wire rope bending stiffness made in china

As shown in Figure 1, a kind of steel wire rope for elevator bending stiffness measuring instrument, is characterized in that it comprises bedplate 1, puller system 2, cylinder 3, dip stick 4, sliding floor 5, slide block 6, contiguous block 7, guide rail I 8, guide rail II 9, slip pinch roller 10, support wheel 11, measures pinch roller 12, holding screw 13 and set screw 14; Bedplate 1 is provided with two parallel chutes 1.1, chute 1.1 is connected with a slip pinch roller 10 respectively by holding screw 13, bedplate 1 between two chutes 1.1 is provided with two parallel guide rails I 8, sliding floor 5 is arranged on two guide rails I 8, puller system 2 and cylinder 3 is connected in sliding floor 5 side, be connected with a measurement pinch roller 12 at the middle part of sliding floor 5 opposite side by contiguous block 7, dip stick 4 is located on the bedplate 1 below sliding floor 5; Guide rail II 9 is arranged on sliding floor 5 and connects on the bedplate 1 of measurement pinch roller 12 side, guide rail II 9 is parallel with sliding floor 5, two support wheels 11 are arranged on guide rail II 9 by slide block 6, and slide block 6 is provided with a set screw 14, and set screw 14 is for being fixed on guide rail II 9 by slide block 6.

Principle of work of the present utility model is, first unclamp holding screw 13 and set screw 14, slidable adjustment two support wheel 11 on guide rail II 9, measurement pinch roller 12 is made to be positioned at the centre of two support wheels 11, by set screw 14, slide block 6 is fixed on guide rail II 9, measuring steel wire 15 is placed on two support wheels 11, slip slip pinch roller 10 is to fix steel wire 15 two ends, slip slip pinch roller 10 is fixed in chute 1.1 by holding screw 13, promote sliding floor 5 by gas piping 16 to cylinder 3 input service pressure gas to slide, measurement pinch roller 12 is made to touch wire rope, now puller system 2 is set to 0, promote sliding floor 5 by cylinder 3 again to slide measurement pinch roller 12 is buckled camber that wire rope reaches required, the numerical value reading puller system 2 thus and the displacement of sliding floor 5 recorded by dip stick 4.

Q. Li, Y. Zhu, D. Xu, J. Hu, W. Min and L. Pang, A negative stiffness vibration isolator using magnetic spring combined with rubber membrane, Journal of Mechanical Science and Technology, 27 (2013) 813–824.

G. F. Demetriades, M. C. Constantinou and A. M. Reinhorn, Study of wire rope systems for seismic protection of equipment in buildings, Engineering Structures, 15 (1993) 321–334.

P. S. Balaji, L. Moussa, M. E. Rahman and L. Vuia, Experimental investigation on the hysteresis behavior of the wire rope isolators, Journal of Mechanical Science and Technology, 29 (2015) 1527–1536.

Z. H. Zhu and S. A. Meguid, Nonlinear FE-based investigation of flexural damping of slacking wire cables, International Journal of Solids and Structures, 44 (2007) 5122–5132.

Y. Prawoto and R. B. Mazlan, Wire ropes: Computational, mechanical, and metallurgical properties under tension loading, Computational Materials Science, 56 (2012) 174–178.

X. Huang and O. Vinogradov, Analysis of dry friction hysteresis in a cable under uniform bending, Structural Engineering and Mechanics, 2 (1994) 63–80.

X. Li, S. Wang and J. Zhou, Analysis of elliptical Hertz contact of steel wires of stranded-wire helical spring, Journal of Mechanical Science and Technology, 28 (2014) 2797–2806.

W. G. Jiang, M. S. Yao and J. M. Walton, A concise finite element model for simple straight wire rope strand, International Journal of Mechanical Sciences, 41 (1999) 143–161.

E. Stanova, G. Fedorko, M. Fabian and S. Kmet, Computer modelling of wire strands and ropes Part I: Theory and computer implementation, Advances in Engineering Software, 42 (6) (2011) 305–315.

E. Stanova, G. Fedorko, M. Fabian and S. Kmet, Computer modelling of wire strands and ropes part II: Finite element-based applications, Advances in Engineering Software, 42 (6) (2011) 322–331.

ASTM A931-08 (2013) Standard test method for tension testing of wire ropes and strand, ASTM International, West Conshohocken, PA, www.astm.org (2013).

Wire rope and cable are each considered a “machine”. The configuration and method of manufacture combined with the proper selection of material when designed for a specific purpose enables a wire rope or cable to transmit forces, motion and energy in some predetermined manner and to some desired end.

Two or more wires concentrically laid around a center wire is called a strand. It may consist of one or more layers. Typically, the number of wires in a strand is 7, 19 or 37. A group of strands laid around a core would be called a cable or wire rope. In terms of product designation, 7 strands with 19 wires in each strand would be a 7×19 cable: 7 strands with 7 wires in each strand would be a 7×7 cable.

Materials Different applications for wire rope present varying demands for strength, abrasion and corrosion resistance. In order to meet these requirements, wire rope is produced in a number of different materials.

Stainless Steel This is used where corrosion is a prime factor and the cost increase warrants its use. The 18% chromium, 8% nickel alloy known as type 302 is the most common grade accepted due to both corrosion resistance and high strength. Other types frequently used in wire rope are 304, 305, 316 and 321, each having its specific advantage over the other. Type 305 is used where non-magnetic properties are required, however, there is a slight loss of strength.

Galvanized Carbon Steel This is used where strength is a prime factor and corrosion resistance is not great enough to require the use of stainless steel. The lower cost is usually a consideration in the selection of galvanized carbon steel. Wires used in these wire ropes are individually coated with a layer of zinc which offers a good measure of protection from corrosive elements.

Cable Construction The greater the number of wires in a strand or cable of a given diameter, the more flexibility it has. A 1×7 or a 1×19 strand, having 7 and 19 wires respectively, is used principally as a fixed member, as a straight linkage, or where flexing is minimal.

Selecting Wire Rope When selecting a wire rope to give the best service, there are four requirements which should be given consideration. A proper choice is made by correctly estimating the relative importance of these requirements and selecting a rope which has the qualities best suited to withstand the effects of continued use. The rope should possess:Strength sufficient to take care of the maximum load that may be applied, with a proper safety factor.

