wire rope cable slings supplier

Unlike synthetic or fiber slings, wire rope offers increased resistance to wear and abrasion and can be used for both hot and cold materials as well as in corrosive applications such as those in marine, construction, aerospace, manufacturing, assembly, transport, shipping, and other industries where wire rope slings are commonly used. Wire ropes fitted with slings in these applications also serve to improve connectivity and prevent fraying of the rope.

Like stranded wire ropes, the slings that they attach too are strictly regulated and must be inspected regularly as mechanical failure puts both machinery and employees at serious risk. To prevent such disruptions, it is important to select the proper sling for a given application.

Slings are most commonly constructed simply by looping or folding the end of a wire rope back onto itself and holding it in place with a firm fitting such as a clamp. Alternatively, the folded segment of wire may be braided or twisted along the main body of rope and otherwise held in place through welding or similar processes.

The rope itself is comprised of cold drawn filaments that are twisted or braided into strands which in turn are helically wrapped around a core. The multilayered formation of wire rope acts as a safety measure as individual strands are more likely to fail than the rope as a whole, allowing the other strands to act as a backup.

Popular materials for wire rope and sling construction include aluminum, nickel alloy, bronze, copper, and titanium, although steel and stainless steel are the most common due to their increased strength and availability.

Additional considerations include the wire rope sling"s dimensions, fatigue strength, its ability to bend without distortion, to withstand abrasion, and environmental conditions as well as the intended use for the sling.

When it comes to using wire rope slings in or on your jobsite, there are a few things to keep in mind in order to make sure that your wire rope sling is ready for use and that it will last for years to come. For starters, be sure to designate a qualified person to inspect all of your slings, fastenings, and attachment each day before use for damage or defects. A thorough inspection of your wire sling should check for:

By regularly performing these inspections that check the condition of your rope, you’ll not only be able to give your wire rope sling the care and maintenance that it needs to work at its best, you’ll be protecting your entire team and jobsite from the potential dangers that can occur if a wire rope sling snaps during use.

American Wire Rope & Sling was acquired by Bishop Lifting in June of 2019. Since its founding in 1933, American Wire Rope & Sling has been a leader in providing rigging, lifting, and overhead crane solutions in the Midwestern region of the United States. With its three locations in Indiana, American Wire Rope & Sling has been a strong addition to Bishop Lifting group of industry-leading crane and rigging companies.

As a group, American Wire Rope & Sling and Bishop Lifting are growing rapidly, so in order to be a unified team, we are now all under one banner, Bishop Lifting, to create value, company unity, and combine our strengths and capabilities across the country to better serve you, our customer.

Manufacture of material handling gripper slings made from 304 or 316 stainless steel, 4130 heat-treated alloy steel, exotic alloys and neoprene. Features include polyurethane plastic-covers, wire mesh construction, interwoven and tolerate abrasive loads. Suitable for handling all types of products such as coiled strips, thin-walled tubing, polished shafting, lumber, paper machine rolls, precast hollow core concrete beams, structural beams, cold drawn flats and irregularly shaped objects. Serves the marine, automotive, beverage, cement, energy, food and mining industries.

Midco Sling has served the heavy lifting needs of customers throughout Texas, Oklahoma, New Mexico, Arkansas and Louisiana since 1976. Specializing in lifting products ranging from fall protection to synthetic slings, Midco Sling carries products from the industry’s most reputable vendors including Crosby, Capital Safety, and Bridon American.

Established over 40 years ago in North Texas, Midco Sling now manufacturers and distributes wire rope from 3 locations to more conveniently serve customers across the Southern States. Midco Sling retains branch locations in Dallas, San Antonio and Longview. These locations allows Midco to stock a wide array of specialty lifting products and enables Midco to efficiently meet a wide range of manufacturing needs.

Wire rope lifting slings, bridles and assemblies provide great durability and high tensile strength for lifting heavy loads. In addition, wire rope lifting slings are lighter in weight and more cost efficient than chain slings. Wire rope slings, sometimes referred to as wire slings, or cable lifting slings, are constructed using a variety of different styles and sizes of steel wire rope. Every style and size of wire rope offers different properties and benefits such as:

Each type of wire rope has benefits and drawbacks. What all wire ropes have in common however, is that they are made up of steel wires which form individual stands. These strands are laid in a helical pattern around a fiber or steel IWRC (independent wire rope core) core.

Wire rope lifting slings, bridles and assemblies are highly customizable, so if you are unable to find what you are looking for, or if you don’t know exactly what you need, call or email our sales team to speak with a rigging product specialist.

The durability of steel cable lifting slings is also put to the test in the harsh environments seen in steel mills and forging facilities. Every steel wire rope configuration will offer different properties and will be better equipped to handle certain applications. Generally, a smaller number of large outer wires will provide more wear, corrosion and abrasion resistance. Conversely, a larger number of smaller outer wires will provide better flexibility and fatigue resistance.

After you decide what construction and size of wire rope fits your application, you must configure the entire sling. Wire rope bridles and assemblies are available in single-leg, double-leg, triple-leg, and quadruple-leg configurations. They most commonly have 2 eyes and are constructed using a mechanical flemish splice. