wire rope breaking strength vs working load made in china

It’s rare for a week to go by here at Industrial Wire Rope without discussions about tensile strength or working load limit. We take it for granted that most people in our industry know there is a difference in the meaning of these terms. Yet, these terms and others are highly interrelated, and we thought an overview of them on one page might be a helpful reference. For those who want to dive deeper into the definitions and how they apply on the job, we’re also providing links to sources with additional information.

Let’s start with Tensile Strength. As we described in a post from 2017, “Tensile strength is a measurement of the force required to pull something such as rope, wire, or a structural beam to the point where it breaks. The tensile strength of a material is the maximum amount of tensile stress that it can take before failure, for example breaking.”

In our immediate world, tensile strength is the force required to break the ropes we offer. Tensile strength is determined by testing. Obviously, it is different for every type of rope, being a function of the material and construction of each type.

Although tensile strength is a definitive quantity measuring the force required to break a rope, working load limit is a measure that takes a wide range of variables into account. And always, the tensile strength of a material is greater than the recommended working load limit.

The working load limit provides consideration for factors such as the abrasion, friction and rubbing the rope is subjected to, the variance in temperature extremes it is exposed to, harmful substances that may come into contact with it, age, and even knots in the rope. Working load limit is defined as “the maximum load which should ever be applied to the product, even when the product is new and when the load is uniformly applied”.

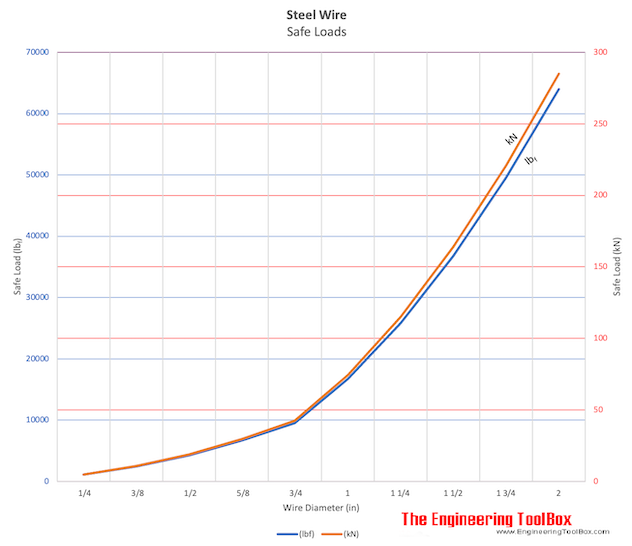

Working load limit is always a fraction of tensile strength, allowing for a generous margin of safety. For wire ropes, it’s common for the working load limit to be set at 20% of tensile strength. However, you generally don’t have to be concerned about doing the math on your own. Rope manufacturers typically mark the working load limit on the products, so the information should be readily available to you.

Wire rope slings adopt precast concrete construction and the main parts include wire rope, inner core, strand, center, steel wire, steel stocks and others.

We can customize various kinds of rigging according to customers’ requirement. Usually, the minimum circumference S of the sling is 50 times the wire rope diameter and the bending radius must be not less than 4 times of the wire rope diameter. The zone between the clamps can’t be bent under lifting force and the length is intended to be the dimension measured between the bearing points of the slings and the measured length of a ferrule-secured sling shall not differ from the nominal length by more than two rope diameters or 1% of the nominal length.

①Vertical hitches are made directly from the crane hook to the load. Full rated capacity of the slings may be used but never exceeded. A tagline should be attached to prevent rotation which can damage the sling. A sling with a hand-tucked splice can’t lay and fail if the sling is allowed to rotate.

②Choker hitches reduce lifting capability of a sling, since this method of rigging affects the ability of the wire rope components to adjust during the lift, places angular loading on the body of the sling, and creates a small diameter bend in the body at the choke point.

Wire rope slings are always packaged in plywood reel/plastic reel/wooden reel/coil in container, and then they will be palletized or put into a crate or a box.

There are various types of wire rope slings including slings with soft eye, hoist slings, slings with soft eye and two legs, steel ferrule secured slings, slings with Flemish eyes, ferrule secured endless slings, slings with steel-ferrule secured end stops, slings with swaged steel tie rod, slings with single hook, slings for crane, slings with sockets, slings with master link and two legs, slings with cuneiform connector, flat wire rope mesh slings, slings with master link and four legs, endless wire rope slings, container lifting slings for sea oil platform, large diameter cable laid slings, slings for lifting reinforcing steel bars, cable laid grommet slings, cable stocking, slings with spliced eye termination and others, and the main products are as following.

