wire rope and rigging consultants for sale

A portion of our work involves performing testing and accident investigation for numerous clients. When we have needed special wire rope fabrication and proof or ultimate break testing, we have decided to call on WCWR as the provider for these operations. Whether we needed to test stainless steel, galvanized, or bright wire rope assemblies, we have willingly put our reputation on the line alongside the professional work provided by WCWR. Their investment in fabrication equipment and their exceptional attention to maintenance and quality control is among the highest in their industry. West Coast delivers on their promises and have always ensured that their technical expertise accompanies each order. Besides delivering quality assemblies, they can be counted on for immediate, quality assistance in solving field problems or unexpected challenges.

We supply all major brands while also offering non-specific vendors for price conscious programs. From meeting their timelines to providing information on our suppliers we value communication with our customers to help them make the best decisions for their safety program.

Unirope LTD. is an ISO 9001 and LEEA-Lifting Equipment Engineers Association certified company, specializing in the manufacturing, distribution, testing, certification and inspection of Lifting- and Rigging Products. Unirope is servicing the industry since 1956.

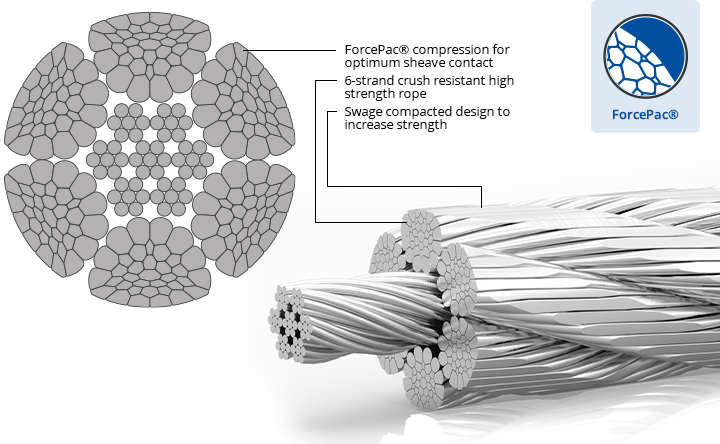

In Germany we manufacture High Performance PYTHON® Wire Rope which we stock in a wide variety of constructions for Tower Cranes, Mobile and Truck Cranes, Overhead Cranes, Gantry Cranes in Construction, Automotive and the Steel Industry. We also stock a large variety of standard and custom designed ropes meeting national and international standards.

The SLINGMAX® product line includes TWIN PATH® Slings made from high strength K-SPEC® fibres, super flexible GATOR FLEX® and TRI-FLEX® wire rope slings, and much more. We also provide a complete range of wire rope fittings, rigging hardware, magnets, clamps, hoists, synthetic ropes, and all types of lifting slings. Find Out More ›

