what is the safety factor of wire rope sling for sale

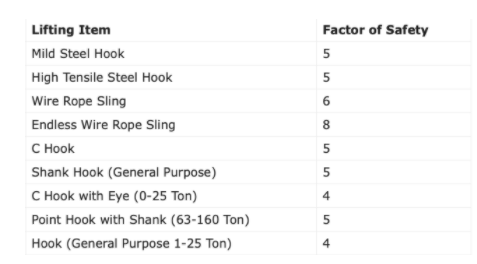

Have you wondered why rigging experts always suggest a sling that has a significantly higher breaking strength than the actual weight of the load you are lifting? The manufacturers know that the rigging used in overhead applications need to have room for error. This is known as the Safety Factor.

Northern Strands manufactures wire rope slings rated up to 36,000 lbs and sells round synthetic slings that are rated up to 140,000 lb capacity. This capacity is the Working Load Limit of the sling, which is the maximum amount of weight or force that the sling"s user is allowed to put on the sling. Note: These slings do not break at the working load limit. These slings are designed with a safety factor of 5:1. This means that 5 times as much force as the working load limit has to be applied to the sling before it potentially fails. This means the wire rope slings have a Breaking Strength of up to 180,000 lbs and the round synthetic slings can withhold up to 700,000 lbs.

Wear - Working load limits are based on slings in brand new condition and a safety factor can help account for normal wear and tear until it is deemed unfit for further use.

Uneven loading - Slings are made up of either wires or fibers that must all share the weight of the load evenly. If any situation arises where the sling is bent or wrapped around an object, there is potential that some of the wires or fibers will be taking on a greater share of the load than others.

Visit Northern Strands website to use the sling tension calculator. The Northern Strands Sling Calculator has been designed to assist you in selecting slings with enough load carrying capacity for your lifting applications. It is your responsibility to assure that the slings you use are appropriate for your application. http://www.northernstrands.com/sling-calculator.aspx

Wire ropes are essential for safety purposes on construction sites and industrial workplaces. They are used to secure and transport extremely heavy pieces of equipment – so they must be strong enough to withstand substantial loads. This is why the wire rope safety factor is crucial.

You may have heard that it is always recommended to use wire ropes or slings with a higher breaking strength than the actual load. For instance, say that you need to move 50,000 lbs. with an overhead crane. You should generally use equipment with a working load limit that is rated for weight at least five times higher – or 250,000 lbs. in this case.

This recommendation is all thanks to the wire rope safety factor. This calculation is designed to help you determine important numbers, such as the minimum breaking strength and the working load limit of a wire rope.

The safety factor is a measurement of how strong of a force a wire rope can withstand before it breaks. It is commonly stated as a ratio, such as 5:1. This means that the wire rope can hold five times their Safe Work Load (SWL) before it will break.

So, if a 5:1 wire rope’s SWL is 10,000 lbs., the safety factor is 50,000 lbs. However, you would never want to place a load near 50,000 lbs. for wire rope safety reasons.

The safety factor rating of a wire rope is the calculation of the Minimum Break Strength (MBS) or the Minimum Breaking Load (MBL) compared to the highest absolute maximum load limit. It is crucial to use a wire rope with a high ratio to account for factors that could influence the weight of the load.

The Safe Working Load (SWL) is a measurement that is required by law to be clearly marked on all lifting devices – including hoists, lifting machines, and tackles. However, this is not visibly listed on wire ropes, so it is important to understand what this term means and how to calculate it.

The safe working load will change depending on the diameter of the wire rope and its weight per foot. Of course, the smaller the wire rope is, the lower its SWL will be. The SWL also changes depending on the safety factor ratio.

The margin of safety for wire ropes accounts for any unexpected extra loads to ensure the utmost safety for everyone involved. Every year there aredue to overhead crane accidents. Many of these deaths occur when a heavy load is dropped because the weight load limit was not properly calculated and the wire rope broke or slipped.

The margin of safety is a hazard control calculation that essentially accounts for worst-case scenarios. For instance, what if a strong gust of wind were to blow while a crane was lifting a load? Or what if the brakes slipped and the load dropped several feet unexpectedly? This is certainly a wire rope safety factor that must be considered.

Themargin of safety(also referred to as the factor of safety) measures the ultimate load or stress divided by theallowablestress. This helps to account for the applied tensile forces and stress thatcouldbe applied to the rope, causing it to inch closer to the breaking strength limit.

A proof test must be conducted on a wire rope or any other piece of rigging equipment before it is used for the first time.that a sample of a wire rope must be tested to ensure that it can safely hold one-fifth of the breaking load limit. The proof test ensures that the wire rope is not defective and can withstand the minimum weight load limit.