Strength Wire rope in service is subjected to several kinds of stresses. The stresses most frequently encountered are direct tension, stress due to acceleration, stress due to sudden or shock loads, stress due to bending, and stress resulting from several forces acting at one time. For the most part, these stresses can be converted into terms of simple tension, and a rope of approximately the correct strength can be chosen. As the strength of a wire rope is determined by its, size, grade and construction, these three factors should be considered.

Safety Factors The safety factor is the ratio of the strength of the rope to the working load. A wire rope with a strength of 10,000 pounds and a total working load of 2,000 pounds would be operating with a safety factor of five.

It is not possible to set safety factors for the various types of wire rope using equipment, as this factor can vary with conditions on individual units of equipment.

The proper safety factor depends not only on the loads applied, but also on the speed of operation, shock load applied, the type of fittings used for securing the rope ends, the acceleration and deceleration, the length of rope, the number, size and location of sheaves and drums, the factors causing abrasion and corrosion and the facilities for inspection.

Fatigue Fatigue failure of the wires in a wire rope is the result of the propagation of small cracks under repeated applications of bending loads. It occurs when ropes operate over comparatively small sheaves or drums. The repeated bending of the individual wires, as the rope bends when passing over the sheaves or drums, and the straightening of the individual wires, as the rope leaves the sheaves or drums, causing fatigue. The effect of fatigue on wires is illustrated by bending a wire repeatedly back and forth until it breaks.

The best means of preventing early fatigue of wire ropes is to use sheaves and drums of adequate size. To increase the resistance to fatigue, a rope of more flexible construction should be used, as increased flexibility is secured through the use of smaller wires.

Abrasive Wear The ability of a wire rope to withstand abrasion is determined by the size, the carbon and manganese content, the heat treatment of the outer wires and the construction of the rope. The larger outer wires of the less flexible constructions are better able to withstand abrasion than the finer outer wires of the more flexible ropes. The higher carbon and manganese content and the heat treatment used in producing wire for the stronger ropes, make the higher grade ropes better able to withstand abrasive wear than the lower grade ropes.

Effects of Bending All wire ropes, except stationary ropes used as guys or supports, are subjected to bending around sheaves or drums. The service obtained from wire ropes is, to a large extent, dependent upon the proper choice and location of the sheaves and drums about which it operates.

A wire rope may be considered a machine in which the individual elements (wires and strands) slide upon each other when the rope is bent. Therefore, as a prerequisite to the satisfactory operation of wire rope over sheaves and drums, the rope must be properly lubricated.

Loss of strength due to bending is caused by the inability of the individual strands and wires to adjust themselves to their changed position when the rope is bent. Tests made by the National Institute of Standards and Technology show that the rope strength decreases in a marked degree as the sheave diameter grows smaller with respect to the diameter of the rope. The loss of strength due to bending wire ropes over the sheaves found in common use will not exceed 6% and will usually be about 4%.

The bending of a wire rope is accompanied by readjustment in the positions of the strands and wires and results in actual bending of the wires. Repetitive flexing of the wires develops bending loads which, even though well within the elastic limit of the wires, set up points of stress concentration.

The fatigue effect of bending appears in the form of small cracks in the wires at these over-stressed foci. These cracks propagate under repeated stress cycles, until the remaining sound metal is inadequate to withstand the bending load. This results in broken wires showing no apparent contraction of cross section.

Experience has established the fact that from the service view-point, a very definite relationship exists between the size of the individual outer wires of a wire rope and the size of the sheave or drum about which it operates. Sheaves and drums smaller than 200 times the diameter of the outer wires will cause permanent set in a heavily loaded rope. Good practice requires the use of sheaves and drums with diameters 800 times the diameter of the outer wires in the rope for heavily loaded fast-moving ropes.

It is impossible to give a definite minimum size of sheave or drum about which a wire rope will operate with satisfactory results, because of the other factors affecting the useful life of the rope. If the loads are light or the speed slow, smaller sheaves and drums can be used without causing early fatigue of the wires than if the loads are heavy or the speed is fast. Reverse bends, where a rope is bent in one direction and then in the opposite direction, cause excessive fatigue and should be avoided whenever possible. When a reverse bend is necessary larger sheaves are required than would be the case if the rope were bent in one direction only.

Stretch of Wire Rope The stretch of a wire rope under load is the result of two components: the structural stretch and the elastic stretch. Structural stretch of wire rope is caused by the lengthening of the rope lay, compression of the core and adjustment of the wires and strands to the load placed upon the wire rope. The elastic stretch is caused by elongation of the wires.

The structural stretch varies with the size of core, the lengths of lays and the construction of the rope. This stretch also varies with the loads imposed and the amount of bending to which the rope is subjected. For estimating this stretch the value of one-half percent, or .005 times the length of the rope under load, gives an approximate figure. If loads are light, one-quarter percent or .0025 times the rope length may be used. With heavy loads, this stretch may approach one percent, or .01 times the rope length.

The elastic stretch of a wire rope is directly proportional to the load and the length of rope under load, and inversely proportional to the metallic area and modulus of elasticity. This applies only to loads that do not exceed the elastic limit of a wire rope. The elastic limit of stainless steel wire rope is approximately 60% of its breaking strength and for galvanized ropes it is approximately 50%.

Preformed Wire Ropes Preformed ropes differ from the standard, or non-preformed ropes, in that the individual wires in the strands and the strands in the rope are preformed, or pre-shaped to their proper shape before they are assembled in the finished rope.

This, in turn, results in preformed wire ropes having the following characteristics:They can be cut without the seizings necessary to retain the rope structure of non-preformed ropes.

They are substantially free from liveliness and twisting tendencies. This makes installation and handling easier, and lessens the likelihood of damage to the rope from kinking or fouling. Preforming permits the more general use of Lang lay and wire core constructions.

Removal of internal stresses increase resistance to fatigue from bending. This results in increased service where ability to withstand bending is the important requirement. It also permits the use of ropes with larger outer wires, when increased wear resistance is desired.

Outer wires will wear thinner before breaking, and broken wire ends will not protrude from the rope to injure worker’s hands, to nick and distort adjacent wires, or to wear sheaves and drums. Because of the fact that broken wire ends do not porcupine, they are not as noticeable as they are in non-preformed ropes. This necessitates the use of greater care when inspecting worn preformed ropes, to determine their true condition.

