wire rope and rigging consultants factory

Starting in 1979, Mr. Parnell enjoyed time with Wire Rope Corporation of America (now WireCo World Group) and River Rigging before he founded Wire Rope & Rigging Consultants in 1986. The company was renamed Industrial Training International in 1995 due to the diversified courses the company developed into cranes, load handling, and inspection domains.

Mr. Parnell achieved the status of Eagle Scout by the early age of 14. His determination and desire to help others has provided him the opportunity to help thousands of organizations with their training needs. Mr. Parnell was elected to spearhead the newest ASME standard on lift planning, P30, in 2013 which led to Engineering-News Record (ENR) magazine"s award of Top 50 Newsmakers of 2013. Mr. Parnell humbly accepted the award explaining that there were dozens of other members and contributors to the Standard making it a success.

Unirope LTD. is an ISO 9001 and LEEA-Lifting Equipment Engineers Association certified company, specializing in the manufacturing, distribution, testing, certification and inspection of Lifting- and Rigging Products. Unirope is servicing the industry since 1956.

In Germany we manufacture High Performance PYTHON® Wire Rope which we stock in a wide variety of constructions for Tower Cranes, Mobile and Truck Cranes, Overhead Cranes, Gantry Cranes in Construction, Automotive and the Steel Industry. We also stock a large variety of standard and custom designed ropes meeting national and international standards.

The SLINGMAX® product line includes TWIN PATH® Slings made from high strength K-SPEC® fibres, super flexible GATOR FLEX® and TRI-FLEX® wire rope slings, and much more. We also provide a complete range of wire rope fittings, rigging hardware, magnets, clamps, hoists, synthetic ropes, and all types of lifting slings. Find Out More ›

Three experts in the crane and rigging industry have collaborated to build a website containing their contact information as well as growth potential for additional experts to be added later. Ron Kohner, President of Landmark Engineering, Larry Means, President of Means Engineering, and Mike Parnell, President of Industrial Training International/ITI Field Services have built the site as a directory for experts who offer Consulting, Expert Witness Testimony, Project Planning, and Risk Analysis.

Ron Kohner is a Registered Professional Engineer (P.E.) and provides engineering services regarding mobile cranes, rigging, and heavy lifting. He is an ASME B30 member.

Larry Means is a Registered Professional Engineer (P.E.) and the newly-elected Chair of the ASME B30 Main Committee. He specializes in wire rope and sling management and related accident investigations.

Mike Parnell is the ASME P30 Chair, ASME B30 Vice Chair, and the newly-elected Chair of ASME B30.9 Slings. He specializes in crane and rigging audits, applications, lift planning, and expert witness testimony.

Jerry Klinke founded ACRA in 1995. After serving in the US Marine Corps as an engineer, Jerry began his industrial career in 1976 working in the Nuclear Power Industry. Ultimately, his diverse background and skills made him the ideal choice to manage the training programs for Skilled Trades at the Nuclear Training Center for American Electric Power.

Jerry is a contributor for industry publications and has written numerous articles on cranes, rigging and technical training issues. He has been a frequent speaker on behalf of safety in the construction industry, promoting standardized testing and qualification of crane operators, riggers, and signalmen. He is an Officer and Board Member for the Association of Crane & Rigging Professionals (ACRP) and is the Continuing Education Program Director for the training sessions offered by the organization.

Dave Decker, President of Becket Training & Consulting has made a life time commitment to improving crane & rigging safety. He has over 35 years" experience in every facet of crane & rigging including operations, maintenance, inspection, management, training and testing. He remains actively involved in writing standards that guide crane users and regulatory bodies by serving on key committees and subcommittees of the American Society of Mechanical Engineers (ASME).

Dave started his career at the Philadelphia Shipyard as a crane mechanic. Later, he went to the Navy Crane Center where he developed and managed the U.S. Navy"s first comprehensive crane & rigging training program, serving 250 Navy bases around the world. For these efforts he was awarded the Meritorious Civil Service Award, the highest honor given to a civilian.

Starting in 1979, Mike Parnell enjoyed time with Wire Rope Corporation of America and River Rigging before he started Wire Rope & Rigging Consultants in 1986. The Company was renamed Industrial Training International in 1995 due to the large amount of overseas work. By listening to clients and seeing voids in the marketplace, Mike and the ITI crew developed a world-class set of programs often imitated by others around the world.

Mike is a member of ASME (American Society of Mechanical Engineers) serving on several Subcommittees and currently chairs both the B30.9 (Slings) and the P30 Main Committee (Lift Planning) and a Vice Chair of B30 Main Committee (Crane & Rigging). He is the founder of ACRP (Association of Crane & Rigging Professionals), and has earned many industry certifications from organizations such as NCCCO (National Commission for the Certification of Crane Operators), CIC (Crane Institute Certification) and NCCER. Parnell has testified in numerous cases as an expert witness for both depositions and courtroom testimonies.

In his home of Washington State, he is a member of the Washington State Rigging Regulations Task Force and still finds time to serve as an Eagle Scout.

CLEVELAND, OH – Mazzella Lifting Technologies, a Mazzella Company, is pleased to announce the acquisition of Denver Wire Rope & Supply. This acquisition will strengthen Mazzella’s footprint west of the Mississippi River and reinforce Mazzella’s commitment to be a one-stop resource for lifting and rigging services and solutions.

Denver Wire Rope & Supply has been in business since 1983 and services a variety of industries out of their location in Denver, CO. Denver Wire Rope & Supply is a leading supplier of rigging products, crane and hoist service, below-the-hook lifting devices, and certified rigging inspection and training. Effective immediately, Denver Wire Rope & Supply will operate as Mazzella / Denver Wire Rope. Terms of the transaction are not being disclosed.

“Denver Wire Rope & Supply will complement the wide range of products and services that Mazzella Companies offers. We are dedicated to being a single-source provider for rigging products, overhead cranes, rigging inspections, and rigging training. Both companies commit to a customer-first mentality, providing the highest-quality products, and leading by example when it comes to safety and sharing our expertise with customers and the market,” says Tony Mazzella, CEO of Mazzella Companies.

This acquisition will provide Mazzella Lifting Technologies with a western U.S. location that will allow them to grow and expand their reach past the Oklahoma City market.

