what is wire rope sling pricelist

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

It also save energy and money. wire rope slings are made from stainless steel, and it"s also an excellent choice for installation or any production of any kind.

There are two types of wire rope sling, steel wire sling, and steel rope sling. Stocking products of different price points, be the first choice and stockists wholesale today. Check out the stainless steel wire sling price, color and design at Alibaba.

We offer Wire Rope Sling that are mainly used for transporting and shifting of load.These are highly acclaimed for features like durability, hardness and tensile strength. The sling is used in construction, marine and automobile industry. The range is also customized as per specification of client.

Naranpura, Ahmedabad No. 203, Vraj Bhumi Apartment, No. 11, Harihar Society Raman Nagar, Mani Nagar, Naranpura, Ahmedabad - 380008, Dist. Ahmedabad, Gujarat

Byculla, Mumbai No. 2/14, Pais Street, Byculla West, Opposite Kinjal Towers Near Veena Killedar Industrial Estate, Byculla, Mumbai - 400011, Dist. Mumbai, Maharashtra

Kalasipalya, Bengaluru No. 1/2, No. 3rd Cross, N. R. Road Nazz Complex, Below Vijaya Bank, Kalasipalya, Bengaluru - 560002, Dist. Bengaluru, Karnataka

Naranpura, Ahmedabad D-40, Ratilal Park, Opposite Devkinandan Jain Temple, Darpan Six Road, Navrangpura, Naranpura, Ahmedabad - 380014, Dist. Ahmedabad, Gujarat

Wire Rope Material: The lifting slings are made from independent wire rope core (IWRC) offering less stretch and resistance to crushing while maintaining sling flexibility. Wire rope slings are fabricated from extra improved plow steel (EIPS).

A low quality wire rope sling can cause injury and damage. A look-alike wire rope sling often found at lower prices is also often advertised to conform to the same safety standards (if at all). Be aware that it may refer to safety ratings in effect decades ago. So for example under the same safety standard a decade ago, a wire rope sling may be rated to 100% without proof load testing while today it may be 300% with proof load testing. Be assured that we only sell the highest quality wire rope slings and our advertised safety standards conform to the current ASME standards.

Working load limits (capacity) of the wire rope lifting slingsvary depending on the angle of use. The capacity is reduced as the angle of use declines. See drawing below how a 1,000 lbs sling capacity is reduced as the angle of use declines. The capacity of the sling is always highest at a 90 degree angle of use and smallest at an angle of 30 degrees (or less).

The chain sling has the advantage of being durable, very flexible and its length can be made adjustable. It will tolerate a wide range of temperatures; however, compared to other types, it is relatively expensive and, depending upon the grade of chain used, relatively heavy.

The wire rope sling is not quite as durable. The wire rope sling is not as flexible as chain but its greater stiffness can be an advantage if it has to be inserted through a small opening or beneath a load. However, when wrapped around a load, the wire rope sling often tends to deform permanently to the shape of the load. Wire rope suitable for slings comes in a variety of grades and constructions. In most cases looping back and securing the loop with a metal sleeve terminates the rope. This forms a loop or soft eye, the simplest form of sling end. Thimbles are used to support and protect the eye from abrasion. Wire rope is generally cheaper and lighter than chain which can be a plus, particularly for applications that require long sling lengths.

The nylon and polyester slings have the advantage of being lightweight in comparison to chain and wire rope slings. They are very flexible and relatively soft; therefore, they are suitable in applications were minimal damage to the load"s surface finish is important. The rope is made endless or terminated with an eye by means of a handmade splice. Similar to a wire rope sling, various terminal fittings are available. Without adequate protection, nylon and poly slings are susceptible to being severed when impinging on even a relatively moderate sharp edge.

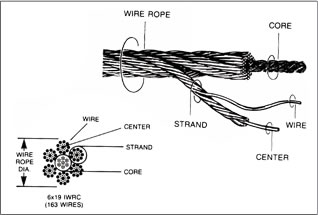

Wire rope is often commonly referred to as cable; they are one in the same. Wire rope is composed of wires, strands, and a core. The basic unit is the wire, which is formed into strands. The strands are wound around the core. Various types of wire rope exist to meet a range of uses and operating conditions. These types are designated by the number of strands; the number, sizes and arrangement of the wires in each strand; and the way in which the wires and strands are wound, or laid, about each other.

