wire rope blasting mats manufacturer

Recyclable and reusable: These mats don’t disintegrate like rubber mats, so you can use them longer and not worry about disposal fees or putting a strain on the environment.

Durability: These mats cannot catch fire like rubber mats and are geared for any blast environment. They are also resistant to all explosive substances, even modern aluminized explosives.

You will love having these Mazzella wire rope blast mats on your site. Although rubber blasting mats made from recycled tire are cheaper, they are not nearly as effective. They will cost you more in the long run since they can degrade, catch fire and will need to be replaced much more frequently than our mats.

TM International, LLC has been a manufacturer of blasting mats, containment tanks and other blast safety equipment since 1909. Our blast mats are better for the environment, more adaptable and safer than rubber mats, making them the best blasting mats on the market. They can be used with electronic, electric or non-electric detonators and on any type of build, mine or blast site. We ship anywhere in the world in a 20" container to ensure low-cost delivery of your new safety gear. Order your Mazzella mats now!

Manufacturer of mats including outside mats including astro turf, rubber brush, spaghetti mat, super tread, tire link, vinyl link, vinyl loop. Scraper mats including brush-n-clean, rib, cocoa mats / road roller mats, gatekeeper, grid-top mats, rib mats, scraper grids & vinyl looper. Entry mats including commercial, laundry mats, logo mats, non-slip entry mats & premier rubber back mats. Workstations & chef"s mats including anti-static mats, anti-fatigue mats, desk chair mats & clear vinyl runners, food service mats, high density mats, modular tiles, multi-purpose drainage system, wood chair mats & industrial & commercial mats. Industrial mats, mops, badges, signs, custom mats washers available.

Blasting mats, Ballistic shields and fragmentation containment equipment. We offer rubber, wire, and rope. Rubber blasting mats tends to last the longest and weigh the most. Cable/wire blasting mats are easily stored, weigh less and allow gases to vent. Rope mats are the lightest but more susceptible to fragmentation. We also have Military blasting mats available. PLEASE CALL FOR PRICING.

The wire rope blasting mat was invented and developed to protect lives and property during the turn of the century New York City 3rd Ave. subway project. The wire rope blasting mat made an immediate impact on the safety standards of blasting operations in high density urban areas. Wire rope blasting mats are the only blasting mat designed to vent gasses which give the blaster more control.

Wire rope blasting mats weigh an astonishing 16 pounds per square foot (65 kg/m). This means you are getting twice as many square feet per truck over rubber, while increasing safety and control. With today"s high fuel costs, this is a definite advantage in day to day operational cost.

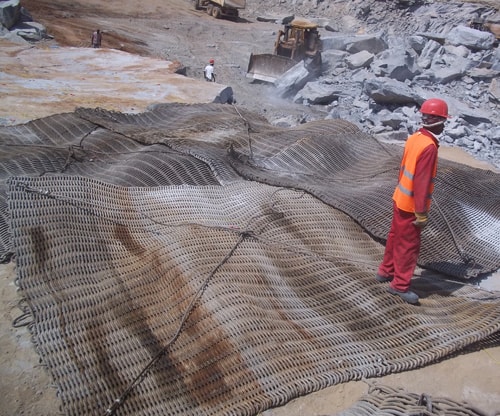

Wire rope blasting mats are the most versatile and flexible units on the market today. This gives it the ability to adapt to any topography, face or blasting operation. Our wire rope blasting mats come complete with a built in bridle system that makes setting our blast mats simple.

Our wire rope blasting mats are extremely durable; they are built to withstand intensive daily use. Wire rope blasting mats are also fireproof, which offers blasters the ability to use new modern aluminized explosives. The wire rope blasting mat is constructed under ISO 9001:2000 standards and is completely recyclable (Green), unlike the rubber tire units.

Whether you are competing in the regional or world markets and looking for a competitive edge. Wire Rope Blasting Mats are an answer for they have never changed in their superior Effectiveness, Durability, Safety and Cost Effectiveness in over 100 years.

With wire rope blasting mats there is NO DISPOSAL cost or environmental issues associated with their use. You"re not buying used car and truck tires, but an Engineered Enviromentally Safe product which can be disposed of at any scrap yard.

Siby Mining and infrastructure is the prime blasting mats manufacturers in the country. A blasting mat is constructed of sliced-up rubber tires held together by ropes, wires, or chains. When explosives are detonated in places like quarries or building sites, blasting mats are employed. The mats are put over the blasting area to limit the explosion, reduce noise and dust, and prevent high-velocity rock shards known as fly rock from causing damage to nearby structures, persons, or the environment.