“Our team and family are excited to be part of the Mazzella Companies. This acquisition strengthens our place in the market and allows our team to continue to provide excellent service and products to our valued customer base and expand our offering,” says Ken Gubanich, President of Denver Wire Rope & Supply.

“Over the years, we have had numerous companies show interest in purchasing Denver Wire Rope & Supply, none seemed to be the right fit. We are looking forward to becoming a part of an aggressive, passionate, and progressive organization. As a family business for over 36 years, it is important to us that our customers/friends, suppliers, and team members continue to be treated with first-class service, products, and employment opportunities. Again, we are very enthusiastic about our future and look forward to being a quality supplier for your crane, safety training, rigging, and hoisting needs for years to come,” says Gubanich.

“We wish Ed and Carol Gubanich all the best in their retirement. We welcome Ken and the other second and third-generation Gubanich family members, as well as the entire Denver Wire Rope Team, into the Mazzella organization,” says Mazzella.

We’ve changed our name from Denver Wire Rope to Mazzella. Aside from the new name and logo, our member experience is virtually unchanged. Here are some common questions and answers related to this change.

In 2019, Denver Wire Rope & Supply was acquired by Mazzella Companies to expand lifting and rigging products and services to the western half of the United States.

In 1954, James Mazzella founded Mazzella Wire Rope & Sling Co. in Cleveland, OH. For over 65 years, the company has grown organically by nurturing historic relationships, expanding its product offerings, and entering new markets through acquisition.

Today, Mazzella Companies is one of the largest privately held companies in the lifting and rigging industries. Since our humble beginnings, we’ve grown to over 800 employees with over 30 locations across North America. Our product offerings have expanded from basic rigging products, to include:Overhead crane fabrication

One thing that hasn’t changed is our commitment to a no-excuses, customer-first mentality that extends from the shop floor to the front office. Some of the major markets Mazzella serves are: Mining, Steel, Oil & Gas, Construction, Energy, Shipbuilding, Vehicle and Durable Goods. Mazzella’s diverse portfolio includes Sheffield Metals a manufacturer and distributor of coated bare metal products for engineered metal roof and wall systems. New Tech Machinery is a manufacturer of portable roof panel and gutter machines—recognized as the world’s finest portable rollformers.

Just the name. We want to be clear that our people, locations, products, and services have not changed. We will be moving to the Mazzella name for all rigging brands under the Mazzella Companies umbrella in order to create a better experience for our customers and employees.

With all the Mazzella rigging locations working as one team and under one name, your level of service and support will be improved exponentially. Nothing will change in terms of the local team you’re used to working with. The same people will still be here—the only thing that will be changing will be the name of the organization they work for. You now have more resources, inventory, and clearer lines of communication. Our goal is to improve your experience and instill confidence and comfort in every interaction.

Mazzella is experiencing rapid growth. With this growth, we can better serve our customers as one team under the Mazzella name, versus many companies operating independently. The only change you will experience will be better service and improved lines of communication between our people and yours.

For sure! We hope to expand our service line across the entire United States. With over 30 locations, your level of service should only be improved and lines of communication more clear.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Carolina’s Rigging & Crane and Charleston’s Rigging & Marine Hardware supplies and services manufacturers, construction, maritime and energy and transportation companies who utilize wire rope, web slings, tie downs, chain and hoist products. Having outgrown its current facilities in Charleston and Richland Counties, Carolina’s Rigging & Crane and Charleston’s Rigging & Marine Hardware will be growing its operations in both counties simultaneously.

In Charleston County, the company will be expanding into a purpose-built fabrication facility at the former Charleston Navy Base, which will include an expanded showroom and a crane and rigging safety training center. Expected to be operational by the summer of 2018, the new space will create 18 jobs and allow for the launch of new product lines and services.

In Richland County, the company will be moving into an existing manufacturing complex located off of Shop Road adjacent to the Pineview Industrial Park. This facility, complete with multiple overhead bridge cranes, large fabrication area and a crane and rigging safety training center, will help support Carolina’s Rigging & Crane customers in the Midlands and throughout the Southeast. To accommodate its growth in the Midlands, Carolina’s Rigging & Crane will be adding 17 jobs in Richland County.

“South Carolina is open for business. In 2018, we will be celebrating our 30th year in business and are laying the groundwork for the next 30 years and beyond. We live and work in a great state that continually does its part to bring manufacturers, jobs and new businesses to South Carolina. With this commitment and investment in South Carolina, we stand ready to support business growth here in the state and beyond,” said CRC and CRMH Owner Skip Sawin.

“As the 2nd generation in our family business, Skip and I are very proud to take our business to the next level. We have a wonderful team of folks at Carolina’s Rigging and Charleston’s Rigging that know how to get things done. It is because of their determination and ambition that we can do this,” said CRC and CMRH Owner Jessica Sage.

“Seeing a homegrown South Carolina company decide to grow its business in not just one, but two counties is tremendous news. We work hard every day to ensure companies have the tools they need at their disposal, and this announcement is proof our efforts are working,” said Governor Henry McMaster.

“We’re excited that a homegrown company like Carolina’s Rigging & Crane and Charleston’s Rigging & Marine Hardware continues to find success. South Carolina’s manufacturing industry has continued to thrive, and Carolina’s Rigging provides a much-needed service to support this powerful driver of our state’s economy,” said Secretary of Commerce Bobby Hitt.

“Celebrating 30 years in business is no small feat, and we are grateful Charleston’s Rigging & Marine Hardware is committed to growing in Charleston County. Their expanded operations at the old Navy base is well suited for their industrial business,” Charleston County Council Chairman Victor Rawl said.

“We’re extremely excited about Carolina Rigging"s decision to expand its operations and presence in Richland County. Carolina’s Rigging is a valued corporate partner with Richland County and today’s announcement shows its continuing commitment to our community. The company’s creation of additional quality jobs is further evidence of the benefits we see when we invest in our future,” said Richland County Council Chair Joyce Dickerson.

