wire rope break pricelist

Maple Leaf Ropes has multiple warehouse locations throughout North America and can provide you with the product you need wherever you need it, give us a call!

Maple Leaf Ropes has multiple warehouse locations throughout North America and can provide you with the product you need wherever you need it, give us a call!

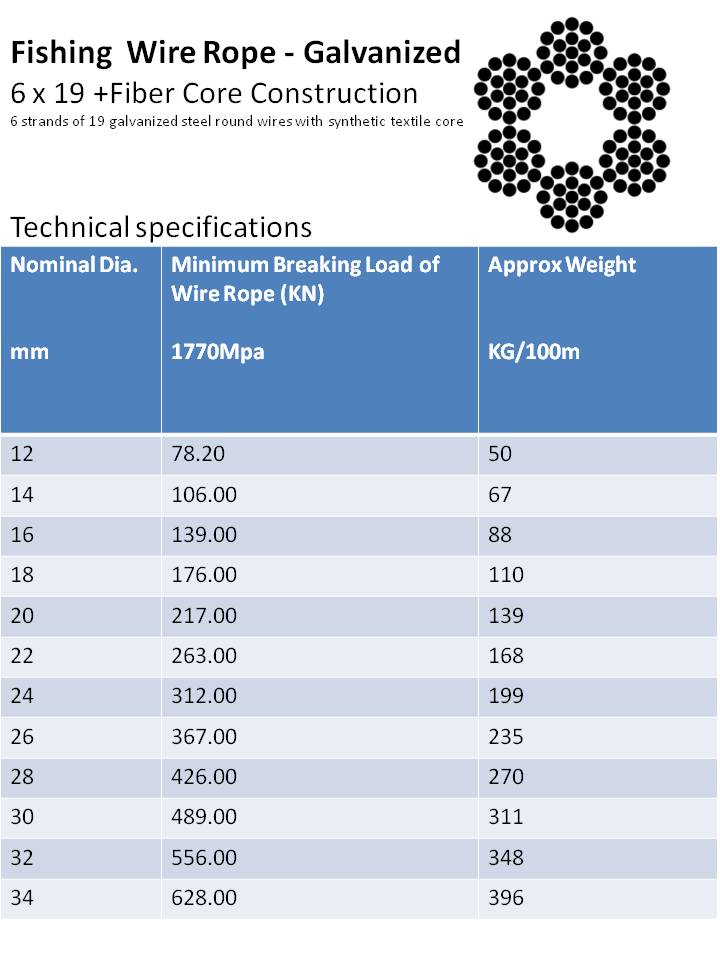

For use in lifting and rigging, securement, and general purpose, the 6x19 wire rope class comprises either a wire rope core or a fiber core. The wire rope core is its own wire rope construction, most commonly 7x7. This is known as IWRC (Interdependent Wire Rope Core), meaning it moves independent to the outer strands. It’s mostly used in winch-type applications. Within the fiber core wire rope, the fiber core is made of natural or synthetic fiber, which can provide excellent flexibility and resistance to contact pressure, and can store lubrication to reduce the friction between wire strands effectively.

The bright class of industrial wire rope is produced without a surface treatment—making the rope less likely to untwist or kink while giving it a stronger crush resistance than lay ropes. Generally, they are fully lubricated to protect the rope from rust and corrosion.

Galvanized wire rope (steel) features a compressed zinc coating for providing excellent corrosion resistance. With higher break strength, yet lower price than stainless steel wire rope, galvanized steel wire rope is widely used in general engineering applications such as winches and security ropes.

The 6x19 wire rope class is made up of six strands of between 16 and 26 wires per strand for additional wire rope strength and durability, with a maximum breaking strength of 69 tons. The 6x19 features IPS (Improved Plowed Steel), EIPS (Extra Improved Plowed Steel), or EEIPS (Extra Extra Improved Plowed Steel) grade wire rope. Also available in USA-made.

The 6x19 galvanized wire rope provides an excellent balance between fatigue and wear resistance. For use in lifting and rigging, securement, and general purpose, the 6x19 wire rope class comprises either a wire rope core or a fiber core.

The wire rope core is its own wire rope construction, most commonly 7x7. This is known as IWRC (Independent Wire Rope Core), meaning it moves independent to the outer strands. The 6x19 has larger outer wires, and is therefore more abrasion resistant, though its fatigue resistance is decreased—but overall, it"s is a good rope for withstanding abrasion or crushing on the drum. Galvanized wire rope (steel) features a compressed zinc coating for providing excellent corrosion resistance. With higher break strength, yet lower price than stainless steel, galvanized steel wire rope is widely used in general engineering applications such as winches and security ropes.

The 6x19 wire rope class is made up of six strands of between 16 and 26 wires per strand for additional wire rope strength and durability, with a maximum breaking strength of 69 tons. The 6x19 features IPS (Improved Plowed Steel), EIPS (Extra Improved Plowed Steel), or EEIPS (Extra Extra Improved Plowed Steel) grade wire rope. Also available in USA-made.

