wire rope breaking strength vs working load for sale

Rope strength is a misunderstood metric. One boater will talk about tensile strength, while the other will talk about working load. Both of these are important measurements, and it’s worth learning how to measure and understand them. Each of these measurements has different uses, and here we’re going to give a brief overview of what’s what. Here’s all you need to know about rope strength.

Each type of line, natural fiber, synthetic and wire rope, have different breaking strengths and safe working loads. Natural breaking strength of manila line is the standard against which other lines are compared. Synthetic lines have been assigned “comparison factors” against which they are compared to manila line. The basic breaking strength factor for manila line is found by multiplying the square of the circumference of the line by 900 lbs.

As an example, if you had a piece of ½” manila line and wanted to find the breaking strength, you would first calculate the circumference. (.5 X 3.14 = 1.57) Then using the formula above:

To calculate the breaking strength of synthetic lines you need to add one more factor. As mentioned above, a comparison factor has been developed to compare the breaking strength of synthetics over manila. Since synthetics are stronger than manila an additional multiplication step is added to the formula above.

Using the example above, letÂ’s find the breaking strength of a piece of ½” nylon line. First, convert the diameter to the circumference as we did above and then write the formula including the extra comparison factor step.

Knots and splices will reduce the breaking strength of a line by as much as 50 to 60 percent. The weakest point in the line is the knot or slice. However, a splice is stronger than a knot.

Just being able to calculate breaking strength doesn’t give one a safety margin. The breaking strength formula was developed on the average breaking strength of a new line under laboratory conditions. Without straining the line until it parts, you don’t know if that particular piece of line was above average or below average. For more information, we have discussed the safe working load of ropes made of different materials in this article here.

It’s very important to understand the fundamental differences between the tensile strength of a rope, and a rope’s working load. Both terms refer to rope strength but they’re not the same measurement.

A rope’s tensile strength is the measure of a brand-new rope’s breaking point tested under strict laboratory-controlled conditions. These tests are done by incrementally increasing the load that a rope is expected to carry, until the rope breaks. Rather than adding weight to a line, the test is performed by wrapping the rope around two capstans that slowly turn the rope, adding increasing tension until the rope fails. This test will be repeated on numerous ropes, and an average will be taken. Note that all of these tests will use the ASTM test method D-6268.

The average number will be quoted as the rope’s tensile strength. However, a manufacturer may also test a rope’s minimum tensile strength. This number is often used instead. A rope’s minimum tensile strength is calculated in the same way, but it takes the average strength rating and reduces it by 20%.

A rope’s working load is a different measurement altogether. It’s determined by taking the tensile strength rating and dividing it accordingly, making a figure that’s more in-line with an appropriate maximum load, taking factors such as construction, weave, and rope longevity into the mix as well. A large number of variables will determine the maximum working load of a rope, including the age and condition of the rope too. It’s a complicated equation (as demonstrated above) and if math isn’t your strong point, it’s best left to professionals.

However, if you want to make an educated guess at the recommended working load of a rope, it usually falls between 15% and 25% of the line’s tensile strength rating. It’s a lotlower than you’d think. There are some exceptions, and different construction methods yield different results. For example, a Nylon rope braided with certain fibers may have a stronger working load than a rope twisted out of natural fibers.

For safety purposes, always refer to the information issued by your rope’s manufacturer, and pay close attention to the working load and don’t exceed it. Safety first! Always.

If you’re a regular sailor, climber, or arborist, or just have a keen interest in knot-tying, be warned! Every knot that you tie will reduce your rope’s overall tensile strength. Some knots aren’t particularly damaging, while others can be devastating. A good rule of thumb is to accept the fact that a tied knot will reduce your rope’s tensile strength by around 50%. That’s an extreme figure, sure, but when it comes to hauling critical loads, why take chances?

Knots are unavoidable: they’re useful, practical, and strong. Splices are the same. They both degrade a rope’s strength. They do this because a slight distortion of a rope will cause certain parts of the rope (namely the outer strands) to carry more weight than others (the inner strand). In some cases, the outer strands end up carrying all the weight while the inner strands carry none of it! This isn’t ideal, as you can imagine.

