wire rope anti vibration mounts quotation

A wire rope isolator is a very high performance shock absorber and vibration isolator that can used in endless applications. Wire rope isolators are very useful vibration dampers because they maintain excellent vibration isolation performance under maximum shock in severe environmental conditions such as chemical pollution or extreme temperatures. They have a long life span and can adapt to elastic displacement in all dimensions, allowing multi-directional vibration isolation and they can be installed in many different ways.

There is elastic support for heavy duty machinery such as generators and vibration isolation for delicate applications such as precision instruments, transportation of missiles and satellites, processors, communication units, protection for navigation and launching systems as well as large scale construction. The working temperature for wire rope isolators is -75°C-+175°C, up to +370°C and each wire rope isolator comes with softened non-linear stiffness. The maximum dynamic displacement is over 70 percent of the space the mount takes up, the dynamic stiffness decreases when the displacement increases.

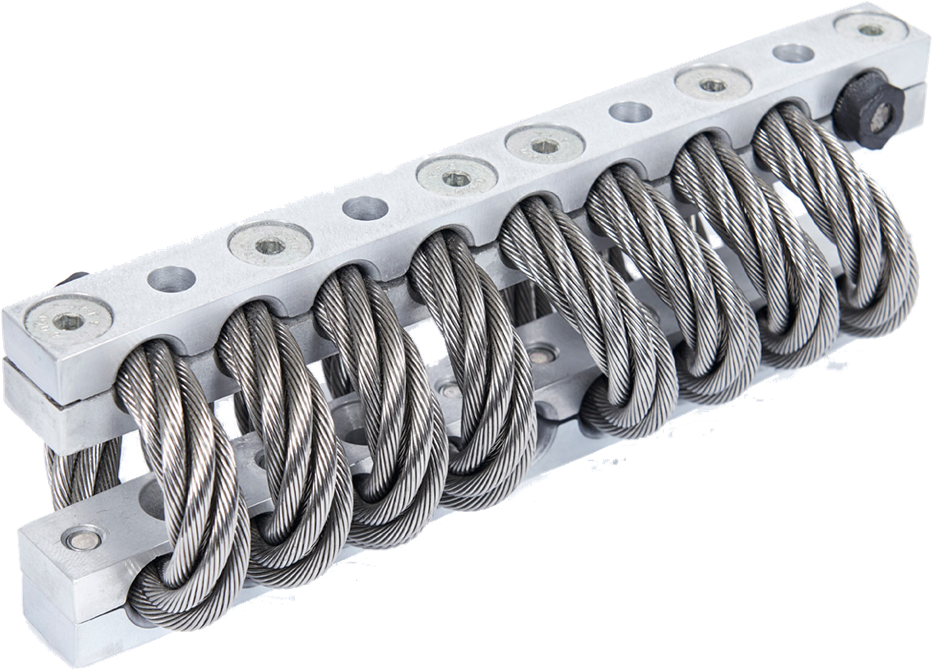

Heavy duty wire rope isolators are large wire rope isolators that feature a large stainless steel braided cable for applications in which the most powerful vibration isolation is required. These wire rope isolators provide multi-dimensional vibration and shock isolation capabilities for all applications. Our heavy duty wire rope mounts are made of high quality stainless steel braided cable threaded through aluminum alloy retaining bars, crimped and mounted for maximum shock and vibration isolation. These vibration isolators provide corrosion-resistance properties as well as maintenance free operation and easy installation in addition to powerful vibration and shock damping. They are also unaffected by harsh environmental conditions and temperatures, oils, abrasives, mycosis, humidity, ozone, grease, chemicals, nuclear radiation, ozone, dust and erosion of organic solvent.

The maximum dynamic displacement is over 70 percent of the space the mount takes up, the dynamic stiffness decreases when the displacement increases. Heavy duty wire rope isolators can be installed in many different ways and are a very versatile wire rope isolator. These mounts also provide elastic support for heavy-duty equipment such as generators.

Shock and vibration rank among the most destructive agents in industrial environments. These disturbances erode the life of mechanical and electronic equipment – driving machinery from service long before necessary. Sometimes this premature deterioration stems from repeated overstress loadings, sometimes from fatigue failures of vital parts, and sometimes from a combination of both.

Isotech offers a variety of wire rope isolators that resolve shock and vibration issues in virtually any application. By selecting wire rope with the proper characteristics – wire diameter, number of strands, cable length, cable twist or lay, and the number of cables per section, we have created wire rope isolators that provide superior equipment protection. Ideally, passive isolation systems require no maintenance, use little space, and keep functioning under varying temperatures and in corrosive environments.

Welcome to Vibro/Dynamics, where we will find effective and excellent solutions for shock and vibration problems. We offer you a great collection of wire rope isolators, constructed of stranded steel cable and contained between metal bars. The isolators’ design is chosen carefully to maximize the quality performance starting with the flexing of the cable loops that function as a spring, and the friction between the cable wires and strands that provides damping. Wire rope isolates are ideal for combined shock and vibration thanks to their large multidirectional deflection capabilities and high non-linear damping ratios. Moreover, our products can last a lifetime with quality performance and mechanism protection.

The VS series isolators are made from helical wire rope which is held with rugged metal retaining bars. No other isolator in the market can match the versatility and performance characteristics of the Helical Cable Isolator. From its multi-axis isolation, to its ability to function in the most hostile of environments, the Helical Cable Isolator combines the best features of other isolation devices into one cost effective product. Originally designed for military applications, it has become increasingly popular in industrial and commercial markets as engineers and designers become more familiar with its capabilities. The VS Series can handle loads of less than one pound (VS2"s) to over 5,000 pounds (VS40"s); and with over 100 standards sizes, AHI has by far the most extensive line in the industry.

