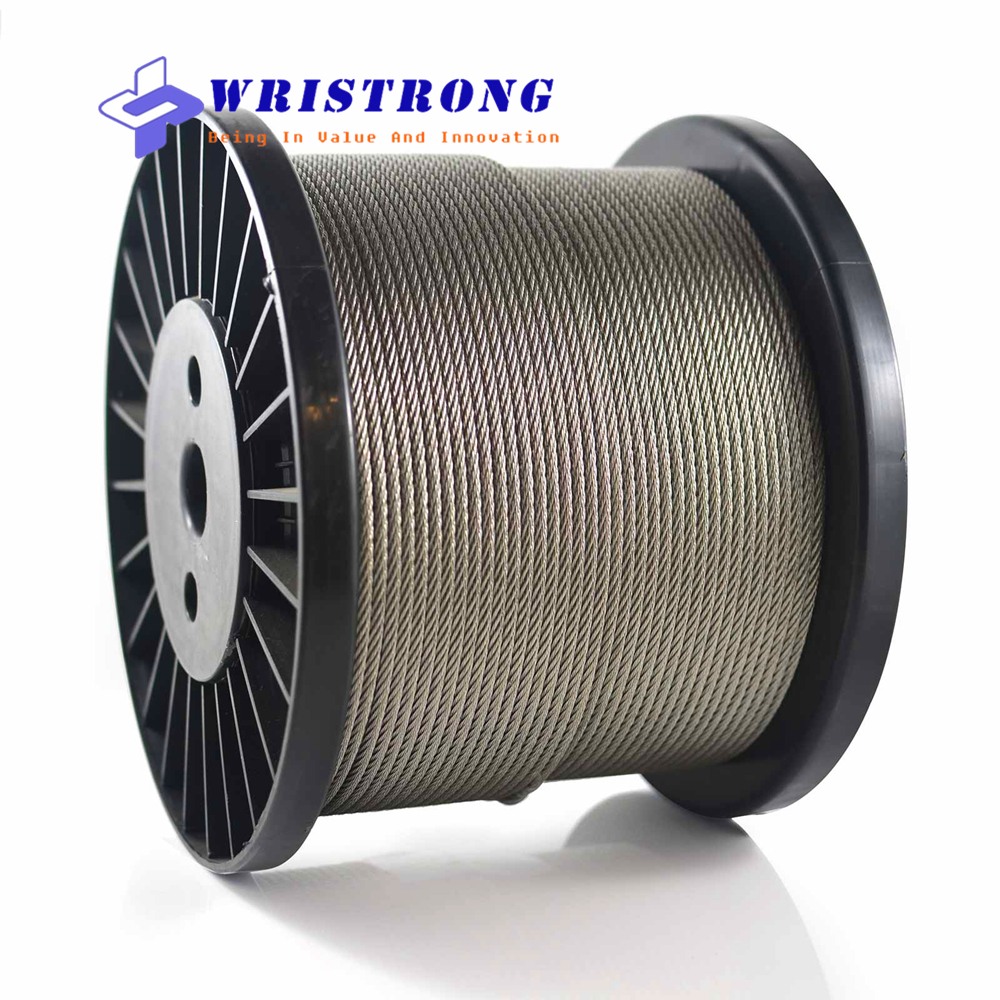

Wire ropes can be seen everywhere around us, they are made of strands or bundles of individual wires constructed around an independent core, suitable for construction, industrial, fitness, commercial, architectural, agricultural, and marine rigging applications.

Wire rod is made from high carbon steel wires(0.35 to 0.85 percent carbon) in a hot rolling process of a required diameter, usually from 5.5mm to 8 mm.

Wire rod is drawn to the required diameter by the 1st drawing machine after descaling dust and rust, adding mechanical properties suitable for application.

Positioning the wires different or the same size lay in multiple layers and same direction, or cross lay and diameter is maintained by one-third of the rope size.

So in theory, it is very simple to manufacture wire ropes. However there are many more details that must be closely monitored and controlled, and this requires time and experienced personnel since it is a super complicated project you cannot imagine.

Hilifting is a professional polyethylene rope manufacturer, our pe rope, short for Polyethylene rope, is made from polyethylene, with high strength, abrasion, and light resistant, easy for operation, suitable for a variety of outdoor and marine applications where high breaking strain is not required.

Characteristic: high tenacity, low elongation,moisture proof,with the highest yield strength, abrasion resistance, corrosion resistance, smoothness and softness, and easy to operate.