In this research paper design and analysis of wire ropes used in elevator have been presented. The main objective of this study is to find the best practices on handling wire ropes for safety and to reduce the downtime of elevators due to wire rope failures. Design calculations have been done to calculate the apt dimensions and design is constructed on Auto Desk inventor software and the analysis have been performed using Ansys. Two configurations of the wire ropes have been studied and from this result it can be concluded that the design of wire rope is possible to relieve mechanical handling and to improve the design of wire ropes making it more durable by possible inclusion of new materials which in turn increases the efficiency and life of wire ropes without compromising safety.

Wire ropes are used for lifting and hoisting in cranes and elevators. They are commonly used for hoisting in elevator cars. The different types of wire ropes have been designed and tested for various applications to carry a tensile load. So, these types of wire are tested for both static and fatigue loading and these loads are transmitted through a flexible member [1,2]. Wire ropes are structural elements commonly used in industries and civil engineering domain. They consist of several steel wires twisted on the central core to improve the axial strength, stiffness and bending flexibility which in turn increases the mechanical properties. Wire ropes are usually made of many structures and they can fulfil their task of carrying tensile load without breaking [3]. Wire ropes are usually subjected to varying axial tensile loads or torsional moments resulting in unstable performances [4]. So, in this context wire ropes are usually analysed for stress and strain to study its mechanical strength [5] and hence research on this wire ropes are significant.

Wire ropes are composed of several twisted wires in a specific arrangement strands and then wound in a helical pattern around the central core. Imrak and Erdonmez [6] have studied new techniques in modelling of wire ropes. Initially they developed a modelling of wire rope using simple straight strand and they adapted this procedure for whole wire rope structure using double helical geometry. They concluded this modelling procedure is easier and effective. Their results showed good agreement with other available literature and is considered simpler.

Fatigue performance in case of wire ropes depends on crack propagation which occurs in the internal and external cross sections of the wire rope and its ability to withstand abrasion and plasticity after long use [7]. So, the design of rope is carefully selected and constructed, and the lubricants are used to reduce the localized friction of individual wires in the strand. Kim et al. [8] have studied effect of wire rope diameter and tensile stress to study the life of wire rope. They considered five wire rope of 8 mm and 10 mm wire diameter and applied a constant tensile load and observed bending fatigue strength for different cycles. They concluded that the fracture surface area was larger in case of larger wire diameter and these data can be used to study the structural integrity in case of wire rope. The applications and the method of manufacturing wires are different for different equipment and it depends upon surface finish, texture lay, whirling grade, stress capacity, tolerance etc. [9]. So, it has become quite normal to expect wire rope construction from varying manufacturers, it becomes necessary to perform some mandatory tests before to determine various responses and reactions to various loading conditions. Barkany et al. [10] have studied non-destructive evaluation and discard criteria of wire rope giving importance to internal damage. They used the electromagnetic non-destructive and other methods to study the broken wire used in crane ropes and hoist ropes. They recommended to conduct magnetic test every year to check the failure criteria of wire rope. Sukhorukov et al. [11] have studied electromagnetic non-destructive inspection to inspect the wire ropes commonly used in oil and gas and mining industries. They concluded that electromagnetic non-destructive methods can be used to meet the challenges to study the failure and discard criteria. Rostami et al. [12] have studied the condition monitoring of a steel wire rope which was broken due to corrosive and fatigue used in case of hoisting elevator. They used finite element analysis to study wave propagation in wire ropes. They concluded by recording those wave propagations to analyse the wire rope. Zhang et al. [13] have studied electromagnetic techniques to study the wire rope. They designed a sensor to detect the broken wire using magnetic flux leakage method. They concluded that the designed sensor was optimized, and the performance of magnetic concentration have been analysed using Finite element method.

Wire ropes that operate on sheaves are subjected to various stresses due to which possible failures may take place. The life of the wire rope tends to decrease when it is subjected to increasing axial load and decreasing sheave bend radii. At the same time, the bending of the ropes on elevator pulleys will increase the cross section of the wire rope at the outer cross section whereas the inner most wires tend to shorten and is considered to be the main cause of damage and wear in the elevator operation units [14,15]. In this context Shi et al. [14] have studied a 3D model using finite element method considering 6+1 wire rope strand to investigate the traction between wire and sheave. They studied the tensile distribution in the wire. They concluded that contact wrap angle is critical in traction capability calculations. Nabijoe and Hobbs [15] have studied the frictional behaviour in case of heavily loaded wire ropes bent over sheaves considering different diameters. They concluded that the reduction in the ratio of D:d (diameter of the sheave and diameter of wire rope) exhibit larger travel distance of the individual wires and the multiple strands of the unit leading to increasing wear and in turn reduction in the life of the rope. Hence, careful consideration of the wire rope selection plays an important role for various types of applications. Vogel [16] have studied the endurance and the lifetime of the wire rope over the sheave. He studied the influence of rope considering the rope length and size factors in case of lift application operations. They concluded the influence of rope length and size factors on the life of the wire rope. Xi et al. [17] have studied the wire rope failures using Non-destructive testing based on magnetic and infrared information. They considered the broken wire for their testing, and they concluded that using this method it is possible to estimate the residual lifetime of the wire rope. From this literature review it is observed that researchers have studied wire ropes which are commonly used in lifting and hoisting in case of cranes and elevators. Most of the researchers have designed wire ropes to study tensile loading considering both static and fatigue loading apart, stiffness and bending flexibility to improve the performance (Mechanical strength) of wire rope. Also, some researchers have designed and studied the strand in case of wire ropes to study its ability to withstand abrasion and plasticity to improve the life of wire ropes. In this research paper wire ropes have been studied for safety purposes to reduce the downtime of elevators and the analysis have been performed using ANSYS considering two configurations of wire ropes by introducing new materials to increase the efficiency and life of wire ropes.