Standard Wire Rope isolators are made from 300 series Stainless Steel Cable & Screws, with Anodized Aluminum retainer bars. Other materials are also available as alternative like retainer bars of Stainless Steel 304, etc. The isolators are ozone, oil, salt spray resistant & can be used for any environmental conditions. Contact AHI for specials material, size, mounting holes, finish etc.

High Damping: The frictional damping generated by the rubbing of the individual strands of cable, gives the isolator a substantial energy dissipating capability (C/Cc 0.20). It is the same damping quality that keeps the transmissibility at resonance low (~2.5).

Look to Enidine for high performance Wire Rope Isolators and Compact Wire Rope Isolators. The wire rope isolators have stainless steel cable and RoHS compliant aluminum retaining bars, which provides excellent vibration isolation. The isolators are corrosion resistant, which makes them environmentally stable and high-performance in a variety of applications. The isolators are completely unaffected by oil, chemicals, abrasives, ozone, and temperature extremes.

The compact wire rope isolator is smaller than a traditional wire rope and can absorb shock and vibration in small spaces. Single point mounting offers flexibility for integration into existing products.

Both compact wire rope isolators and wire rope isolators can be used on galley components where motors and fans produce vibrations onto surrounding structures. They can also be used to control vibration and thermal expansion.

We stock a range of Anti Vibration Mounts as displayed below, however in most cases we are able to supply custom material combinations to meet your ...

Metal cushions are mouldings made from a wire mesh set with elastic properties which are used on their own or in combination with fittings. They optimise oscillation isolation and reduce ...

ROSTA anti-vibration mounts type AWI are intended for the absorption of medium and low frequency vibrations. The AWI elements are used in pairs (type R and L) in most ...

Cushyfoot mountings have two rubber elements, used in shear and compression, to provide excellent stiffness characteristics for the isolation of a wide range of vibration ...

These mounts offer a low profile, easy to install design with an integral fail-safe device to provide shock and failure protection for mobile, marine or seismic stationary application and for applications ...

... rubber as standard but other compounds are available on request. Stainless steel metal parts are also available on request for substantial volume orders.

... CAVOFLEX is used to isolate vibrations - whether they are created or received by suspended equipment or as shock absorbing mounts due to its high damping capacity and deflection capacity.

Within our extensive range of vibration mounts are two elements that can be used across industries. Our spring mounts, made from rubber and steel, are generally used for vibration isolation in compression. These components are necessary to isolate all machinery that has reciprocating or rotating parts. These parts create vibration through the imbalance of the moving parts.

Reducing vibration in work environments is crucial, as these preventable shudders and trembles can cause noise pollution, malfunctioning and reduction of the machine lifespan and that of surrounding machines, and damage to the health of operators. To mitigate these issues, it is important to install these mounts to isolate vibrations.

Our AVM mounts are composed of rubber body, steel spring and plate, and aluminium spring caps. They are particularly suitable for use with HVAC, compressors, refrigeration units, centrifuges, crushers, vibrating screens and generators. Elesa are passionate about meeting your needs with our wide range of standard components.

If you require AVM mounts with special executions, simply get in touch. We are happy to accommodate the following variations on request:Vibration dampers with one spring, with pins or threaded holes with a baseplate

Also in our range are wire rope isolators made from stainless steel. These are generally used for isolating vibrations and shock absorption, where axial holding force, resistance to compression, and shear force is required. Our AVC rope isolators are available with four, six, or eight coils. These components are particularly suitable for use with HVAC, pumps, purification and desalination plants, instrumentation panels, and in the railway, naval, and military industries.

As with our AVM mounts, we are able to provide our AVC rope isolators with the following special executions on request:Vibration dampers with cable with AISI 304 stainless steel bars

Isolation Dynamics Corp. offers the very best vibration engineering solutions like our mechanically fastened wire rope isolators and isolation assemblies for a variety of applications – including architectural foundations, oil pumps, compressors, and rugged naval electronics enclosures. Learn more about our IDC isolators below!

Find out all of the information about the Vibrostop product: round anti-vibration mount AVAU series. Contact a supplier or the parent company directly to get a quote or to find…

Hoan multi-application wire rope vibration isolator overcomes the defect of passive wire rope vibration dampers that damping is not adjustable, but because the structure of the mechanical system is complex and the price is expensive, it is mainly used for vibration isolation of some advanced cars or heavy cars. #wirerope #isolator #vibration

Finally, there is an advanced solution for the harmful vibrations that can arise during handling and transport of artworks. Turtle has developed the new T+ securing system for optimum vibration reduction. Recent scientific research has shown that the advanced T+ corner block performs 100% better in terms of vibration reduction than a standard museum double-walled wooden crate. Shock absorption during transport is 90%.

Turtle’s research focuses on protecting artworks during transport. We recently carried out studies into the performance of various types of art transport materials in terms of vibration reduction. This was done under the auspices of the vibration expert Prof. Kerstin Kracht. The studies showed that vibrations were reduced most efficiently by wire rope isolators.

The advanced Turtle corner block T+ is especially designed to transport a wide range of paintings with optimal vibration reduction and shock absorption in the Turtle uNLtd.

The wri need two regide surfaces to which the fixation plates are attached. The vibration energy enters from the bottom surface and is led into the steel wires. The flown steel wires absorb the vibrational energy and release the reduced vibration to the top surface.

8613371530291

8613371530291