Rope Services Direct supplies a variety of anti-spin non rotating wire rope (also called rotation resistant wire-rope). All standard rope wirehas a tendency to develop torque and therefore prone to rotation, whereas non-rotating wire ropes are designed so that the wire-rope outer rotational force naturally counteracts the inner strands rotational force. This is in the event that a rope is subjected to a load.

Rope elongation and rotation occurs on standard ropes when loaded, which can therefore spin the load, quite possibly out of control, which can be dangerous. When the rope rotates in this way the strands will begin to unravel. This causes the rope to lose strength and will undoubtedly fail, which could be catastrophic. It is for these reasons that non rotating wire rope is commonly used for many types of lifting applications including main hoist rope, whip rope,crane rope, off-shore and deck rope and more.

Non rotating wire rope or rotation resistant wire rope has a different construction to standard. as wires and strands are not laid in the same direction like they would be on standard rope. Inner and outer strands of wires are laid in opposite directions. For example the inner may be constructed in left hand lay whilst the outer layer is in right hand lay. The nature of this construction means that torsional forces on the inner and outer wires/strands will counteract each other and therefore minimising the risk of unraveling.

It is worth noting that the number of strand layers will have an effect of the resistance of rotation. A 2 layer rope has less resistance than a 3 layer rope. Therefore the more layers the rope has the greater rotation resistance it will have.

These types of ropes can be classified as spin resistant, rotation resistant or non rotation resistant. Classed on the basis of the number of rotations a certain length of rope does when a force of 20% of the MBF is applied; with 1 turn or less the rope will be classified as non rotating; with rotations between 1 & 4 the rope is classed as low rotation and for rotations between 4 & 10 the rope will be classified as spin resistant, any higher and the rope is NOT rotation resistant at all.

Correct usage and care with handling will prolong the working life. This is due to the friction on the inner wires caused by the strand crossover’s which will eventually cause the inner wires to break up. This is more apparent on non rotating wire rope with two layers. Ropes with 3 or more strand layers will distribute the radial pressures more evenly. Which will reduce friction and stress on the inner wires.

Regular,thorough inspectionsof non rotating rope are essential due to the fact that it is the inner strands that often break first and broken internal wires often go unnoticed as they are difficult to see.Rope Services Direct offer inspectionson all rope with certification issued on completion.

Holding both ends of the rope will prevent unraveling. Correctly fitted terminations will help to prevent damage. Kinking and unraveling may occur and they can also have an effect on the rotational balance if not fitted correctly.

A wide variety of wire rope sling price options are available to you, You can also choose from unisex, wire rope sling price,As well as from support, {2}, and {3}.

There are a variety of cables and wires that are used for various purposes. They can either be hidden underground or pass overhead. Crane Cable is one such cable wire rope made out of several strands of metal wires that are twisted together into a helix form to make them into a single rope. Initially, wrought iron was used to make these Crane Cables however, these days steel is the primary material used. Apart from this high carbon steel and galvanized steel are also used in manufacturing these cables. Dents or flaws in the ordinary link chain can lead to severe failure whereas, damage in these EOT Crane Cablecan be easily covered up. Ther are ideally used for lifting elevators, in the transmission of mechanical power, and in cranes.

Crane Lifting Cables are resistant to corrosion and have excellent ductility for optimal fatigue. They have a high breaking strength compared to steel crane wire rope. The radially elastic rope structure absorbs the dynamic force thus giving it high impact resistance. Crane Cable Wires are said to be cost-effective as a strong and durable structure helps in reducing maintenance costs and downtime. They can be coated with bright phosphate or galvanized depending upon the customers’ requirements.

Crane Electrical Cable is available in rotating, rotation, compact, or non-compact structures. Most of the wire ropes have the tendency of developing torque and are thus prone to rotation. However, non-rotation wires are designed in a way that their outer rotation naturally counteracts the inner strands rotation. Crane Hoist Cable can be used in tower crane ropes or offshore crane ropes.

Overhead Crane Cable reel should be capable of winding it automatically. The drive torque of the crane cable should not be less than the max winding torque of the winding crane cable. The cable conductor should be as small as possible when the Crane Rope laying acts on the traction force.

The Crane Wire Rope does not have a reinforcement core, the maximum tension allowed on the copper conductor cross-section is 20N/mm2. We at Bhuwal Insulation Cable Pvt. Ltd. not only provide you the best quality Tower Crane Cable but also the parts required to assemble them. Our long-standing reputation in providing the best quality product at a competent price has made us one of the leading Crane Cable manufacturers in India.

Cables or cords are the wire ropes which have diameters smaller than 3/8 inches, While wire ropes have diameters greater than 3/8 inches. if there are two or more wire concentrically laid then it is known as strand

Warrington: Two layers of wires around a center with one diameter of wire in the inner layer and two diameters of wire alternating large and small in the outer later

6 by 19 is a type of wire rope which can withstand fatigue resistance, abrasion and prevents crushing on drums. it is available in diatmeter range of 3mm to 6 mm. While 7 by 19 are wire rope which has diameters ranging between 3 mm to 16 mm which can be use in different applications.

8613371530291

8613371530291