As specialist for manufacturing quality steel wire ropes over 20 years, our company can supply strong, durable and reliable ropes that capable to minimize your downtime and maximize cost effectiveness. Decades of experience we owned make us know clearly the work you do and capable to provide professional guidance.

We select the best steel or stainless steel as raw material for wire rope manufacturing. Our products are manufactured under strict quality managements and test before they leave the factory.

Our engineers can provide professional advice about picking up optimal steel wire ropes for their application, installation guidance to ensure maximum return in their wire rope system.

As one of the largest manufacturers in China, we can purchase better materials at a lower price. Then we transmit this saving to our customers by providing the most competitive price.

If you are going to pick up steel wire ropes that suit your project perfectly, you must have an ideal about the construction about them. Our company can supply bright wire rope, galvanized wire rope, stainless steel wire rope, compacted wire rope, rotation resistant wire ropes, mining wire rope, elevator wire rope, crane wire rope and gas & oilfield wire ropes. Here are some details to solve the problem that may puzzle you whether you are browsing the web or picking up steel wire ropes.

Bright steel wire ropes mean no surface treatment is applied to the rope. Therefore, they have the lower price among these three wire ropes. Generally, they are fully lubricated to protect the rope from rust and corrosion.

Galvanized steel wire ropes feature compressed zinc coating for providing excellent corrosion resistance. With higher break strength yet lower price than stainless steel, galvanized steel wire ropes are widely used in general engineering applications such as winches and security ropes.

Stainless steel wire ropes, made of quality 304, 305, 316 steels, are the most corrosive type for marine environments and other places subjected to salt water spray. Meanwhile, bright and shiny appearance can be maintained for years rather than dull as galvanized steel wire ropes.

Steel wire ropes are composed of multiple strands of individual wires that surrounding a wire or fiber center to form a combination with excellent fatigue and abrasion resistance. These wires and strands are wound in different directions to from different lay types as follows:

Beside above lay types, alternative lay ropes which combine regular lay and lang lay together and ideal for boom hoist and winch lines, can also be supplied as your request.

Two main methods about seizing steel wire ropes in conjunction with soft or annealing wire or strands to protect cut ends of the ropes form loosening.

Wire rope is commonly comprised of wire core and strand, which is made using various types of steel including galvanized, coated and non-coated. The steel wire ropes are also named as wire cables and steel wire, which are featured with high strength, flexibility, abrasion resistance, corrosion resistance and rotation resistance. This makes them well-suited for varieties of uses such as pulling, fixing and bearing in the marine, architectural and construction.

The wire ropes can be assembled into steel wire rope slings being used with lifting equipment or winches to meet lifting and rigging needs in different industries.

The wire ropes are classified according to the strand and wires. Shown below are just some typical types of wire ropes. Wire ropes are also available in customized constructions.

This construction is used where ropes are dragged on the ground or over rollers, and resistance to wear and abrasion are important factors. The wires are quite large and will stand a great deal of wear. In fact, this construction is sometimes called “coarse laid” because of the large wires. The 6x7 is a stiff rope and needs sheaves and drums of large size. It will not withstand bending stresses as well as ropes with smaller wires. Because of the small number of wires, with the resulting higher percentage of load carried by each wire, a larger factor of safety should be considered with 6x7 ropes than with ropes having a larger number of wires.

The 6x19 Classification of wire rope is the most widely used. With its good combination of flexibility and wear resistance, rope in this class can be suited to the specific needs of diverse kinds of machinery and equipment. The 6x19 Seale construction, with its large outer wires, provides great ruggedness and resistance to abrasion and crushing. However, its resistance to fatigue is somewhat less than that offered by a 6x25 construction. The 6x25 possesses the best combination of flexibility and wear resistance in the 6x19 Class due to the filler wires providing support and imparting stability to the strand. The 6x26 Warrington Seale construction has a high resistance to crushing. This construction is a good choice where the end user needs the wear resistance of a 6x19 Class Rope and the flexibility midway between a 6x19 Class and 6x37 Class rope.

The 6x36 Class of wire rope is characterized by the relatively large number of wires used in each strand. Ropes of this class are among the most flexible available due to the greater number of wires per strand, however their resistance to abrasion is less than ropes in the 6x19 Class. The designation 6x36 is only nominal, as in the case with the 6x19 Class. Improvements in wire rope design, as well as changing machine designs, have resulted in the use of strands with widely varying numbers of wires and a smaller number of available constructions. Typical 6x37 Class constructions include 6x33 for diameters under 1/2", 6x36 Warrington Seale (the most common 6x37 Class construction) offered in diameters 1/2" through 1-5/8", and 6x49 Filler Wire Seale over 1-3/4" diameter.

Alternate Lay, sometimes referred to as reverse lay, is a stranded rope where the type of lay of the outer strands is alternately regular lay followed by lang lay such that three of the outer strands are regular lay and three are lang lay. Alternate lay wire rope has the extra flexibility of lang lay in combination with the structural stability of regular lay. It unites the best features of both types of wire rope. Alternate lay is made with relatively large outer wires to provide increase of abrasion resistance to scrubbing against sheaves and drums. Finer inside wires and flexibility enable alternate lay ropes to absorb severe bending stresses. It is well suited to winding applications where abrasion and crushing can occur. Alternate lay wire rope applications include boom hoists and numerous types of excavating equipment like clamshells, shovels, cranes, winches and scrapers.

The 8x19 Classification rotation resistant ropes are recommended for hoisting unguided loads with a single-part or multipart line. The eight outer strands are manufactured in right lay, with the inner strands being left lay. These ropes are slightly stronger and significantly more rugged than the 19x7 construction. However, the rotation-resistant properties of the 8x19 rotation-resistant ropes are much less than those of the 19x7 construction. These ropes are manufactured in right regular lay in the 8x19 Seale and 8x25 Filler Wire constructions.

19x7 is recommended for hoisting unguided loads with a single-part line. The rotation-resistant properties of this rope are secured by two layers of strands. The inner strands are left lay, while the 12 outer strands are right lay, which enables one layer to counteract the other layer"s rotation. The rotation-resistant characteristics of the 19x7 wire ropes are superior to those of the 8x19 Class wire ropes.

SFP 19 is recommended for both multipart load and single-part fast line applications where rotational stability of the lifted load is needed, such as for use as a long fall on offshore pedestal cranes, rough and all terrain cranes, and crawler cranes. SFP 19 provides:

Fatigue Resistance. Improved fatigue properties are derived through the combination of the flexible 19x19 construction and die drawn strands. The drawn strand surfaces minimize the interstrand and interlayer nicking that take place in round rotation resistant ropes.

Abrasion Resistance. Die drawn ropes provide improved abrasion resistance as compared with round wire ropes because of the greater wire and strand bearing surfaces contacting sheaves and drums.

Resistance to Drum Crushing. SFP 19 wire ropes are resistant to the effects of drum crushing due to the compacted strands and smoothness of the rope surface.

Superior Rotation Resistance. The SFP 35 rope is the most rotation resistant rope manufactured by WW. Due to its rotation resistant properties, SFP 35 may be used with a swivel in both single part and multipart reeving.

Flexibility. SFP 35"s multiple strand construction provides increased flexibility which improves service life and high speed spooling. The compacted compacted multiple strand construction also reduces sheave and drum abrasion and provides excellent resistance to drum crushing.

6-PAC is recommended for use where the rope is subjected to heavy use or where conditions are extremely abusive, such as offshore pedestal, crawler and lattice boom equipped truck crane boom hoist applications. 6-PAC is also recommended for winch lines, overhead cranes, multipart hoist lines where rotation-resistant ropes are not required, and other applications where flexibility, high strength and resistance to crushing are important, and a cost-effective 6-strand rope is desired.

Fatigue Resistance. Improved fatigue properties are derived from the combination of 6-PAC"s flexible constructions and the compacted strands. The compacted strand surface minimizes the interstrand and interlayer nicking that take place in standard 6-strand ropes.

Abrasion Resistance. 6-PAC"s compacted strand design provides improved abrasion resistance as compared to standard 6-strand ropes because of the increased wire and strand surfaces contacting sheaves and drums.

Drum Crushing. 6-PAC dramatically increases the amount of wire contact with the drums and sheaves, reducing the wire rope, sheave and drum wear normally associated with standard wire rope.

Recommended for applications where abrasion and fatigue resistance is required, such as for winch lines, chokers, skylines, and haul backs, as well as any application where a swaged rope is used

8-PAC is recommended for hoist ropes for steel mill ladle cranes and hoist and trolley ropes for container cranes, or other hoisting applications with heavy duty cycles or where severe bending occurs.