First, the wire rope and other lifting accessories (such as hooks or slings) are set up as needed for the particular task. Then weight or force is slowly added until it reaches the maximum allowable working load limit.

Some wire rope distributors will conduct proof loading tests before you purchase them. Be sure to investigate the criteria of these tests before purchasing, as some testing factors may need to be changed depending on your requirements.

When purchasing wire ropes for overhead lifting or other heavy-duty applications, understanding the safety dynamics and limits is critical. These terms can get confusing, but all of thesefactors serve an important purpose.

Our company has served as a wire rope distributor and industrial hardware supplier for many years. We know all there is to know about safety factors. We will help you find the exact wire ropes that will meet your requirements, no matter what project you have in mind.

There is no doubt that working around rigging equipment can be dangerous. These large machines and equipment can cause devastating injuries if they are used incorrectly. Just a few years ago, aconstruction worker was killeddue to rigging equipment that was not loaded properly. A rebar slipped from the crane, striking the worker in the head.

Failing to use safe equipment or loading it properly can also result in hefty fines from safety violations. Every year, OSHA markshundreds of violationsto construction sites and companies due to rigging equipment issues. These are most commonly related to inspections, operation, and assembly of the equipment.

An inspection from a qualified person, such as a crane operator, is required before rigging equipment is used for any purpose. The inspector must look for any visible signs of damage or wear, as well as any indications that something could go wrong.

Machinery inspection– If there is any rust, dents, scratches, or other damage on any piece of equipment, it should be noted during the inspection. While some wear and tear will not impact the rigging equipment, it could be a sign that it needs to be repaired or replaced eventually.

Wire ropes and chains– These pieces of rigging equipment can be damaged over time. Any signs of kinks, wear, or corrosion must be noted, and the rope or chain must be replaced.

One of the most important things to do before using rigging equipment is to double-check the specified working load limit. The weight of all equipment used in the hoisting operation must be calculated for each load to ensure that it is within the working load limit of the lifting mechanism, sling, or hook that is in use.

Since some of these calculations must be estimated, most rigging equipment has a safety factor rating. This essentially accounts for additional weight which could be caused by miscalculations or friction.

For example, thewire rope safety factoris provided as a ratio that compares the minimum break strength (MBS) to the maximum load limit. So, if the MBS for a wire rope is 10,000 lbs. and the safety factor is 6:1, the maximum load limit would be 60,000 lbs.

Construction sites are required to post and provide charts so operators can easily check these working load limits. However, operators should be well versed in the process of calculating these measurements themselves.

The weather can be a major safety issue in some incidences when utilizing rigging equipment. For example, heavy winds will swing the load, making it far more difficult to control. According toOSHA’s standards, rigging equipment cannot be used if the wind is above 20 mph.

If the visibility is impaired by rain or fog, this should also be taken into consideration. Even the temperature can impact how well the rigging equipment works. Extreme cold can cause more brittle metal pieces to crack. This can also make lifting loads more difficult, as they may be frozen to the ground.

Poor quality rigging equipment will break down faster, especially with continuous use. It is important to partner with a rigging equipment supplier that will provide you with top-quality hardware that is also designed for specific applications, purposes, and environments.

Certain materials will simply work better for specific applications. For example, any equipment that is exposed to moisture should utilize stainless steel ropes and strands, as they are naturally rust-resistant. Galvanized metal is also best for high-friction applications, as the zinc coating protects the steel beneath from wearing down quickly.

All rigging equipment operators must complete NCCCO (National Commission for the Certification of Crane Operations) training for the crane type and weight load. There are differentNCCCO licensesfor various types of cranes, such as:

Crane and rigging equipment operators are required by law to complete adequate training and pass their certification exams for various types of equipment. These licenses may need to be renewed periodically.

There are also physical evaluations that operators must pass to run rigging equipment. They must have at least 20/30 vision in one eye with or without the use of glasses. Operators must also have adequate hearing ability (with or without a hearing aid), as well as the physical stamina to operate the rigging apparatus.

There is no excuse for putting people at risk when it comes to using rigging equipment. All of these safety factors must be considered before using this type of machinery.

Of course, the quality of the equipment used to secure and lift each load plays an important role in the safety of the operation. Elite Sales is a trusted rigging equipment supplier which offers only highly rated hardware for industrial purposes.

Original equipment wire rope and replacement wire rope must be selected and installed in accordance with the requirements of this section. Selection of replacement wire rope must be in accordance with the recommendations of the wire rope manufacturer, the equipment manufacturer, or a qualified person.

Wire rope design criteria: Wire rope (other than rotation resistant rope) must comply with either Option (1) or Option (2) of this section, as follows:

Option (1). Wire rope must comply with section 5-1.7.1 of ASME B30.5-2004 (incorporated by reference, see § 1926.6) except that section"s paragraph (c) must not apply.