In rigging, we all know that the setup is only as strong as its weakest link. Any failure is a potentially dangerous situation that puts your entire operation in jeopardy. Every component must be relentlessly reliable. Synthetic rope is one such tool that bears heavy responsibility. While incredibly strong and durable, it often immediately supports a load; if it were to fail, the results would be catastrophic.

You will likely never seeused in a rig as they are weaker and less durable than their synthetic counterparts. With this in mind, let’s discuss the advantages of synthetic rope.

Synthetic rope is made from nylon, polyester, or polypropylene fibers. These ropes can be made using one or a combination of these synthetic fibers. Much like a natural rope, these fibers are drawn out into strands and then woven together. The end result is a durable, strong rope that can bear markedly more weight and tension than its natural counterpart.

Because of the materials used, synthetic rope is better able to withstand friction, making it more durable. It should be noted that how much you use the rope and its length of service will directly affect how long it lasts. Sporadic use could see it surviving for up to 10 years, whereas heavy use will require replacement every year or two. Synthetic rope is great for outdoor uses, as it is resistant to rot and mildew that can arise from exposure to moisture.

Synthetic rope is useful for a host of additional purposes. Its resistance to moisture makes it ideal for use in marine applications, but it has various advantages outside of the rigging sphere. It serves as an excellent climbing rope due to its abrasion resistance – it can handle rough edges of the terrain without fail. This is also what makes it perfect for rigging in film and theater. Where creative problems often require creative solutions, crews know they can rely on these ropes to hold the scene together. Synthetic rope can also be used effectively in towing and hauling applications.

has been a leader in wire rope and rigging supplies in the Gulf Coast region since 1966. We provide quality supplies and reliable service to each one of our clients so they can meet the tough demands of the industry with confidence and excellence. We are happy to share our decades of experience to help you find the best solution for whatever undertaking you have in front of you. From synthetic rope and slings to wire rope and chains, we have a comprehensive product offering to completely outfit your rig.today to level up your operation.

Wire rope is arguably the most important asset that arigging equipment providercan supply. It forms the backbone of every operation, helping to execute every lift and move heavy loads with precision and security. Withoutwire rope, the rigging, overhead lifting and securement industries couldn’t meet demands.

For these reasons, it is absolutely crucial to make sure wire rope is properly maintained.Storing wire ropesafely and intentionally will help lengthen its working life and improve the safety of your daily operations. Keep reading to discover the key considerations and tips for storing wire rope.

The best method of storing wire rope is on a reel. This helps to maintain the shape and function of the rope over time by avoiding kinks and tangles, which can damage the integrity of the rope and reduce its safety and usefulness. Reels also help centralize wire rope into space-efficient units that can be transported and even stacked.

Once spooled onto a reel, it will be simple and easy to remove the desired length of wire rope when needed. Whether you are working with drilling rigs, cranes or winches, we recommend that you have your wire rope installed and removedby an experienced professional.

Wire rope is a vital piece of equipment, and it should be stored as such. Water, salt, dust, steam, temperature extremes and chemical fumes canwreak havocon the structure and strength of wire rope. Therefore, store your wire rope supply in a cool, dry, covered, and well-ventilated place. An indoor location is best, but if you must store wire rope outdoors, make sure it is covered with waterproof material.

Additionally, make sure no part of the rope is touching the ground, and that the base of the wire rope reel is elevated at least a few inches in case of flooding. Water immersion can cause the wire rope to corrode and its lubricant to wear off. . When in doubt, check with your rigging equipment provider about wire rope spooling to ensure it is done right.

Inspections of various pieces of rigging equipment are required by law on a regular basis – and wire rope is no exception. Work with your rigging equipment provider to have your wire rope inspected if it has been stored for an extended period of time. A full-scalerigging inspectioncan also help you determine where and how to store your wire rope on the front-end of a project. A qualified rigging equipment inspector will be able to address the quality and condition of all your rigging and lifting gear, furnishing detailed reports on their findings.

At Southwest Wire Rope, our team has been serving the needs of the rigging, overhead lifting and securement industries with unwavering excellence for 56 years. If you’re searching for a rigging equipment provider, wire rope spooling and storage help or a certified inspector, turn to the professionals at Southwest Wire Rope. Our experienced team can provide insights and recommendations for the type of wire rope, end fittings, hardware, and operational procedures that best suit your facilities and equipment. We look forward to answering your questions and forming a lasting partnership. For more information, browse ourservice offering.

Over the past 56 years, the rigging, overhead lifting and securement industries have changed dramatically. With the advancement of technology and digitization of data, alongside more capacity and power in today’s machines, the industry has reached a new level. Increased demand andeconomic pressuresare pushing today’s rigging operations harder than ever before, and around-the-clock productivity has become the norm.

While the past six decades have ushered in sweeping changes, some things have remained the same. For that entire time, Southwest Wire Rope has remained a stalwartrigging equipment providerwith a reputation for quality and service. We’ve been providing rigging inspections, testing, and the strongest wire rope on the market for years – and we have no intention of slowing down. Here’s how we continue to uphold and define industry standards.

To ensure that each facility and piece of operating equipment is up to code, rigging inspections are required by regulators. At Southwest Wire Rope, we employ a team ofcertified inspectorsthat can investigate every aspect of a rig, from the heavy machinery down to the shackles. With attention to detail cultivated by hundreds of years of combined rigging experience, our inspection team offers industry-leading guidance and professional recommendations. Reporting fromTESSALinkasset management software adds to our comprehensive service offering.

In addition to routine inspections, the Southwest Wire Rope team also performed destructive (break) testing of up to 1.7 million pounds from two separate locations. Need field spooling? We provide on-site installation and removal of wire and synthetic ropes on drilling rigs, cranes and winches. Through our steadfast commitment to raising the bar, we make sure our clients are meeting and exceeding all industry requirements.

At our core, we are rigging equipment providers, and we strive to strengthen our offerings and expertise on a daily basis. In 1983, we introduced our trademark proprietary brand of wire rope to the market, characterized by an iconic gold strand. Nearly 40 years later, “Gold Strand” wire rope is still recognized as the strongest and most reliable wire rope on the market.

Additionally, we have acomplete offeringof wire rope fittings, synthetic and round slings, chains, and other rigging hardware. We pride ourselves on being experts in the rigging equipment space, providing not only the tools to get the job done, but also the guidance to do it right.