2-Leg bridle slings constructed of two wire rope assemblies that are attached to an oblong ring are designed for general lifting when the attachment can be made directly to the load. The lifting ends of the wire rope legs can be fitted with a variety of hooks, eyes, or rings to allow attachment to nearly any object. The advantage of wire rope slings is that they are resistant to corrosion, heat, sunlight and most chemicals and they are custom built to meet your specific needs for any application.

3-Leg bridle wire rope slings constructed of three wire rope assemblies that are attached to an oblong ring are designed to handle unbalanced loads. The lifting ends of the wire rope legs can be fitted with a variety of hooks, eyes, or rings to allow attachment to nearly any object. We carry a range of wire rope slings in our hire fleet with soft eye configurations at each end, available in various capacities and effective working lengths.

4-Leg bridle wire rope lifting slings constructed of four wire rope assemblies that are attached to an oblong ring are designed for balanced or unbalanced loads and for heavy lifts when the weight can easily be distributed over four points. The lifting ends of the wire rope legs can be fitted with a variety of hooks, eyes, or rings to allow attachment to nearly any object.

The endless wire rope slings are orbicular, economical and adaptable slings with no fixed wear points, using special technology and the most advanced equipment and known for its softness, high tension and increased suspension points. They are suitable to lift and move tubes, pipes and long metal parts which suited in small and limited spaces and for high/large lifting loads, they are also adaptable for special bulk hoisting requirements of different conditions, such as transformers, shipbuilding and special machinery (where the warning mark locates cannot be used as lifting point)

Slings can be realized with galvanized or ungalvanized wire rope, special rope protected by strong PVC sleeve to resist against sharp edges without damaging the goods surface is also available as per your request.

7. According to the strength, wire rope slings can be divided into vertical breaking strength, chocker breaking strength, basket breaking strength, and except for standard eye size, thimble eye size, there are others of different eye hook capacity.

④Evidence of heat damage or if a wire rope sling having a fiber core is exposed to temperatures in excess of 200° F or if a wire rope sling having a steel core is used at temperatures above 400° F or below minus 60° F.

⑤Corrosion of the rope or end attachments or not laying and opening up of a tucked splice. Also, when end attachments that are cracked, deformed, or worn.

⑦Avoid twists, kinks and knots before lifting, store wire rope slings where they will not be subjected to dirt, moisture, extreme heat, corrosion or mechanical damage.

⑧Protect the sling body against sharp edges and corners of loads, protrusions or abrasive surfaces. Sharp bends can distort wire rope and reduce its strength.

⑨Never "shock load" wire rope slings, the actual force caused by a sudden application of load can easily exceed rated capacities and damage slings and abruptly releasing a load can also damage the slings.

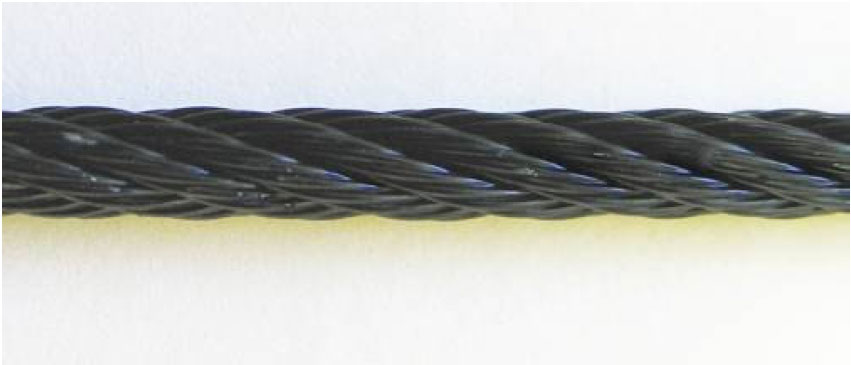

Wire rope and cable are each considered a “machine”. The configuration and method of manufacture combined with the proper selection of material when designed for a specific purpose enables a wire rope or cable to transmit forces, motion and energy in some predetermined manner and to some desired end.

Two or more wires concentrically laid around a center wire is called a strand. It may consist of one or more layers. Typically, the number of wires in a strand is 7, 19 or 37. A group of strands laid around a core would be called a cable or wire rope. In terms of product designation, 7 strands with 19 wires in each strand would be a 7×19 cable: 7 strands with 7 wires in each strand would be a 7×7 cable.

Materials Different applications for wire rope present varying demands for strength, abrasion and corrosion resistance. In order to meet these requirements, wire rope is produced in a number of different materials.