Important characteristics of wire rope relate to the number and size of the outer wires. A small number of large outer wires result in better resistance to wear and corrosion. A large number of small wires result in better flexibility and resistance to fatigue.

The core acts as the axial member about which the strands are laid. Wire rope cores are made in two different forms. The one used most extensively is a wire rope of suitable size to serve as a core. It is called as independent wire rope core (IWRC). IWRC has increased tensile strength, offers less stretch, and is resistant to crushing; however, is less flexible. The other type is a wire strand core (WSC). This consists of a multiple-wire strand, and may be the same construction as the main rope strands.

Two grades of carbon steel wire are offered. The bulk of commercial wire rope lifting sling is made from improved plow steel (IPS) or extra improved plow steel (EIPS) which has a higher tensile strength.

Hand Splicing: Because no metal sleeve is required to secure the eye in the hand spliced sling, it exhibits more flexibility than mechanically splice slings of equal diameter. They have a more narrow profile and therefore can fit through tight spaces. Without benefit of a metal sleeve, lifts must be limited to applications where the wire rope sling is restrained from rotation and possible unlaying of the sling body.

Mechanical Splicing:Mechanically spliced eyes do not suffer the limitations of hand splicing, are economical, and offer the highest rated capacity of any spliced wire rope sling. This wire rope sling is fabricated by unlaying the rope body into two parts, one containing half the number of strands, the other having the remaining strands and core. The rope is unlayed far enough back to allow the eye to be formed by looping one part in one direction and the other part in the opposite direction and laying the rope back together. The strands are rolled back around the rope body and a metal sleeve is slipped over the ends and pressed (or swaged) to secure the ends to the body of the wire rope sling.

All Departments1x19 Stainless Steel Strand1x7 Guy Strand6x26 Wire RopesApparelBlocks and PulleysCable RailingClearanceCordageDecalsFall ProtectionGrade 70 Transport ChainHard Hat StickersHeadwearLIFTGEAR MerchRotation Resistant Wire RopesSafety MerchSynthetic Tycan® ChainSynthetic Tycan® Chain SlingsWashington Wire RopeIMPORT- WRCManual Chain HoistsGrade 70 Binder Chains7x19 Aircraft CableWire Rope SlingsLever Chain HoistsBeam ClampsGrade 100 ChainPlate Clamps6x36 Wire RopesG100 Chain SlingsDSS - DOUBLE SWIVEL SHACKLESEB - SWIVEL EYE BOLTWeb SlingsBest SellersOffroad RecoveryOffroad Recovery RopesTowing SuppliesLoad and TransportWire RopeChain and AccessoriesClampsDSR - DOUBLE SWIVEL HOIST RINGSRound SlingsAMHHoists and ClampsWire Rope ClipsSynthetic SlingsCODIPROLifting SlingsMade in USASafety ShacklesSUPER STRONG ShacklesShacklesRigging Hardware

Here at Murphy Industrial Products, Inc., we provide a wide range of wire rope chokers to help you get the job done on time. You can get ones that have fiber cores or independent wire ones. One of the advantages of choosing a wire cable sling is that it can resist damage from heat. Plus, it can be a lot stronger than a traditional rope is. Ones that have fiber cores also come with the advantage of resisting heat. However, they can also get damaged if the environment is not right.

You can choose to use wire lifting cable slings because of how strong they are. They can resist abrasions well, and they tend to last for a long time. You do not have to worry about how light or heavy your materials are when lifting them. Plus, the temperature of them will not affect the performance of the rope.

Wire rope slings are mainly for heavy duty jobs that require lifting hoisting, and/or towing and anchoring heavy loads. Wire slings can handle heat and offer superior abrasion resistance. These slings can be used in almost any condition. They offer a flexible design that will conform to just about any shape need be to secure the load.

The eye loops on our sling cable are created with a flemish splice, which is a splice where the wire cable is detached into two parts then re-laid back in the opposite direction to form the loop. The ends are then secured with a carbon steel sleeve around the splice.

Different wire rope sling builds will offer different benefits and will work better in varying conditions and applications. A good rule of thumb is the smaller number of large outer wires offers better wear and corrosion resistance, while a larger number of small wires provides a better level of flexibility and resistance to fatigue.