But we don’t stop there. If one of our clients needs a skip pan, spreader bar, or other custom lifting device, we maintain a large inventory of heavy equipment for rent. We continue to reinforce excellence in all we do through the provision and outfitting of cutting-edge equipment solutions.

Finally, we continue to sharpen our skills and cement our place in the rigging industry by defending our reputation as the top rigging equipment servicer and provider in the industry. With every rigging inspection we complete and every client request we field, we seize the opportunity to build upon decades of excellence and provide exceptional products and services. Our team never shrinks back from the challenge. On the contrary, we relish the ability to enter new projects with the weight of a 56-year reputation on our shoulders. The responsibility to uphold and further this legacy informs everything we do – from the largest repairs, to the smallest reports.

Our team has been serving the needs of the rigging, overhead lifting, and securement industries with an unwavering dedication to quality and excellence for over half a century. If you’re searching for a rigging equipment supplier, or need your system inspected by a certified inspector, turn to the professionals at Southwest Wire Rope. Our experienced team can provide insights and recommendations for the type of wire rope, end fittings, hardware, and operational procedures that best suit your facilities and equipment. We look forward to answering your questions and forming a lasting partnership. For more information, browse ourservice offering.

The commodity that “holds up” the rigging, lifting, and overhead securement industries is indisputably wire rope. Combining strength with flexibility, wire rope helps operations of all sizes move heavy loads where they need to go with safety and ease. Without enough properly tested and verified wire rope on hand, the output and productivity of the entire plant can grind to a standstill.

Because every project has different requirements, various types of wire rope are designed and fabricated to serve different purposes. With a variety of orientations, strengths, and load capacities, it’s important to know exactly which variety works best for your job. Here’s a breakdown of the major categories.

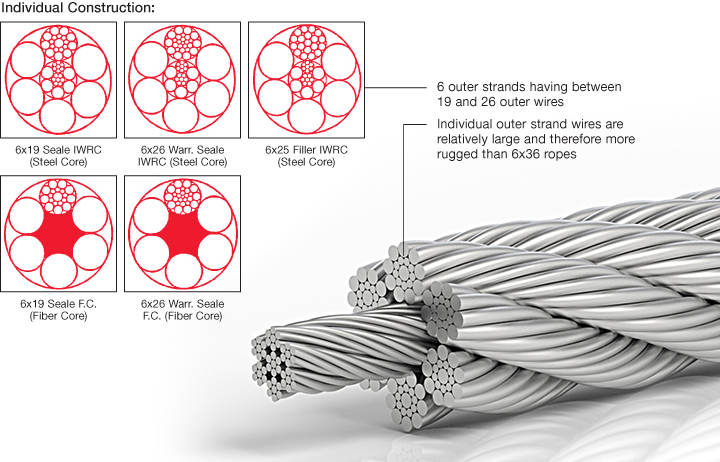

The “class” of wire rope refers to the number of wires that compose a strand, as well as how many strands surround the core. For example, 6×31 FC wire rope consists of 6 strands containing 31 wires each, which are wrapped around a fiber core.

General purpose wire rope– the variety most commonly used for daily rigging operations such as lifting, overhead securement, pulling, and establishing tension – most often contains six strands and an Independent Wire Rope Core (IWRC). Each of these strands can contain anywhere from 16 to 49 wires, with more wires increasing the flexibility of the rope.

General purpose wire rope can range in diameter from ¼ inch to 6 inches, with larger diameter ropes having breaking strengths of hundreds or even thousands of tons. For a detailedwire rope strength chart, consult our cataloghere.

Most cranes and some overhead lifting and securement devices require specialized wire rope that prevents the load from rotating. This is often achieved by having layers of compacted strands, oriented in a tightly-knit pattern around a core and layed in alternating directions. For example, the Oliveira NR Maxipact PPI contains 18 outer strands, forming wire rope that can be effectively implemented in a non-rotating environment at temperatures from -50°C to +80°C.

Compacted varieties of crane wire rope provide increased fatigue resistance, strength, stability, and abrasion resistance. Often considered thestrongest wire ropeon the market, these types of wire rope are perfect for mining, industrial, construction, logging, and oilfield applications.

Other rotation resistant varieties come in 19×7 and 8×19 classes with an IWRC; for more detailed information, view thewire rope strength chartand select Wire Rope > Crane.

Finally, in addition to customized lengths and types of wire rope, a qualified rigging equipment provider can also supply pre-fabricatedwire rope slings. These slings are outfitted with eyes or sockets that affix the load to a lifting device. Wire rope slings come in dozens of orientations, sizes, and diameters, allowing for ultimate customization when outfitting your rigging operation. Check out the catalog or connect with a rigging equipment professional for guidance and to place your custom order

The professionals atSouthwestWire Rope have been serving the needs of the rigging, overhead lifting, and securement industries with an unwavering dedication to quality and excellence since 1966. If you are in the market for industry-leading lifting gear, or need your system inspected by a certified inspector, turn to the pros at Southwest Wire Rope. Our experienced team can provide insights and recommendations for the type of wire rope, end fittings, hardware, and operational procedures that best suit your facilities and equipment. We look forward to answering your questions and forming a lasting partnership. For more information, browse ourservice offeringand get in touch.

The lifting industry is not just about machine strength. Success in this business also requires precision, planning, endurance, poise, and training. In a highly competitive market that faces increasing pressures on a monthly basis, only the fittest lifting operations will continue to thrive in changing economic headwinds.

In addition to the competence and experience of your crew, your equipment is the largest differentiator between your lifting operation and the competition. Investing in material that is built to stand the test of time by aleading supplierwith an illustrious reputation will help ensure your machinery runs smoothly. In short, you need the best andstrongest assetsin order to thrive in the lifting business. Here are some of the most important components that will help you achieve that goal.

Cut to precision lengths in dozens of diameters, customizedwire ropecan help bring your operation to the next level. For more than 50 years, the team at Southwest has been helping the industry’s biggest players outfit their facilities with the best wire rope in the business. Our technicians can work alongside you to help determine the optimal thickness and orientation for your operation.

