wire rope austin free sample

D&A Wire Rope offers a variety of options for cable railings. We have end fittings for wood and steel posts, straight runs, and stairs. Our team can help you determine the best fittings for your job.

There are many options for cable railings on the internet, but none provide you with the benefits of buying local. The biggest benefit of buying local is the ability to fit a "test run" before ordering for the entire project. A test run is one cable for each section to ensure proper fit and tightening.

D&A Wire Rope takes pride in having served the Central Texas area for over 20 years.Our experience and expertise helps your job site work safely, efficiently, and economically.

We stock a wide variety of high quality lifting, rigging, and load securement products, including industry standard Crosby. We stock lifting slings of all types (wire rope, chain, nylon, polyester), lengths of wire rope, chain, and rope cut to order, shackles, hooks, and all associated fittings and equipment.

We strive to provide each customer with exceptional service.All assemblies are manufactured in our Austin, Texas facility, which enables us to provide a customized product with a short turn-around to keep your job site working.

Rigging, Lifting, Load security, Slings, Wire Rope, Chain, Nylon and Polyester Webbing, Cordage, Fittings, Proof-Testing, Towing Supplies, Architectural Cable, Stainless Steel Railings, Cable Railing Systems, Cable Tension Systems, Marine Cable, Marine Fittings…

CLEVELAND, OH – Mazzella Lifting Technologies, a Mazzella Company, is pleased to announce the acquisition of Denver Wire Rope & Supply. This acquisition will strengthen Mazzella’s footprint west of the Mississippi River and reinforce Mazzella’s commitment to be a one-stop resource for lifting and rigging services and solutions.

Denver Wire Rope & Supply has been in business since 1983 and services a variety of industries out of their location in Denver, CO. Denver Wire Rope & Supply is a leading supplier of rigging products, crane and hoist service, below-the-hook lifting devices, and certified rigging inspection and training. Effective immediately, Denver Wire Rope & Supply will operate as Mazzella / Denver Wire Rope. Terms of the transaction are not being disclosed.

“Denver Wire Rope & Supply will complement the wide range of products and services that Mazzella Companies offers. We are dedicated to being a single-source provider for rigging products, overhead cranes, rigging inspections, and rigging training. Both companies commit to a customer-first mentality, providing the highest-quality products, and leading by example when it comes to safety and sharing our expertise with customers and the market,” says Tony Mazzella, CEO of Mazzella Companies.

“Our team and family are excited to be part of the Mazzella Companies. This acquisition strengthens our place in the market and allows our team to continue to provide excellent service and products to our valued customer base and expand our offering,” says Ken Gubanich, President of Denver Wire Rope & Supply.

“Over the years, we have had numerous companies show interest in purchasing Denver Wire Rope & Supply, none seemed to be the right fit. We are looking forward to becoming a part of an aggressive, passionate, and progressive organization. As a family business for over 36 years, it is important to us that our customers/friends, suppliers, and team members continue to be treated with first-class service, products, and employment opportunities. Again, we are very enthusiastic about our future and look forward to being a quality supplier for your crane, safety training, rigging, and hoisting needs for years to come,” says Gubanich.

“We wish Ed and Carol Gubanich all the best in their retirement. We welcome Ken and the other second and third-generation Gubanich family members, as well as the entire Denver Wire Rope Team, into the Mazzella organization,” says Mazzella.

We’ve changed our name from Denver Wire Rope to Mazzella. Aside from the new name and logo, our member experience is virtually unchanged. Here are some common questions and answers related to this change.

In 2019, Denver Wire Rope & Supply was acquired by Mazzella Companies to expand lifting and rigging products and services to the western half of the United States.

In 1954, James Mazzella founded Mazzella Wire Rope & Sling Co. in Cleveland, OH. For over 65 years, the company has grown organically by nurturing historic relationships, expanding its product offerings, and entering new markets through acquisition.

D&A Wire Rope Inc has worked on 6 jobs in the last 12 months. Subs and vendors reported being paid on-time on 100% of projects. This contractor scores a C for payment and ranks in the bottom 15% of small U.S. contractors.