Some knots cause certain fibers to become compressed, and others stretched. When combined together, all of these issues can have a substantial effect on a rope’s ability to carry loads.

Naturally, it’s not always as drastic as strength loss of 50% or more. Some knots aren’t that damaging, some loads aren’t significant enough to cause stress, and some rope materials, such as polypropylene, Dyneema, and other modern fibers, are more resilient than others. Just keep in mind that any knots or splices will reduce your rope’s operations life span. And that’s before we talk about other factors such as the weather or your rope care regime…

The tensile strength is the load at which a new rope, tested under laboratory conditions, can be expected to break. Rope strength is the approximate average for new rope tested under ASTM test method D-6268. To estimate the minimum tensile strength of a new rope, reduce the approximate average by 20%. Age, use and the type of termination used, such as knots, will lower tensile strengths significantly.

One area of misunderstanding that needs to be brought to the surface is the proper interpretation of rope strength, appropriate usage and care. Let"s start by defining two important terms: "tensile strength" and "working load". Tensile strength is the average strength ofnewrope under laboratory conditions. This is determined by wrapping the rope around two large diameter capstans and slowly adding tension to the line until it breaks. The manufacturer"s recommended working load is determined by taking the tensile strength and dividing it by a factor that more accurately reflects the maximum load that should be applied to a given rope to assure a comfortable safety margin and longevity of the line. Of course that factor varies with the type of fiber and the weaving construction. There are however always exceptions, most notably the fact that rope is susceptible to degradation and damage in numerous ways that are not controllable by the manufacturer.

It may surprise you to find out that the working load for most kinds of rope is between 15% and 25% of the tensile strength. Now consider the fact that any time you tie a knot in a rope you effectively cut the tensile strength in half. The knot when tensioned cuts the line. While certain kinds of knots damage the line less than others, the 50% loss of tensile strength is a good general rule to live by. Research has shown that the figure 8 knot reduces the tensile strength by approximately 35% instead of 50% for other common knots tested.

At Ravenox, we use a third-party mechanical services company to test the failure point or break strength of our ropes. There are two common types of breaks: the sharp break and the percentage break. The sharp break is referred to the measurement when load or force drops by 5% from its peak load measurement. A percentage break is another form of break and is generally determined by the sample material and its relationship to load degradation from a peak load measurement. We measure the percentage break.

In the shipping industry, items like winch straps and ratchet straps use two common measuring metrics. One of them is the working load limit, while the other is the strap’s break strength. At first glance, it’s understandable why some people might mix the two up. They kind of mean the same thing, don’t they? In this article, we’ll look at break strength vs. working load limit, explaining the differences and why those differences are so important.

We’ll start with break strength since this term is more self-explanatory than the other. Put simply, the break strength of a piece of rigging is the amount of weight that would cause the weakest part of the rigging to fail. Ideally, you’ll never actually test a rigging’s break strength, as the weight of the loads they’ll carry will usually be much lower than this limit.

If a cargo strapping system consists of fittings, webbing, and a tensioning device that all have a break strength of 12,000 pounds, that strapping system’s break strength would be 12,000. However, if one of those components (the fittings, webbing, or tensioning device) has a lower break strength of 9,000 pounds, then the entire strapping system has a break strength of 9,000 instead.

The difference in break strength vs. working load limit comes into play when you understand the concept of the working load limit means. A rigging’s working load limit is the amount of weight that it can handle under normal conditions. This number will always be smaller than the break strength, and that piece of rigging should never hold more than its working load limit.

The working load limit of a rigging system is equal to 1/3 the amount of the break strength. As such, a strapping system with a working load limit of 5,000 pounds has a break strength of 15,000 pounds. Remember, the working load limit will determine how much you should allow the system to hold, not the break strength.

Logistick makes our products able to stand the test of time. Our cargo strapping systems have all undergone extensive testing for both working load limit and break strength, so you can rest easy and trust the numbers you see. If you have any questions about our products or how they work, please give us a call. We’ll be happy to help you out.

