wire rope association supplier

Our Association was formed in 1975 and incorporated the following year by a group of concerned businessmen who felt there was a need for sling fabricators and special rigging components manufacturers to join together to form a trade association.

Our Association was formed in 1975 and incorporated the following year by a group of concerned businessmen who felt there was a need for sling fabricators and special rigging components manufacturers to join together to form a trade association. Originally created by representatives from nine companies in the United States, in two decades the organization grew to address the needs of over 400 member companies worldwide.

AWRF promotes interests common among companies manufacturing, fabricating, or distributing lifting, rigging and load securement devices made of chain, rope, and synthetic products. The association works to establish, acquire, preserve, and disseminate various technical information, and encourages the development of safety standards and programs, and product identification procedures. Assistance has been provided for establishing and maintaining adequate products liability insurance, as well as other insurance needs of the industry. Common problems and purposes of the industry, such as those involving production, distribution, service and safety are reviewed and advanced by lawful means on a regular basis.

We represent RopeBlock in North America and distribute blocks, overhaul balls & sockets through three channels: industrial distribution, crane dealers and crane manufacturers.

Currently, Tadano, Tadano Mantis, Broderson, Elliott, Terex & Manitowoc/Grove are some of the crane manufacturers that purchase RopeBlock products for use on their equipment.

Wire rope manufacturers produce their products in order to provide a high load capacity, versatile alternative to weaker ropes like manila rope or hemp rope. Wire rope products are used for a wide variety of motion transmission applications, among them: lifting, baling, tie down, hoisting, hauling, towing, mooring, anchoring, rigging, cargo control, guidance and counterbalance. They can also be used as railing, fencing and guardrailing.

Wire rope is a must-have for many heavy duty industrial applications. From mining to forestry to marine and beyond, there’s wire rope for almost every job. Some of the many industries in which wire rope is popular include: construction, agriculture, marine, industrial manufacturing, fitness, sports and recreation (plastic coated cables for outdoor playground equipment and sports equipment), electronics, theater (black powder coated cables for stage rigging), mining, gas and oil, transportation, security, healthcare and consumer goods.

Wire rope as we know it was invented just under 200 years ago, between 1831 and 1834. At that time, the goal was to create a rope strong enough to support work in the mines of the Harz Mountains. Invented by Wilhelm Albert, a German mining engineer, this wire rope consisted on four three-stranded wires. It was much stronger than older rope varieties, such as manila rope, hemp rope and metal chain rope.

While studying at Freiburg School of Mines, a man named L.D.B. Gordon visited the mines in the Harz Mountains, where he met Albert. After he left, Gordon wrote to his friend Robert Stirling Newall, urging him to create a machine for manufacturing wire ropes. Newall, of Dundee, Scotland, did just that, designing a wire rope machine that made wire ropes with four strands, consisting of four wires each. After Gordon returned to Dundee, he and Newall, along with Charles Liddell, formed R.S. Newall and Company. In 1840, Newall received a patent for “certain improvements in wire rope and the machinery for making such rope.”

In 1841, an American manufacturer named John A. Roebling began producing wire rope for suspension bridges. Soon after, another set of Americans, Josiah White and Erskine Hazard, started incorporating wire rope into coal mining and railroad projects, forming Lehigh Coal & Navigation Company (LC&N Co.). In 1848, wire rope from their wire rope factory in Mauch Chunk, Pennsylvania provided the lift cables needed to complete the Ashley Planes Project. This project sought to improve the performance and appearance of the freight railroad that ran through Ashley, Pennsylvania, by adding lift cables. This increased tourism and increased the railroad’s coal capacity. Before, cars took almost four hours to return; after, they took less than 20 minutes.

Wire rope likewise changed the landscape (again) in Germany, in 1874, when an engineering firm called Adolf Bleichert & Co. used wire rope to build Bi-cable aerial tramways. These allowed them to mine the Ruhr Valley. Several years later, they also used wire rope to build tramways for the German Imperial Army and the Wehrmacht. These tramways were wildly successful, opening up roads in Germany and all over Europe and the USA.

Since the 1800s, manufacturers and engineers have found ways to improve wire rope, through stronger materials and material treatments, such as galvanization, and different rope configurations. Today, wire rope makes possible many heavy industrial processes. It has become a necessity of the modern world.

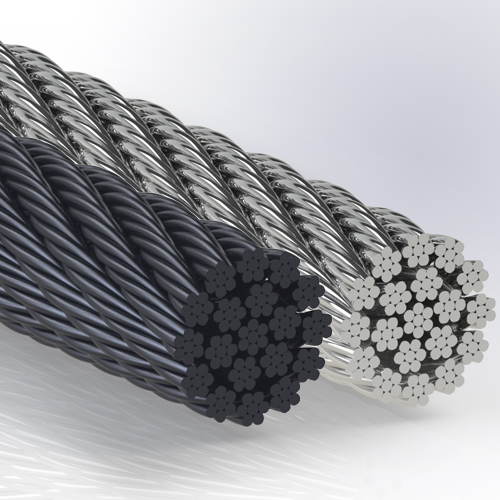

Strands are made by tightly twisting or braiding individual wire together. One strand could have anywhere between two and several dozen wire filaments depending on the necessary strength, flexibility, and weight capacity.

One of the most dynamic elements of wire cables is the inner core. The strands are wrapped around the core, and it can be made of different metals, fibers, or even impregnated fiber materials. For heavy applications, cores are often made of a different strand of wire called an independent wire rope core (IWRC). An IWRC has a considerable amount of flexibility and it is still very strong. In fact, at least 7.5% of the strength increase in a wire rope can be attributed to an IWRC.

While they sometimes use other metals, like aluminum, nickel, copper, titanium, and even bronze for some applications, manufacturers primarily produce wire rope from steel. This is because steel is very strong and stretchable. Among the most common types they use are: galvanized wire, bright wire, stainless steel and cold drawn steel.

Of the wire rope steels, cold drawn carbon steel wire is most popular, although stainless steel wire rope is sometimes employed as well. Stainless steel rope is most popular for its anti-corrosive properties. Bright wire rope, a type of ungalvanized steel wire rope, is also popular. For added strength and durability, galvanized steel wire rope/galvanized steel cables are a very popular choice. Galvanized aircraft cable, for example, is always a must in aerospace.

When choosing or designing a custom wire rope for your application, suppliers consider factors such as: the environment in which the rope will function, required rust resistance, required flexibility, temperature resistance, required breaking strength and wire rope diameter. To accommodate your needs, manufacturers can do special things like: make your rope rotation resistant, color code your rope, or add a corrosion resistant coating. For instance, sometimes they specially treat and coat a cable with plastic or some other compound for added protection. This is particularly important to prevent fraying if the wire rope is often in motion on a pulley.

Manufacturers and distributors identify the differences in wire cable by listing the number of strands and the amount of wires per strand so that anyone that orders understand the strength of the cable. Sometimes they are also categorized by their length or pitch. Common examples of this include: 6 x 19, 6 x 25, 19 x 7, 7 x 19, 7 x 7, 6 x 26 and 6 x 36.

More complex wire rope identification codes connote information like core type, weight limit and more. Any additional hardware like connectors, fasteners, pulleys and fittings are usually listed in the same area to show varying strengths and degrees of fray prevention.

Cable wire rope is a heavy-duty wire rope. To give it its high strength, manufacturers construct it using several individual filaments that are twisted in strands and helically wrapped around the core. A very common example of cable wire rope is steel cable.

Spiral rope is made up an assemblage of wires with round or curved strands. The assemblage features at least one outer layer cord pointed in the opposite direction of the wire. The big advantage of spiral ropes is the fact that they block moisture, water and pollutants from entering the interior of the rope.

Similarly, stranded rope steel wire is made up of an assemblage of spirally wound strands. Unlike spiral rope, though, its wire patterns have crisscrossing layers. These layers create an exceptionally strong rope. Stranded rope may have one of three core material types: wire rope, wire strand or fiber.

Wire rope chain, like all chains, is made up of a series of links. Because it is not solid, wire rope chain is quite flexible. At the same time, it is prone to mechanical failure.

Wire rope slings are made from improved plow wire steel, a strong steel wire that offers superior return loop slings and better security. The plow wire steel also shields rope at its connection points, which extends its working life. Wire rope slings, in general, provide their applications with increased safety, capacity and performance. Wire rope sling is a rope category that encompasses a wide range of sub-products, such as permaloc rope sling, permaloc bridle slings and endless slings. These and other wire rope slings may be accompanied by a wide variety of sling terminations, such as thimbles, chokers and hooks.