Superior Performance. 8-PAC has higher breaking strength and gives superior performance in difficult hoisting applications compared to standard 6-strand and 6-strand compacted ropes.

Abrasion Resistance. 8-PAC compacted strand design provides improved abrasion resistance as compared to standard 6 and 8 strand ropes because of the increased wire and strand surfaces contacting the sheaves and drums.

SUPER-PAC is a double compacted product ideal for applications where abrasion and drum crushing are an issue. When compared with standard ropes, SUPER-PAC provides: Better resistance to multi-layer drum crushing. SUPERPAC dramatically reduces the damage at cross over points on smooth face drums, such as those found on many boom hoist systems on mobile cranes. This is achieved by compaction of the strands and the rope, making a tough but flexible product.

Superior Fatigue Resistance. SUPER-PAC is engineered for overall performance, its wire tensile strength being the key to its superior fatigue resistant properties. In addition to contribution to SUPERPAC’s EEEIP breaking strength, the wire used in the manufacture of SUPER-PAC remains ductile, minimizing the occurrences of external and internal wire breaks caused by operating stresses.

TRIPLE-PAC was developed for the most demanding hoist applications. TRIPLE-PAC offers the extra high strength and crushing resistance needed for applications such as boom hoist ropes, boom pendants and multipart load lines.

TRIPLE-PAC provides superior abrasion and fatigue resistance as compared with most compacted ropes due to WW’s unique design of compacting the IWRC, individual strands and the rope itself. Other benefits include:

High Strength. TRIPLE-PAC is designed to provide a nominal strength of 35% above EIP. WW achieves this strength through selected grades of steel and TRIPLEPAC’s unique design and manufacturing processes.

Superior Resistance to Multilayer Drum Crushing. TRIPLE-PAC provides superior resistance to crushing through its design. Its triple compaction provides a denser cross section, enabling the rope to withstand the rigors of multilayer spooling. Damage at the cross over points is also significantly reduced.

BXL is infused with a specially- engineered polymer, creating a well-balanced matrix. BXL is recommended for numerous hoist, marine and logging rope applications. BXL provides: Fatigue Resistance. Improved fatigue resistance is derived from the cushioning and dampening effect of the polymer on the wires and strands. BXL also evenly distributes stresses which may lead to fatigue breaks.

Abrasion Resistance. The polymer acts as a barrier between the individual strands, preventing penetration of any adverse material. BXL distributes and reduces contact stresses between the rope and sheave, reducing wire rope wear.

Service Life. BXL minimizes corrugation and wear normally associated with standard rope usage by restricting water and dirt penetration and eliminating pickup of abrasive materials.

This rope is particularly suitable where severe conditions of crushing and abrasion are encountered on the drum or where a higher strength design factor is required than can be obtained with a similar round rope.

The triangular strand shape not only provides better resistance to crushing, but also offers a greater exposed surface area for contact with sheaves, drums or underlying layers of spooled rope. This feature, in connection with the use of Lang lay construction, distributes the abrasive wear over a greater number and length of wires. The smooth surface of the rope also helps minimize wear on drums and sheaves.

ROEPAC is a three strand compacted rope with high breaking strength and stable construction making it perfect as a pulling rope for overhead transmission lines and underground conduits. It’s flexibility and flat surface provides snag-free guidance of the attached lines.

Abrasion Resistance. Compacted design provides improved abrasion resistance compared to standard 6 strand ropes because of the increased wire and strand surfaces contacting the sheaves and drum.

Recently, the 3.5mm diameter micro-sealed steel wire rope developed by Shandong Seal Cable Co., Ltd. was officially put into use in the oilfield market.

⑴Filling factor is up to more than 90%, which is the top of all kinds of steel wire ropes. The total breaking tensile force is about 20% higher than ordinary steel wire ropes of the same diameter.

⑵The whole steel wire rope is similar to a round bar, with a large support surface, less pressure on the unit area. It"s conversion section structure makes the stress distribute uniformly and prolong the used life.

(3) The smooth and sealing surface and the unique structure enable the load-bearing capacity is about 20% stronger than that of ordinary single-strand ropes of the same diameter.