It’s rare for a week to go by here at Industrial Wire Rope without discussions about tensile strength or working load limit. We take it for granted that most people in our industry know there is a difference in the meaning of these terms. Yet, these terms and others are highly interrelated, and we thought an overview of them on one page might be a helpful reference. For those who want to dive deeper into the definitions and how they apply on the job, we’re also providing links to sources with additional information.

Let’s start with Tensile Strength. As we described in a post from 2017, “Tensile strength is a measurement of the force required to pull something such as rope, wire, or a structural beam to the point where it breaks. The tensile strength of a material is the maximum amount of tensile stress that it can take before failure, for example breaking.”

In our immediate world, tensile strength is the force required to break the ropes we offer. Tensile strength is determined by testing. Obviously, it is different for every type of rope, being a function of the material and construction of each type.

Although tensile strength is a definitive quantity measuring the force required to break a rope, working load limit is a measure that takes a wide range of variables into account. And always, the tensile strength of a material is greater than the recommended working load limit.

The working load limit provides consideration for factors such as the abrasion, friction and rubbing the rope is subjected to, the variance in temperature extremes it is exposed to, harmful substances that may come into contact with it, age, and even knots in the rope. Working load limit is defined as “the maximum load which should ever be applied to the product, even when the product is new and when the load is uniformly applied”.

Working load limit is always a fraction of tensile strength, allowing for a generous margin of safety. For wire ropes, it’s common for the working load limit to be set at 20% of tensile strength. However, you generally don’t have to be concerned about doing the math on your own. Rope manufacturers typically mark the working load limit on the products, so the information should be readily available to you.

Have you picked up a ratchet strap and saw numbers labeled on the strap, and wonder what they mean? Chances are you"re reading the working load limit or break strength. Every piece of load-bearing equipment states these requirements to let you know how much weight that piece of rigging is capable of securing.

When it comes to securing fragile or heavy loads, it is crucial that the product can secure the load without breaking. Although these terms are normally stated, there is confusion about what these terms mean. Read on below to learn what working load limit, break strength, and safety factor mean.

Many people ask about the working load limit, and this is a term to not mix up with breaking strength. Abbreviated as WLL, it is the rating that should never be exceeded when using a product like a ratchet strap. Before using a piece of load-bearing equipment, always make sure to look at the working load limit before use as it is the maximum allowable loading force.

Something to keep in mind is the working load limit is always 1/3 of the breaking strength. So if a ratchet strap has a breaking strength of 15,000 pounds, then the strap will have a working load limit of 5,000 pounds.

The break strength is equally as important as the WLL. The break strength also refers to the point at which your load-bearing equipment will fail. It is expressed in pounds and/or kilograms, and will actually fail if you go over the required amount.

When a ratchet strap is made with webbing, end fittings, and a ratchet all with a 10,000-pound breaking strength, then the break strength of the overall product will stay 10,000 pounds. However, if the same strap has a ratchet with an 8,000-pound break strength, then that would reduce the product"s strength to 8,000.

Safety factor, also known as Design Factor, determines the ratio between the working load limit and break strength. The working load limit"s rating should never exceed when using a sling or tiedown, and this safety factor provides an allowance for shock loading, G force, and other unforeseen factors.

When selecting a ratchet strap, lifting sling, shackle, or any other product, select the product that has suitable characteristics for the type of load, environment, and attachment to the vehicle.

At US Cargo Control, we want you to be safe when securing heavy loads. If you have any questions about the safety requirements, give our team a call at 800-404-7068 or email us at customerservice@uscargocontrol.com.

Wire rope is the lifeline of your tow truck. We’ll help you understand the terminology, construction and ratings of wire rope. We’ll also give you advice on what type of rope to buy, how to attach it to a hook without losing towing capacity, how to inspect and maintain it, how to prevent damage, and how to tell when it’s time to replace it. We’ll also give the pros and cons of synthetic versus wire rope.