Stainless Steel This is used where corrosion is a prime factor and the cost increase warrants its use. The 18% chromium, 8% nickel alloy known as type 302 is the most common grade accepted due to both corrosion resistance and high strength. Other types frequently used in wire rope are 304, 305, 316 and 321, each having its specific advantage over the other. Type 305 is used where non-magnetic properties are required, however, there is a slight loss of strength.

Galvanized Carbon Steel This is used where strength is a prime factor and corrosion resistance is not great enough to require the use of stainless steel. The lower cost is usually a consideration in the selection of galvanized carbon steel. Wires used in these wire ropes are individually coated with a layer of zinc which offers a good measure of protection from corrosive elements.

Cable Construction The greater the number of wires in a strand or cable of a given diameter, the more flexibility it has. A 1×7 or a 1×19 strand, having 7 and 19 wires respectively, is used principally as a fixed member, as a straight linkage, or where flexing is minimal.

Selecting Wire Rope When selecting a wire rope to give the best service, there are four requirements which should be given consideration. A proper choice is made by correctly estimating the relative importance of these requirements and selecting a rope which has the qualities best suited to withstand the effects of continued use. The rope should possess:Strength sufficient to take care of the maximum load that may be applied, with a proper safety factor.

Strength Wire rope in service is subjected to several kinds of stresses. The stresses most frequently encountered are direct tension, stress due to acceleration, stress due to sudden or shock loads, stress due to bending, and stress resulting from several forces acting at one time. For the most part, these stresses can be converted into terms of simple tension, and a rope of approximately the correct strength can be chosen. As the strength of a wire rope is determined by its, size, grade and construction, these three factors should be considered.

Safety Factors The safety factor is the ratio of the strength of the rope to the working load. A wire rope with a strength of 10,000 pounds and a total working load of 2,000 pounds would be operating with a safety factor of five.

It is not possible to set safety factors for the various types of wire rope using equipment, as this factor can vary with conditions on individual units of equipment.

The proper safety factor depends not only on the loads applied, but also on the speed of operation, shock load applied, the type of fittings used for securing the rope ends, the acceleration and deceleration, the length of rope, the number, size and location of sheaves and drums, the factors causing abrasion and corrosion and the facilities for inspection.

Fatigue Fatigue failure of the wires in a wire rope is the result of the propagation of small cracks under repeated applications of bending loads. It occurs when ropes operate over comparatively small sheaves or drums. The repeated bending of the individual wires, as the rope bends when passing over the sheaves or drums, and the straightening of the individual wires, as the rope leaves the sheaves or drums, causing fatigue. The effect of fatigue on wires is illustrated by bending a wire repeatedly back and forth until it breaks.

The best means of preventing early fatigue of wire ropes is to use sheaves and drums of adequate size. To increase the resistance to fatigue, a rope of more flexible construction should be used, as increased flexibility is secured through the use of smaller wires.

Abrasive Wear The ability of a wire rope to withstand abrasion is determined by the size, the carbon and manganese content, the heat treatment of the outer wires and the construction of the rope. The larger outer wires of the less flexible constructions are better able to withstand abrasion than the finer outer wires of the more flexible ropes. The higher carbon and manganese content and the heat treatment used in producing wire for the stronger ropes, make the higher grade ropes better able to withstand abrasive wear than the lower grade ropes.

Effects of Bending All wire ropes, except stationary ropes used as guys or supports, are subjected to bending around sheaves or drums. The service obtained from wire ropes is, to a large extent, dependent upon the proper choice and location of the sheaves and drums about which it operates.

A wire rope may be considered a machine in which the individual elements (wires and strands) slide upon each other when the rope is bent. Therefore, as a prerequisite to the satisfactory operation of wire rope over sheaves and drums, the rope must be properly lubricated.

Loss of strength due to bending is caused by the inability of the individual strands and wires to adjust themselves to their changed position when the rope is bent. Tests made by the National Institute of Standards and Technology show that the rope strength decreases in a marked degree as the sheave diameter grows smaller with respect to the diameter of the rope. The loss of strength due to bending wire ropes over the sheaves found in common use will not exceed 6% and will usually be about 4%.

The bending of a wire rope is accompanied by readjustment in the positions of the strands and wires and results in actual bending of the wires. Repetitive flexing of the wires develops bending loads which, even though well within the elastic limit of the wires, set up points of stress concentration.