Blasting Mats are used to protect workers from the harmful effects of blasting. Blasting mats can be used in a variety of industrial settings. They can be used at construction sites, mines, and quarries. The main purpose of blasting mats is to prevent injuries by providing protection for workers who are near or around the blast site. Blasting mats may also be used to reduce noise levels in surrounding areas. This helps to protect the hearing of nearby residents and property owners. Finally, blasting mats can be used to control dust and debris during blasting operations.

Depending on the magnitude of the blast charge, the type of mat, and the degree of protection required, mats can be utilized singly or in layers. They can be hung from cranes or affixed to structures horizontally on the ground or vertically. The mats are frequently referred to as blasting curtains when used vertically. To avail these mats from the top blasting mats manufacturers,give us a call during business hours.

These mats are longer lasting in rough terrain and can be modified to make specialized products, such as high velocity shooting range products and blast curtains.

The RHINO Mat is known for its toughness and longer lasting characteristics in heavy duty construction regions. Battle tested in Northern Ontario Canada, our mats NEVER use grommets and are manufactured with a minimum 3/4” NEW wire rope cable. All of our mats have engineered rings and steel components so that you can assure your rigging people the pick up points are top notch. Rhino Blast Mats are available on our Rental and Leasing programs as well. Just like a Rhino, they are tough skinned and don’t stop once they get going, they are“Built to Blast”.

• ALL MATS have options for lifting rings - standard is 10” inside diameter, inserted in our proprietary tie up patterns that use 3 or 4 wire ropes at all times, or an optional clevice/shackle to extend ray.

The Armadillo is renowned for its pliability and versatility in releasing a high volume of high velocity blast gases, to minimize the height that the mat rises into the air, after the shot detonates. The over/under weave of the cut and punched tires has been further modified to incorporate our affectionately named, “smiley frown” pattern and this is what makes these mats so versatile, just like an Armadillo. A quality product, custom manufactured,“Built to Blast”.

A blasting mat is a mat usually made of sliced-up rubber tires bound together with ropes, cables or chains. They are used during rock blasting to contain the blast, prevent flying rocks and suppress dust.

Blasting mats are used when explosives are detonated in places such as quarries or construction sites. The mats are placed over the blasting area to contain the blast, suppress noiseenvironment in proximity to the blast site.

Blasting mats are often used in combination with blasting blankets as an additional layer over the mats. The blankets are larger than the mats designed to retain the fragments that have managed to pass through the mat. Blasting blankets are used for both horizontal and vertical blasting.

Blasting mats made from used tires can serve a double purpose as road stabilizers, or road surface, in locations where roads leading to the blasting site are unstable or nonexistent,

A number of materials are used for making blasting mats and new materials with different properties are constantly being introduced into this field.old tires held together by steel cables, mats woven from manila rope or wire cables, logs or conveyor belts.wire netting can also be used.

Blasting mats made from rope woven on wires were first used during the construction of the IRT Third Avenue Line in New York City in the early 1900s. They were used to protect the surrounding buildings and were favored since they prevented fly rock but vented gasses.

Mats made from recycled tires can be fashioned in a number of ways depending on how the tires are cut. Some examples are tread mats, sidewall mats and mats from non-flattened sections of tires.

When charges are used to dig foxholes, an improvised blasting mat made from whole tires tied together with rope to reduce noise and fly rock, is recommended in the A Soldiers Handbook (United States). A tarp may also be used as a blasting blanket.

Over the years, a number of incidents with fatal outcomes have been caused by fly rock. In most of these, blasting mats were not used or they were placed over the blasting face in an incorrect manner.Cape Ray, Newfoundland and Labrador when a 7 kg (15 lb) fly rock travelled about 250 m (820 ft) from the blast site

Although designed to prevent accidents, as blasting mats weigh between 3,000 and 6,000 lb (1,400 and 2,700 kg), they have also caused injuries when falling on workers on construction sites.

Blasting mats must be thoroughly inspected before each use to ensure there are no blown out segments or broken cables, by a blaster. Blasting mats will deteriorate with each use to the point where they become ineffective for their intended purpose. Only trained experienced and adequately supervised crews should be used in the placement of these devices over a loaded shot. A common complaint is accidental breakage of bus wires, leg wires or pinching off the non electric tubes that may result in the misfire of the shot.

"Blasting Examiners Protocols" (PDF). www2.worksafebc.com. WorkSafeBC. 1 May 2011. p. 17. Archived from the original (PDF) on 27 February 2013. Retrieved 25 September 2015.