“Wire rope,” “line,” “rope” or “wire” are the only correct ways to refer to wire rope, but many tow operators refer to it as cable. Wire rope is not cable. Cable is only an acceptable term when referring to a piece of wire rope that is terminated on both ends. When that cable is connected to a power source, such as a winch, it’s no longer acceptable to call it cable.

The Egyptians were among the first to twist and braid strands of plant material together to form rope. Today’s rope is made of different materials and using different methods, but the basic principle remains the same: smaller diameter material is twisted to form strands, and then those strands are twisted to form the rope (or wire, if the rope is made from steel).

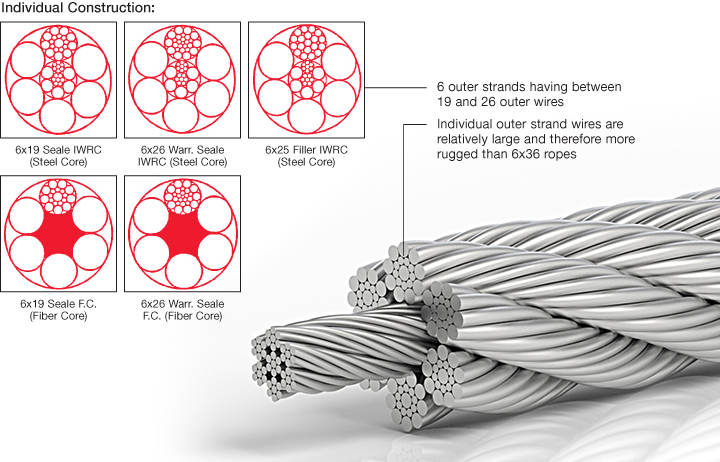

The pictures below show a 6 x 19 wire rope. The ‘19’ refers to the number of smaller diameter wires that are twisted together to form a single strand. The ‘6’ refers to the number of strands that are twisted together to make the wire. The middle of the rope, which isn’t included in either number, is referred to as “the core.”

You might have seen the term “lay” when a manufacturer specifies the type of wire to be used on a piece of their equipment. Lay refers to the direction of the twist of the wires in a strand (right or left) and to the direction that the strands are laid in the rope (regular or lang).

When you inspect a rope with regular lay, the wires appear to run straight down the length of the rope. With lang lay, the wires twist in the same direction as the strands, giving the appearance that the wires run across the rope. Regular lay rope is the most common wire sold today.

Just because your wire rope says it’s rated for an ultimate load (UL, or breaking strength) of 39,000 lbs doesn’t mean you can use that rope to tow 39,000 lbs. That’s because every wire rope has a working load limit (or WLL), which is the actual mass or force the product can support. It’s the working load limit you shouldn’t exceed, not the ultimate load limit.

So why don’t rope manufacturers make our lives easier by giving the WLL on their packaging instead of the UL? That’s because wire rope can handle different weights depending on how it’s being used. Different industries have different WLLs.

For example, standard 1/2” 6 x 19 wire rope has an ultimate load of 26,600 lbs. The working load limit for towing and recovery is 26,600 divided by 4, which is 6,650 lbs.

Synthetic rope is becoming a popular tool in the towing and recovery industry for many reasons. It has a significantly higher rating compared to standard wire, it is much lighter and, because it has no memory, there is less risk of damage caused by bird nesting.

Over the last few years, synthetic rope has also become more available to our industry. There are a wide range of distributors stocking the common sizes.

As with any synthetic product, synthetic rope is more susceptible to damage from sharp edges, but synthetic ropes made with Dyneema fiber is incredibly durable.

The three most common terminations used when attaching a hook to a wire rope are a Flemish eye with thimble splice, open swage socket, and wedge and socket (Becket). The most common of all the terminations is the Flemish eye with thimble splice.

In all cases except the open swage socket (pictured below), the rated capacity of wire rope is reduced when a termination is added to the end of the wire. When a Flemish eye with thimble splice is installed properly, it preserves 90 to 96% of the rope’s rated capacity.