⑷ The adjacent layers of steel wire are twisted in opposite directions, making the wire rope with abilities of non-spinning, large lay pitch, and small structural stretch.Shandong Seal Cable Co., Ltd. was established in 2015 and is headquartered in Jinan City, Shandong Province, China with a registered capital of 202 million yuan. It is an innovative enterprise mainly engaged in independent research and production of new type E-M logging cables and micro-sealed steel wire ropes. At present, SEAL CABLE has more than 20 related patents of independent intellectual property rights, including 3 invention patents. The company has strong technical force, advanced production technology, perfect quality assurance system, complete inspection methods and test equipment and facilities. SEAL CABLE follows the people-oriented management philosophy, adheres to technology innovation, and wholeheartedly provides brand-new products and experiences to customers.

Yasheng UHMWPE Rope is made by ultra high molecular weight polyethylene(UHMWPE) fiber,Using Yasheng’s proprietary rope design and manufacturing precision technology to produce the best UHMWPE Rope in China, it is stronger than steel wire rope of the same diameter,and it’s weight only 1/8 of steel wire rope.On a weight for weight basis, UHMWPE is 15 times stronger than steel wire.

Yasheng UHMWPE Rope is treated with our unique coating process and special sunshine and heat treatment process that to reach its best performance and anti-abrasion characteristics.

s1: respectively twisting 1600D ultra-high molecular weight polyethylene fiber and 3600D ultra-high molecular weight polyethylene film-split fiber to obtain ultra-high molecular weight polyethylene fiber yarn with the diameter of 0.6mm and ultra-high molecular weight polyethylene film-split fiber yarn with the diameter of 0.8mm, wherein the twist number is 25T/m, and the twist direction is S. Here, the ultra-high molecular weight polyethylene fiber yarn may be an ultra-high molecular weight polyethylene fiber without twisting.

And (3) slowly passing the twisted yarns through a glue pool, soaking the twisted yarns in waterborne polyurethane orange glue for 30s, and extruding the redundant glue through a yarn hole with the diameter being less than 20% of the twisted yarn diameter. And drying the yarn impregnated with the glue water by a constant-temperature oven at 50 ℃ and then rolling again, wherein the drying time is 2 min.

S2: respectively twisting 3 ultrahigh molecular weight polyethylene fiber yarns and 3 ultrahigh molecular weight polyethylene split fiber yarns to obtain ultrahigh molecular weight polyethylene fiber rope yarns with the diameter of 1.5mm, wherein the cross section is shown in figure 2A, and the cross section is shown in figure 2B. Wherein the twist number is 25T/m during twisting, and the twist direction is S.

S3: 4 PET round filaments with the diameter of 1mm and the fineness of 9600D are used as a supporting framework, 7 ultra-high molecular weight polyethylene fiber rope yarns and 11 ultra-high molecular weight polyethylene film-split fiber rope yarns are twisted together to prepare a rope with the diameter of 8mm, the breaking strength of 30KN and the breaking friction times of 600 times, the cross-sectional view is shown in figure 1, 11 in the figure is a pure UHMWPE fiber rope yarn, 12 is a pure UHMWPE film-split fiber rope yarn, and 13 is a supporting framework. Wherein the lay length of the rope is 56mm, and the lay direction is Z.

s1: the ultra-high molecular weight polyethylene fiber with the fineness of 1600D and the ultra-high molecular weight polyethylene split fiber with the fineness of 3600D are mixed and twisted to prepare a mixed yarn with the diameter of 1mm, wherein the ultra-high molecular weight polyethylene fiber accounts for 30 wt%, the ultra-high molecular weight polyethylene split fiber accounts for 70 wt%, the twist is 25T/m, and the twist direction is S.

And (3) slowly passing the twisted yarns through a glue pool, soaking the twisted yarns in waterborne polyurethane orange glue for 30s, and extruding the redundant glue through a yarn hole with the diameter being less than 20% of the twisted yarn diameter. And drying the yarn impregnated with the glue water by a constant-temperature oven at 50 ℃ and then rolling again, wherein the drying time is 2 min.

S3: 4 PET round filaments with the diameter of 1mm and the fineness of 9600D are used as a supporting framework and twisted together with 18 mixed rope yarns to prepare a rope with the diameter of 8mm, the breaking strength of 26KN and the breaking friction times of 750 times, wherein the lay length is 56mm, and the lay direction is Z.

s1: respectively twisting 1600D ultra-high molecular weight polyethylene fiber and 3600D ultra-high molecular weight polyethylene split fiber to prepare ultra-high molecular weight polyethylene fiber yarn with the diameter of 0.6mm and ultra-high molecular weight polyethylene split fiber yarn with the diameter of 0.8mm, wherein the twist is 25T/m, and the twist direction is S.