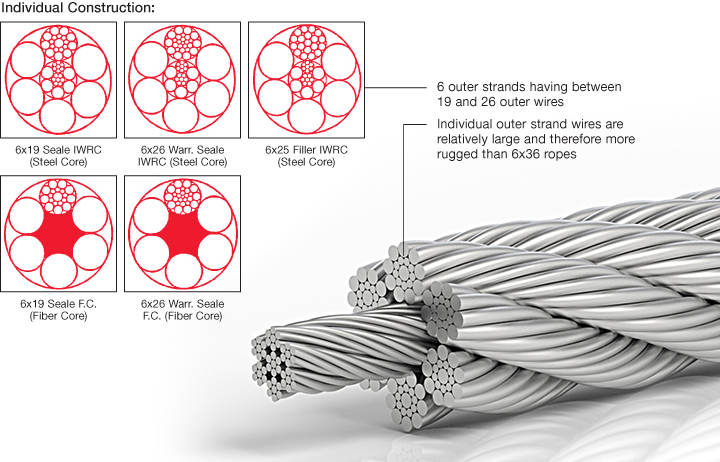

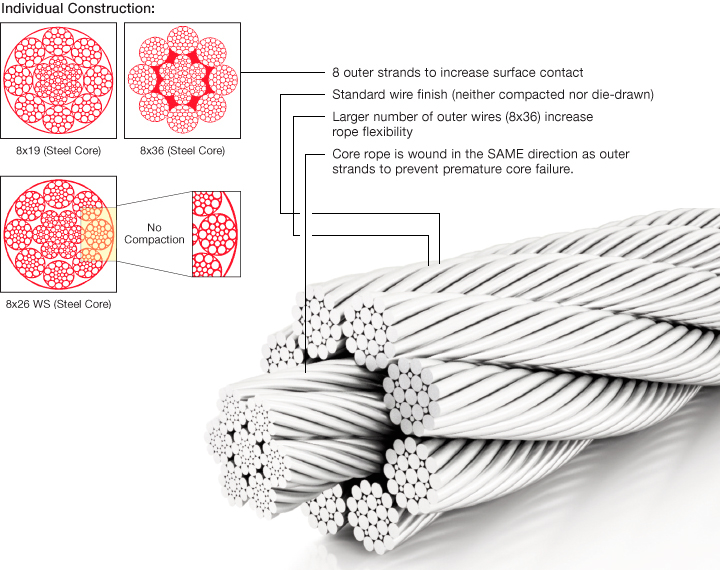

Olsen Chain & Cable wire rope and cable slings allow you to safely lift even the most difficult loads. Cable and wire rope slings are manufactured with various grades of wire rope with different rope lays (the direction the wires and strands are twisted). Olsen Chain & Cable also manufactures Independent Wire Rope Core (IWRC) or fiber core.

Olsen wire rope and cable slings allow you to safely lift even the most difficult loads. They are strong, safely grip and lift some hot materials, and are built to better tolerate abrasive wear. We produce various types, including:

Wire rope slings are manufactured with various grades of wire rope using different rope lays (the direction the wires and strands are twisted). Olsen Chain & Cable wire rope slings are strong, bend without distortion, safely grip and lift even hot materials and are built to handle abrasive wear. We produce various types, including Independent Wire Rope Core (IWRC) or fiber core.

If fiber core wire rope slings are exposed to temperatures above 180° F (82° C), retire these slings. For metallic core wire rope slings of any grade, follow manufacturer’s recommendations on use at temperatures above 400° F (204° C) or below minus 40° F (minus 40° C).

Most wire rope slings are made of Independent Wire Rope Core (IWRC) or fiber core. Fiber core is a bit more flexible but less resistant to environmental damage. Wire rope core has great strength and is more resistant to heat damage.

Properly match components. Ensure that the fitting is the right shape and size so it accurately seats in the hook or lifting device. For multiple-leg slings used with nonsymmetrical loads, have a qualified person do an analysis so you don’t overload any leg. Select multiple-leg slings according to OSHA guidelines for wire rope slings.

OSHA rates loads based on material strength, design factor, type of hitch, angle of loading, diameter of curvature over which the sling is used and fabrication efficiency. Never exceed the working load limit and avoid shock loads. Refer to OSHA guidelines for wire rope sling rated loads.

Properly hitch slings, pad sharp edges, balance loads, don’t drag slings, keep them free of knots or twists and don’t pull a sling from under a load when the load is on the sling.

Have each person who will use your wire rope sling know and follow its type of load, hitch and rated load capacity. Contact us for clarification. Follow other safe operation procedures, including selecting the right sling, keeping people safe distances away from the sling and its load during movement, properly rigging loads and inspecting all slings daily and according to OSHA-approved ASME guidelines.

Do not use worn or damaged slings or attachments. Discard or refurbish them. Use damaged slings only after they are reconditioned, and proof tested by the sling manufacturer or a qualified refurbishing source. Keep certificates of proof test. You may also use Olsen Chain & Cable’s lifting equipment inspection services

Miami Cordage & Florida Wire & Rigging Works is a family owned and operated manufacturer and distributor of fiber and wire rope, custom lifting and boating assemblies, rigging supplies and hardware. We originally began as a distributor of marine and industrial supplies to the Southeastern U.S. and Caribbean Basin. Over the years as both our business and market expanded, we began manufacturing fiber rope and acquired Florida Wire & Rigging Works. Today, our manufacturing capabilities continue to grow and we are now the only fiber rope manufacturer in the U.S. that creates custom-color double braid and 12-strand rope. In addition, relatively new to our product line is Dyneema SK-75 fiber rope and a 3-strand nylon rope with a specialty coating designed specifically for use with windlasses.