It is crucial to choose a quality sling to prevent damage to your equipment. Slings found at low prices might not meet the current safety standards. That could cause it to break during use.

Many people like wire rope since they are so durable. Plus, they are useful for many applications, making them a flexible option. Are you looking for the right lifting wire rope slings for your facility? Feel free to reach out to Murphy Industrial Products, Inc. to find out more about our products. We are happy to help you decide on the right cable sling to meet your company’s needs.

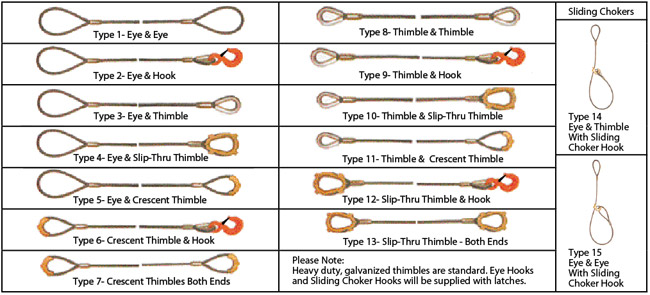

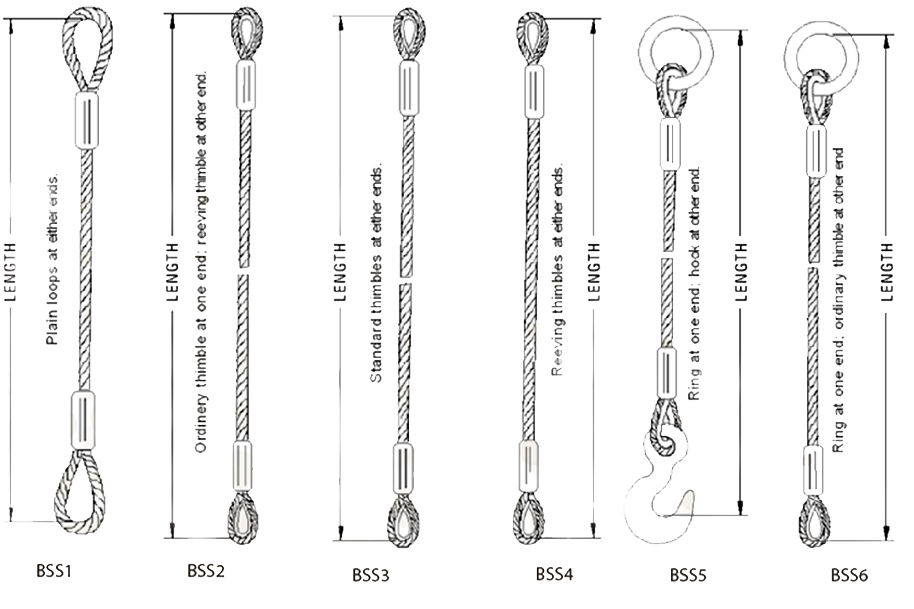

Single Leg Wire Rope Slings are ideal for lifting and rigging. Offering capacities up to 3.2 Tonnes we can provide prices on application for larger capacities. All of our wire rope slings are proudly manufactured in the UK and can be customised online to your requirements. Any of our one leg Wire Rope Slings can be fitted with the following terminations:

How much does a wire rope sling cost? How much does a shackle or a web sling cost? These are legitimate questions that we hear every day from prospective customers looking to purchase rigging products for their next lifting project.

Similar to other consumer goods like cars, electronics, and appliances, there are several factors that can raise or lower the price of rigging equipment. Our intention in this article isn’t to beat around the bush, but instead we want to provide you with some practical guidelines, as well as influential factors that can affect the cost of lifting and rigging products, including:Where do you buy your rigging gear?

Like most products and services, rigging gear can be purchased from a traditional brick and mortar location, or can be purchased online through a specialty supplier or catalog and supply house with an e-commerce site. If you’ve done some research and looked at different online suppliers, you’ll notice that there can be a huge disparity in pricing between the same types of rigging products for sale online and in a physical rigging shop.

For instance, a common Eye and Eye 2” Wide, Two-Ply Web Sling (EE2-802 X 10’) had the following prices listed on three different e-commerce websites: $24.00, $32.00, and $42.00. That same web sling was being sold for $26.00 at a brick and mortar rigging shop.