The wedge and socket (pictured below) is the least recommended termination and should only be used to repair a wire that has been damaged in the field. The termination efficiency for the wedge and socket is 80% of the wire’s rated capacity. That means if we install a wedge and socket on the standard 1/2” 6 x 19, our working load limit is reduced to 5,320 lbs (WLL of 6,650 lbs x 0.8 = 5,320 lbs).

We don’t recommend using wire rope clips to terminate a hook on wire rope. Many times these clips are not installed correctly, which significantly reduces the termination efficiency.

Grade of steel. Wire rope is constructed with different grades of steel the same way that chain is manufactured. The most common wire rope grade is extra improved plow steel (EIPS) but you can also select extra extra improved plow steel (EEIPS) that is 10% stronger.

Steel core vs fiber core. When wire rope is constructed, the strands and wires are wrapped around a center core made of either independent wire rope core (IWRC) or fiber core (FC). IWRC, which is made of steel, provides additional strength. Fiber core cushions the strands by accepting lubricant more effectively. For the towing industry, we feel that the benefit of increasing our single line rating with steel core wire outweighs the benefits that fiber core offers.

Strength of rope. When it comes to wire rope, as with many things in life, you get what you pay for. A 1/2” standard 6 x 19 steel core wire rope has a working load limit of 6,650 lbs. If you go for a ½” Python COMPAC 6 steel core rope, your WLL increases to 7,550 (14% increase). Opt for a ½” Python COMPAC 35 steel core rope and your WLL increases to 9,100 (a 37% increase over then standard wire). The COMPAC 35 rope will cost you three times the price of the standard 6-strand wire, though.

Lang lay or regular lay. There are advantages and disadvantages to both lang and regular lay wire rope, depending on the application. Most manufacturers specify the types and lays of wire rope to be used on their piece of equipment. Be sure to consult the operator’s manual for proper application.

Quality of manufacturer. Talk to your wire rope supplier about the rope manufacturer. Imported wire rope is very common in today’s marketplace and many of these suppliers are quality manufacturers. The only way you can tell the quality is by asking questions about the product you’re buying.

It’s important to regularly inspect your wire rope for damage. The most common signs of damage are broken strands, kinks, and flat spots from improper wrapping on the winch drum. Constantly inspect your wire during a recovery to ensure that the winch is gathering wire properly on the winch drum and the wire is properly layered on the winch. If you want to prolong the life of your rope, take the time to unwind and rewind your wire at the first sign of overlapping or bird nesting and always stay within the working load limit.

Depending on the amount of wear and tear your wire is exposed to, you may need to replace it more often. In order to determine when you need to replace your wire, you must unwind it from the winch drum and inspect each foot of wire to determine if it needs attention. This is also a perfect time to lubricate your wire when you wind it back onto the winch. We recommend replacing your wire rope at the first sign of overloading.

It’s important to remember that most wire ropes fail from the inside out. Wire rope lubricant prolongs the life of your wire by protecting it from rust and corrosion while at the same time keeping it flexible. The best lubricant is one that was specifically designed for wire rope. Select a lubricant that doesn’t contain acids or alkalis. We recommend a moly or asphalt-based lubricant. Don’t apply used oils.

In order to protect ourselves and others from injury we must have the confidence in the equipment we are using. You can now speak to your rope supplier with confidence. Ask questions about the product you are about to buy. You never know if it is a quality manufactured piece of equipment.

Wire ropes are essential for safety purposes on construction sites and industrial workplaces. They are used to secure and transport extremely heavy pieces of equipment – so they must be strong enough to withstand substantial loads. This is why the wire rope safety factor is crucial.

You may have heard that it is always recommended to use wire ropes or slings with a higher breaking strength than the actual load. For instance, say that you need to move 50,000 lbs. with an overhead crane. You should generally use equipment with a working load limit that is rated for weight at least five times higher – or 250,000 lbs. in this case.

This recommendation is all thanks to the wire rope safety factor. This calculation is designed to help you determine important numbers, such as the minimum breaking strength and the working load limit of a wire rope.