Not all chains are created equal. Every chain is tested to ensure it lives up to the Southwest legacy. Our team is familiar with every major type of chain configuration and linkage, so we can help you secure heavy loads and maximize your lifting potential while keeping your crew safe.

Synthetic round and synthetic web slings are the crucial components that keep your operation tightly bonded while remaining fluid and flexible. With various colors, lengths, and strengths available, the possibilities are quite literally endless.

When it comes to lifting gear, every sling, strap, link, wire rope strand, and piece of hardware is vital to the overall success of the operation. Investing in customized below-the-hook products that are expertly fitted to your unique needs and capacity will help make your facility safer and your equipment more effective.

The professionals atSouthwesthave been serving the needs of the rigging and lifting industries with an unwavering dedication to quality and excellence for years. If you are in the market for industry-leading lifting gear, or need your system inspected by a certified inspector, turn to the pros at Southwest Wire Rope. We look forward to answering your questions and forming a lasting partnership. For more information, browse ourservice offeringand get in touch.

In the rigging and lifting industries, proof tests are regularly performed to ensure that the equipment to be used can withstand the load it was manufactured to handle. These tests are performed for several reasons – specification requirement, manufacturer’s recommendation, and customer request are the most common.

As mentioned, we perform proof tests for a variety of reasons.One such test commonly performed in the business is aproof load test. A heavy-duty undertaking, a proof load test unveils the true strength of a piece of rigging or lifting gear. Here’s everything you need to know about this specific type of test, as well as how to keep your crew safe during one.

A proof load test is just what it sounds like: it proves whether a piece of rigging equipment can bear the load it is designed to. The test is administered in a controlled, measured fashion with a particular multiple of the maximum designed load (generally 1.1 to 1.5 times) and a specified length of time. After the test is completed, the operator will issue a certification confirming the workable load of the wire rope or other rigging component in question.

Whether the rig is overdue for a full inspection, the newly minted wire rope is being put to the test, or older equipment is being evaluated to determine if it is still fit for use, a proof load test is an immensely valuable tool. Every rigging component in the operation should be tested regularly, and a proof load test is one of the most complete and strenuous methods for doing so. Testing also helps keep the rigging equipment and the business as a whole within the boundaries of the OSHA, Department of Labor, and manufacturers’ codes that govern the industry.

The best way to keep your employees safe during a proof load test is to entrust the entire ordeal totrained professionals. Proof load tests are incredibly dangerous if not done with the proper equipment and control measures, as breakage can occur.

AtSouthwest Wire Rope, we provide proof load testing and destructive (break) testing of various lifting devices up to 1.7 million lbs. Proof load testing can be performed using specialized rigging and custom built test jigs that replicate the ultimate field installation of complex and highly engineered products. As you can imagine, this specially designed equipment is operated by industry veterans. By outsourcing the tests to an industry partner like Southwest, you can keep your crew out of harm’s way.

In reality, the advent of performing the test and verifying the strength of the equipment is also keeping your crew safe. Using wire rope or lifting gear until failure is a dangerous proposition and never recommended. Instead, get your equipment certified with a proof load test and gain the peace of mind your professionals deserve.

Don’t leave the safety of your equipment to chance. Partnering with a full-service provider who can offer in-depth product knowledge and inspection services will save you hours of confusion and stress when it comes to meeting code – all while maintaining the safety of your crew.

The professionals atSouthwesthave been serving the needs of the rigging and lifting industries with an unwavering dedication to quality and excellence for years. If you are in the market for leading rigging and lifting gear, need your system tested, or are simply looking for an expert opinion, turn to the pros at Southwest Wire Rope. We look forward to answering your questions and forming a lasting partnership. For more information, browse ourservice offeringand get in touch.

Lifting hundreds of tons of material on a daily basis requires a lot: high-quality gear, a competent and well-trained team, efficient systems, and a drive to succeed.

Due to the nature of the industry, the regulators at OSHA and other regulatory bodiesalsorequire a lot. In the lifting space, safety always comes first. Meeting the codes that govern the operation of your plant or rig are in your best interest…but this can also be a time-consuming and difficult task.

In order to stay in business and run at maximum capacity, your lifting gear needs to be meeting or exceeding code at all times. Here are some tips for handling this simply and effectively – so you can focus on getting things done.

When it comes to lifting gear, one faulty sling, strap, link, wire rope strand, or other piece of hardware can put the entire operation in jeopardy. Investing in equipment that isand is backed by the quality and reputation of awill help ensure your machinery runs smoothly. Codes were developed in the first place to protect your crew from dangerous breakage, equipment wear, and malfunctions, so starting with the best materials is the most effective way to ensure you’re always in line with recent codes.

A destructive or “break” test measures the tensile strength of wire rope by using magnetic and hydraulic arms to pull opposite ends of the rope apart. The test continues until the wire strands begin to fail, and eventually, the wire rope gives out. This is an extremely loud and dangerous endeavor – a break test should never be conducted without the proper equipment and certifications. Work with an industry provider who can conduct a wire rope break test usingin a safe and controlled setting. The results of this test will be printed on a load testing certification, which will help you satisfy regulations.

When it comes to your health, you trust the expert opinions of medical professionals to give you a diagnostic update after performing the relevant tests. In the lifting industry, on-site inspection services serve the same purpose for determining the health and safety of your operations.

Working with a provider who offersservices will keep your lifting gear in check. A qualified inspector will issue reports and grades on the strength and condition of your lifting gear, so you have a clear idea which elements need replacing. Regulators mandate these inspections as well, so scheduling the inspection in and of itself is necessary to meet code.

Every rigging and lifting operation is required to furnish and maintain a comprehensive set of safety procedures that regulate the facility, its equipment, and the personnel involved. If your team has grown, you have brought new equipment into service, or your operational procedures have changed, your safety protocols need to be updated to reflect this. In addition to updated manuals and emergency procedures, educating your staff on the fulfillment of these duties is vital. An incomplete set of protocols or an untrained staff is grounds for immediate shutdown, so consult with a lifting industry provider for guidance on development or updating of your plans.

Keeping your lifting gear at max capacity while satisfying the regulations of OSHA and other regulatory bodies is not something you should pursue alone. Partnering with a full-service provider who can offer in-depth product knowledge and inspection services will save you hours of confusion and stress when it comes to meeting code.