Option (2). Wire rope must be designed to have, in relation to the equipment"s rated capacity, a sufficient minimum breaking force and design factor so that compliance with the applicable inspection provisions in § 1926.1413 will be an effective means of preventing sudden rope failure.

Type I rotation resistant wire rope ("Type I"). Type I rotation resistant rope is stranded rope constructed to have little or no tendency to rotate or, if guided, transmits little or no torque. It has at least 15 outer strands and comprises an assembly of at least three layers of strands laid helically over a center in two operations. The direction of lay of the outer strands is opposite to that of the underlying layer.

Type II rotation resistant wire rope ("Type II"). Type II rotation resistant rope is stranded rope constructed to have significant resistance to rotation. It has at least 10 outer strands and comprises an assembly of two or more layers of strands laid helically over a center in two or three operations. The direction of lay of the outer strands is opposite to that of the underlying layer.

Type III rotation resistant wire rope ("Type III"). Type III rotation resistant rope is stranded rope constructed to have limited resistance to rotation. It has no more than nine outer strands, and comprises an assembly of two layers of strands laid helically over a center in two operations. The direction of lay of the outer strands is opposite to that of the underlying layer.

Type I must have an operating design factor of no less than 5, except where the wire rope manufacturer and the equipment manufacturer approves the design factor, in writing.

When Types II and III with an operating design factor of less than 5 are used (for non-duty cycle, non-repetitive lifts), the following requirements must be met for each lifting operation:

A qualified person must inspect the rope in accordance with § 1926.1413(a). The rope must be used only if the qualified person determines that there are no deficiencies constituting a hazard. In making this determination, more than one broken wire in any one rope lay must be considered a hazard.

Each lift made under § 1926.1414(e)(3) must be recorded in the monthly and annual inspection documents. Such prior uses must be considered by the qualified person in determining whether to use the rope again.

Rotation resistant ropes may be used as boom hoist reeving when load hoists are used as boom hoists for attachments such as luffing attachments or boom and mast attachment systems. Under these conditions, all of the following requirements must be met:

The requirements in ASME B30.5-2004 sections 5-1.3.2(a), (a)(2) through (a)(4), (b) and (d) (incorporated by reference, see § 1926.6) except that the minimum pitch diameter for sheaves used in multiple rope reeving is 18 times the nominal diameter of the rope used (instead of the value of 16 specified in section 5-1.3.2(d)).

The operating design factor for these ropes must be the total minimum breaking force of all parts of rope in the system divided by the load imposed on the rope system when supporting the static weights of the structure and the load within the equipment"s rated capacity.

Wire rope clips used in conjunction with wedge sockets must be attached to the unloaded dead end of the rope only, except that the use of devices specifically designed for dead-ending rope in a wedge socket is permitted.

Prior to cutting a wire rope, seizings must be placed on each side of the point to be cut. The length and number of seizings must be in accordance with the wire rope manufacturer"s instructions.

Scope. This section applies to slings used in conjunction with other material handling equipment for the movement of material by hoisting, in employments covered by this part. The types of slings covered are those made from alloy steel chain, wire rope, metal mesh, natural or synthetic fiber rope (conventional three strand construction), and synthetic web (nylon, polyester, and polypropylene).