Welcome to HHI Lifting, home of the biggest sling shop and testing facility in a single location in the country. Our company, Holloway Houston, supplies everything essential for your industrial lifting needs with high-quality equipment and cutting-edge testing services made accessible at our top-notch testing facility.

Learn more about the many products in our rigging rentals department by exploring our website, including spreader bars, wire rope slings, shackles, turnbuckles, skip pans, and several other items. Furthermore, our whole array of synthetic slings and wire rope products.

At Silver State Wire Rope and Rigging, Inc. we pride ourselves in providing you and your company comprehensive wire rope and rigging solutions. With our locations in Las Vegas and Northern Nevada, we offer a full range of conventional and custom engineered rigging products and solutions, as well as a full spectrum of tension and non-destructive testing. This testing includes magnetic field testing of wire rope tension testing of wire ropes and mining rope tension testing to CSA G-4 test protocols.

Along with general purpose and high performance wire rope, cable, slings, and specialized cables, we have a complete range of rigging hardware items and field rigging services. Silver State Wire Rope and Rigging, Inc. also offers rigging rental items for many of the projects you have.

With a primary focus on safety, Silver State Wire Rope and Rigging, Inc. is the only company of its kind in the state for wire rope and rigging solutions. With general offices, manufacturing facility and warehousing in Las Vegas and Elko, Nevada and several product divisions, we specialize in a broad spectrum of wiring and rigging-related services. About Us

As an established supplier of services and materials to numerous commercial enterprises and governmental agencies, we employ only the best master riggers and artisans in our industry to help you get a quality rigging solution for your project. Regardless of its size, every job order is to the highest standard of safety and the letter of the Rigger’s Code. View Catalog

Our company works hard to achieve the goal of providing our customers with quality and real solutions for moving and controlling forces and loads in a wide array of situations. Every environment which will use our products is unique, so we will go the extra mile to evaluate the situation to provide the safest option for the project.

Wire rope is an essential tool for safety when mining. As Nevada’s and California’s number one choice in the active mining industry, we can make sure no matter what the job is, we’ll supply full-service wire rope that meets your jobs requirements and safety standards. Learn More

The entertainment industry in Las Vegas is a shining star that brings people from all over the world. However, for the show to go on, these highly skilled professionals needs the safest wire rope money can buy. Bring any show or event to life with Silver State Wire Rope and Riggings professional and safety-first wire rope services. Learn More

Utility jobs vary from job site to job site, each having unique needs and wire rope requirements to get the job done safely and efficiently. Our wire rope is designed to fit the specific requirements on all types of utility work sites, so you can save money and be safe on the job!

Wire rope is an essential tool for safety when mining. As Nevada’s and California’s number one choice in the active mining industry, we can make sure no matter what the job is, we’ll supply full-service wire rope that meets your jobs requirements and safety standards. Learn More

Need an OSHA Rigging certified company with accreditation in Nevada and California? Silver State Wire Rope and Rigging is certified, and our training services are always on top of any new OSHA standards for wire rope, rigging. Our training services cover all types of rigging needs such as entertainment, utility, mining, and more. Learn More

Most construction and manufacturing sites have some type of rigging hardware. This is because rigging and lifting heavy loads are necessary for multiple industries. Experienced riggers can make it look easy, but the reality is rigging and lifting heavy loads can be a difficult task. Human error is the most common reason for rigging accidents.… Read more

Most construction and manufacturing sites have some type of rigging hardware. This is because rigging and lifting heavy loads are necessary for multiple industries. Experienced riggers can make it look easy, but the reality is rigging and lifting heavy loads can be a difficult task. Human error is the most common reason for rigging accidents.…October 10, 2022

Routine equipment instructions are critical when it comes to rigging and lifting hardware. These routine inspections have many benefits, the most vital being workplace safety. Routine inspections can detect and potentially prevent equipment failure, leading to extensive damage or even fatal injuries on the job site. Additional benefits include increased productivity and reduced maintenance and…September 5, 2022

Rigging hardware plays a vital role on many construction sites. Rigging hardware is typically used to lift and move heavy loads on construction sites. It takes knowledge and experience to ensure safe practices are followed when using rigging equipment. However, there are some common mistakes that many amateurs make when utilizing rigging equipment. Continue reading…August 18, 2022

Wire ropes are incredibly versatile. This versatility allows them to be utilized by many different industries. However, to meet people’s exact needs, they are constructed in different styles, weights, and sizes. Various tools help users get the most out of their wire ropes. When it comes to wire ropes, you have many choices. Continue reading…June 22, 2022

Our team of experts will help you discover the best solution for your project. Our options are cost-effective for your company and will leave you worry-free due to our comprehensive and safe approach to your project. Contact us today!