The professionals athave been serving the needs of the rigging and lifting industries with an unwavering dedication to quality and excellence for years. If you are in the market for leading rigging and lifting gear, need your system tested, or are simply looking for an expert opinion, turn to the pros at Southwest Wire Rope. We look forward to answering your questions and forming a lasting partnership. For more information, browse ourand get in touch.

Today’s rigging operations are expected to perform at their best around the clock. With demand surging andenormous growthforecasted for the industry, the main concerns are often lift capacity, output, and production time. However, when heavy machinery and powerful devices are involved, safety always comes first.

At the core of any reputable rigging operation is a dedication to the safety and security of its crew. At the end of the day, your people will determine the performance of your rig, so you need to protect them.

Rigging equipment is complex and advanced, but it still requires qualified professionals to run at its best. Your team members are your most important asset, so choosing a crew that is situationally aware and intentional in their actions goes a long way in creating a safe environment on the rig. Every worker should know the standard operating procedures for safety-related events and always put the safety of their colleagues ahead of performance.

We’ve all heard that a chain is only as strong as its weakest link. In the rigging business, one faulty sling, strap, link, or wire rope strand, or piece of rigging hardware can jeopardize your entire operation. Investing in equipment that iscrafted to lastand backed by the quality of aleading supplierwill help ensure your machinery runs smoothly and your crew is protected from breakage or equipment wear.

Instead of relying on theintuitionthat your rigging operation is safe, you can have peace of mind byprovingit. Working with a rigging services provider who can offer Proof Load Testing, Break Testing, andon-site inspectionswill keep your rigging operation certified to the industry standard. To schedule a test today, clickhere.

When you first went into the rigging business, you were undoubtedly required to develop a comprehensive set of safety procedures that relate to facility management, personnel, and equipment operation. As your team has grown and your inventory has changed, it’s important to keep your safety protocols updated. If you need help developing safety procedures tailored to your rigging operation and equipment,get in touchwith the team at Southwest today.

Keeping your operation safe yet productive is not an endeavor you should pursue alone. Partnering with a full-service provider who can offer years of industry experience and in-depth product knowledge on every piece of specialized equipment will save you hours of confusion and stress. As your operation changes to meet current demand, work with a provider who can help outfit, secure, and optimize your rigging and lifting facilities with special attention to the safety of your crew.

The professionals at Southwest have been serving the needs of the rigging and lifting industries with an unwavering dedication to quality and excellence for years. If you are in the market for leading rigging equipment, need your rigging system tested, or are simply looking for an expert opinion, turn to the pros at Southwest Wire Rope. We look forward to answering your questions and forming a lasting partnership. For more information, browse ourproductsandservicesorcontact a reptoday.

When you think about the major adjectives that describe a rigging operation, one of the first and most important answers would be “strong.” Strength is not only the defining feature of an effective rigging operation, but also the key to increased load capacity, and thereby output, which leads to higher profit margins and wages. Strength, then, is what we’re after.

One of the most reliable ways to increase the strength of a rigging operation is by investing in high-quality wire rope. Formed from a steel core and wrapped with concentric wire strands, wire rope is an extremely versatile asset that can bear hundreds of thousands of pounds of load, yet remain flexible. For more than 50 years,Southwest Wire Ropehas been supplying some of the strongest and most recognizable wire rope products on the market.

To determine the true strength of wire rope, though, we need to put it to the test. Destructive or “break” testing can be dangerous, but is a useful measuring tool to gauge the strength of wire rope. Here’s everything you need to know about break testing.

Put simply, a destructive or break test measures the tensile strength of wire rope by using magnetic and hydraulic arms to pull opposite ends of the rope apart. The test continues until the wire strands begin to fail, and eventually, the wire rope gives out. This results in an extremely loud explosive noise and frayed metal remnants, which can be extremely dangerous. At the conclusion of the test, the true strength of the rope is evident based on the load reading at the point of breakage.

A break test should absolutely never be conducted without the proper equipment, certified staff, and safety protocols. If you are unsure whether you can perform a break test at your rigging site, then the answer is undoubtedly no. Only specialized machinery operated by trained professionals is fit to manage a destructive test, and attempting a DIY test is a recipe for a regulatory violation and a potential safety hazard.

The only way to know the true strength of a piece of wire rope is to perform a break test in a certifiedtesting facility. As wire rope specialists, the team at Southwest is trained in conducting safe, effective tests of all of our products. If you need your wire rope certified, are curious about the capacity of your rigging system, or are interested in stronger products, we can help. In addition to testing, Southwest is a leader in on-site rigging inspections, rental equipment, field spooling, and other services. Get in touch with a rigging professional today to learn how we can helpoutfityour rigging operation for maximum performance.

The professionals at Southwest have been serving the needs of the rigging and lifting industries with an unwavering dedication to quality and excellence for years. If you are in the market for leading rigging equipment, need your rigging system tested, or are simply looking for an expert opinion, turn to the pros at Southwest Wire Rope. We look forward to answering your questions and forming a lasting partnership. For more information, browse ourproductsandservicesorcontact a reptoday.

In the rigging world, we are always pushing for “more.” More lift power, more loads, more hours on the rig, etc. This industry is full of diligent, hard workers who strive to get the absolute most out of their crews and their equipment.

One such way that many operators attempt to increase output is by increasing the capacity of each load. More productive loads means jobs get completed faster and more efficiently, and the next project can begin. So, how can we increase the strength and speed of our operation through better lift capacity? Keep reading to hear some ideas from the veterans atSouthwest Wire Rope.

As you probably learned during your first training hours, position and angling are immensely important when it comes to lifting. While a straight vertical lift of a single, stable object can be completed at near maximum capacity of your machines, every additional variable you introduce will reduce your lift strength.

The same principles that govern lifting motions of your body apply to lifting loads as well. Lifting a small weight near your torso is much easier than lifting the same weight when your arm is fully extended. The added tension in an extended arm makes the job more difficult. As the boom of your crane extends and becomes more angled, load capacity decreases substantially.

Changing the type, thickness, or orientation of yourslings and chainsetup can make a dramatic difference. Increasing the diameter by one-eighth of an inch, for example, can increase your nominal strength by 12 tons.