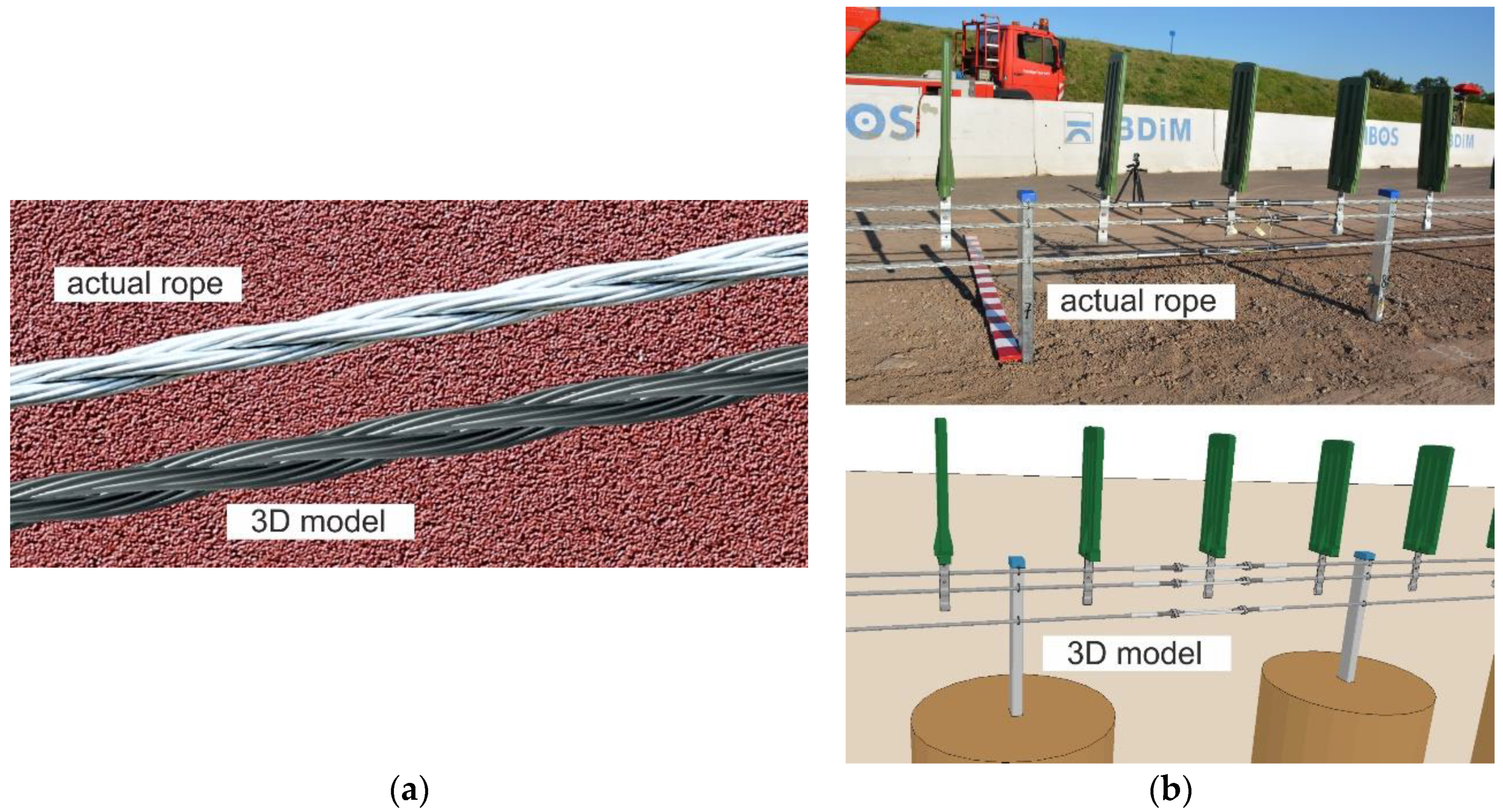

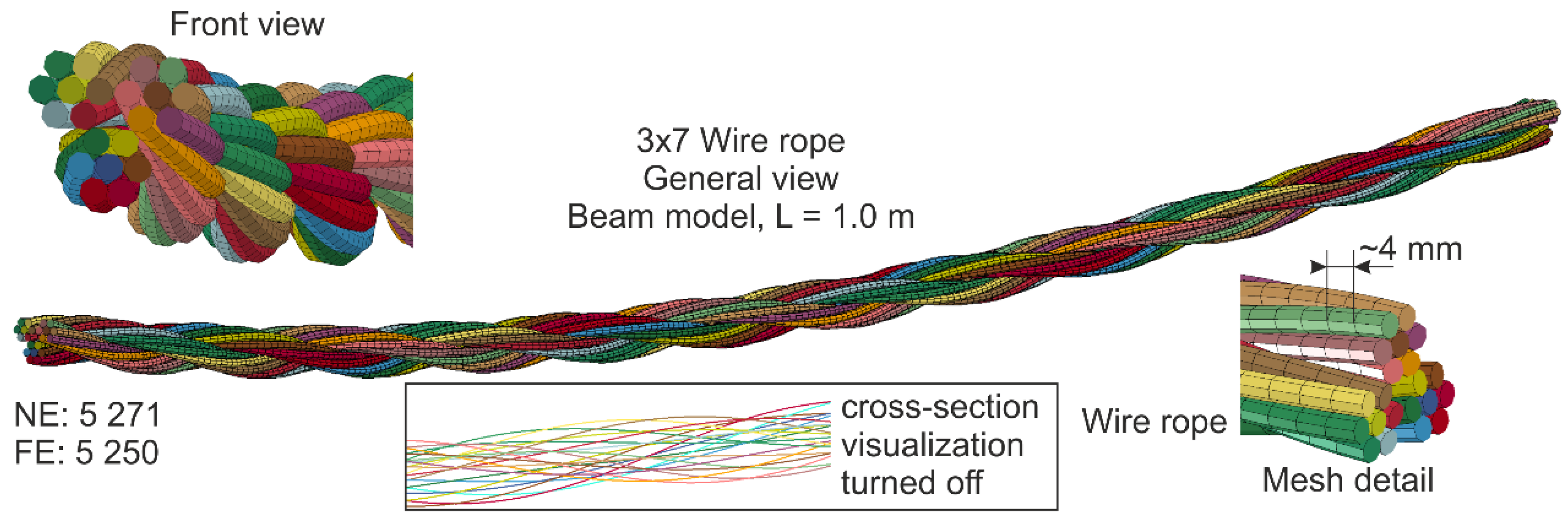

The base model of the wire rope is Autodesk inventor and the analysis are performed using Ansys software. Two configurations of wire ropes have been designed and their diameters is selected as 22 mm and 24 mm and the corresponding model is as shown in Figure 1. The corresponding dimension and other properties of the wire rope is as shown in Table 1. The maximum load considered is 45 kN and the wire rope diameter selected is 22 mm. The wire rope configuration selected for the analysis is as shown in Table 2 and Table 3.

Kp = (Dt/Dp) where Kp = Ratio factor for difference in sheave and wire dia, Dt = Dia. of Sheave [mm] = 400 mm, Dp = Avg. Dia. Of all the sheaves [mm] 400/5 = 80 mm.