Rigging shops have long been the stalwarts of the lifting and rigging industries. Rigging shops typically have a showroom or storefront with a wide selection of sling hooks, shackles, chain, synthetic slings and wire rope. They also traditionally buy the raw materials for wire rope, webbing, steel and chain and have a shop where they can make the lifting and rigging products themselves.

The variety of rigging equipment and expertise that the rigging shops offer is unparalleled as you can speak directly with a knowledgeable salesperson to get a product recommendation. They also offer added convenience—if they have the part(s) that you’re looking for in stock, you can stop in that same day and walk out the door with what you need. This also eliminates the added expense of paying for freight to ship rigging equipment that can be large and heavy.

But do they have the best prices? Sometimes they do, but most of the time they fall somewhere in the middle of the price spectrum. The same web slings we mentioned earlier had prices ranging from $24.00 to $42.00 from three e-commerce retailers. A rigging shop might fall somewhere in the middle around $26.00 for that same web sling.

Many rigging shops pride themselves on carrying product in bulk and in a full range of sizes and configurations. While this is convenient for the customer, it also increases the shop’s inventory carrying costs, which get passed on to the end-user as a premium item price increase.

If you’re looking for the added benefit and expertise of speaking with a knowledgeable salesperson, want to browse an extensive inventory, and may have an immediate need for a piece of rigging hardware, chain sling, roundsling, or wire rope, then a rigging shop might be your best bet.

More and more, it’s becoming commonplace to order rigging gear from online retailers. For those that don’t need product variety, or value in-store sales expertise, many rigging shops and industrial suppliers are offering their products for sale through their websites, as well.

A common 1/2” X 10’, 6 X 25 Wire Center, Wire Rope Sling comes in at $29.00, $43.00, and $67.00 from three different online retailers. So, why is there such a wide pricing range for what appears to be the same product?

When doing some rigging cost comparisons, you may notice that the lowest prices seem to come from the websites that only sell lifting and rigging equipment. However, these lifting and rigging websites tend to focus on the common “bread and butter” lifting and rigging equipment and may not have a large inventory of rigging products to select from. They may also make up for their low prices by bumping up the cost of their shipping and handling fees.

Online suppliers with the more expensive wire rope and web slings tend to be larger catalog and supply houses that offer an impressive array of all types of industrial products, including rigging gear. They also offer the convenience of selling items like gloves, eye protection, spray paint, etc.—an added convenience factor that allows you to buy everything that you need from one source.

Catalog supply houses may also offer prepaid freight, or have cheaper shipping rates since they move so much product in and out the door that they receive volume freight discounts that they can then pass on to the customer.

Basic lifting and rigging gear has many options and price ranges as we noted above. When you get into non-standard sizes and lengths, your choices of where to buy are reduced due to the special nature of these products, and this leads to an increase in price, as well.

Size is always a factor when it comes to the cost of lifting and rigging products. For example, a 1-ton screw pin anchor shackle can be found for around $9.00 per piece, a 9.5-ton shackle sells for around $80.00 a piece, and a 25-ton shackle can run close to $300.00 per piece. Simply put, the more steel and more material required to produce the product, the more it’s going to cost you.

This is also true for lengths of wire rope and chain. Larger diameter wire rope, and larger and longer lengths of chain and wire rope, often fall out of the “standard” product range of suppliers other than rigging shops. If a shop has to special order a piece due to a non-standard size or length, that extra time and effort to acquire the piece will get passed on to the customers as a price markup.

High-performance and specialty items also cost more. For instance, 3/4″ 6 X 37 with wire center rope would cost around $2.50 per foot. A high-performance cable like a 3/4” Dyform 18 would cost about $4.50 per foot. But in the right application, the Dyform 18 will last much longer to justify the higher initial cost, and may also save labor costs because the customer won’t have to perform cable changes as frequently.

If you’re at your factory or job site and have a lifting application but don’t know how to make a lift or what to use to make the lift…what should you do? What most people do is contact their local rigging shop to speak with a lifting specialist. Hopefully, the shop’s specialists can help walk you through the solution over the phone, or they may prefer to come on-site and assess the job and recommend the best lifting solutions for your project.

However, highly-trained lifting specialists are compensated for their time and knowledge applied to a lifting project and therefore will increase the cost of your rigging solution. Unfortunately, you’re not going to solve your problem by e-mailing a catalog house or e-commerce rigging website’s customer service team. Their businesses are built to move rigging hardware, wire rope slings, chain slings, and synthetic slings out the door in a quick and efficient manner.

They’re not necessarily set up to offer support, troubleshoot, or help solve lifting challenges. Utilizing a lifting specialist might cost you more upfront, but will save you time and money in the long run by increasing your lifting efficiencies and providing a solution that will get the job done safely.

The cost of imported vs. domestic rigging products is a bit more involved and complicated. You have to determine if you are comfortable with an import product based on the country of origin and also make sure that it meets the same quality standards and specifications as its domestic counterpart.

Generally, imported products are cheaper in price, and in many cases, the quality is comparable to products made domestically. For instance, an imported 1/2” x 10’ 6 X 25 swaged wire rope sling would cost about $20.00—the same sling made by a company who manufactures their rigging gear in the United States would charge around $30.00.

For companies that import their rigging products, their business is built on offering their customers standard run-of-the-mill rigging products in the most popular sizes and configurations. Their manufacturing locations are built to churn out product in large batches and operate with little to no overhead. By doing so, an import supplier can offer their products at a discounted price. Unfortunately, they can’t offer their customers much in terms of variety or customized solutions.

If you do a little bit of research online, you’ll see that some of the companies that sell lifting and rigging equipment offer quantity discounts and some do not. You may see some promotions like “free shipping for orders over $50.00!” If you buy rigging equipment with some regularity, then you know that $50.00 is not a high bar to reach. You may recall from earlier in this article that one 9.5-ton shackle costs around $80 per piece, so you can hit that minimum pretty easily with the purchase of only one part.

The shops that are going to offer the most significant discount to their customers will be the brick-and-mortar rigging shops. They can, and will, offer substantial discounts for a large-quantity order, or for their high-volume customers.

Let’s face it, medium to large users of rigging equipment are not going to order their rigging products online—they will overwhelmingly buy from rigging shops because they can utilize their staff’s expertise, and also take advantage of rush or same-day delivery—two things that online sellers of rigging equipment and industrial equipment just can’t compete with.

If you’ve ever worked in a retail or service-based environment, you already know the typical customer response to the question, “when do you need it by?” The answers are often, “yesterday!” or “as soon as you can get it to me….today.” No matter what the answer is, the theme in the lifting and rigging industry is usually, “I need it now.”

So, now the pressure is on the seller to deliver the product within their customer’s time frame, or else risk losing the business. One thing that many people don’t understand is that it costs a company more money to structure itself to handle rush orders, same or next-day deliveries, and emergency repair or replacement for rigging equipment. Some of these added expenses include:Maintaining a large and diverse inventory to ensure product is in stock and available for fulfillment

These extra expenses to the seller may present themselves in the form of an additional fee for rush delivery and fulfillment on your order, or you may see it as a higher cost in freight. And you know what? You may be okay paying a few extra dollars for a sling from a local rigging shop if you know that they’re equipped to deliver an emergency replacement if your equipment were to break or fail.

Bottom line, rush orders increase the cost of your rigging products. However, if you have smaller quantities, know what you want and can wait a few days to receive your equipment, then the online rigging stores and catalog and supply houses are still a very viable option for you.

The least expensive option isn’t always the smartest buy. Research, due diligence, and working with industry experts will lead you to the best product for your application and ultimately, the best bang for your buck in the long run.

Benjamin Franklin once said, “An investment in knowledge pays the best interest.” Where you buy, what you buy, how much you buy, and how quickly you need it, all have a major determination on the price that you’ll pay for lifting and rigging gear. The time that you spend determining how these factors can get you the most value for your rigging dollar will be well spent.

At Mazzella, we provide ideal lifting solutions—offering all styles of lifting slings, rigging hardware, wire rope, overhead cranes and hoists, and engineered lifting devices. We also have locations all across the United States—fully stocked with different sizes and configurations of rigging products for your next project.

The most common sling Marine & Industrial supplies is wire rope slings and assemblies. These can be made into two, three or four-leg bridles. Wire rope slings can also be braided into multiple parts making them more flexible and able to handle larger capacities by increasing the diameter of the sling.

