wire rope assy supplier

Wire assemblies are also useful in motion control and mechanical automation applications for not only lifting but pulling and support as well. Wire rope assemblies allow for the incorporation of wire cables into machinery or other equipment for use improving connectivity and versatility and to prevent damage, such as fraying, to the rope mechanisms.

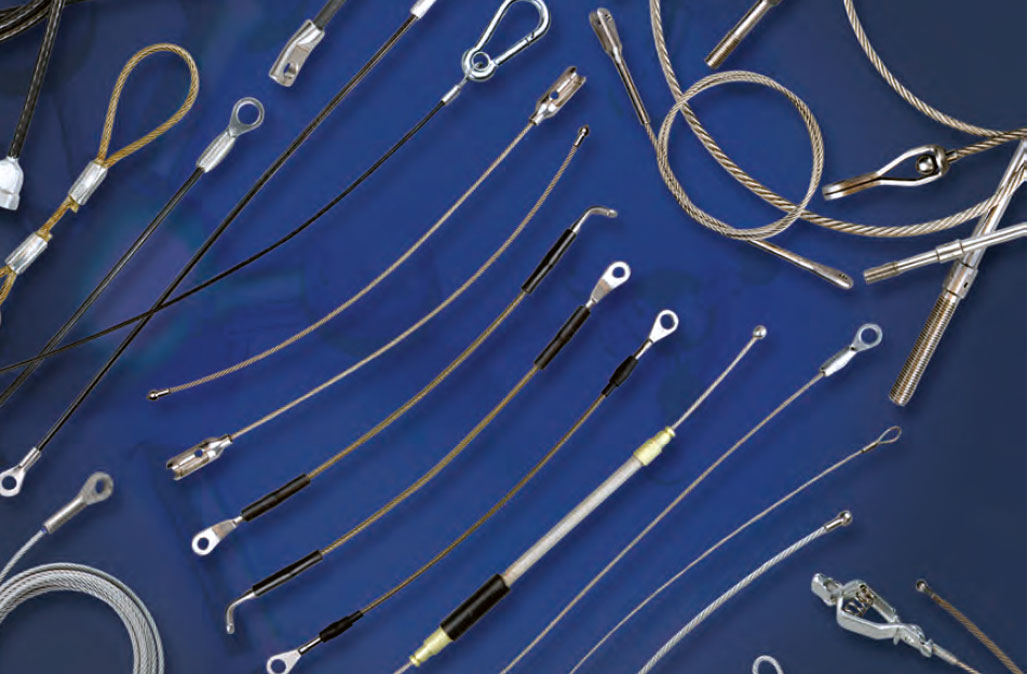

The capacity of a given system is determined by the type and placement of wire rope fittings in the assembly. Common fittings include clamps, clips, sleeves, links, hooks, forks, eyes, studs, and pins. The utility and added security afforded by wire rope assemblies allows their use in both commercial and residential arenas in addition to their traditional applications in the industrial sector.

As cables for heavy-duty hoisting vary considerably from those used to support a home shelving unit, it is vital that the intended use be considered when selecting the proper assembly. Wire rope manufacturers often provide a range of wire fitting options in order to accommodate the many different uses for the cables.

While specific fittings and terminations are achieved through various metal stamping, die cutting, or swaging techniques, the process of wire rope making is fairly uniform, though specifics will vary.

Wire ropes comprise the base or body of every assembly, these are the lengths of stranded wire cable that run between two fittings or pieces of equipment. Each rope consists of three main elements. Cold drawn metallic filaments are twisted or braided into strands which are in turn helically wrapped around a core, which may be metal or fiber based. The number of strands per cable and filaments per strand are used to identify wire ropes as are the lay or style in which each component was assembled.

Fittings and wires are commonly made of the same materials; most popular are durable metals. Steel and stainless steel, titanium, nickel alloys, and other metals are selected based on specific properties such as resistance to wear and corrosion, tensile strength, and weight to strength ratios.

Further considerations for wire rope assemblies include diameter, length, flexibility, difficulty of flattening, temperature resistance, and average lifespan.