The fatigue effect of bending appears in the form of small cracks in the wires at these over-stressed foci. These cracks propagate under repeated stress cycles, until the remaining sound metal is inadequate to withstand the bending load. This results in broken wires showing no apparent contraction of cross section.

Experience has established the fact that from the service view-point, a very definite relationship exists between the size of the individual outer wires of a wire rope and the size of the sheave or drum about which it operates. Sheaves and drums smaller than 200 times the diameter of the outer wires will cause permanent set in a heavily loaded rope. Good practice requires the use of sheaves and drums with diameters 800 times the diameter of the outer wires in the rope for heavily loaded fast-moving ropes.

It is impossible to give a definite minimum size of sheave or drum about which a wire rope will operate with satisfactory results, because of the other factors affecting the useful life of the rope. If the loads are light or the speed slow, smaller sheaves and drums can be used without causing early fatigue of the wires than if the loads are heavy or the speed is fast. Reverse bends, where a rope is bent in one direction and then in the opposite direction, cause excessive fatigue and should be avoided whenever possible. When a reverse bend is necessary larger sheaves are required than would be the case if the rope were bent in one direction only.

Stretch of Wire Rope The stretch of a wire rope under load is the result of two components: the structural stretch and the elastic stretch. Structural stretch of wire rope is caused by the lengthening of the rope lay, compression of the core and adjustment of the wires and strands to the load placed upon the wire rope. The elastic stretch is caused by elongation of the wires.

The structural stretch varies with the size of core, the lengths of lays and the construction of the rope. This stretch also varies with the loads imposed and the amount of bending to which the rope is subjected. For estimating this stretch the value of one-half percent, or .005 times the length of the rope under load, gives an approximate figure. If loads are light, one-quarter percent or .0025 times the rope length may be used. With heavy loads, this stretch may approach one percent, or .01 times the rope length.

The elastic stretch of a wire rope is directly proportional to the load and the length of rope under load, and inversely proportional to the metallic area and modulus of elasticity. This applies only to loads that do not exceed the elastic limit of a wire rope. The elastic limit of stainless steel wire rope is approximately 60% of its breaking strength and for galvanized ropes it is approximately 50%.

Preformed Wire Ropes Preformed ropes differ from the standard, or non-preformed ropes, in that the individual wires in the strands and the strands in the rope are preformed, or pre-shaped to their proper shape before they are assembled in the finished rope.

This, in turn, results in preformed wire ropes having the following characteristics:They can be cut without the seizings necessary to retain the rope structure of non-preformed ropes.

They are substantially free from liveliness and twisting tendencies. This makes installation and handling easier, and lessens the likelihood of damage to the rope from kinking or fouling. Preforming permits the more general use of Lang lay and wire core constructions.

Removal of internal stresses increase resistance to fatigue from bending. This results in increased service where ability to withstand bending is the important requirement. It also permits the use of ropes with larger outer wires, when increased wear resistance is desired.

Outer wires will wear thinner before breaking, and broken wire ends will not protrude from the rope to injure worker’s hands, to nick and distort adjacent wires, or to wear sheaves and drums. Because of the fact that broken wire ends do not porcupine, they are not as noticeable as they are in non-preformed ropes. This necessitates the use of greater care when inspecting worn preformed ropes, to determine their true condition.

Wire rope is the sinew that enables winch muscle to be applied where it is needed. Wire rope positions the dredge, crowds the cutter into the solids bank and supports the ladder.

Table 9 below provides information on the strength of various sizes of one popular style of wire rope, 6 x 19 IWRC. The rope is made up of 6 strands, each of which is made up of from 16 to

A. LAY is the direction in which the strands “lay” as you look along a length of wire rope. Strands that veer to the right are RIGHT Lay. Strands that veer to the left are LEFT Lay. It makes no difference which way you look down the rope.

B. RELATIONSHIP has to do with the direction the strand wires lay in relation to the direction in which the strands lay. If the strand wires spiral in the direction opposite the direction the strands spiral the rope is REGULAR Lay. If the strand wires spiral in the same direction as the strands spiral the rope is LANG Lay.

The sketch below shows a typical dredge ladder rigging with a bail load of 50,000 lb. and how to determine the number of parts of line. The parts of line can be determined by counting the number of cable segments that run between the hoist block to the bail block. The parts of line determines the extent of the multiplying effect that makes it possible for a single line coming off the winch drum with a relatively small line pull to lift a heavy load. A friction factor must be applied along with the line part multiplier to calculate the actual lift capability.