The safety factor is a measurement of how strong of a force a wire rope can withstand before it breaks. It is commonly stated as a ratio, such as 5:1. This means that the wire rope can hold five times their Safe Work Load (SWL) before it will break.

So, if a 5:1 wire rope’s SWL is 10,000 lbs., the safety factor is 50,000 lbs. However, you would never want to place a load near 50,000 lbs. for wire rope safety reasons.

The safety factor rating of a wire rope is the calculation of the Minimum Break Strength (MBS) or the Minimum Breaking Load (MBL) compared to the highest absolute maximum load limit. It is crucial to use a wire rope with a high ratio to account for factors that could influence the weight of the load.

The Safe Working Load (SWL) is a measurement that is required by law to be clearly marked on all lifting devices – including hoists, lifting machines, and tackles. However, this is not visibly listed on wire ropes, so it is important to understand what this term means and how to calculate it.

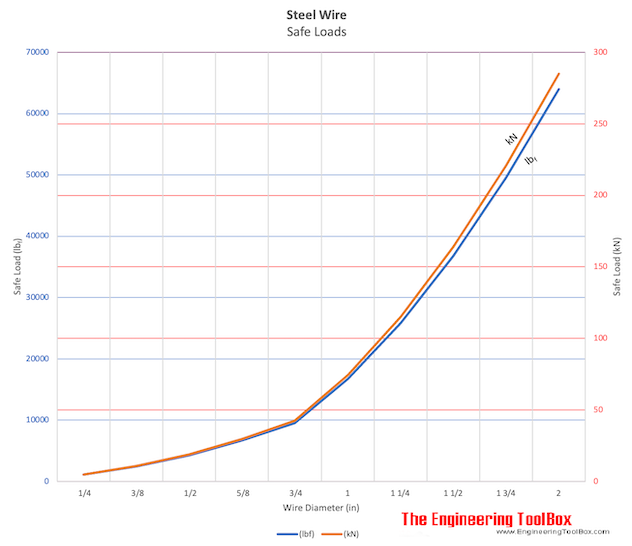

The safe working load will change depending on the diameter of the wire rope and its weight per foot. Of course, the smaller the wire rope is, the lower its SWL will be. The SWL also changes depending on the safety factor ratio.

The margin of safety for wire ropes accounts for any unexpected extra loads to ensure the utmost safety for everyone involved. Every year there aredue to overhead crane accidents. Many of these deaths occur when a heavy load is dropped because the weight load limit was not properly calculated and the wire rope broke or slipped.

The margin of safety is a hazard control calculation that essentially accounts for worst-case scenarios. For instance, what if a strong gust of wind were to blow while a crane was lifting a load? Or what if the brakes slipped and the load dropped several feet unexpectedly? This is certainly a wire rope safety factor that must be considered.

Themargin of safety(also referred to as the factor of safety) measures the ultimate load or stress divided by theallowablestress. This helps to account for the applied tensile forces and stress thatcouldbe applied to the rope, causing it to inch closer to the breaking strength limit.

A proof test must be conducted on a wire rope or any other piece of rigging equipment before it is used for the first time.that a sample of a wire rope must be tested to ensure that it can safely hold one-fifth of the breaking load limit. The proof test ensures that the wire rope is not defective and can withstand the minimum weight load limit.

First, the wire rope and other lifting accessories (such as hooks or slings) are set up as needed for the particular task. Then weight or force is slowly added until it reaches the maximum allowable working load limit.

Some wire rope distributors will conduct proof loading tests before you purchase them. Be sure to investigate the criteria of these tests before purchasing, as some testing factors may need to be changed depending on your requirements.

When purchasing wire ropes for overhead lifting or other heavy-duty applications, understanding the safety dynamics and limits is critical. These terms can get confusing, but all of thesefactors serve an important purpose.

Our company has served as a wire rope distributor and industrial hardware supplier for many years. We know all there is to know about safety factors. We will help you find the exact wire ropes that will meet your requirements, no matter what project you have in mind.

All Hayn Rigging Turnbuckles are designed to exceed the breaking strength of 1x19 stainless steel rope in their corresponding wire size. However a safe working load of 40% of these amounts should not be exceeded!