At Southwest Wire Rope, we’ve spent the past56 yearsbecoming experts in fabricating the highest quality rigging and lifting products on the market. From rope and chains, to synthetic web and round slings, along with all the hardware you’ll need, we can help you outfit your crane with the best equipment to ensure it’s running at maximum capacity. If you need guidance on which attachments work best for you, we’re here to help.

bringing in arigging consultant. An on-site inspector is vital to staying within the codes of the various regulators, but can also provide valuable advice on which hardware and lifting products might be useful to increase your capacity.

Working alongside a rigging expert who has both practical knowledge on the operation of cranes as well as industry expertise on the outfitting side of the business can pay dividends. Our team will help you create the best lifting solution for your business through our decades of experience backed with rigorous testing.Get in touchwith us today to get started.

The professionals at Southwest have been serving the needs of the rigging and lifting industries with an unwavering dedication to quality and excellence for years. If you are in the market for leading rigging equipment, need your rigging tested, or are simply looking for an expert opinion, we can help. We look forward to answering your questions and forming a lasting partnership. For more information, browse ourproductsandservicesorcontact a reptoday.

In rigging, we all know that the setup is only as strong as its weakest link. Any failure is a potentially dangerous situation that puts your entire operation in jeopardy. Every component must be relentlessly reliable. Synthetic rope is one such tool that bears heavy responsibility. While incredibly strong and durable, it often immediately supports a load; if it were to fail, the results would be catastrophic.

You will likely never seeused in a rig as they are weaker and less durable than their synthetic counterparts. With this in mind, let’s discuss the advantages of synthetic rope.

Synthetic rope is made from nylon, polyester, or polypropylene fibers. These ropes can be made using one or a combination of these synthetic fibers. Much like a natural rope, these fibers are drawn out into strands and then woven together. The end result is a durable, strong rope that can bear markedly more weight and tension than its natural counterpart.

Because of the materials used, synthetic rope is better able to withstand friction, making it more durable. It should be noted that how much you use the rope and its length of service will directly affect how long it lasts. Sporadic use could see it surviving for up to 10 years, whereas heavy use will require replacement every year or two. Synthetic rope is great for outdoor uses, as it is resistant to rot and mildew that can arise from exposure to moisture.

Synthetic rope is useful for a host of additional purposes. Its resistance to moisture makes it ideal for use in marine applications, but it has various advantages outside of the rigging sphere. It serves as an excellent climbing rope due to its abrasion resistance – it can handle rough edges of the terrain without fail. This is also what makes it perfect for rigging in film and theater. Where creative problems often require creative solutions, crews know they can rely on these ropes to hold the scene together. Synthetic rope can also be used effectively in towing and hauling applications.

has been a leader in wire rope and rigging supplies in the Gulf Coast region since 1966. We provide quality supplies and reliable service to each one of our clients so they can meet the tough demands of the industry with confidence and excellence. We are happy to share our decades of experience to help you find the best solution for whatever undertaking you have in front of you. From synthetic rope and slings to wire rope and chains, we have a comprehensive product offering to completely outfit your rig.today to level up your operation.

Lifting hundreds of tons of material on a daily basis requires a lot: high-quality gear, a competent and well-trained team, efficient systems, and a drive to succeed.

Due to the nature of the industry, the regulators at OSHA and other regulatory bodiesalsorequire a lot. In the lifting space, safety always comes first. Meeting the codes that govern the operation of your plant or rig are in your best interest…but this can also be a time-consuming and difficult task.

In order to stay in business and run at maximum capacity, your lifting gear needs to be meeting or exceeding code at all times. Here are some tips for handling this simply and effectively – so you can focus on getting things done.

When it comes to lifting gear, one faulty sling, strap, link, wire rope strand, or other piece of hardware can put the entire operation in jeopardy. Investing in equipment that isand is backed by the quality and reputation of awill help ensure your machinery runs smoothly. Codes were developed in the first place to protect your crew from dangerous breakage, equipment wear, and malfunctions, so starting with the best materials is the most effective way to ensure you’re always in line with recent codes.

A destructive or “break” test measures the tensile strength of wire rope by using magnetic and hydraulic arms to pull opposite ends of the rope apart. The test continues until the wire strands begin to fail, and eventually, the wire rope gives out. This is an extremely loud and dangerous endeavor – a break test should never be conducted without the proper equipment and certifications. Work with an industry provider who can conduct a wire rope break test usingin a safe and controlled setting. The results of this test will be printed on a load testing certification, which will help you satisfy regulations.

When it comes to your health, you trust the expert opinions of medical professionals to give you a diagnostic update after performing the relevant tests. In the lifting industry, on-site inspection services serve the same purpose for determining the health and safety of your operations.

Working with a provider who offersservices will keep your lifting gear in check. A qualified inspector will issue reports and grades on the strength and condition of your lifting gear, so you have a clear idea which elements need replacing. Regulators mandate these inspections as well, so scheduling the inspection in and of itself is necessary to meet code.

Every rigging and lifting operation is required to furnish and maintain a comprehensive set of safety procedures that regulate the facility, its equipment, and the personnel involved. If your team has grown, you have brought new equipment into service, or your operational procedures have changed, your safety protocols need to be updated to reflect this. In addition to updated manuals and emergency procedures, educating your staff on the fulfillment of these duties is vital. An incomplete set of protocols or an untrained staff is grounds for immediate shutdown, so consult with a lifting industry provider for guidance on development or updating of your plans.

Keeping your lifting gear at max capacity while satisfying the regulations of OSHA and other regulatory bodies is not something you should pursue alone. Partnering with a full-service provider who can offer in-depth product knowledge and inspection services will save you hours of confusion and stress when it comes to meeting code.

The professionals athave been serving the needs of the rigging and lifting industries with an unwavering dedication to quality and excellence for years. If you are in the market for leading rigging and lifting gear, need your system tested, or are simply looking for an expert opinion, turn to the pros at Southwest Wire Rope. We look forward to answering your questions and forming a lasting partnership. For more information, browse ourand get in touch.