Wire rope offers its user many advantages. First, design of even distribution of weight among strands makes it ideal for lifting extremely heavy loads. Second, wire rope is extremely durable and, when matched properly to the application, can withstand great stress and elements like corrosion and abrasion. In addition, it is very versatile. Its many iterations and the ways in which the rope can treated means that users can get rope custom fit for virtually any application.

Depending on the type of wire rope with which you are working and your application, you may want to invest in different accessories. Among these accessories are: wire rope clips, steel carabiners, fittings, fasteners and connections.

To ensure that your wire rope quality remains high, you must regularly inspect them for wear and degradation. The right wire rope should be selected for a particular use. Watch out for performance-impacting damage like: rust, fraying and kinks. To make sure that they stay in tip-top shape, you should also clean and lubricate them as needed. Check for this need as a part of your regular inspection.

Rope care is about more than inspection. It’s also about making an effort to use and store them properly every time you use them. For example, never exceed your rope’s rated load and breaking strength. Doing so will not only cause the weakening of your cable, but it may even cause immediate breakage. In addition, always store your wire rope cable in a dry and warm area, away from those elements that could cause premature rusting or other damage. Finally, always carefully wind your wire rope when you’re done with it, so as to avoid kinks. If you follow all these tips and treat your wire rope assemblies well, they will reward you with a long and productive service life.

Always make sure that you purchase wire rope that matches your industry and regional standards. Some of the most widely referenced standards organizations for wire rope include: ISO, ASTM International and OSHA. Talk over your specifications and application with your wire rope supplier to figure out what’s best for you.

If you’re in the market for a wire rope or a wire rope assembly, the best way to know you’re getting something that will both perform well and be safe if by working with a vetted professional. Find one among the list we’ve provided on this page. Check out their profiles to get an idea of the services and products they offer. Pick out three or four to whom you’d like to speak, and reach out. Talk to them about your specifications, standard requirements and budget. Ask about lead times and delivery options. Once you’ve spoken with all of them, compare and contrast their answers. You’ll know you’ve found the one when you talk to a wire rope company that is willing to go above and beyond for your satisfaction.

AWPA provides its members with industry data. General information regarding imports of rod, wire and wire products into the US, by volume and value, are available in the aggregate and by country of import. In addition, AWPA provides other data to assist members in bench marking themselves against other wire companies.

Wire rope is a complex mechanical device that has many moving parts all working in tandem to help support and move an object or load. Wire ropes are attached to a crane or hoist and are fitted with swivels, shackles or hooks. These are suitable for lifting or lowering elevators and are also used for supporting suspension bridges or towers.

In this article, we"ll cover details on the top U.S. providers of wire ropes, along with our featured list of top wire rope suppliers on Thomasnet.com.

Below is a list of featured suppliers of wire rope from our platform. Included with these companies is their location, year established and the number of employees.

Below we have assembled information on the top suppliers of wire rope in the U.S. based on currently available public sales data. The table also includes the company name, location and the number of employees.

With the help of the provided details on the wire rope suppliers in the United States in the above tables and descriptions, we hope you can use this data to further aid your sourcing decisions.

WorldWide Enterprises, Inc. is a leading distributor of assorted wire ropes, cables, marine and industrial hardware, chain, and anchors for the Challenge Rope Course and other industries.

“Ropes Course Warehouse is a wholesale distributor specializing in aircraft cable, wire rope, carabiners, quick links, fasteners, rope and rope assemblies, tools, zip trolleys, climbing gear, safety products and more.“

“AWRF promotes interests common among companies manufacturing, fabricating, or distributing lifting, rigging and load securement devices made of chain, rope, and synthetic products. The association works to establish, acquire, preserve, and disseminate various technical information, and encourages the development of safety standards and programs, and product identification procedures. Assistance has been provided for establishing and maintaining adequate products liability insurance, as well as other insurance needs of the industry. Common problems and purposes of the industry, such as those involving production, distribution, service and safety are reviewed and advanced by lawful means on a regular basis.” – About AWRF – Associated Wire Rope Fabricators

The Association of Crane and Rigging Professionals (ACRP) is a nonprofit association whose mission is dedicated to improving crane operations and rigging activities in all industries. This is accomplished by providing educational opportunities to its members and the public.