When it comes to rigging like ratchet straps, winch straps, and just about any other type of strap in the industry, working load limit (WLL) and breaking strength are commonly used measuring metrics.

Every piece of load-bearing wire or rigging equipment carries its own working load limit and break strength rating. These numbers let the user know how much weight that piece of rigging is capable of securing. Though they are usually clearly stated, there is often some confusion about what the two terms mean.

WLL refers to the maximum allowed weight that a piece of rigging can handle under normal conditions. For instance, a winch strap with a WLL of 6,000 pounds should not be used to secure any load above that weight, as it exceeds what it is rated for. WLL is 1/3 of the breaking strength rating, therefore a strap with a WLL of 6,000 pounds would have a breaking strength of 18,000 pounds.

For example, if a ratchet strap is made with end fittings, webbing, and a ratchet that are all rated for 10,000 pounds breaking strength, the overall strength of the product is 10,000 pounds. If any component of the ratchet strap has a lower breaking strength though, the break strength of the unit drops to the rating of the weakest component.

It is critical to understand the differences between the two figures and to make sure that any time you are securing a load, you do so with capable rigging. A failure could not only be costly, but dangerous as well.

A similar rope to 6x7 but the fibre core is replaced by a wire strand, resulting in a greater resistance to crushing and added strength, lacks flexibility on larger diameter ropes.

This rope is widely used for General Purpose Engineering, It has good strength and flexibility with reasonably good resistance to abrasion and crushing.

It turns out that there is little margin of safety with steel cable equipped winches. Why is this? Unlike the lifting industry, the recreational pulling industry is unregulated, consequently winch manufacturers typically equip winches with steel cables with minimum breaking strengths that are very close to the max winch capacities. The lifting industry requires a 5:1 safety factor due to the overhead dangers. The pulling industry does not. In fact many steel equipped winches possess a safety factor of less than 1.5!

Take for instance common 5/16 steel cable supplied on most winches up to 10K capacities. The working load limit (WLL) on common 5/16 steel cable is only 2000 pounds. The minimum breaking strength is approximately 10K pounds. So in many cases a 10K winch can be supplied with a steel cable with a minimum breaking strength of 10K. Take a look at the steel cable writeup from our friend Tyler at Roundforge (Roundforge.com) for more comprehensive data on steel cable types and classes.

One of the reasons that cable failures are relatively infrequent is mostly due to vehicle recoveries being in the 4-5k pulling load range, well below the cable breaking strength. Also, often times steel cables can possess ultimate strengths above the minimum breaking loads. So what’s the takeaway here? Due to the little margin of safety in steel cables, make sure you properly maintain the cable and be on the lookout for weakening factors like kinks, broken wires etc., and when possible use a snatch block to reduce the cable load.

Picture supplied by our friend James Pickard. James snapped his steel cable while using the UltraHook. The UltraHook possesses a breaking strength of 31,000 pounds(hook opening) to 48,000 pounds(shackle pin mount). Engineering facts matter.

WARN | CRAWL Magazine | SpiderWebShade | Carolina Metal Masters | TNT Customs | sPOD | Rock Krawler Suspension | BFGoodrich Tires | Raceline Wheels | Radflo Shocks | Savvy Off Road | Synergy Manufacturing | Off-Road Solutions | 4WD Toyota Owner Magazine | Overland Journal | Expedition Portal | Barlow Adventures | I4WDTA – The International 4-Wheel Drive Trainers Association LLC | Ultra4 Racing | ULTRA4 EUROPE | King of The Hammers | COMEUP | Mile Marker Winch | Superwinch | 4×4 Magazine | XTREME4x4MAGAZINE | Jp Magazine | Extreme 4×4 Nation | Tread Magazine | Jeepfreeks | Modern Jeeper | Poly Performance | Safe-Xtract | Off-Road Safety Academy – Blue Sky Adventures, Inc. | PITTS 4×4 CO.