The two-wire rope model is constructed, and these wire ropes were tested against static structural analysis by applying a load of 45 kN. Stress analysis have been conducted on both the models (Configurations 1 and 2). The corresponding dimensions and the views of configurations 1 and 2 is as shown in Figure 2 and Figure 3. The analysis is performed by taking a small cross section of the wire rope considering one end as fixed and negative load is applied on the other end in the opposite directions. The model of configurations 1 and 2 and the corresponding meshed model of configurations 1 and 2 is as shown in Figure 4 and the number of nodes for the model meshing is 318166.

Figure 5 shows the displacement diagrams of wire ropes (configurations 1 and 2) for a load of 45 kN. From Figure 5a it is observed that wire rope is displaced in the low region of deformation, however, the far end of the wire rope shows individual strand displacement of up to 7.675 mm maximum. This wire rope is of the configuration 7*19 which is considered unfamiliar and unconventional. From this it can be stated that with the usage of wire terminations or wire rope sling terminations the above deflections may be avoided which guaranty a sturdy and secure wire rope with high strength and high level of tolerance.

The wire rope configurations considered for the second case represents wire rope of 6*49 design as compared to configurations 1 is as shown in Figure 5b. This wire rope configurations have been analyzed using Auto desk inventor using stress component displacement analysis and the number of nodes considered is 318166. This type of design is unconventional and never been constructed or analyzed for application. From this result it can be concluded that for a load of 45 kN, this wire rope has performed very well, and all the strand separation is intact which can be observed from Figure 5b. From this result it can be stated that the configuration 2 design is highly desirable in elevator lifting wire rope as it is having minimum strand separation and will guarantee maximum safety.

Table 4 shows the wire rope physical properties for GCS (Galvanized carbon steel) and galvanized steel considered for the analysis. From this table it is observed that mass of the wire rope made of GCS has 0.0381284 kg while the mass of the galvanized steel is 0.299812 kg. From this table it is also observed that area of GCS is 99805 mm2 whereas the area of galvanized steel is 58189.6 mm2. The density as well as center of gravity of both these cases can also be observed in Table 4.

This paper discussed about the design and analysis of a wire rope used in elevator system. The analysis has been performed considering two configurations of wire rope considering GCS and Steel Galvanized. From the analysis the following conclusions have been drawn.The static structural analysis using ANSYS has been performed by considering the two wire strand configurations of wire ropes to increase the efficiency and life of the wire rope without compromising the safety of rope.

From this analysis it is observed that wire strand configuration 1 has shown internal strand to strand displacement and the factor of safety was less than 5 which is not recommended as per industry standards whereas, the strand configuration 2 has shown no internal displacement and has performed better as compared to configuration 1 and the factor of safety was higher as compared to the configuration 1 and is good design.

The wire rope design using Autodesk inventor software and the analysis have been performed using Ansys. From this analysis it can be concluded that design of wire rope considered for the study increases the efficiency and life of the wire rope without compromising safety.

W.S. Utting, N. Jones, The response of wire rope strands to axial tensile loads − Part II. Comparison of experimental results and theoretical predictions, Int. J. Mech. Sci. 29, 621–636 (1987)

C. Yuanpei, M. Fanming, G. Xiansheng, Full contact analysis of wire rope strand subjected to varying loads based on semi-analytical method, Int. J. Solids Struct. 117, 51–66 (2017)

H. Mouradi, A. Barkani, E.I. Biyaali, Investigation on the main degradation mechanisms of steel wire ropes: a literature review, J. Eng. Appl. Sci. 11, 1206–1217 (2016)

A. Barkani, A. Benali, M. Ghorba, M. Chergui, A. Choukir, Nondestructive evaluation methods of broken wire ropes of lifting, Int. J. Res. Rev. Mechatr. Des. Simul. 2, 126–136 (2012)

V.V. Sukhorukov, D.A. Slesarev, A.V. Vorontsov, Electromagnetic inspection and diagnostics of steel ropes: technology, effectiveness and problems, Mater. Evaluat. 72, 1019–1027 (2014)

J. Rostami, P.W. Tse, M. Yuan, Detection of broken wires in elevator wire ropes with ultrasonic guide waves and tone-burst wavelet, Struct. Health Monitor. 19, 1–14 (2020)

Y. Zhang, L. Jing, W. Zhan, J. Tan, A sensor for broken wire detection of steel wire ropes based on magnetic concentrating principle, Sensors (Basel Switzerland) 19, 1–14 (2019)

W. Vogel, Influences of lifetime of wire ropes in traction lifts, 5th symposium of the mechanics of slender structures, J. Phys. Conf. Ser. 721, 1–5 (2016)

L. Xi, Z. Juwei, S. Jingzhou, Quantitative nondestructive testing of broken wires for wire rope based on magnetic and infrared information, J. Sens. 2020, 1–14 (2020)

Cite this article as: Anil Babu Seelam, Mohammad Saif Jawed, Sachidananda Hassan Krishanmurthy, Design and analysis of elevator wire ropes, Int. J. Simul. Multidisci. Des. Optim. 12, 20 (2021)

Wire rope isolators are mainly used to isolate vibration and protect precise equipment. However, the issue of regulation of vibration isolators taking into account the nonlinearity of their characteristics was poorly understood in the modern literature. In this paper, the influence of structural parameters (diameter ratio and lay pitch of the single strand, and lay pitch and bending radius of the wire rope) on stiffness-damping characteristics of the Polycal WRI was investigated by the simplified finite element analysis method. The stiffness and damping prediction models including structural parameters and material properties were established. The results showed that the stiffness-damping characteristics were the best; when the diameter ratio of wire strand was 1.1, the inside layer wire pitch length was 6 times the diameter of the wire strand, the outside layer wire pitch length was 11 times the diameter of the wire strand, the pitch length of the wire rope was 7.5 times its diameter, and the bending radius was equal to 46.5 mm. The errors of the prediction for prestiffness and softened stiffness were within 5%, and the errors of prediction for the energy dissipation coefficient were within 10%.

Vibration is common in our lives. Especially in many industries, vibration is caused by the equipments operation, fluid flushing in pipes, and aero engine. This is harmful for operation safety [1–3]. Many vibration reduction and vibration suppression methods have been studied. Vibration isolators are widely applicable to production and living. Particularly, it is widely used in equipments with high load and vibration reduction requirements. In recent years, new type of vibration isolators and design of vibration isolation systems are hot topic for scholars. Wire rope isolator (WRI) has excellent rigidity damping characteristics, especially with high bearing capacity. It is widely used in mechanical manufacturing and construction. Therefore, it is necessary and significant to study the characteristics of the WRI with different structural parameters.