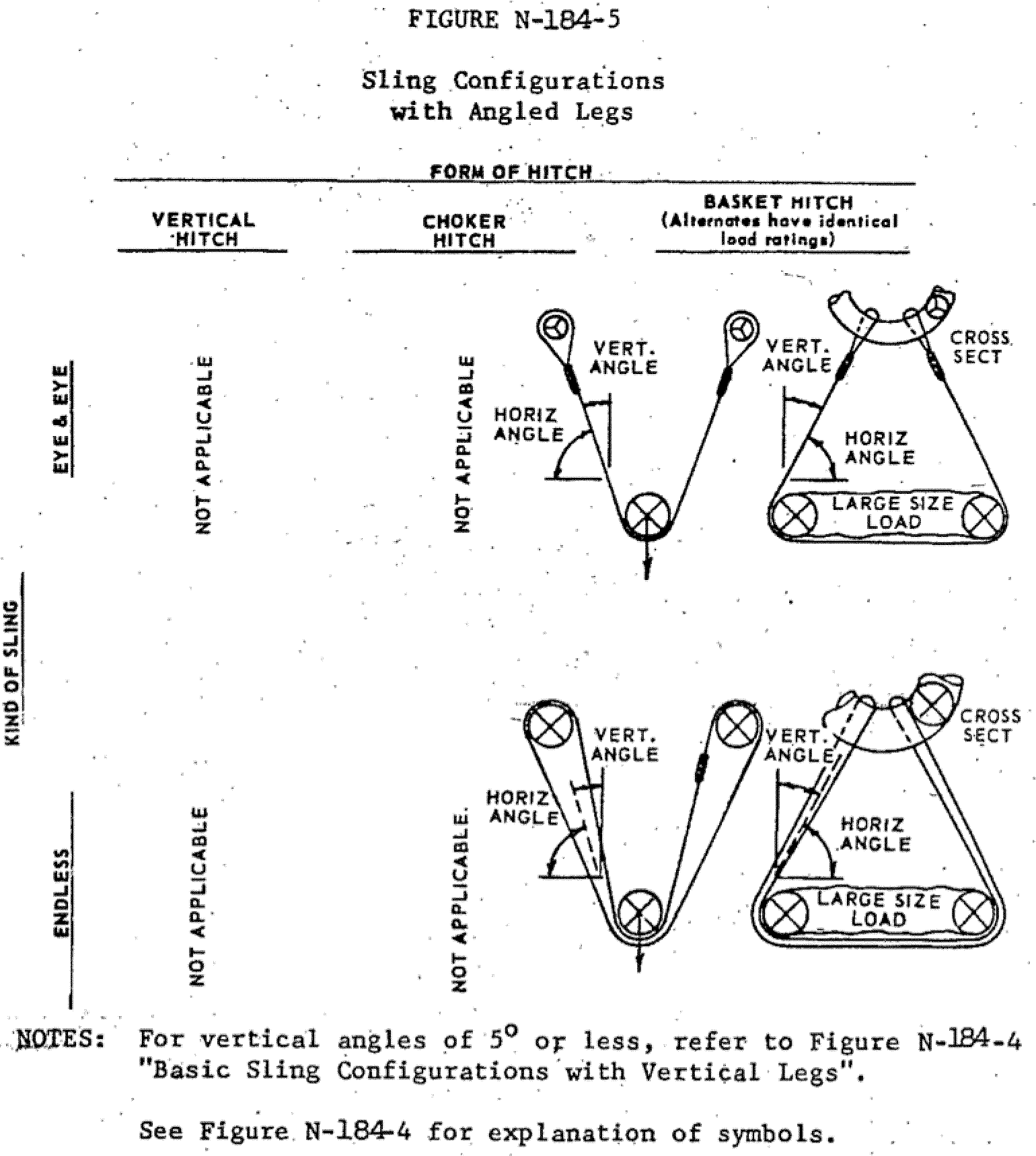

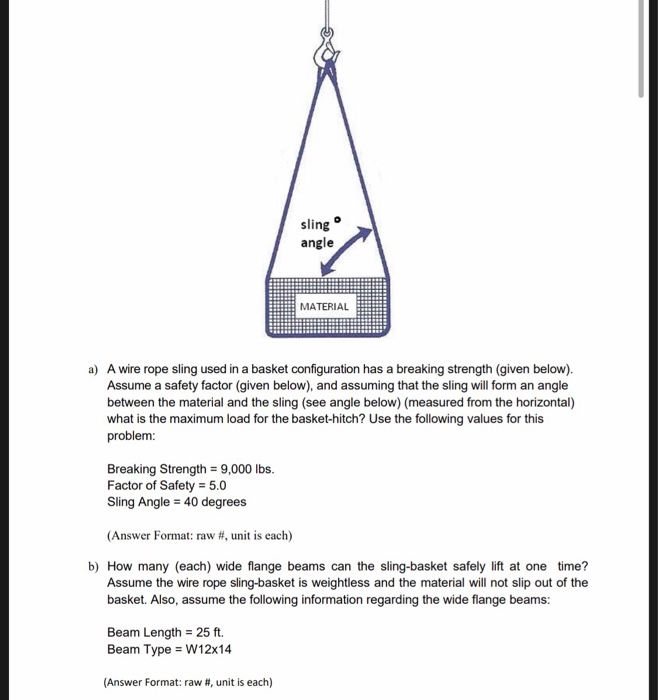

Definitions. Angle of loading is the inclination of a leg or branch of a sling measured from the horizontal or vertical plane as shown in Fig. N-184-5; provided that an angle of loading of five degrees or less from the vertical may be considered a vertical angle of loading.

Basket hitch is a sling configuration whereby the sling is passed under the load and has both ends, end attachments, eyes or handles on the hook or a single master link.

Cable laid endless sling-mechanical joint is a wire rope sling made endless by joining the ends of a single length of cable laid rope with one or more metallic fittings.

Cable laid grommet-hand tucked is an endless wire rope sling made from one length of rope wrapped six times around a core formed by hand tucking the ends of the rope inside the six wraps.