Using the sketch above, consider what could happen if the ladder became stuck underwater. The effective winch drum diameter may be reduced to only about 60% of its full-drum diameter because cable has been pulled off the drum to lower the ladder. Were this the situation, the line pull would increase from the rated 11,600 lb. shown to an actual 19,300 lb. This changes the safety factor for ¾” cable from a working 5 to 1 to an actual 2.7 to 1. If the winch has a full-drum line pull capability greater than 11,600 lb. rating., the line pull could be much higher and put the ¾” cable further in danger of parting. Do not skimp on rigging!

Often generically referred to as Crosby clips and occasionally as bulldogs we offer both forged and malleable wire rope clips. Forged clips are required for use in overhead lifting. The malleable clips are recommended for non critical light duty applications such as guard rails, guy wires etc. The efficiency rating on the proper number of properly applied wire rope clips is 80% of the strength of the wire rope. We offer both offshore and Genuine Crosbie Wire Rope Clips. Fist Grips have a couple of advantages over Wire Rope clips in that they are impossible to apply incorrectly and they damage the rope less in situations where the clip will be removed.

Wire rope clips must be re tightened after applying load. In accordance with good rigging practice wire rope and its terminations should be regularly inspected.

Unfortunately, polyester melts at approx. 250°C (~480°F). Research has shown that a 2k luminair-housing can reach temperatures of about 190°C (~370°F), with the truss-chord straight over it being almost 140°C (~280°F). Accidents have been reported of round slings being melted by spots, pyro or the heat of the rays, and as a result, trusses have fallen. When round slings are used, a safety backup must be applied such as a wire rope or chain sling.

So rather than have a backup steel sling why not make the sling out of steel but softer than a single cable. A steel round sling has a normal outside webbing for soft slings, but instead of the polyamide core, the steel round sling has a core made of many small steel cables, which makes it resistant to high temperatures. The steel wires within the steel round are as flexible as a normal soft sling, but have a much better fire resistance. The steel round can be used in circumstances where the normal soft slings are not allowed.

The outside webbing is black, including an identification label and a hidden inspection window to inspect the steel wires within the sling. The wire-rope core has better heat resistance than the truss itself.

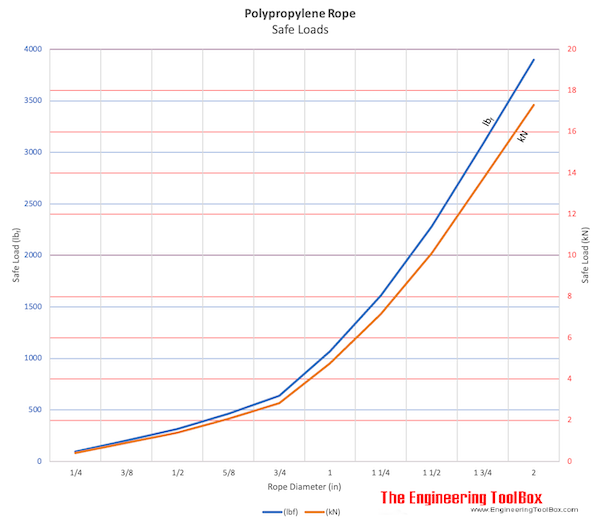

Down Stage Right can supply most of your rope and cordage requirements from twill tape and black cotton tie line to large diameter manila and polyester ropes and braids. To make life very very confusing the synthetic fibre ropes are all available in either a 3 strand, solid braid, double braid or parallel core configuration in nylon, polyester or more exotic materials. Polyester ropes are available in a spun or non spun finish. Due to the huge number of different sizes, colours, materials and braid types combinations (and to simplify things) Down Stage Right Industries stocks several favourites that we have found the theatrical industry usually purchases. If you need a particular rope we are happy to bring in the particular configuration and colour that you want. Please call for details or recommendations for a particular product.

The primary advantage of sash cords are their handling characteristics and their knot holding ability. It does not have the strength or durability of double braids. Available in white as a cotton polyester blend or in black as spun polyester. Sash braid is generally a coarser cousin of solid braid.