The magnetic rope testing method is one of the common ways of damage detection for steel wire ropes. This is a non-destructive method, having the advantage of a serviceable methodology operating in the frame of available European regulations [1]. This method usage is restricted to steel wire ropes, and it is able to provide useful information related to multiple cracks due to fretting fatigue on peculiar locked coil structure ropes.

One other direction for non-destructive testing and damage detection in cables and wire ropes is represented by the investigations on guided wave propagation phenomena. Hereby, in [2], the authors analyzed the ultrasonic guided waves with application on SHM of multi-wire cables, because of their advantages, including requires a single measurement, large coverage of the acoustic field, and long-range propagation capability. This method presents some difficulties related to the propagation behaviors of guided waves and signal analyses, due to the mechanical coupling of multi-wire ensembles. This was the motivation of the authors to investigate the ultrasonic guided waves propagation in such waveguides. It should be noted that this study contains theoretical, computational, and experimental approaches regarding this problem.

Another interesting study is presented in [3], where, beyond the advantages of guided ultrasonic waves for SHM applications, the authors treated the dispersion curves as a main tool intended for deployment of any guided wave application. An experimental based technique was presented, which provides rapid generation of dispersion curves, in the presence of unknown properties for both material and inspected structure. It should be underlined that the proposed method uses a single source and two acquisition points, thus is experimentally simple to use. The method was validated using synthesized signals, finite element simulations, and experimental tests, with the final accuracy of 1% of the velocity. The authors supposed that the relative error in the calculated velocity due to misplacement is the same as the relative distance error, due to the linearity of velocity–distance relationship [3]. Thus, the reported accuracy has results for 1 mm error of transducer position and 100 mm spacing [3].

A numerical investigation, related to elastic guided waves propagation within a single helical wire, in terms of dispersion curves, was proposed by Treyssède [4]. The finite element method was used to study the wave propagation inside periodic structures, and a new method that avoids the tedious writing of equilibrium equations in a curvilinear coordinate system was developed. The author compared numerical results with the Pochhammer–Chree solutions for infinite isotropic cylinder, in order to evaluate the convergence and accuracy. In addition, for low frequency range, the results were validated with a helical Timoshenko beam model.

Baltazar et al. [5] proposed an interesting experimental based analysis. They considered multi-wire aluminum conductor steel reinforced cable and analyzed the guided waves propagation using time–frequency techniques. A notch, made transversal to the pulse propagation, was used to artificially damage the cable. They concluded that a conversion of longitudinal to flexural modes appeared due to the mechanical contact among the wires. These findings demonstrate that it is difficult to carry out an analysis based on longitudinal or transversal mode identification exclusively.

Kwun and Bartels [6] presented some experimental investigations and observations related to elastic wave dispersion within bounded solids of various configurations. They used an efficient technique consisting of a short elastic wave pulse transmission into the inspected material, with detection of transient waveforms of the transmitted wave, with the help of two non-contacting magnetostrictive devices, followed by classical joint time–frequency analysis of acquired signal. These studies were performed for a large group of solids, between them being a multi-wire rope, and the results were discussed in the frame of available theory.

Schaal et al. [7] considered a structural health investigation algorithm, based on the Hilbert transform applied on the acquired signals from induced guided ultrasonic waves. A practical application on damage detection in multi-wire rope was presented. The proposed algorithm evaluates the time-of-flight of the wave packets, and it can distinguish between the packets from different waves independently. The wave amplitude was also considered as a practical method for damage identification. Note that the method was tested on laboratory setup for single- and multi-wire ropes.

According to the above-mentioned studies, theoretical, computational, and experimental, any of the proposed approaches can be assessed by using proper post-processing techniques applied onto the acquired guided wave signals. Thus, an interesting and useful research was proposed by Wilcox [8]. Starting from the hypotheses that the pulse of energy will spread out in space and time if a guided wave mode is dispersive, which constrains the choice of operating point for a long-range application, the author proposed a signal processing method, which enables the relaxation of this constraint. The author of [8] reported the theoretical basics and an efficient numerical implementation of this method. In addition, an application to experimental signals was provided, in which the improvement in spatial resolution was demonstrated.