Bushman Equipment offers custom-engineered material handling solutions for below-the-hook and floor-based applications. As they say, “If you can make it, we can move it!”

Lift it, stack it grab it, hook it, upend it, invert it, weigh it or transfer it – Bushman has the right equipment for increased productivity, extended performance, and minimizing maintenance requirements and downtime. We are proud to offer their products to our customers!

The Flip-Rite® Handling System’s power slings gently lift and rotate objects. The slings enclose the center of gravity providing a controlled, stable motion. Optional features may include the Level-Rite®, a powered load leveling device or custom fixtures for turning highly irregular shapes. Contact us for more information!

Recently, we completed work on this Crosby 4-leg sling. Each 2 3/4 sub-assembly has two legs. 1 1/4″ wire rope was separated, spliced, and braided; once the thimbles were installed, it was placed in the thimble vice in order to slide the swage socket over the braided wire rope.

Houston Wire & Cable Co. (Nasdaq: HWCC), Houston, Texas, on Wednesday announced that it has agreed to sell its Southwest Wire Rope business in an asset transaction for $5 million.

The sale of Southern Wire Rope, a Houston-based provider of lifting slings and wire rope and rigging products, excludes $2.6 million of trade accounts receivable, which HWCC will retain. HWCC said it expects to use the net sales proceeds and accounts receivable collections to further reduce revolver debt.

“Southwest Wire Rope is a company that for over 50 years has been a leading supplier of quality lifting slings, wire rope and rigging supplies to the lifting industry,” said James L. Pokluda III, HWCC president and CEO. “We wish them much success in the future. Proceeds from the sales of Southern Wire and Southwest Wire Rope allow us to reduce debt, which lessens financial risk in these uncertain times.”

Pacific Wire Rope is a family-owned and operated company that has been supplying local industry in the Lower Mainland with the rigging materials they depend on since 2001. We provide smart solutions for improved material handling. Ensure safety and best work practices by contacting one of our team members today.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

ITI has been an innovator and pioneer in rigging training for nearly 30 years and conducts more rigging training for corporate clients in North America than any other provider due to its expertise, size of training staff, and deep course curriculum. Under the broader category of Rigging, courses are further classified into the following sub-categories:

The “meat and potatoes” of rigging training. ITI Rigging Applications courses cover the full gamut of skill and experience levels with options available for true neophytes to seasoned veterans and everyone in-between…

Removal criteria for wire rope, wire rope slings, synthetic web/round slings, chain slings, rigging hardware, and below-the-hook lifting devices is the focus here. Personnel qualification is available.

ITI endorses the national certification program offered by the National Commission for the Certification of Crane Operators (NCCCO) and provides training to prepare candidates for NCCCO written and practical exams. Exam administration with Certified Practical Examiners (ITI Instructors) is also offered.

Designed for lift planners, crane and rigging managers, and other non-engineers who conduct lift planning activities, ITI’s Fundamentals of Rigging Engineering courses are LEEA accredited and approved by ASME.

ITI offers signalperson training for personnel who use hand and voice signals in crane operations. Qualification and Certification Exams through NCCCO are offered.

Knowledge of hoisting and rigging equipment and materials is one of the most important factors in jobsite occupational health and safety. Recognizing its capabilities and limitations not only improves efficiency but minimizes hazards and helps prevent accidents. This program covers not only the fundamentals of ropes and knots, but also hoisting equipment from cranes to chainfalls, as well as rigging hardware from rope clips to spreader beams. Equally important is the attention paid at every step to the correct procedures for equipment inspection, maintenance, and operation. Participants must successfully complete and pass both the theoretical and practical components of this course to receive their record of training (ROT).

Amick Associates, Inc. has 2 certified inspectors (soon to be 5). Level III Rigging Gear Inspectors/Instructors are available to assist you with your overhead lifting questions and applications.