Cable laid rope sling-mechanical joint is a wire rope sling made from a cable laid rope with eyes fabricated by pressing or swaging one or more metal sleeves over the rope junction.

Choker hitch is a sling configuration with one end of the sling passing under the load and through an end attachment, handle or eye on the other end of the sling.

Equivalent entity is a person or organization (including an employer) which, by possession of equipment, technical knowledge and skills, can perform with equal competence the same repairs and tests as the person or organization with which it is equated.

Female handle (choker) is a handle with a handle eye and a slot of such dimension as to permit passage of a male handle thereby allowing the use of a metal mesh sling in a choker hitch. (See Fig. N-184-1.)

Master coupling link is an alloy steel welded coupling link used as an intermediate link to join alloy steel chain to master links. (See Fig. N-184-3.)

Master link or gathering ring is a forged or welded steel link used to support all members (legs) of an alloy steel chain sling or wire rope sling. (See Fig. N-184-3.)

Diagam howing Two slings with indicators for sling width, overall length, bearing to bearing length, and fabric length. Further indicators point to both male handles, handle eye, female handle, and slot depth

Diagram indicates Forms of Hitch and Kind of Sling. Eye&Eye Vertical Hitch. Eye&Eye Choker Hitch. Eye&Eye Basket Hitch (Alterates have identical load rations). Endless Vertical Hitch. Endless Choker Hitch. Endless Basket Hitch (Alternateve have identical load ratings). Notes: Angles 5 deg or less from the veritcal may be considered vertical angles. For slings with legs more than 5 deg off vertical, the actual angle as shown in Figure N-184-5 must be considered. Explanation of Symbols: Minimum Diameter of Curvature. Represents a contact surface which shall have a diameter of curvature at least double the diameter of the rope from which the sling is made. Represents a contact surface which shall have a diameter of curvature at least 8 times the diameter of the rope. Represents a load in a choker hitch and illustrates the rotary force on the load and/or the slippage of the rope in contact with the load. Diameter of curvature of load surface shall be at least double the diameter of the rope.

Diagram indicates Form of Hitch and Vertical Hitch. Kind of Sling. Eye&Eye Vertical Hitch Not Applicable. Eye&Eye Choker Hitch Not Applicable. Eye&Eye Basket Hitch (Alternates have identical load ratings). Endless Vertical Hitch Not Applicable. Endless Choker Hitch Not Applicable. Endless Basket Hitch (Alternates have identical load ratings). Notes: For vertical angles of 5 deg or less, refer to Figure N-184-4 ""Basic Sling Configurations with Vertical Legs"". See Figure N-184-4 for explanation of symbols.

Proof test is a nondestructive tension test performed by the sling manufacturer or an equivalent entity to verify construction and workmanship of a sling.

Reach is the effective length of an alloy steel chain sling measured from the top bearing surface of the upper terminal component to the bottom bearing surface of the lower terminal component.

Strand laid endless sling-mechanical joint is a wire rope sling made endless from one length of rope with the ends joined by one or more metallic fittings.

Strand laid grommet-hand tucked is an endless wire rope sling made from one length of strand wrapped six times around a core formed by hand tucking the ends of the strand inside the six wraps.

Strand laid rope is a wire rope made with strands (usually six or eight) wrapped around a fiber core, wire strand core, or independent wire rope core (IWRC).

Employers must not load a sling in excess of its recommended safe working load as prescribed by the sling manufacturer on the identification markings permanently affixed to the sling.

Inspections. Each day before being used, the sling and all fastenings and attachments shall be inspected for damage or defects by a competent person designated by the employer. Additional inspections shall be performed during sling use, where service conditions warrant. Damaged or defective slings shall be immediately removed from service.

Hooks, rings, oblong links, pear shaped links, welded or mechanical coupling links or other attachments shall have a rated capacity at least equal to that of the alloy steel chain with which they are used or the sling shall not be used in excess of the rated capacity of the weakest component.

In addition to the inspection required by paragraph (d) of this section, a thorough periodic inspection of alloy steel chain slings in use shall be made on a regular basis, to be determined on the basis of

experience gained on the service life of slings used in similar circumstances. Such inspections shall in no event be at intervals greater than once every 12 months.

The employer shall make and maintain a record of the most recent month in which each alloy steel chain sling was thoroughly inspected, and shall make such record available for examination.

The thorough inspection of alloy steel chain slings shall be performed by a competent person designated by the employer, and shall include a thorough inspection for wear, defective welds, deformation and increase in length. Where such defects or deterioration are present, the sling shall be immediately removed from service.