1. Turn back the specified amount of rope from the thimble. Apply the first clip one base width from the dead end of the wire rope. Place the U-bolt over the dead end; the live end rests in the clip saddle. Tighten the nuts evenly to the recommended torque.

3. Space additional clips, if required, equally between the first two. Turn on nuts, take up any rope slack, and tighten all nuts evenly to the recommended torque.

4. Apply the initial load and retighten the nuts to recommended torque. The rope will stretch and shrink in diameter when loads are applied. Inspect the clips periodically and retighten. Recommended torque values are based on the threads being clean, dry and free of lubrication.

Loads may slip or fall if proper eye bolt assembly and lifting procedures are not used. Always inspect eye bolts before use and never use eye bolts that show signs of wear or damage. Never use eye bolts if eye or shank is elongated or bent. Be sure all threads are clean. Do not exceed the following working load li

Fibrous and synthetic rope, wire rope and cable must be inspected regularly. No product, even when used in the proscribed manner, can function forever at its rated capacity. The end user must inspect the product frequently for any condition (abrasion, abuse, negligence, normal wear and tear, etc.) which, should the product be left in use, might result in its failure.

Working load is based upon static or moderately dynamic lifting/pulling operations. Instantaneous changes in load, up or down, in excess of 10% of the sling"s rated working load constitutes hazardous shock load, and would void normal working load recommendations.

These products are not designed or recommended for use in the entertainment rigging business, but are offered as a service to our customers who indulge in climbing or similar recreational activities. It is the responsibility of the end user to be properly trained in the inspection, maintenance and use of these products.

Typically the diameter of halyards and sheets is determined by clutches, cleats and blocks on board of your ship. If you are into yacht racing or rigging a new boat, it can be good to calculate the minimum required breaking load of sheets and halyards in order to reduce weight of ropes onboard. Calculating the required breaking load is a more precise approach for determining the diameter of sheets and halyards.

It is a good idea to build in some safety margin in your calculations. Often a safety factor of 4 is used, which means that a rope will receive a workload of only 25% of the breaking load. This is so called Safe Working Load. In practice, however, sails are usually reefed or the boat is in a safe harbour before a rope is loaded to its maximum. That is why we use a safety ratio for cruising yachts of 2 and even 1.5 for racing yachts.

Bear in mind that the weakest link counts. A splice typically reduces the strength by 5-10% but a knot can take off 50% of the strength. For these calculations we assume that the ropes will be spliced.

For halyards and genoa sheets you can easily calculate the breaking strength by multiplying your sheet size in square meters with 30 (for spinnakers take 13). This allows you to handle your sails still at 7 Bft (41-47knots). We have done the maths for you in the table below. Loads can vary slightly for e.g. catamaran, but variations are usually covered by the safety factor.

For halyards with a 1:2 purchase, you can divide the breaking strength by two. Please note that clutches, cleats, blocks and shackles still bear the full load though!

If the purchase on the mainsheet is four, the load on the mainsheet is divided by four. But note that the forces applied on the mainsheet travellers and blocks will stay the same!

To calculate loading on a genoa lead car, the deflection of the sheet should be taken in account. Most #1 genoas will deflect about 45° whilst a #3 genoa may deflect 75° or more.

Galvanized wire rope is categorized by number of strands in its construction. We supply most of them but we concentrate on the two major categories of galvanized (and ungalvanized or bright) wire rope. These “classes” are referred to as 6x19 and 6x36. Within each category of galvanized wire rope there are different “constructions” illustrated in the tables below.

Wire rope, galvanized and ungalvanized is used for many kinds of projects and applications. No matter the application galvanized wire rope must be used properly to insure the safest working conditions. All of our galvanized wire rope is manufactured to meet or exceed Federal Specification RRW-410 and is mill certified.

All of these general purpose wire ropes are available in full reels, custom cut sizes or as part of a custom made wire rope sling. Contact us today for more information.

Galvanized wire rope also comes in different strength categories (IPS and EIPS) and different cores (FC or fiber core and IWRC or independent wire rope core). Relevant data for each is listed in the table below.

8613371530291

8613371530291