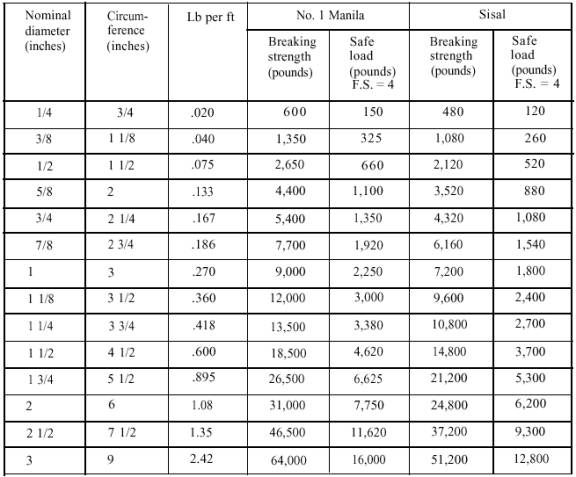

Often mislabeled as hemp, manila is significantly stronger and is used in for hand lines in counterweight rigging and as general purpose spot line rope. We only carry #1 grade sea worthy manila. Manila has generally been replaced by synthetics in our industry

Working loads are guidelines only. Once put into service rope is continually deteriorating. Manila rope will deteriorate in storage even under ideal conditions.

Solid braid ropes are sometimes referred to as “sash cord” because this pattern was used to raise sash windows. It is formed by braiding 8 to 18 strands in a reasonably complicated pattern with all the strands rotating in the same direction on the braider. The individual stitches are oriented in the same direction as the rope. The center may contain a filler core. These ropes maintain their round shape well and therefore work exceptionally well in pulleys and sheaves. They tend to have high elongation and are generally less strong than other forms of construction, and are difficult to splice.

"Double braid" ropes, also referred to as "Marine Ropes" or "Yacht Braid" or “2 in 1” are perhaps the most well known braided rope on the market today. They are constructed of a hollow braided rope, which acts as a core inside another braided rope. The combination of the 2 ropes in 1 results in a rope with higher tensile strength than commonly found in twisted ropes. The inner rope and outer rope are generally designed to share the load fairly evenly. Double braid ropes have a torque free construction, and are easily spliced. However, caution must be exercised where double braid ropes are run over pulleys, through hardware or in any situation where the outer rope may slide along on the inner rope and bunch up. This condition, often called "milking", will cause dramatic loss of strength by causing the entire load to go onto the inner rope, because the sheath is bunched up and therefore not under the same tension as the inner rope. Polyester double braid ropes big advantage is that they do not have the same stretch as nylon. They can also be made with a soft “spun” covering giving a better hand feel. The elasticity of nylon ropes can absorb sudden shock loads that would break other ropes.

Manufactured by New England Ropes Stage Set X is a superior replacement for manila with a longer life, much higher strength and no slivers. This rope was specially developed as a replacement for manila hand lines in counterweight rigging and we find it to be Cadillac of the synthetic hand line ropes. Multiline II is a three stranded rope with the same ideals in mind. It is more economically priced and has slightly different handling characteristics.

PRODUCT DESCRIPTION: New England Ropes" Stage-Set X is the softest, strongest and most environmentally stable product available in the theatre industry for counterweight systems. It"s parallel core of polyester fibre contained within a helically wrapped polyester tape and covered by a braided polyester jacket, remains firm and round under all load conditions and resists crushing in rope locks.

Compliance to the above specifications is based upon testing according to the Cordage Institute Standard Testing Methods for Fiber Rope and/or ASTM D-4268 Standard Methods of Testing Fiber Ropes.

Tensile strengths - Are approximate average for new, unused ropes. To estimate the minimum tensile strength of a new rope, reduce the approximate average by 15% (Cordage Institute defines minimum tensile strength as two standard deviations below the average tensile strength of the rope).

Good resistance to the passage of electrical current. However in rope form, dirt, surface contaminants, water entrapment and the like can significantly affect dielectric properties. Extreme caution should be exercise any time a rope is in the proximity of live circuits.

No blanket working load recommendation can be made because it depends on the application and conditions of use, especially potential danger to personnel. It is recommended that the user establish working loads and safety factors based on professional and experienced assessments of risks. The working load is a guideline for the use of a rope in good condition for non-critical applications and should be reduced where life, limb, or valuable property is involved, or exceptional service such as shock, sustained loading, severe vibration, etc.

The Cordage Institute specifies that the Safe Working Load of a rope shall be determined by dividing the Minimum Tensile Strength by the Safety Factor. Safety factors range from 5 to 12 for non-critical uses, 15 for life lines.

PRODUCT DESCRIPTION: Multiline II is a 3-strand composite rope, its unique construction combines filament and staple/spun polyester wrapped around a polyolefin core (smaller than 1/2" diameter does not have polyolefin core). Multiline II feels and handles like manila, yet provides greater durability, higher strength, lighter weight, and a consistent supple feel over time.