Proof testing. The employer shall ensure that before use, each new, repaired, or reconditioned alloy steel chain sling, including all welded components in the sling assembly, shall be proof tested by the sling manufacturer or equivalent entity, in accordance with paragraph 5.2 of the American Society of Testing and Materials Specification A391-65, which is incorporated by reference as specified in § 1910.6 (ANSI G61.1-1968). The employer shall retain a certificate of the proof test and shall make it available for examination.

Safe operating temperatures. Employers must permanently remove an alloy steel-chain slings from service if it is heated above 1000 degrees F. When exposed to service temperatures in excess of 600 degrees F, employers must reduce the maximum working-load limits permitted by the chain manufacturer in accordance with the chain or sling manufacturer"s recommendations.

Worn or damaged alloy steel chain slings or attachments shall not be used until repaired. When welding or heat testing is performed, slings shall not be used unless repaired, reconditioned and proof tested by the sling manufacturer or an equivalent entity.

Effect of wear. If the chain size at any point of the link is less than that stated in Table N-184-1, the employer must remove the chain from service.

Slings shall be removed from service if hooks are cracked, have been opened more than 15 percent of the normal throat opening measured at the narrowest point or twisted more than 10 degrees from the plane of the unbent hook.

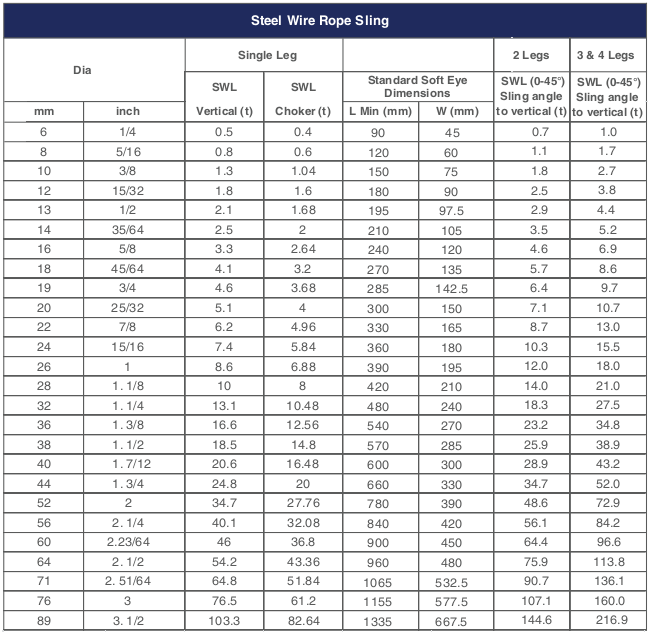

Sling use. Employers must use only wire-rope slings that have permanently affixed and legible identification markings as prescribed by the manufacturer, and that indicate the recommended safe working load for the type(s) of hitch(es) used, the angle upon which it is based, and the number of legs if more than one.

Cable laid and 6 × 19 and 6 × 37 slings shall have a minimum clear length of wire rope 10 times the component rope diameter between splices, sleeves or end fittings.

Safe operating temperatures. Fiber core wire rope slings of all grades shall be permanently removed from service if they are exposed to temperatures in excess of 200 °F. When nonfiber core wire rope slings of any grade are used at temperatures above 400 °F or below minus 60 °F, recommendations of the sling manufacturer regarding use at that temperature shall be followed.

All welded end attachments shall not be used unless proof tested by the manufacturer or equivalent entity at twice their rated capacity prior to initial use. The employer shall retain a certificate of the proof test, and make it available for examination.

Hooks that have been opened more than 15 percent of the normal throat opening measured at the narrowest point or twisted more than 10 degrees from the plane of the unbent hook.

Sling marking. Each metal mesh sling shall have permanently affixed to it a durable marking that states the rated capacity for vertical basket hitch and choker hitch loadings.

Sling testing. All new and repaired metal mesh slings, including handles, shall not be used unless proof tested by the manufacturer or equivalent entity at a minimum of 1½ times their rated capacity. Elastomer impregnated slings shall be proof tested before coating.

Safe operating temperatures. Metal mesh slings which are not impregnated with elastomers may be used in a temperature range from minus 20 °F to plus 550 °F without decreasing the working load limit. Metal mesh slings impregnated with polyvinyl chloride or neoprene may be used only in a temperature range from zero degrees to plus 200 °F. For operations outside these temperature ranges or for metal mesh slings impregnated with other materials, the sling manufacturer"s recommendations shall be followed.

Once repaired, each sling shall be permanently marked or tagged, or a written record maintained, to indicate the date and nature of the repairs and the person or organization that performed the repairs. Records of repairs shall be made available for examination.

Sling use. Employers must use natural and synthetic fiber-rope slings that have permanently affixed and legible identification markings stating the rated capacity for the type(s) of hitch(es) used and the angle upon which it is based, type of fiber material, and the number of legs if more than one.