And (3) slowly passing the twisted yarns through a glue pool, soaking the twisted yarns in waterborne polyurethane orange glue for 30s, and extruding the redundant glue through a yarn hole with the diameter being less than 20% of the twisted yarn diameter. And drying the yarns impregnated with the glue water by a constant-temperature oven at 50 ℃, and then rolling again, wherein the drying time is 2 min.

S2: the 1 ultra-high molecular weight polyethylene fiber yarn and the 2 ultra-high molecular weight polyethylene split fiber yarns are mixed and twisted to prepare a mixed fiber rope yarn with the diameter of 2mm, and the cross section is shown in fig. 2C. Wherein the twist number is 25T/m during twisting, and the twist direction is S.

S3: 4 PET round filaments with the diameter of 1mm and the fineness of 9600D are used as a supporting framework and twisted together with 18 mixed fiber rope yarns to prepare a rope with the diameter of 8mm, the breaking strength of 34KN and the breaking friction times of 710 times, wherein the lay length is 56mm, and the lay direction is Z.

s1: 1) respectively twisting ultra-high molecular weight polyethylene fiber with the fineness of 1600D and ultra-high molecular weight polyethylene split fiber with the fineness of 3600D to prepare ultra-high molecular weight polyethylene fiber yarn with the diameter of 0.6mm and ultra-high molecular weight polyethylene split fiber yarn with the diameter of 0.8 mm;

2) the ultra-high molecular weight polyethylene fiber with the fineness of 1600D and the ultra-high molecular weight polyethylene split fiber with the fineness of 3600D are mixed and twisted to prepare a mixed yarn with the diameter of 0.8mm, wherein the ultra-high molecular weight polyethylene fiber accounts for 30 wt%, and the ultra-high molecular weight polyethylene split fiber accounts for 70 wt%.

And (3) slowly passing the twisted yarns through a glue pool, soaking the twisted yarns in waterborne polyurethane orange glue for 30s, and extruding the redundant glue through a yarn hole with the diameter being less than 20% of the twisted yarn diameter. And drying the yarn impregnated with the glue water by a constant-temperature oven at 50 ℃ and then rolling again, wherein the drying time is 2 min.

S2: the 1 ultrahigh molecular weight polyethylene fiber yarn, the 1 ultrahigh molecular weight polyethylene split fiber yarn, and the 1 mixed yarn were twisted together to produce a mixed fiber rope yarn with a diameter of 2mm, and a cross-sectional view is shown in fig. 2D. Wherein the twist number is 25T/m during twisting, and the twist direction is S.

S3: 4 PET round filaments with the diameter of 1mm and the fineness of 9600D are used as a supporting framework and twisted together with 18 mixed fiber rope yarns to prepare a rope with the diameter of 8mm, the breaking strength of 33KN and the breaking friction times of 550 times, wherein the lay length is 56mm, and the lay direction is Z.

The utility model also includes that 1 rope prepared in the example 1 is used as a core, 6 ropes are used as strands to prepare a rope with the diameter of 26mm, the breaking strength of 280KN and the breaking friction times of 7500 times in a twisting mode, the cross section is shown in figure 3, and the perspective view is shown in figure 4. Wherein the lay length of the cable is 175mm, and the lay direction is Z. The breaking strength of the cable prepared by the method reaches the strength of a common steel wire rope, and the cable also has certain bending resistance compared with a polymer rope, and can replace the steel wire rope in practical application.

The utility model also comprises 8 strands of the rope obtained in example 1 braided into a rope having a diameter of 29mm, a breaking strength of 300KN and a number of rubbings at break of 7000, with an intercept of 186mm and a lay direction of Z.

The utility model provides a composite rope and a cable prepared from the rope. Compared with the steel wire rope, the material is soft, is not easy to hurt people, and has high strength; compared with the rope made of the ultra-high molecular weight polyethylene fiber, the rope has certain hardness and good wear resistance; the added supporting framework can well improve the bending resistance of the rope. The rope does not need any protective measures in actual use, and can be widely applied to the fields of high-end protection and rope nets.

While the utility model has been described with reference to preferred embodiments, it will be understood by those skilled in the art that various modifications and combinations can be made to the utility model without departing from the scope of the utility model.

Actual operating loads may vary. NEVER exceed the recommended design factor of 20% of catalogue strength. Wire Rope must have the strength required to handle the maximum load plus a design factor. The design factor is the ratio of the breaking strength of the rope to the maximum working load.