A full service national trade association with a nationwide network of exceptional chapters, AGC represents nearly 30,000 leading firms in the industry – including general contractors, specialty contractors and service providers and suppliers. AGC members play a powerful role in sustaining economic growth, in addition to producing structures that add to productivity and the nation’s quality of life. AGC is truly the “voice and choice” of the construction industry.

AWRF promotes interests common among companies manufacturing, fabricating, or distributing lifting, rigging and load securement devices made of chain, rope, and synthetic products. The association works to establish, acquire, preserve, and disseminate various technical information, and encourages the development of safety standards and programs, and product identification procedures.

The Cordage Institute is an international association of rope, twine, and related manufacturers, their suppliers, and affiliated industries. Its mission is to create value for its members by educating product users, the standards writing community, government agencies, and other entities on the proper use of industry products through the dissemination of standards.

The Florida Attractions Association, founded in 1949, is a trade association representing 90+ family-oriented attractions. In addition, over 75 industry suppliers, allied trade associations, and destination marketing organizations are members of the Florida Attractions Association.

For more than 75 years, the Florida Transportation Builder’s Association (FTBA) has been Florida’s voice for the road and bridge building industry in Florida. Based in Tallahassee, FTBA is a nonprofit organization that exists to promote the importance of a strong, effective and integrated transportation system statewide.

Founded in 1918, IAAPA is the largest international trade association for permanently situated amusement facilities worldwide. The organization represents over 4,000 facility, supplier, and individual members from more than 93 countries. IAAPA strives to help members improve their efficiency, marketing, safety, and profitability while maintaining the highest possible professional standards in the industry.

SC&RA is an international trade association that is committed to providing the unique information and any other lawful activities members need to safely, legally and profitably transport, lift and erect oversize and overweight items. Members are involved in specialized transportation, machinery moving and erecting, industrial maintenance, millwrighting, crane and rigging operations, manufacturing and rental. SC&RA helps members run more efficient and safer businesses by monitoring and affecting pending legislation and regulatory policies at the state and national levels; researching and reporting on safety concerns and best business practices; and providing four yearly forums where these and other relevant member issues can be advanced.

The Web Sling & Tie Down Association (WSTDA) is a tax-exempt, non-profit, technical association dedicated to the development and promotion of voluntary recommended standards and associated reference materials.

The Association of Crane and Rigging Professionals (ACRP) is a nonprofit association whose mission is dedicated to improving crane operations and rigging activities in all industries. This is accomplished by providing educational opportunities to its members and the public.

A full service national trade association with a nationwide network of exceptional chapters, AGC represents nearly 30,000 leading firms in the industry – including general contractors, specialty contractors and service providers and suppliers. AGC members play a powerful role in sustaining economic growth, in addition to producing structures that add to productivity and the nation’s quality of life. AGC is truly the “voice and choice” of the construction industry.

AWRF promotes interests common among companies manufacturing, fabricating, or distributing lifting, rigging and load securement devices made of chain, rope, and synthetic products. The association works to establish, acquire, preserve, and disseminate various technical information, and encourages the development of safety standards and programs, and product identification procedures.

The Cordage Institute is an international association of rope, twine, and related manufacturers, their suppliers, and affiliated industries. Its mission is to create value for its members by educating product users, the standards writing community, government agencies, and other entities on the proper use of industry products through the dissemination of standards.

The Florida Attractions Association, founded in 1949, is a trade association representing 90+ family-oriented attractions. In addition, over 75 industry suppliers, allied trade associations, and destination marketing organizations are members of the Florida Attractions Association.

For more than 75 years, the Florida Transportation Builder’s Association (FTBA) has been Florida’s voice for the road and bridge building industry in Florida. Based in Tallahassee, FTBA is a nonprofit organization that exists to promote the importance of a strong, effective and integrated transportation system statewide.

Founded in 1918, IAAPA is the largest international trade association for permanently situated amusement facilities worldwide. The organization represents over 4,000 facility, supplier, and individual members from more than 93 countries. IAAPA strives to help members improve their efficiency, marketing, safety, and profitability while maintaining the highest possible professional standards in the industry.