Safe operating temperatures. Natural and synthetic fiber rope slings, except for wet frozen slings, may be used in a temperature range from minus 20 °F to plus 180 °F without decreasing the working load limit. For operations outside this temperature range and for wet frozen slings, the sling manufacturer"s recommendations shall be followed.

Splicing. Spliced fiber rope slings shall not be used unless they have been spliced in accordance with the following minimum requirements and in accordance with any additional recommendations of the manufacturer:

In manila rope, eye splices shall consist of at least three full tucks, and short splices shall consist of at least six full tucks, three on each side of the splice center line.

In synthetic fiber rope, eye splices shall consist of at least four full tucks, and short splices shall consist of at least eight full tucks, four on each side of the center line.

Strand end tails shall not be trimmed flush with the surface of the rope immediately adjacent to the full tucks. This applies to all types of fiber rope and both eye and short splices. For fiber rope under one inch in diameter, the tail shall project at least six rope diameters beyond the last full tuck. For fiber rope one inch in diameter and larger, the tail shall project at least six inches beyond the last full tuck. Where a projecting tail interferes with the use of the sling, the tail shall be tapered and spliced into the body of the rope using at least two additional tucks (which will require a tail length of approximately six rope diameters beyond the last full tuck).

For all eye splices, the eye shall be of such size to provide an included angle of not greater than 60 degrees at the splice when the eye is placed over the load or support.

Removal from service. Natural and synthetic fiber rope slings shall be immediately removed from service if any of the following conditions are present:

Attachment of end fittings to webbing and formation of eyes. Stitching shall be the only method used to attach end fittings to webbing and to form eyes. The thread shall be in an even pattern and contain a sufficient number of stitches to develop the full breaking strength of the sling.

Diagram depicting three of six types of sling constructions. Type I Triangle Choker typer. Contains Triangle Fitting, measured pull to pull when flat, choker slot, choker fitting, and fitting eye. Type II Triangle Triangle. Length Measured pull to pull when flat. Type III Eye and Eye with Flat Eyes. Length between Lap and Eye.

Diagram depicting the final three types of six of sling constructions. Type IV Eye and eye with Twisted Eyes. Length measured Eye Perpendicular to Sling Body. Type V Endless Type. Type VII Return Eye.

Safe operating temperatures. Synthetic web slings of polyester and nylon shall not be used at temperatures in excess of 180 °F. Polypropylene web slings shall not be used at temperatures in excess of 200 °F.

Each repaired sling shall be proof tested by the manufacturer or equivalent entity to twice the rated capacity prior to its return to service. The employer shall retain a certificate of the proof test and make it available for examination.

The LKING STEEL LIMITED 6 x 37 IWRC (independent wire rope core) single-leg wire rope sling has eye-and-eye endings and a mechanical splice for lifting loads with vertical, choker, or basket configurations in general industry applications. The 6 x 37 IWRC construction contains six strands of wire rope with approximately 37 wires per strand wrapped around a separate 7 X 7 wire rope, which has seven strands with seven wires per strand, in the center of the sling. This construction provides more flexibility than a 6 x 7 or 6 x 19 wire rope sling. The wire rope construction has more abrasion and heat resistance than a web sling. This eye-and-eye sling has an eye, or loop, on both ends, and can be used with vertical, choker, and basket lifting configurations. The eyes are secured with a mechanical (also called Flemish) splice that is stronger than a hand splice. This sling has a minimum D/d ratio of 25 and meets American Society of Mechanical Engineers (ASME) specification B30.9 and Occupational Safety and Health Administration (OSHA) specification 1910.184.

Slings are used to lift heavy objects for industrial applications. Types of slings include web slings, wire rope slings, chain slings, and mesh slings. The appropriate type of sling for an application depends on the strength-to-weight ratio, flexibility and resistance to bending, resistance to abrasion and cutting, resistance to crushing, resistance to stretching, and resistance to high temperatures and other environmental stressors. Slings have one, two, three, or four legs; or a continuous loop of webbing or wire rope. Legs are support branches that extend from a single point at the top of the sling to the item being lifted so the weight of the load is distributed evenly among the branches. Slings have eyes (loops) or alloy steel fittings on the ends.