The characteristics of the WRI are studied through the experimental and theoretical methods [4–11]. Chen et al. [12] investigated the contact statues of a steel wire rope from the perspective of theoretical analysis. The result shows that the effect of the lay angle on the stiffness of the wire rope is different under different loads. Tinker and Cutchins [13] obtained the data of stiffness and damping characteristics of the WRI through dynamic experiment. It is also found that the damping of the WRI is related to coulomb-type friction. Demetriades et al. [14] studied the response characteristics under different loads for different structures of the WRI. The result indicated that the WRI exhibits the same characteristics under shear and roll loads. Wang et al. [15] experimentally investigated the effects of load frequency, amplitude and structural parameters on the dynamic characteristics of O-type WRIs. He found that the loading amplitude and geometric parameters of the isolator directly affects the dynamic characteristics of the isolator, while the loading frequency has no effect on it. Gerges [9] investigated the tension-compression mode of the wire rope spring. He presented a semianalytical model for a wire rope vibration isolator through experiment. Rashidi and Ziaei-Rad [7] investigated the quasi-static and dynamic characteristics of the WRI. It is suggested that there is not obviously relationship between hysteresis loops and loading velocity under quasi-static load. The dynamic results indicated that by increasing the frequency of excitation, the area of the hysteresis loop starts decreasing. Finally, a hysteresis analytical prediction model with high coincidence degree was established.

The finite element analysis method can reduce the cost of the experiment, and thus has been widely used in studying the characteristics of the WRI and wire ropes. Jiang et al. [16] found effective simplified finite element analysis method of analyzing the contact statues of wire ropes. It was found that the local contact deformation affects the accuracy of the results. Wang et al. [17] investigated the mechanical behavior of the YS9-8 × 19 braided wire rope under tensile load. By comparing the results of finite element analysis and experiment, the error between them was small, and the accuracy of the model was verified. By the finite element method, Xiang et al. [18] obtained the elastic-plastic contact stresses under axial and torsion loads of wire ropes, and investigated the elastic-plastic behavior of it. The finite element analysis results have a good agreement with the experimental test results, and a new prediction model was proposed. Yu et al. [19] applied the beam finite element method to analyzing axial tensile properties of the 91-wire strand. By comparing with the experiment results, the beam FEM could be used to predict the tensile properties of the steel wire rope. Song et al. [20] analyzed distributions of stress and deformation in the braided wire rope subjected to torsional loading. He found that the wires in the strands have the tendency to be screwed tightly and are in a stretched state when the lay direction of the strand coincides with its torsion direction. Cao and Wu [21] established the finite element model of wire ropes with different structural parameters and analyzed the stress distribution and deformation under cantilever beam state. The accuracy of the results of finite element analysis was slightly lower than the theoretical calculation results. Du et al. [22] presented a simulation of the 6 × 36 + WS RHRL wire rope. It is found that the stress of the wire rope was uneven, and the maximum stress occurs at the side of the wire. Yong et al. [23] conducted a finite element analysis of the IWRC636WS wire rope, and the elastic behavior of the wire rope under tensile loads was simulated. It is reported that nonlinear relationship between the axial tension and the axial elongation of the wire rope. Cen et al. [24] found effective simplified finite element analysis method by combining finite element method with experimental test. This method can be used to analyze the characteristics of the Polycal WRI. The above studies have studied the characteristics of wire ropes and vibration isolators by experiments and finite element methods and obtained some results. Considering the complexity of the wire rope isolator structure, there is less research on the relationship between the structural parameters of the WRI and the stiffness and damping characteristics of the WRI. Therefore, it is necessary to study the relationship between them, and provide guidance for practical engineering applications.

In this paper, the stiffness and damping characteristics of WRIs with different structural parameters were investigated. These structural parameters were number of wire ropes, material of wire, rope diameter (D), rope lay pitch (), single wire rope diameter (d), single wire strand lay pitch (), and wire rope diameter ratio (nr). A stiffness-damping prediction model consists of structural parameters of the Polycal WRI were established, which aims to provide powerful help for the structural design and wire rope selection of the Polycal WRI.

The energy dissipation coefficient is a key parameter evaluating the effective vibration isolation property of a WRI. It is an important reference for evaluating the damping characteristics of the WRI. Because of sliding friction between the wire strands and the internal friction of wires, the isolators exhibit nonlinear hysteretic behavior. Typical load-displacement curve of the WRI is shown in Figure 1. The damping characteristics of the WRI are related with the area which is enclosed by the loading and unloading curve of the WRI under compression. The energy dissipation coefficient C was calculated as follows:where Aloop was the area of the hysteresis loop (N·mm), Fmax and Fmin were the maximum and minimum loads (N), respectively, of the WRI in the compression loading-unloading process. Xmax and Xmin were the maximum and minimum displacement (mm) in the loading-unloading process.

In most of the wire rope isolators, during the load-bearing process, the upper and lower pallets are mainly supported by the curved steel wire rope, and the bending stiffness and deformation process of the steel wire rope play a decisive role. Therefore, this paper mainly uses the stiffness and energy dissipation coefficient as indicators to measure the effectiveness of the wire rope isolators.

As shown in Figure 2(a), the WRI was composed of two pallets and twelve 6 × 19 IWS wire ropes. In this paper, the simplified finite element method is used to obtain the WRI load-displacement hysteresis loop, and the WRI stiffness damping of different structural parameters is discussed. We have referenced the simplified finite element method which was established by Cen et al. [24]. This method mainly simplified the single strand into a single wire. The 6 × 19 IWS wire rope was simplified into the 1 × 7 wire rope, as presented in Figure 2(b). Based on the simplified method, this paper studies the stiffness and damping characteristics of the isolators with different structural parameters and establishes the prediction model of the stiffness damping of the wire rope isolator with structural parameters as variables.

This paper is mainly based on the GGQ-99 Polycal WRI. By changing structural parameters, the diameter ratio and lay pitch of the single strand and lay pitch and bending radius of the wire rope, different finite element models were set.