Compliance to the above specifications is based upon testing according to the Cordage Institute Standard Testing Methods for Fiber Rope and/or ASTM D-4268 Standard Methods of Testing Fiber Ropes.

Tensile strengths - Are approximate average for new, unused ropes. To estimate the minimum tensile strength of a new rope, reduce the approximate average by 15% (Cordage Institute defines minimum tensile strength as two standard deviations below the average tensile strength of the rope).

Good resistance to the passage of electrical current. However in rope form, dirt, surface contaminants, water entrapment and the like can significantly affect dielectric properties. Extreme caution should be exercise any time a rope is in the proximity of live circuits.

No blanket working load recommendation can be made because it depends on the application and conditions of use, especially potential danger to personnel. It is recommended that the user establish working loads and safety factors based on professional and experienced assessments of risks. The working load is a guideline for the use of a rope in good condition for non-critical applications and should be reduced where life, limb, or valuable property is involved, or exceptional service such as shock, sustained loading, severe vibration, etc.

The Cordage Institute specifies that the Safe Working Load of a rope shall be determined by dividing the Minimum Tensile Strength by the Safety Factor. Safety factors range from 5 to 12 for non-critical uses, 15 for life lines.

Approximately 0.3–0.6% carbon content.Balances ductility and strength and has good wear resistance; used for large parts, forging and automotive components, commonly most of the drop forged shackles, turnbuckles, or any other need heat treatment rigging items are made in Medium carbon steel (C1045). You can

In the rigging industry, the most commonly produced type of carbon steel is low carbon steel and medium carbon steel, because they can be formed very easily due to the right wt% C, and after heat treating(Quenched & Tempered), their mechanical properties will be changed to ductility, hardness, yield strength, or impact resistance.

Alloy steel is steel that is alloyed with a variety of elements to improve its mechanical properties. Most commonly, all steel is an alloy, including carbon steel, while in the rigging industry field, the phrase “alloy steel” refers to a very specific type of carbon steel, combined with the element, manganese, chromium, or both, this increased strength and to help fight the brittleness that many types of untreated steel display, especially after the heat treatment. It is used in our

Stainless steel also known as inox steel (meaning inoxidizable from the French word inoxydable), is actually a type of alloy steel mixed with a minimum of approximately 11% chromium, nickel, molybdenum, and extremely low carbon as one of its elements. The other alloying elements may vary according to the structural and chemical properties required for the stainless steel.

Normally, when carbon steel is exposed to moisture, it undergoes a chemical transformation, known as oxidation, that changes their properties, although stronger and more durable, if there is no additional protection against rust on the surface, such as hot dipped galvanized, zinc plated or painted.

Carbon steel and alloy steel are stronger and harder than stainless steel for high carbon content changes the characteristics of steel, whereas alloy steel is the strongest of the three, for its includes element, manganese, chromium, modify the properties of the metal, especially after the Quanched and Tempered, and it can resistant to rust and corrosion without galvanization.

Although carbon steel lacks the corrosion-resistant properties of its stainless steel counterpart, and not stronger and harder than alloy steel, it is less expensive and can create a wide range of steel alloy specific applications by adding the element combinations.

As specialist for manufacturing quality steel wire ropes over 20 years, our company can supply strong, durable and reliable ropes that capable to minimize your downtime and maximize cost effectiveness. Decades of experience we owned make us know clearly the work you do and capable to provide professional guidance.

We select the best steel or stainless steel as raw material for wire rope manufacturing. Our products are manufactured under strict quality managements and test before they leave the factory.

Our engineers can provide professional advice about picking up optimal steel wire ropes for their application, installation guidance to ensure maximum return in their wire rope system.

If you are going to pick up steel wire ropes that suit your project perfectly, you must have an ideal about the construction about them. Our company can supply bright wire rope, galvanized wire rope, stainless steel wire rope, compacted wire rope, rotation resistant wire ropes, mining wire rope, elevator wire rope, crane wire rope and gas & oilfield wire ropes. Here are some details to solve the problem that may puzzle you whether you are browsing the web or picking up steel wire ropes.

Bright steel wire ropes mean no surface treatment is applied to the rope. Therefore, they have the lower price among these three wire ropes. Generally, they are fully lubricated to protect the rope from rust and corrosion.

Galvanized steel wire ropes feature compressed zinc coating for providing excellent corrosion resistance. With higher break strength yet lower price than stainless steel, galvanized steel wire ropes are widely used in general engineering applications such as winches and security ropes.

Stainless steel wire ropes, made of quality 304, 305, 316 steels, are the most corrosive type for marine environments and other places subjected to salt water spray. Meanwhile, bright and shiny appearance can be maintained for years rather than dull as galvanized steel wire ropes.