This is a general purpose sling. It is adaptable for basket and straight pull hitches. This type of sling is used more widely than any other type of sling for general materials handling. We recommend TRI-FLEX® Slings for sizes 1’’ diameter and larger for their economical, light and flexible durability.

We carry rope and cable grommet slings that are adaptable to a variety of fittings. Rope grommets are used for high resistance to abrasion and cable grommets are used where extra flexibility is needed.

This is a combination of three Tri-Flex ® Wire Rope slings wrapped together helically to form a nine-part finished body sling. After a heavy lift is finished, the product can be taken apart to form three individual Tri-Flex® slings for smaller lifting work. This product was developed for construction projects where there are a few heavy lifts. A superior strength sling because it has twelve parts of wire rope in the loop for greater strength than traditional nine part wire rope slings that have only ten parts of wire rope in the loops.

These slings provide the best combination of strength and flexibility. Because of the patented TRI-FLEX® SLING construction, there is a large savings in materials and machine costs in the larger sizes; this, combined with ease and use make TRI-FLEX® SLINGS the only sling for smart buyers.

This is a high performance nine-part wire rope sling from Slingmax® Inc. Its efficiencies are more than 90%, meaning a rigger can get a lighter Gator-Rex™ sling with the same capacity as traditional nine-part slings. This sling features a hand-tuck body. It will develop its full strength on small pins with a D/d ratio of 1:1 where D is the pin diameter and d is the sling body diameter.

Ultra flexible slings for short heavy lift connection. These can be made shorter than standard multi-part slings, but maintain all of the advantages. They are the most flexible grommets in the world.

This product assists larger lifts that require a shorter sling. This is identical to the Gator-Max™ sling with parallel eyes except it has metal sleeves for the splice connection.

This flexible sling is developed for heavy lifts that can be easily inspected. This sling has a nine-part body style with wires in the eyes that are crossed or interwoven so no wrapping is needed.

Marine & Industrial offers quality service, inspection and repair. In order to avoid damage and to further protect your slings, we can help you protect your materials with our 650,000 lbs. test bed, N-4 Testing Technology and our inspectors who are Level III qualified by the Rigging Institute.

We offer a variety of products including wire and synthetic rope, slings of various types, cable, chain, rigging hardware and marine equipment, to name a few. Our products are known for their durability and reliability.

If you are interested in learning more about wire rope, the different types of designs, or how the product is used, contact Bilco wire rope for more information and facts!

Engineers, who create wire rope, design wire ropes with different grades of steel, finishes, and resistances in to attain the most durable and sturdy wire. Different styles of wire rope have varying crush rates, abrasion rates, bending fatigue, and corrosion resistances.

With so many industries being dramatically affected by today’s pandemic and resulting economy, we’re all left to wonder what the futures of our businesses hold.

If you’re in the rigging industry, you’ve likely had similar thoughts. Over the next few weeks, we’ll talk repeatedly about what the future of our field might look like. Today, we want to talk specifically about wire rope slings.

These flexible steel cords have become commonplace in hoisting, towing, and anchoring projects. However, a decrease in all rigging equipment purchases has many wire rope sling manufacturers asking, “What does the future of this product look like?”

As key producers of wire rope slings in the rigging industry, we at Holloway Houston Inc. want to take a look at the growing importance of wire rope slings and what we can expect from them over the next couple of years – if not longer.

The first thing we need to address is the division between galvanized wire ropes and stainless steel wire ropes in the sling industry. Wire rope slings might be an overall popular rigging tool, but in order for manufacturers to make smart bets about the future, we need to understand both types and how they’re useful.

Stainless steel wire ropes are also corrosion-resistant but more durable when it comes to harsh environmental conditions. Stainless steel can even withstand long exposure to saltwater and acid.

Generally, manufacturers who produce galvanized wire ropes sell predominantly to the aircraft industry. In fact, the 7×7 galvanized wire rope has been dubbed the “aircraft cable” because of its tough construction and flexibility.

However, this “aircraft cable” is often sold to industrial and marine companies because it’s fairly resistant to wear but also affordable. It’s a versatile piece of rigging hardware and one that seems to boast long-term promise for manufacturers.

On the other hand, stainless steel wire ropes are the best option for work sites that need the strongest product. It’s known for its high durability and safety features, which means many of the best brands for lifting accessories are interested in producing stainless steel options for years to come.