CLEVELAND, OH – Mazzella Lifting Technologies, a Mazzella Company, is pleased to announce the acquisition of Denver Wire Rope & Supply. This acquisition will strengthen Mazzella’s footprint west of the Mississippi River and reinforce Mazzella’s commitment to be a one-stop resource for lifting and rigging services and solutions.

Denver Wire Rope & Supply has been in business since 1983 and services a variety of industries out of their location in Denver, CO. Denver Wire Rope & Supply is a leading supplier of rigging products, crane and hoist service, below-the-hook lifting devices, and certified rigging inspection and training. Effective immediately, Denver Wire Rope & Supply will operate as Mazzella / Denver Wire Rope. Terms of the transaction are not being disclosed.

“Denver Wire Rope & Supply will complement the wide range of products and services that Mazzella Companies offers. We are dedicated to being a single-source provider for rigging products, overhead cranes, rigging inspections, and rigging training. Both companies commit to a customer-first mentality, providing the highest-quality products, and leading by example when it comes to safety and sharing our expertise with customers and the market,” says Tony Mazzella, CEO of Mazzella Companies.

This acquisition will provide Mazzella Lifting Technologies with a western U.S. location that will allow them to grow and expand their reach past the Oklahoma City market.

“Our team and family are excited to be part of the Mazzella Companies. This acquisition strengthens our place in the market and allows our team to continue to provide excellent service and products to our valued customer base and expand our offering,” says Ken Gubanich, President of Denver Wire Rope & Supply.

“Over the years, we have had numerous companies show interest in purchasing Denver Wire Rope & Supply, none seemed to be the right fit. We are looking forward to becoming a part of an aggressive, passionate, and progressive organization. As a family business for over 36 years, it is important to us that our customers/friends, suppliers, and team members continue to be treated with first-class service, products, and employment opportunities. Again, we are very enthusiastic about our future and look forward to being a quality supplier for your crane, safety training, rigging, and hoisting needs for years to come,” says Gubanich.

“We wish Ed and Carol Gubanich all the best in their retirement. We welcome Ken and the other second and third-generation Gubanich family members, as well as the entire Denver Wire Rope Team, into the Mazzella organization,” says Mazzella.

We’ve changed our name from Denver Wire Rope to Mazzella. Aside from the new name and logo, our member experience is virtually unchanged. Here are some common questions and answers related to this change.

In 2019, Denver Wire Rope & Supply was acquired by Mazzella Companies to expand lifting and rigging products and services to the western half of the United States.

In 1954, James Mazzella founded Mazzella Wire Rope & Sling Co. in Cleveland, OH. For over 65 years, the company has grown organically by nurturing historic relationships, expanding its product offerings, and entering new markets through acquisition.

Today, Mazzella Companies is one of the largest privately held companies in the lifting and rigging industries. Since our humble beginnings, we’ve grown to over 800 employees with over 30 locations across North America. Our product offerings have expanded from basic rigging products, to include:Overhead crane fabrication

One thing that hasn’t changed is our commitment to a no-excuses, customer-first mentality that extends from the shop floor to the front office. Some of the major markets Mazzella serves are: Mining, Steel, Oil & Gas, Construction, Energy, Shipbuilding, Vehicle and Durable Goods. Mazzella’s diverse portfolio includes Sheffield Metals a manufacturer and distributor of coated bare metal products for engineered metal roof and wall systems. New Tech Machinery is a manufacturer of portable roof panel and gutter machines—recognized as the world’s finest portable rollformers.

Just the name. We want to be clear that our people, locations, products, and services have not changed. We will be moving to the Mazzella name for all rigging brands under the Mazzella Companies umbrella in order to create a better experience for our customers and employees.

With all the Mazzella rigging locations working as one team and under one name, your level of service and support will be improved exponentially. Nothing will change in terms of the local team you’re used to working with. The same people will still be here—the only thing that will be changing will be the name of the organization they work for. You now have more resources, inventory, and clearer lines of communication. Our goal is to improve your experience and instill confidence and comfort in every interaction.

Mazzella is experiencing rapid growth. With this growth, we can better serve our customers as one team under the Mazzella name, versus many companies operating independently. The only change you will experience will be better service and improved lines of communication between our people and yours.

For sure! We hope to expand our service line across the entire United States. With over 30 locations, your level of service should only be improved and lines of communication more clear.

8613371530291

8613371530291