Dyneema, a popular brand of multi-strand HMPE rope made by the Dutch multinational DSM, is offered in a range of fiber types and weaves-from SK 99 down to SK 25, with the smaller number indicating lower density, lower strength fibers. DSM has factories in the U.S. as well as China, where a line of generic HMPE ropes-identified only by tensile strength (bearing neither the Dyneema name or SK number)-are made. Other name-brand HMPE products include Spectra by Honeywell, and Acera by Timm/Willhelmsen.

In this report, we will compare the characteristics of conventional Dyneema to that of heat-set Dyneema, which is stronger and stretches less than conventional Dyneema of the same dimension and weave. We will also compare generic HMPE to the Dyneema brand SK cordage.

In any assembled rope, stretch comes in two forms: construction stretch, when knots, splices, and the braids tightens under load; and fiber stretch, when the rope fibers elongate. During heat setting, the fibers are stretched and heated in a carefully regulated process, which effectively accelerates the construction stretch that normally occurs under load. New England Ropes STS (stronger than steel) is a heat-set Dyneema.

We limited our testing to New England Ropes Dyneema products (New England Ropes) and one generic HMPE (Dyneema) product marketed through Amazon as winch cable.

In the lab, testers compared strength by pulling to failure a short length of each rope sample with eye splices at each end. Abrasion resistance was tested using a 75-pound weight swinging like a pendulum and dragging the unprotected rope across a cinder block about 20 times per minute for 10 minutes (see photo).

There is also an ongoing lifeline test. In 2012, we fitted a PS test boat with New England Ropes STS Dyneema lifelines for a long-term test. At present, the lifelines are showing no significant wear, nor do they reveal any indication that they’ve lost any significant strength. We plan to load test them in the future.

Shortly after the test began, after a few racing failures, World Sailing (then ISAF) restricted the use of Dyneema lifelines to inshore racing (Categories 4 and 5). Their concern was the lack of field data. Eventually, the risk factors were identified. Most commonly, stanchions that previously held bare wire cable had developed burrs at the edges.

In 2015 World Sailing once again allowed HMPE lifelines, though only for multihulls and near-shore racing (Categories 4 and 5). To combat chafe, World Sailing increased the specified diameters for smaller lines. Data collected so far suggests these lifelines will remain as strong as steel through a five- to eight-year lifespan, depending on use. The World Sailing specifications for sailing boat lifelines are available online at https://www.sailing.org/specialregs

Although World Sailing permits smaller diameter lines, we recommend a minimum of -inch Dyneema for the top lifeline. This guarantees a longer service life for just a few dollars more. The most important installation step-other than following splicing instructions-is to very carefully prepare the stanchion holes, removing all burrs and polishing with 1200 grit sandpaper. Chafe guards can also be inserted, made from 2-inch lengths of plastic tubing or nylon tubular webbing (see Fiber Protection Plan, PS September 2015).

New England Ropes STS (heat set Dyneema) is quite firm. It reminded us of the Amsteel cables used in our pull testing rig, which have seen hard use. New England Ropes HTS 78 and Endura 12 (conventional Dyneema) are a very supple line with the same braid as STS. Safeway Lines Tow Cable (generic Dyneema, aka HMPE) has a considerably looser weave and is slightly more prone to snagging. By the time of publication, we could no longer find this brand, although nearly identical products are offered under other brand names. All of the tested ropes spliced very easily.

Strength. Heat-set Dyneema has a slight advantage over normal Dyneema in initial strength, the result of the fibers and the molecules within them being better aligned. However, data from ropes suggest that this process also happens naturally under high load, and were inclined to believe that. We’ve see the changes that occur in highly loaded rigging and in cables that have been repeatedly loaded to high fractions of breaking strength on test stands; the rope becomes firm, like heat set, and stretch is reduced.

Fatigue. The argument against heat setting is that it is just a carefully controlled, accelerated aging process. The rope is made stronger and less stretchy, but lifespan is curtailed. Manufacturers of heat-set rope emphasize that heat-set ropes are stronger and thus have an inherently longer fatigue life. We’ve found no third party data comparing heat set vs. conventional HMPE fatigue life.