Today’s rigging operations are expected to perform at their best around the clock. With demand surging andenormous growthforecasted for the industry, the main concerns are often lift capacity, output, and production time. However, when heavy machinery and powerful devices are involved, safety always comes first.

At the core of any reputable rigging operation is a dedication to the safety and security of its crew. At the end of the day, your people will determine the performance of your rig, so you need to protect them.

Rigging equipment is complex and advanced, but it still requires qualified professionals to run at its best. Your team members are your most important asset, so choosing a crew that is situationally aware and intentional in their actions goes a long way in creating a safe environment on the rig. Every worker should know the standard operating procedures for safety-related events and always put the safety of their colleagues ahead of performance.

We’ve all heard that a chain is only as strong as its weakest link. In the rigging business, one faulty sling, strap, link, or wire rope strand, or piece of rigging hardware can jeopardize your entire operation. Investing in equipment that iscrafted to lastand backed by the quality of aleading supplierwill help ensure your machinery runs smoothly and your crew is protected from breakage or equipment wear.

Instead of relying on theintuitionthat your rigging operation is safe, you can have peace of mind byprovingit. Working with a rigging services provider who can offer Proof Load Testing, Break Testing, andon-site inspectionswill keep your rigging operation certified to the industry standard. To schedule a test today, clickhere.

When you first went into the rigging business, you were undoubtedly required to develop a comprehensive set of safety procedures that relate to facility management, personnel, and equipment operation. As your team has grown and your inventory has changed, it’s important to keep your safety protocols updated. If you need help developing safety procedures tailored to your rigging operation and equipment,get in touchwith the team at Southwest today.

Keeping your operation safe yet productive is not an endeavor you should pursue alone. Partnering with a full-service provider who can offer years of industry experience and in-depth product knowledge on every piece of specialized equipment will save you hours of confusion and stress. As your operation changes to meet current demand, work with a provider who can help outfit, secure, and optimize your rigging and lifting facilities with special attention to the safety of your crew.

The professionals at Southwest have been serving the needs of the rigging and lifting industries with an unwavering dedication to quality and excellence for years. If you are in the market for leading rigging equipment, need your rigging system tested, or are simply looking for an expert opinion, turn to the pros at Southwest Wire Rope. We look forward to answering your questions and forming a lasting partnership. For more information, browse ourproductsandservicesorcontact a reptoday.

When you think about the major adjectives that describe a rigging operation, one of the first and most important answers would be “strong.” Strength is not only the defining feature of an effective rigging operation, but also the key to increased load capacity, and thereby output, which leads to higher profit margins and wages. Strength, then, is what we’re after.

One of the most reliable ways to increase the strength of a rigging operation is by investing in high-quality wire rope. Formed from a steel core and wrapped with concentric wire strands, wire rope is an extremely versatile asset that can bear hundreds of thousands of pounds of load, yet remain flexible. For more than 50 years,Southwest Wire Ropehas been supplying some of the strongest and most recognizable wire rope products on the market.

To determine the true strength of wire rope, though, we need to put it to the test. Destructive or “break” testing can be dangerous, but is a useful measuring tool to gauge the strength of wire rope. Here’s everything you need to know about break testing.

Put simply, a destructive or break test measures the tensile strength of wire rope by using magnetic and hydraulic arms to pull opposite ends of the rope apart. The test continues until the wire strands begin to fail, and eventually, the wire rope gives out. This results in an extremely loud explosive noise and frayed metal remnants, which can be extremely dangerous. At the conclusion of the test, the true strength of the rope is evident based on the load reading at the point of breakage.

A break test should absolutely never be conducted without the proper equipment, certified staff, and safety protocols. If you are unsure whether you can perform a break test at your rigging site, then the answer is undoubtedly no. Only specialized machinery operated by trained professionals is fit to manage a destructive test, and attempting a DIY test is a recipe for a regulatory violation and a potential safety hazard.

The only way to know the true strength of a piece of wire rope is to perform a break test in a certifiedtesting facility. As wire rope specialists, the team at Southwest is trained in conducting safe, effective tests of all of our products. If you need your wire rope certified, are curious about the capacity of your rigging system, or are interested in stronger products, we can help. In addition to testing, Southwest is a leader in on-site rigging inspections, rental equipment, field spooling, and other services. Get in touch with a rigging professional today to learn how we can helpoutfityour rigging operation for maximum performance.

The professionals at Southwest have been serving the needs of the rigging and lifting industries with an unwavering dedication to quality and excellence for years. If you are in the market for leading rigging equipment, need your rigging system tested, or are simply looking for an expert opinion, turn to the pros at Southwest Wire Rope. We look forward to answering your questions and forming a lasting partnership. For more information, browse ourproductsandservicesorcontact a reptoday.

In the rigging world, we are always pushing for “more.” More lift power, more loads, more hours on the rig, etc. This industry is full of diligent, hard workers who strive to get the absolute most out of their crews and their equipment.

One such way that many operators attempt to increase output is by increasing the capacity of each load. More productive loads means jobs get completed faster and more efficiently, and the next project can begin. So, how can we increase the strength and speed of our operation through better lift capacity? Keep reading to hear some ideas from the veterans atSouthwest Wire Rope.

As you probably learned during your first training hours, position and angling are immensely important when it comes to lifting. While a straight vertical lift of a single, stable object can be completed at near maximum capacity of your machines, every additional variable you introduce will reduce your lift strength.

The same principles that govern lifting motions of your body apply to lifting loads as well. Lifting a small weight near your torso is much easier than lifting the same weight when your arm is fully extended. The added tension in an extended arm makes the job more difficult. As the boom of your crane extends and becomes more angled, load capacity decreases substantially.

Changing the type, thickness, or orientation of yourslings and chainsetup can make a dramatic difference. Increasing the diameter by one-eighth of an inch, for example, can increase your nominal strength by 12 tons.

At Southwest Wire Rope, we’ve spent the past56 yearsbecoming experts in fabricating the highest quality rigging and lifting products on the market. From rope and chains, to synthetic web and round slings, along with all the hardware you’ll need, we can help you outfit your crane with the best equipment to ensure it’s running at maximum capacity. If you need guidance on which attachments work best for you, we’re here to help.

bringing in arigging consultant

8613371530291

8613371530291