Each use for a custom wire rope cable assembly has its own unique purpose. We can assist you in designing a custom cable assembly to fit your specific needs.

Tyler Madison, Inc. specializes in cable size from 3/64" - 3/8" in diameter and 270 lbs. - 14,400 lbs. in breaking strength. We will put our years of experience to work in helping you design and produce exactly what you need. We have manufactured quality custom wire rope cable assemblies for leading companies in the following industries:Aerospace

Tyler Madison is an industry leading manufacturer of wire rope cable assemblies and custom wire and cable. Our knowledge and experience give us the capability to manufacture standard and custom wire rope assemblies and products for a variety of industrial clients. With in-house engineering and design services, you can get the exact kinds of wire rope assemblies and steel wire cable products that you are looking for from one place at an affordable price. Call us today to find out what types of cable assemblies we can do for you!

Wire rope assemblies are completed cable systems that involve the cable or cables as well as any fittings in the form of additional hardware or rope termination techniques.

Wire ropes are used in a range of industries such as mining, oil rigging, bridge construction, marine, aerospace, transportation and material handling among others that require various heavy-duty lifting applications.

Wire assemblies are also useful in motion control and mechanical automation applications for not only lifting, but pulling and support as well. Wire rope assemblies allow for the incorporation of wire cables into machinery or other equipment for use improving connectivity, versatility and preventing damage, such as fraying, to the rope mechanisms. The capacity of a given system is determined by the type and placement of wire rope fittings in the assembly.

Common fittings include clamps, clips, sleeves, links, hooks, forks, eyes, studs and pins. The utility and added security afforded by wire rope assemblies allows their use in both commercial and residential arenas in addition to their traditional applications in the industrial sector. As cables for heavy-duty hoisting vary considerably from those used to support a home shelving unit, it is vital that the intended use be considered when selecting the proper assembly. Wire rope manufacturers often provide a range of wire fitting options in order to accommodate the many different uses for the cables.

While specific fittings and terminations are achieved through various metal stamping, die cutting or swaging techniques, the process of wire rope making is fairly uniform though specifics will vary. Wire ropes comprise the base or body of every assembly, these are the lengths of stranded wire cable that run between two fittings or pieces of equipment.

Each rope consists of three main elements. Cold drawn metallic filaments are twisted or braided into strands which are in turn helically wrapped around a core, which may be metal or fiber based. The number of strands per cable and filaments per strand are used to identify wire ropes as are the lay or style in which each component was assembled.

Further considerations for wire rope assemblies include diameter, length, flexibility, difficulty of flattening, temperature resistance and average lifespan. Assemblies are carefully regulated and should be inspected regularly to avoid potentially costly and dangerous mechanical failure.

Fittings and wires are commonly made of the same materials; most popular are durable metals. Steel and stainless steel, titanium, nickel alloys and other metals are selected based on specific properties such as resistance to wear and corrosion, tensile strength and weight to strength ratios.

For over 40 years, we have served nearly every industry with top-quality wire rope and cable solutions. Whether you"ve been working with wire rope for years, require a highly specialized solution, or are still searching for what you need, we can help.

ISO 9001 & AS 9120 certified 8(m)WOSB certified custom manufacturer of corrossion resistant galvanized aircraft stainless steel metal safety cable and wire braid materials include braided cords with wire center for aeronautical, aerospace, halyard, helicopter lead line, sailboat, rigging, hoisting, automotive applications and more. Wire rope products are available in 1x7 strand through 6x36 strand for aircraft cable, non rotating and non flexible applications. Custom coatings and finishes available for aerospace, automotive, safety applications. Also offers custom braids in specialty colors, finishes, and materials such as aramid, ceramic, Dyneema®, fiberglass, Kevlar®, linen, Nomex®, plasma, Spectra®, tarred, marlin, Technora™, Twaron®, and Vectran™. Galvanized aircraft wire ropes and cables available in 302/304, 305, and 316 stainless steel and zinc-coated carbon steel materials. Offers non-flexible types in 1 x 7 and 1 x 19 strand models. Suitable for aeronautical, logging, hoisting, aircraft control, and winching applications.