In this presented model, the data source of the simulation of the WRIs refers to papers of Cen et al. [24], Jiang et al. [25], and Erdonmez and Imrak [26]. The material properties of the center and side wires are defined by the bilinear elastic-plastic kinematic hardening model in the ABAQUS material library, as shown in Table 1. By compression of corresponding strands, the max equivalent compression stress of the strand and equivalent compression elastic modulus are equal to and Ep, respectively. Ee is equal to the equivalent tension elastic modulus which is measured by the tension of the strands. The density is ρ = 7850 kg·m−3, and the Poisson’s ratio is μ = 0.3 [24].

The stiffness of the WRI determines the load-bearing capacity of the vibration isolation system, regardless of whether the WRI is subjected to a static load or a strong impact load. The softening load of the WRI and the subsequent softening stiffness both affect the efficiency of vibration isolation and stability of the entire isolator system. The damping characteristic reflects the ability to absorb shock vibration energy of the isolator in the vibration isolation system. There are many factors that affect the static stiffness and damping characteristics of the WRI, including the selection of the wire rope, number of wire ropes, material of steel wire, wire rope diameter (D), rope lay pitch (), single wire rope diameter (d), single wire strand lay pitch (), wire rope diameter ratio (nr), and arc wire rope bending radius (R).

As shown in Figure 3, the diameter ratio (nr) of the 1 + 6 + 12 center strand or the lay strand is defined as follows:where rc and rs are the diameters of the center wire and lay wire in the single strand, respectively.

Figure 3 shows the 1 + 6 + 12 single-strand wire rope. It was stipulated that the 1 + 6 + 12 single-strand wire rope has the same other structural parameters; the first layer wire pitch length was 6 times the diameter of the single wire rope, and the second layer wire pitch length was 11 times the diameter of the single wire rope. The diameter of the wire rope was 8 mm in the study of the GGQ-99 Polycal WRI. The diameter of the center strand was 2.839 mm, and the diameter of the lay strand was 2.581 mm. Obviously, the former was 1.1 times more than the latter. The lay pitch length was 60 mm (7.5 times diameter of the wire rope), and the bending radius was 46.5 mm of the arc wire rope. The diameters of the center wire and lay wire in different strands with different diameter ratios of the GGQ-99 are listed in Table 2.

According to the simplified FEM model, the tensile and compression of the single strand with different diameter ratios were calculated. The elastic tensile and compression modulus and compression ultimate load of the single strand were obtained. These mechanical parameters were used to calculate the stiffness-damping characteristics of the WRI. It is presented in Table 3. It could be seen that the elastic tensile modulus significantly reduced with increased diameter ratio. But the elastic compression modulus increased with increased diameter ratio. The compression ultimate load is kept steady basically with increased diameter ratio. The reason is that the compression ultimate load indicated the friction properties between the center wire and lay wire. The friction between the center wire and lay wire was retained about the same during calculating the model with different diameter ratios. So, the compression ultimate loads showed little changes.

According to the simplified FEM model, the compression loading-unloading processes of the GGQ-99 WRI with different diameter ratios were simulated. Different load-displacement hysteresis loop curves of the WRI are shown in Figure 4. The ratio between the prestiffness K1 and softened stage stiffness K2 indicated the impact resistance for the WRI. The smaller this value, the better the impact resistance. The energy dissipation coefficient was used to evaluate the damping characteristic. The higher this value, the better the damping characteristic. The results are shown in Figure 5.

As shown in Figure 4, the compression load of the WRI increased with increasing of the diameter ratio of the wire strand. This result is related to the elastic compression modulus of the single strand. As shown in Figure 5, the ratio of K1 to K2 was increased with increasing of the diameter ratio of the wire strand. The ratio of K1 to K2 reached the minimum when the diameter ratio was equaled to 1.1. It means that the GGQ-99 WRI was easier to maintain the stability of the vibration isolation system through large deformation. The energy dissipation coefficient for the WRI decreased with increasing of the diameter ratio of the wire strand. When the ratio of the strand was equaled to 1.1, the energy dissipation coefficient reached maximum. These results indicate that the Polycal WRI has better damping characteristics, which could effectively consume the impact load and eliminate the vibration from the isolation system.

Based on the diameter ratio of the wire strand to 1.1, the main purpose of this section is to study the effect of the outer layer side wire pitch length () on the stiffness-damping of the Polycal WRI. During the process of creating the simulation model, the first layer side wire of the strand steel wire rope () was unchanged and equal to 6 times the diameter of the wire strand. The was 7 times, 8 times, 9 times, 10 times, and 11 times the diameter of the wire strand. The relation between the pitch length and diameter of the wire strand (d) is expressed in equation (3). The geometric dimensions of the single wire strands with different pitch lengths are shown in Table 4.

As shown in Table 5, the equipment tensile modulus, compression modulus, and softened stress of the wire strands with different were obtained by axial tension and compression. The modulus of the tension was continuously increased with increasing of the outer layer side wire pitch. The modulus of the compression had a small variation with increasing of the outer layer side wire pitch basically, and the maximum load of the corresponding compression process decreased.

The equipment tensile and compression performance of wire strands with different were used to define the bilinear elastic-plastic kinematic hardening material properties of the center and lay strand assembled in the GGQ-99 WRI. As shown in Figure 6, the load-displacement hysteresis loops of different lay pitches had a small variation. Besides, the modulus of the compression was not changing with increasing of the outer layer side wire pitch. Combined stiffness-damping characteristics of the GGQ-99 WRI with the different wire strand pout are shown in Figure 7. When the was 11 times the diameter of the wire strand, the ratio of K1 to K2 reached the minimum. At the same time, the Polycal WRI had large prestiffness and the most obvious softening characteristics, not only could withstand large loads but also could easily maintain the stability of the vibration isolation system through large deformation under the action of large loads. The energy dissipation coefficient of the WRI remained basically unchanged, when the ratio of the outside lay pitch and the diameter of the strand increased.

In the process of compression loading-unloading of the Polycal WRI, not only the slippage of the wires exists in the strand but also the overall slippage of the strands in the rope. Therefore, the influence rule of the pitch length on the wire rope is discussed in this section. The diameter ratio, the inside layer wire pitch length and outside layer wire pitch, was equaled to 1.1. It was 6 times the diameter of the wire strand and 11 times the diameter of the wire strand, respectively. The relation between the pitch length and diameter of the wire rope (D) is expressed in equation (4). Table 5 lists the geometric dimensions of the single wire strands with different pitch lengths. The load-displacement hysteresis loops of the GGQ-99 WRI with different pitch lengths are shown in Figure 8.