Steel wire ropes are composed of multiple strands of individual wires that surrounding a wire or fiber center to form a combination with excellent fatigue and abrasion resistance. These wires and strands are wound in different directions to from different lay types as follows:

Beside above lay types, alternative lay ropes which combine regular lay and lang lay together and ideal for boom hoist and winch lines, can also be supplied as your request.

Two main methods about seizing steel wire ropes in conjunction with soft or annealing wire or strands to protect cut ends of the ropes form loosening.

6 x 19 CLASS BRIGHT WIRE ROPE IWRC (EIPS)* STEEL CORE - 6 x 19 wire rope is a general purpose steel rope that’s widely used and is commonly used for winch lines, skylines and chokers. This wire rope overs a great overall combination of both flexibility and wear resistance.

* EIPS (Extra Improved Plowed Steel) wire rope has roughly 10% more strength than regular IPS. Independent wire rope core ( IWRC ) provides added strength, reduces the amount of stretch. IWRC wire rope also is resistance to heat and provides extra corrosion resistance over a typical bright wire finish.

While talking to people at a recent trade show it hit me: There is a lack of information in the marketplace concerning the quality of available wire rope . Most people feel that there is one general level of cable quality, usually based on their experience with imported wire rope. Let"s take a minute to clear up the confusions many people have about wire rope availability and performance.

When I dig a little deeper, I always find out that the cable they are using is low quality import material, often from China, that never seems to perform the way they intended. Short service life, broken wires and low break strength are often tolerated because the wire rope is just so very cheap. And the lowering of quality and performance from your wire rope tends to feed on itself: Inexpensive cable performance is sub-par, so the purchaser becomes conditioned to poor performance. This translates into a buying decision focused solely on the price of the wire rope, which in turn leads to distributors looking for less and less expensive material, which dictates the quality, and so on.

Ultimately, this cycle results in wire rope that is manufactured to just meet the thresholds of performance required by specification, and nothing more. Some applications can accept this material, but the majority of customers would be best served by selecting a higher quality wire rope.

When the performance is a key element of your application, you should be requesting a high quality domestic wire rope. Why should you purchase a domestic rope? Domestic manufacturers work with smaller lot sizes and focus on quality.

It will require a larger investment to purchase and employ the higher quality material, but that will end the downward quality spiral created by using the least expensive cable you can find. You will notice, first and foremost, that your cable will last longer and perform at an improved level. You will also notice that the added cost for purchasing a domestic wire rope is minimal when compared to the extended life you will receive.

So for your next purchase, request a domestic wire rope for your application. Here are some general rules to ensure you receive the best cable available:

1. Not all wire rope is created equal. There are specifications for wire rope, including Federal Specification RR-W-410 and Military Specification MIL-DTL-83420, both detailing the level of quality and performance required for specific applications. When purchasing a wire rope, be sure to reference one of these specifications to ensure you receive a higher quality material.

2. Just because you purchased the rope from a domestic source does not mean that it is domestic.Make sure you specifically request a domestic wire rope.

3. Domestic Wire rope is available.there are several manufacturers that would be more than delighted t quote your requirements. You can find a list of companies on the Domestic Wire Rope Committee web site.

A 6X19 class wire rope contains 6 strands with 16 through 26 wires per strand. Our 6x19 class typically has either 19 (6X19) or 26 (6X26) wires per strand. It is a general purpose rope most commonly used for wire rope chokers and other rigging. 6X19 and 6X26 offfer great abrasion resistance and crush resistance when spooling.

A 6X37 class wire rope contains 6 strands with 27 through 49 wires per strand. Our 6X37 typically has 36 wires per strand. It is a general purpose wire rope with excellent flexibility for spooling. With the smaller wires per strand, the trade off for excelelnt flexibility is reduced abrasion resistance.

IWRC (Independent Wire Rope Core) wire ropes offer more crush resistance when spooling while FC (Fiber Core) wire ropes offer more flexibility. FC wire ropes are not as crush resistant when spooling compared to an IWRC wire rope.

Rigging and safety gear purchased from Westech Rigging Supply should be used in strict accordance with all industry and OSHA standards. At no time should rigging or safety gear be used beyond its certified load ratings (aka Working Load Limits). Normal wear and tear should be expected with use of rigging and safety gear; therefore, all gear should be thoroughly inspected before each and every use. Worn or unsafe rigging and safety gear should never be used.

8613371530291

8613371530291