A vertical lifting configuration connects a crane hook directly to a load with a single, vertical sling, usually by means of a hook. In a choker configuration, the sling wraps entirely around the load, and one loop passes through the other to form a slip noose, or choker. In a basket configuration, the sling passes under the load and both ends of the sling connect to the crane hook. Load capacity is the maximum weight to be lifted in a vertical configuration. The capacity in a choker configuration is approximately equal to the vertical capacity times 0.8. The capacity in a basket configuration, with sling ends at a 90-degree angle, is approximately equal to twice the vertical capacity. Load capacity in a basket configuration decreases if the angle of the sling is less than 90 degrees. For example, a sling with a capacity of 2,000 lb. in a vertical configuration will have an approximate capacity of (2,000)(0.8)=1,600 lb. in a choker configuration and an approximate capacity of (2,000)(2)=4,000 lb. in a basket configuration, if the sling ends are at a 90-degree angle to the load. A wire rope sling"s capacity in a basket configuration applies only when the configuration meets the sling"s minimum D/d ratio, which is the ratio of the diameter of the rope"s curve around the load (D) to the diameter of the sling (d). If the minimum D/d ratio is not met, the capacity of the sling is decreased.

LKING STEEL LIMITED Lifting Technologies manufactures lifting solutions including slings, cranes, and hoists. Founded in 1967, the company is headquartered in Shanghai, China.

B) if the 2legswire rope sling, the hanging points should be on both sides of the goods and the hooks are above the center of gravity of the suspended objects.

C) if it is three legs or four legs wire rope sling, the hanger must be proportioned on the plane around the cargo and the hook is located directly above the center of gravity of the suspended object.

The load which a new wire rope may handle under given operating conditions and at an assumed design factor. A design factor of five is chosen most frequently for wire rope. (Operating loads not to exceed 20% of catalog breaking strength). Operating loads may have to be reduced when life, limb, or valuable property are at risk, or other than new wire rope is used. A design factor of 10 is usually chosen when wire rope is used to carry personnel. (Operating loads not to exceed 10% of catalog breaking strength). Responsibility for choosing a design factor with the user.

Rope sockets, thimbles, sleeves, hooks, links, shackles, sheaves, blocks, etc., must match in size, materials and strength, to provide adequate safety protection. Proper installation is crucial for maximum efficiency and safety.

The end point in a wire rope sling’s useful service life is prior to the failure of the sling. It must be removed from service when normal wear or accidental damage weakens the sling to the degree that an adequate factor of safety no longer exists.

The term “Breaking Strength” is never used with reference to slings. Slings have a “Rated Capacity” that is determined by the manufacturer. A sling should never be used to lift a load that is greater than the published “Rated Capacity” for the particular sling and for the type of hitch being used. The design factor used in the calculation of a sling’s Rated Capacity compensates for normal dynamic loading and builds useful life into the sling.

Selection of a sling to lift a load is based on selecting a sling with a Rated Capacity at least equal to the weight of the load. The sling must also be proper to allow the user to select a hitch that will conform to the shape of the load and keep it under control during the lift, The use of multiple leg slings is not recommended when the angle between any leg and the vertical is greater than 450• In any case when lifting headroom is restricted and a larger leg angle is necessary, care must be exercised in selecting a sling with a proper Rated Capacity at the leg angle which will be used. A visual inspection of the sling must be conducted before each lift to make sure the sling is in new or near new condition. A manufacturer’s Rated Capacity applies only to an undamaged sling.

Slings used in selected industries are presently covered by specific codes seffing standards for the removal of a sling from service. However, many industries are presently without standards. Safety is the prime consideration on all jobs and the user must inspect a sling before each lift, and must remove the sling from service upon observation of any of the following conditions:

Our responsibility is limited to the sling as purchased new; and the responsibility for safe operation, maintenance and use rest with the purchaser.Whenever a sling is being rigged, tensioned or used to lift a load, a potentially hazardous condition exists and extreme caution should be used by riggers and personnel in the area. In all cases, safe rigging practices must be employed.

Wire rope tends to kink during uncoiling or unreeling, especially if it has been in service for a long time. In order to unreeling the wire rope is to run a steel pipe or strong rod through the center and mount the reel on drum jacks or other supports so the reel is off the ground. In this way, the reel will turn as the rope is unwound, and the rotation of the reel will help keep the rope straight.

During unreeling, pull the rope straight forward and avoid hurrying the operation. As a safeguard against kinking, never unreel wire rope from a stationary reel.

To uncoil a small coil of wire rope, simply stand the coil on edge and roll it along the ground. Never uncoil it by pulling on the end because such practice can kink or twist the rope.

The closer the position of the wire rope to the vertical, the safer it will be operated in safer conditions and with a longer lifespan, tension inside being distributed much more evenly between the strands and wires.

Non-rotating wire ropes have strands twisted around the core and the lay direction for outer strands is opposite to immediately inner strands. The outer rotational force of the rope will counteract the rotational force of the inner strands, leaving a wire rope that is resistant to rotating.

They have a long flexibility and lifespan, thanks to the winding of wires and strands in such a way that they generate low values for torsion time and tension when subjected to a load.

8613371530291

8613371530291