ISO 9001:2000 certified manufacturer & distributor of standard & custom rigging equipment & supplies including wire rope cable assemblies & military wire rope assemblies. Products include wire ropes, single & multi-cavity swaging tools, wire rope cutters, oval swage sleeves, stop sleeves, heavy duty thimbles, wire rope clips, quick links, wire termination stake eyes, shank & plain balls swages, lifting eyebolts & nuts, bow & twisted shackles, rope pulleys, round rings, turnbuckles, fixed eyes, swivel eyes & swivel shackles, sailboat halyard kits, arborist flip lines, climbing helmets & ascenders & descenders. Types of hooks include snap hooks, chain & tow snap hooks, carbine type snap hooks, ladder hooks & carabiners & safety snap hooks.

Continental Cable employs 65 people specializing in the manufacture of custom mechanical wire rope cable assemblies. Other product lines include stainless steel and galvanized aircraft cable, a complete line of cable related hardware and tools and plastic coated cable.

SWR manufactures high quality wire rope assemblies for a wide variety of applications. All assemblies are manufactured in-house by our fully trained engineers with each assembly being supplied with full traceability and test certificates in line with our ISO9001 Quality Management System.

Our standard production encompasses wire rope slings and assemblies from 0.5mm through to 32mm diameter, in galvanised, stainless steel and plastic covered wire rope. Including the equipment to produce bespoke solutions to your specific requirements. Whilst we produce assemblies to order, above are some of the standard ranges readily available from stock.All materials are fully traceable and we have our own in-house proof load and destruction testing facility.

At Carl Stahl Sava Industries, manufacturing a comprehensive family of cable, stainless steel wire rope fittings and tools only explain a portion of what makes us so special as a cable assembly manufacturer. In addition to possessing an ISO 9001:2015 certification, Sava is also FDA and ITAR registered, as well as RoHS and REACH certified. Our wire rope manufacturing process leverages almost 50 years of engineering and manufacturing expertise that customers around the world have grown to depend upon every single day. Additionally, Sava’s sales professionals boast over 100 years of combined technical experience helping organizations just like yours meet the most complex and sophisticated application requirements.

To quickly see top wire rope assembly manufacturers and industrial suppliers that ... Wire rope assemblies are completed cable systems that involve the cable or ...

Manufacturer of wire rope assemblies, lanyards, custom cable assemblies. Wire rope cables for latches, doors, tethers, locks, support cables, restraint cables.

A wide variety of assembly wire rope options are available to you, You can also choose from unisex, assembly wire rope,As well as from black, red, and brown. And whether assembly wire rope is waterproof, {2}, or {3}.

We advise you on the selection of the suitable wire rope or the right strand for your application. Thanks to the wide range of options, we can offer steel wire ropes for a wide variety of applications. All TechnoCables are manufactured from wires of high tensile strength. Years of experience and a continuous quality assurance chain from incoming goods to dispatch are a guarantee for the highest level of reliability and quality. This makes us your reliable partner for all rope applications.

We offer ropes in the range under 1 mm to 8 mm. Fine ropes with a small diameter are used in medical technology for example. Wire ropes with a larger diameter in mechanical engineering or in the field of sun protection.strands 0.09 mm - 5.0 mm

The selection of the suitable material depends on the area of application. Steel wire ropes are in many cases the most economical option. For many areas of application, ropes made of galvanized steel have adequate corrosion protection. We recommend the use of stainless steel cables for applications with a high corrosion potential.Galvanized steel ropes and strands

Strands are made by stranding wires and are the basic for further rope manufacturing. 3 to 37-wire strands are stranded here. As the number of wires increases, the flexibility of the rope and thus the fatigue strength increases. A strand, rope or fiber insert can be used as the insert.Steel wire ropes

Order wire rope separately from the factory or a reputable supplier. The breaking strength of new wire rope should be 5 times the size of the largest load for lifting applications, and 3 times the size of the largest load for pulling applications. Contact a reputable wire rope supplier for more information.

8613371530291

8613371530291