Another efficient possibility of recorded signals post-processing, for the case of ultrasonic guided waves was presented in [9]. The basic idea is an entropy-based method to identify the small changes within non-stationary acquired signals. The authors supposed that propagated waves are composed of an infinite number of dispersive vibration modes, which implies difficulties on their analysis. Their method was based on the discrete wavelet transform and the concept of the entropy evolution of non-stationary signals. The analyses were performed using an experimental system, for single- and multi-wire ropes, and the results provide good correlation between the entropy value and level of damage within the wire rope. A high level of correlation was observed even for single-wire damage or condition changes of mechanical contact among the wires. It has to be noted that the proposed method provides low sensitivity to the noise within the signals.

This brief state of the art regarding wire ropes condition monitoring cannot be ended without mentioning some relevant review articles. Firstly, the review article of Schlanbusch et al. [10] refers to the condition monitoring for steel wire ropes. The authors studied offshore wire ropes, firstly presenting the main sources of degradation that typically affect the functionality and, sometimes, accelerate the failure of these ropes. After this introduction, the available non-destructive testing techniques were surveyed, with underlining the electromagnetic based methods that are widely used in mining and construction fields. The review considers the developments within the last years related to the topics of electromagnetic method, acoustic emissions, ultrasound, X- and γ-rays, fiber optics, optical and thermal vision, and current signature analysis. Each method is thoroughly presented. Discussions are focused on the primary methods’ capabilities as follows: proper detection and localization of broken wire, loss estimation of metallic cross-sectional area, robustness (supposing the rough offshore environment), evaluation of both rope and end fittings, and the ability to perform operational tests and analyses.

The authors of [11] provided a useful overview of non-destructive damage detection studies of wire ropes. They also discussed the core issues within this topic. The damage type is firstly introduced, and its causes are systematically explained. Then, the main non-destructive detection techniques are summarized, including electromagnetic detection method, optical detection method, ultrasonic guided wave detection method, and acoustic emission detection method [11].

Condition monitoring of strands wire ropes clearly benefits from the multiple methods available. The previous mentioned review articles [10,11] thoroughly describe the latest technologies in this area. This briefly introduction mainly contains references to electromagnetic and guided wave propagation-based methods because of their good operability and wide utilization within various fields of engineering applications. The authors do not propose to present a comprehensive review of available literature on this research domain. The goal of this short introduction is to underline the following aspects: (a) the availability of various methods and techniques for damage identification within wire ropes; (b) the studies have mainly focused on localization of potential damages, losing sight of the fact that the damage magnitude counts more than position regarding the wire rope failure that finally imposes cable changing; and (c) the gaps regarding vibration-based investigation methods. Additionally, the authors consider that none of the available methods can provide enough capabilities regarding performing operational investigation in the case that the continuously monitoring mode is required.

Hereby, within the field of current signature analysis, the operational dynamic regime investigations, followed by proper post-processing procedures, allow continuous providing of useful information related to permanent structural health monitoring, potential damage detection, and failure imminence estimation. This paper proposes a vibration-based technique for damage monitoring within strands wire rope. Application simplicity, reduced set of experiments, continuous mode operating, and operational investigation enabling frame are the advantages of this technique.