As shown in Figure 8, the compression load of the WRI increased with increasing of the pitch length of the wire rope. The increase of the pitch length contributed to the increase of the angle between the center strand and lay strand. The bearing axial load of the lay strand increased with angle between center strand and lay strand decreasing. So, the compression load of the WRI was increased with the increasing of the pitch length of the wire rope.

The stiffness-damping characteristics of the GGQ-99 WRI with different pitch lengths of wire ropes are shown in Figure 9. As shown in Figure 9, both the ratio of K1 to K2 and the energy dissipation coefficient of the WRI fluctuated with the increase of the pitch length of the arc rope. When the rope pitch was equaled to 7.5 times the diameter of rope, the ratio of K1 to K2 was the smallest and less than 0.2 and the energy dissipation coefficient was the biggest.

The characteristics of the Polycal WRI depend on the structure of the wire rope, including the diameter of the single strand, the pitch length of the single strand, and the bending radius of the wire rope. In this section, the influence of the bending radius (R) of the arc rope on the stiffness-damping characteristics of the Polycal WRI is studied. The diameter ratio of the wire strand was 1.1. The inside layer wire pitch length was 6 times the diameter of the wire strand. The outside layer wire pitch length was 11 times the diameter of the wire strand, and the pitch length of the wire rope was 7.5 times its diameter. The bending radius was equal to 46.5 mm, and the bending radius of the wire rope was 50 mm, 55 mm, 60 mm, and 65 mm, respectively. The FEM models of the GGQ-99 WRI with different bending radii are shown in Figure 10. The load-displacement hysteresis loops of the GGQ-99 WRI with different bending radii of arc ropes are shown in Figure 11.

As shown in Figure 11, the compression load of the WRI increased with increasing bending radius of arc ropes. Because the compression load of the WRI was inversely proportional to the curvature of the wire rope, the curvature of the wire rope decreased with increasing bending radius of arc ropes. The compression load of the WRI increased with increasing bending radius of arc ropes.

The stiffness-damping characteristics of the GGQ-99 WRI with different bending radii of the wire rope are shown in Figure 12. The ratio of K1 to K2 increased with increasing bending radius. However, the energy dissipation coefficient of the WRI decreased with increasing bending. When the bending radius was equal to 46.5 mm, the ratio of K1 to K2 was the smallest and the energy dissipation coefficient was the biggest.

In conclusion, the stiffness-damping characteristics were the best; when the diameter ratio of the wire strand was 1.1, the inside layer wire pitch length was 6 times the diameter of the wire strand, the outside layer wire pitch length was 11 times the diameter of the wire strand, and the pitch length of the wire rope was 7.5 times its diameter. The bending radius was equal to 46.5 mm.

In the previous section, the influence rules of the diameter ratio of the wire strand (nr), the pitch length of the wire strand (), the pitch length of the wire rope (P), and the bending radius (R) for the stiffness-damping performance of the Polycal WRI were discussed. The prediction model of the stiffness-damping characteristic of the WRI was established by using the dimensionless diameter ratio of the wire strand (nr), the pitch length of the wire strand (), the pitch length of the wire rope (P), and the bending radius (R). The theoretical basis of equations (5) and (6) is the theorem in dimensional analysis. According to the principle of dimensional analysis, all structural parameters are transformed into a dimensionless form, and the number of variables is reduced to obtain the corresponding calculation formula as follows:where E1 is the elastic modulus of the steel wire material (E1 = 193000 MPa), H is the height of the GGQ-99 WRI (H = 99 mm), and D is the diameter of the arc rope (D = 8 mm). The x, k, and c are the undetermined coefficients in the stiffness and damping models, respectively.

As shown in Table 6, all values of the prestiffness K1, softened stiffness K2, and energy dissipation coefficient C of the GGQ-99 Polycal WRI with different structural parameters were obtained. The coefficient values are listed in Table 7. By using the MATLAB software, equations (5) and (6) were formulated fitting with the corresponding structural parameters, respectively.

As shown in Table 8, the errors of the prestiffness and softened stiffness fitting formulas of the WRI were all within 10%, and more than half of the errors were within 5%. The error of the energy dissipation coefficient of the WRI with the formula was basically within 20%, and more than half of the errors were within 10%. It could be considered that the formula fitted in this study is accurate and reliable by analysing the error results of the overall data. In the design of the Polycal WRI, the stiffness-damping characteristics could be quickly obtained.

The wire rope structural parameters of the GGQ25-62 Polycal WRI are given in Table 9. Besides, the values of H, D, and R are 62 mm, 4.68 mm, and 27.15 mm, respectively.

Through the out-of-plane compression loading-unloading experiment of the WRI, its stiffness-damping characteristics were obtained. Figure 13 shows the load-displacement curve of the GGQ25-62WRI, and the values of K1, K2, and C could be calculated from this figure, and Table 10 also shows the specific values.

The fitted value was compared with experimental data. As shown in Table 11, the errors of the prestiffness and softened stiffness fitting formulas of the WRI the values were all within 20%. The reason for this phenomenon is that the finite element is an analysis under ideal conditions. During the test, the vibration isolator is in a complex state, and there will be some nonlinearity characteristics. Therefore, it can be seen that the predicted value given by the prediction model is in good agreement with the experimental value.

This paper firstly presented the results of the mechanical properties of the wire rope with different diameter ratios and lay pitches of the single strand. By using the corrected simplified finite element method of the Polycal WRI, the influence of the diameter ratio and lay pitch of the single strand and the lay pitch and bending radius of the wire rope on the stiffness and damping characteristics of the Polycal WRI were studied. Several key conclusions are summarized as follows:(1)The stiffness-damping characteristics were best; when the diameter ratio of wire strand was 1.1, the inside layer wire pitch length was 6 times the diameter of the wire strand, the outside layer wire pitch length was 11 times the diameter of the wire strand, the pitch length of the wire rope was 7.5 times its diameter, and the bending radius was equal to 46.5 mm.(2)The effective prediction models of stiffness and damping about the structural parameters of the wire rope were established, which combined the properties of a steel wire material and the overall structure of the WRI. More than half of the errors of the prestiffness and softened stiffness fitting formulas of the Polycal WRI were within 5%. And more than half of the errors of the energy dissipation coefficient of the WRI were within 10%. The fitted value was compared with the experimental data, the errors were within 20%, and the prediction model was verified.

8613371530291

8613371530291