All things considered; we see places for both kinds of wire rope slings in the near future. Still, we’ll continue to monitor trends in one direction or the other.

A big part of understanding the future of wire rope slings is looking at their current usage. Right now, most companies are using wire rope slings because they are:

One big industry that seems to benefit substantially from these features is offshore service. Almost every aspect of offshore (and subsea) operations involves some sort of lifting, whether its a complicated heavy lift or a simple movement of stores and spares.

Wire rope slings, especially when made of stainless steel, are the perfect rigging slings for coastal or at-sea conditions. They’re resistant to salt abrasion and strong enough to handle the enormous loads of many marine job sites. There are even certified divers that use wire rope slings to confidently tackle difficult lifting operations under the ocean waves.

Still, between 2019 and 2025, it’s estimated that oil demand will increase. A higher increase for oil means more rigging projects on drilling platforms – and therefore more use of highly durable, strong wire rope slings.

You’ll also find that many construction sites rely heavily on wire rope slings. They need durability and resistance – especially in harsh weather conditions.

In the future, our teams at Holloway Houston Inc. predict that wire rope slings will continue to become increasingly customizable as we learn to make them more resistant to moisture, heat, UV rays, and a variety of chemicals.

The slowdown in world economic growth has certainly thrown a wrench into many manufacturers’ budgets and sales. However, wire rope slings sales have maintained a relatively optimistic growth rate for years, and we expect to see a steady demand for the product – pandemic or not.

Some experts, according to the Wire Rope Slings Sale Market Size 2020 Analysis, even believe that in the next few years, the wire rope slings sales market will rise at a considerable rate.

Considering that, our teams at Holloway Houston Inc. will continue to include wire rope slings in our rigging equipment designs and sales for the foreseeable future.

Making any kind of prediction is difficult during 2020, but we feel confident in the continuous demand for wire rope slings as one of the most reliable pieces of rigging hardware.

Speaking of what we’re doing at our facilities, we’re continuing to manufacture and assemble a wide variety of rigging slings. We have clients in the oil, aerospace, OEM, and construction industries, and we’ll continue to provide them with the innovative products they need.

As always, every sling purchased at Holloway Houston Inc. comes with a complete data book to ensure traceability. They also have stainless steel tags marked with invoice numbers, so you always know exactly which product you’re working with during a rigging project.

Our goal at Holloway Houston Inc. is to tirelessly strive for customer satisfaction and loyalty, no matter the difficulties our industries and others face. Our products, including all rigging slings, are created on a foundation of integrity and commitment to quality.

We might not know exactly what the next few years hold, but we do know this: all of our products are chosen from and built by the world’s leading manufacturers. Holloway Houston Inc. will continue to produce new products that excel in safety, reliability, and performance.

If you have any questions about wire rope slings or other kinds of rigging equipment, please call 713-674-8352. You can also reach out via our contact page. Our rigging and lifting manufacturing experts are always ready to help.

Wire rope slings are strong, efficient, and reliable accessories in the material handling industry. Wire rope functions as a excellent sling material in applications where a combination of strength and abrasion are necessary. Wire rope slings are available in an array of configurations to fit almost any application.

Wire rope is a machine composed of a number of precise, moving parts, designed and manufactured to bear a very definite relation to one another. In fact, some wire ropes contain more moving parts than many complicated mechanisms. For example, a 6-strand rope with 49-wire strands laid around an independent wire rope core contains a total of 343 individual wires. All of these wires must work together and move with respect to one another if the rope is to have the flexibility necessary for successful operation.

Midco Sling has served the heavy lifting needs of customers throughout Texas, Oklahoma, New Mexico, Arkansas and Louisiana since 1976. Specializing in lifting products ranging from fall protection to synthetic slings, Midco Sling carries products from the industry’s most reputable vendors including Crosby, Capital Safety, and Bridon American.

Established over 40 years ago in North Texas, Midco Sling now manufacturers and distributes wire rope from 3 locations to more conveniently serve customers across the Southern States. Midco Sling retains branch locations in Dallas, San Antonio and Longview. These locations allows Midco to stock a wide array of specialty lifting products and enables Midco to efficiently meet a wide range of manufacturing needs.

8613371530291

8613371530291