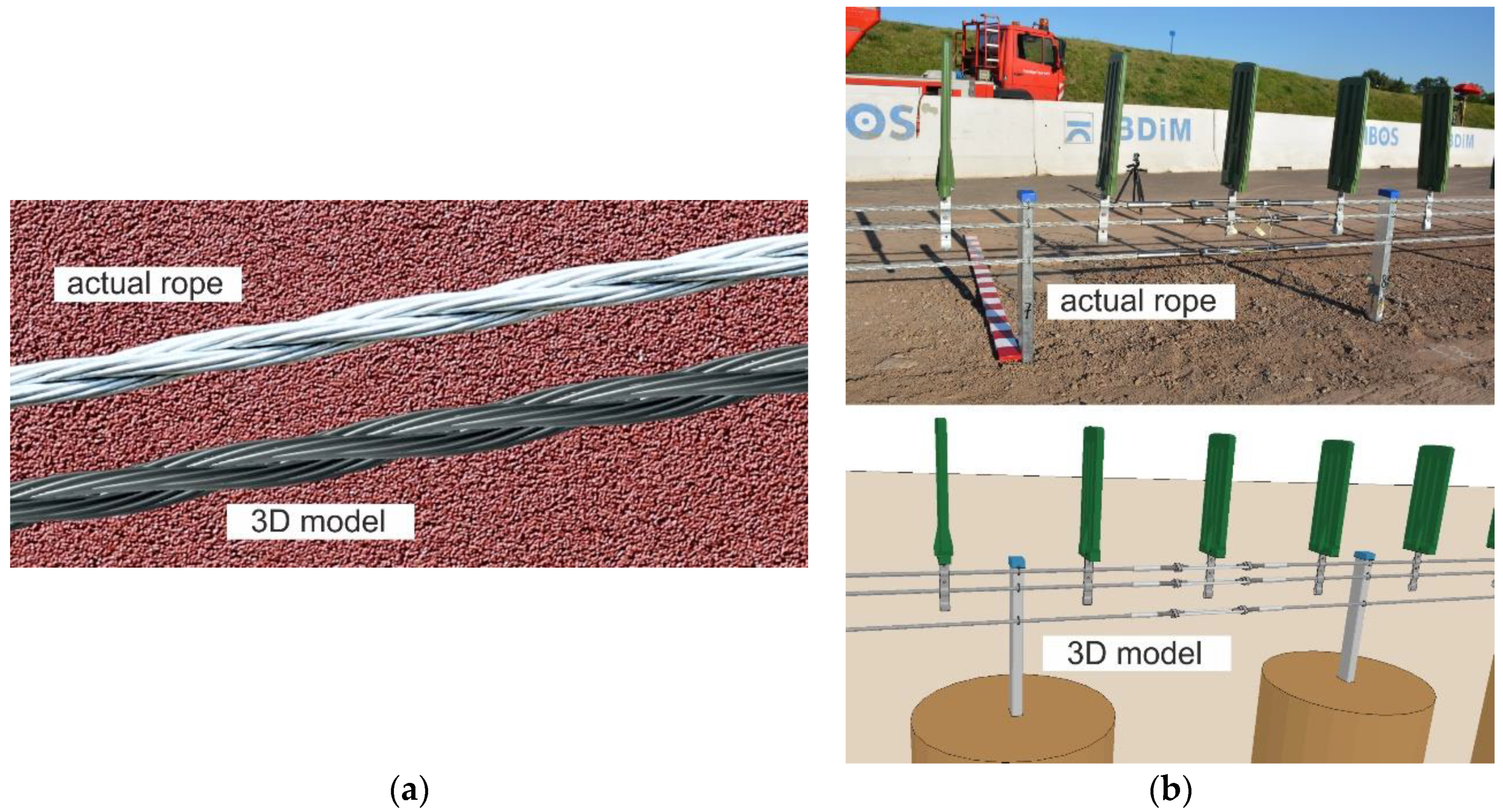

This paper presents an experimentally-based approach for a multi-wire steel strands rope (MWSSR) sample with fiber core (FC), together with a group of useful post-processing techniques, to provide accurate data regarding the changes within the current dynamic signature of MWSSR system due to certain steel wire degradation. The experimental setup for wire rope dynamics investigations, wire rope sample characteristics, testing schedule, and theoretical basics for signals processing are fully detailed within Section 2. The results yielded for tree significant cases of artificially induced damages within the rope structure are presented in Section 3. The results are individually analyzed and comparatively discussed within Section 4. Section 5 contains a few concluding remarks that try to underline the relevance of proposed methodology in this study.

8613371530291

8613371530291