SC&RA is an international trade association that is committed to providing the unique information and any other lawful activities members need to safely, legally and profitably transport, lift and erect oversize and overweight items. Members are involved in specialized transportation, machinery moving and erecting, industrial maintenance, millwrighting, crane and rigging operations, manufacturing and rental. SC&RA helps members run more efficient and safer businesses by monitoring and affecting pending legislation and regulatory policies at the state and national levels; researching and reporting on safety concerns and best business practices; and providing four yearly forums where these and other relevant member issues can be advanced.

The Web Sling & Tie Down Association (WSTDA) is a tax-exempt, non-profit, technical association dedicated to the development and promotion of voluntary recommended standards and associated reference materials.

PersonalWe are on hand to personally guide you through the entire process, we translate the jargon, we recommend what’s best, and we are always here in person. No nonsense, just straight talking people who always exceed expectations through our extensive wire rope knowledge and superior service.

OIPEEC is a worldwide association of scientists, experts, researchers, manufacturers and users dedicated to study properties and behavior of wire and fiber ropes.

OIPEEC collects and disseminates studies related to a wide range of applications such as, elevators, cranes, ropeways, rope for construction, large mooring lines, hoisting ropes for mines, deep-water lifting ropes, and industrial ropes.

American Wire Rope and Sling (AWRS) is part of ECP American Steel, LLC and its family of companies, including American Steel & Crane. Based in Fort Wayne, Indiana, AWRS has a long history of service to Indiana’s professional contractors and manufacturers that dates back to 1933.

Through quality service, American Wire Rope and Sling continues this tradition of providing name-brand products for the rigging industry. Proudly, AWRS has grown from its original home in Fort Wayne to one of the largest rigging houses in Indiana with branches in Indianapolis and Mishawaka.

Over the years, we have been the first in Indiana to: manufacture Single-Path & Twin-Path® round slings; manufacture and private-label our own line of nylon and polyester web slings; manufacture SLINGMAX® High Performance Fiber (HPF) slings and other products; patent a load-leveling device and HPF bridle slings; implement electronic sling inspections; operate six wire rope swaggers; operate five test beds including the largest in Indiana; operate 12 sewing machines; and operate two round sling machines.

AWRS is the only Indiana rigging house to hold membership in the leading industrial associations: Associated Wire Rope Fabricators (AWRF) and the Web Sling and Tie-Down Association (WSTDA). Individuals on our executive staff have served on the board and chaired various committees of these industry-leading associations.

To some, it’s just rope, cable or wire. To us, it’s the critical element to anchor, pull, lift, suspend, transmit or move your world. We have the innovative products, technical solutions and customized services to help you – wherever you are, whatever you need. The only limit is your imagination.

AWRF is a leading organization for sling fabricators and special rigging components manufacturers. The association works to promote safety standards for manufacturing, fabrication, and the distribution of lifting, rigging, and load securement devices.

“AWRF has an outstanding history of promoting the common interests of all stakeholders in the rigging industry. The association’s commitment to improving product identification procedures, technical expertise, and rigging safety has resulted in safer working conditions and saved lives. We are very proud to be a part of this exceptional organization,” said Kris Koberg, CEO of DICA. “With the addition of LiftGuard Magnetic Sling Protectors (formerly Linton Rigging Gear Supplies), helping contribute to safe rigging practices is an essential part of our mission to make your setup safe.”

For ease of use and additional safety, LiftGuard Edge Protectors attach magnetically to metallic surfaces and can be used with synthetic, wire rope or chain slings. LiftGuard Sling Protectors reduce liability issues by eliminating the need to use make-shift load or sling protection.

Founded in the 1800s, Industrial Wire Rope Supply Company is a family-owned business with corporate office in Cincinnati and a branch office in St.Charles, Missouri. We provide Wire Rope, Wire Rope Fittings, Fiber Rope, Chain, Nylon Slings, and Wire Rope Slings worldwide.

Wire Rope Fittings – Wire Rope Clips, Chain Shackles, Anchor Shackles, High-strength Alloy Shackles, Equalizing Thimbles, Gold Nose Sockets, and Turnbuckles

8613371530291

8613371530291