As a practical matter, it probably doesn’t make much difference. Correctly sized ropes will fail from chafe or UV damage long before fatigue becomes an issue. Colligo performed a 10-year study of Dynice Dux (heat-set Dyneema) that showed a straight-line decay from full strength to half strength in eight years. Obviously, usage and climate has an effect, so the recommendation for cruisers in the tropics is for replacement in five to seven years-fine considering the overspecified sizes for Dux. However, at the rate that Dyneema loses strength, the only thing keeping up the mast at 15 years will be wishful thinking. If you have Dyneema standing rigging, respect the replacement schedule.

Abrasion. Several riggers told us heat set Dyneema was less abrasion resistant than conventional Dyneema when used with a turning block, tackle, or adjustable backstay. However, during the pendulum torture test, none of the samples showed any appreciable damage after being tested for an hour across wood. Not a fiber was out of place, implying that even cheap Dyneema has a very long service life if properly installed. Polyester double braid showed 10-20 percent chafe damage under the same conditions.

The cinder block, on the other hand, was highly damaging to all of the samples. In all cases, some of the strands were chafed more than 50 percent through, but no strand chafed completely through. The accompanying photos reflecting chafe can be misleading because the weave of the heat set Dyneema remains tight, while the looser weave of the generic cable show damage more readily.

However, when corrected for differences in fiber strength, there was relatively little difference in abrasion or strength loss between the heat-set Dyneema and the cheap tow cable. The tow cable was abraded a bit more, but it was SK 65 fiber versus SK 78. The looser weave may also have contributed to the additional chafe.

The other interesting result was the performance of polyester double braid. In previous research (Abrasion and Break Testing, PS March 2015), Dyneema was much more durable in linear, push-pull testing than polyester, but in side-to-side testing over rough surfaces, the tightness of the braid is more important than the material. This is why polyester mooring bridles, such as Yales well-respected Maximoor, often outperform Dyneema pendants.

The best product depends on the job to be done. For standing rigging and other applications where minimal stretch and maximum strength are required, heat-set Dyneema from a reputable rope manufacture is the top choice. However, where flexibility and abrasion resistance are important-split backstays, lifelines, and low friction ring tackles, for example-conventional Dyneema will run much more smoothly.

Is there a difference in fatigue life? Were not sure. The heat set Dyneema does not like flexing around a pulley and the minimum recommended bend radius is greater.

The only clear advantage of heat set Dyneema is that when used for standing rigging, there is less construction stretch, making installation and rig tuning quicker and more predictable. In our experience, after a few months of hard use, regular Dyneema does seem to behave like heat set rope.

What about non-critical and low strain applications? The HMPE tow cable packs a lot of strength in a small space and offers a strength/dollar ratio that no other fiber can touch. On smaller boats Dyneema is nearly always over specified because the smaller sizes are just too difficult to handle. Dyneema is commonly used in low friction ring systems not because it is amazingly strong, but because it glides around turns so well.

We’ve also found many applications related to anchoring and mooring loops and pendants, where generic Dyneema delivers incredible strength in minimal space, and incredible durability if covered with a chafe guard. However, the difficulty in identifying the manufacturing source of some brands and confirm quality control keeps us skeptical. Although our field experience with generic HMPE rope has been very good to date, cost savings would be quickly erased by a failure in some critical application.

During the chafe testing, wear ranged from 20 to 50 percent of the original diameter, and breaking strength testing after chafe testing was generally proportional to the amount of damage.

None of the twisted strands comprising the woven rope chafed through completely. In the adjacent images, the weave was separated for closer inspection.The Endura 12-strand held 42 percent of its strength after chafe testing.

Compared to the damage caused by the cinder block (images 1-3), the wood-chafe was far less aggressive. The generic Safeway Tow Cable, is shown here after the wood test.

A 6X19 class wire rope contains 6 strands with 16 through 26 wires per strand. Our 6x19 class typically has either 19 (6X19) or 26 (6X26) wires per strand. It is a general purpose rope most commonly used for wire rope chokers and other rigging. 6X19 and 6X26 offfer great abrasion resistance and crush resistance when spooling.

A 6X37 class wire rope contains 6 strands with 27 through 49 wires per strand. Our 6X37 typically has 36 wires per strand. It is a general purpose wire rope with excellent flexibility for spooling. With the smaller wires per strand, the trade off for excelelnt flexibility is reduced abrasion resistance.

IWRC (Independent Wire Rope Core) wire ropes offer more crush resistance when spooling while FC (Fiber Core) wire ropes offer more flexibility. FC wire ropes are not as crush resistant when spooling compared to an IWRC wire rope.

8613371530291

8613371530291