Alexander Robertson, Thomas; King, John Alfred (16 March 1976). "Blasting Mats" (PDF). www.docs.google.com. United States Patent. Retrieved 25 September 2015.

Blasting mats can be made of rubber, wire, or rope products.FLINTSTONE BLAST MATS are produced from the rubber tread of steel belted truck tyres, laid flat in two overlapping layers in brickbat style, and sewn with 6 lengths of 14mm galvanised steel cable, with galvanised fittings. The steel belting embedded within the vulcanised rubber gives our mats extreme strength and penetration resistance, and the thickness and density of the rubber provides the necessary weight, protection, and stability.

Often required in the mining and civil engineering, a heavy, tearresistantblasting mat is used to cover the surface, and sometimes the face, of a blasting area to prevent the dangerous projection of rock fragments.

The weight in the solid rubber, the strength of the steel belting, and the quality steel rope cables, make our blast mats a long lasting value for money must-have for many blasting projects.

Blast mats can also be utilized in many other operations from road and track protection and machinery pads, to subsea uses, temporary boat ramps, swamp mats, and more.

Our manufacturing capabilities allow us to produce various size steel cabled, steel belted, rubber mats from 1.0 m x 1.0 m to maximum 3.1 m x 7.0 m and weight is up to 1400 kg. Our mats are at least 60kg/m2, giving them the necessary weight to perform the task.

Australian Standard AS2187.2-2006 states in Section 12.3: "Where protection from the possibility of fly is necessary, blasting mats or other suitable controls shall be used."

A well-designed blast will always be improved by having the increased safety factor provided by the use of blast mats. Mats are an essential addition to even the best of blasting designs in sensitive areas, where flyrock poses a risk of injury to persons or damage to property.

Just one direct hit to persons or third party property (or even a near miss) can result in personal tragedy, legal implications, licence suspensions, and increased insurance premiums.

Mats hung in front of the face generally incur increased wear and tear as they tend to get buried under the muck pile and can suffer damage during recovery, dependent on the blast result and the methods of retrieval.

The steel cabling and lifting loops make our mats practically “operator-proof” whether used in blasts or positioned and repositioned many times over for other uses such as track and road carpeting, machinery pads, or water edge ramps, plant and equipment, or mudmats.

With well-designed blast plans and sensible contractor handling such as removing the bulk of rock from buried mats after the blast rather than hooking and pulling out through the broken rock, our mats have been shown to last over a hundred blasts, and still counting.

When blasting in urban areas or near sensitive assets, both the explosives and blasting regulator in your jurisdiction, and your insurance company, will require you to take all reasonable and necessary steps to prevent the dangerous projection of rock fragments.

The five environmental hazards from blasting are ground vibration, airblast overpressure, dust, fumes, and flyrock. There are prescribed upper limits for vibration, overpressure, dust, and fumes. The use of blasting mats is an effective control strategy.

Our design makes our mats flexible for better coverage.Mazzella Wire Rope Blasting Mats have been effectively serving the Blasting, Construction and Demolition industries for over 100 years.

Blasting mats should always be used to cover the blasting site in order to protect the surroundings against damageor serious accidents. Bergma blasting mats provide the best protection from the negative effects while using explosive materials: elimination of fly rocks, reduction of shock wave and noise.

Bergma is constantly working to improve the blasting mats and find the best solutions that no one else has thought about. The results are so innovative thus have been patent protected. If something really needs to be created, there are no cheap or fast solutions.

Our blast mats are produced from the most wear resistant parts of recycled truck tires and sewn together with galvanized steel wires. Every single blasting mat we produce now is reinforced with double wire on both ends and this pattern has been patented. The mats are free of wire locks that could cut the connections between boreholes. Compact and strong Bergma blasting mats differ significantly from all other mats in the market.

Today it has to be paid for a delivery of old, used blasting mats for approved recycling. Bergma mats last longer what means less purchase and waste. Save your money and time and significantly contribute to protecting our environment!

Heavy Duty Double Layered Blasting Mats.Manufactured from truck tyres and steel wire rope with double end lifting loops.Stock size - 2.4m Width x 4m Length - 625kg.Other sizes made to order;

HOLEYBELT is very light (compared with woven tyre matting), very strong, and very easy to roll up for storage. It rolls out flat each time and is easy to peg or tie down when the cattle are on them for several days at a time. I have 4 mats 1200mm wide X 2.5m long (4ft x 8ft) which double as truck mats and show mats.

8613371530291

8613371530291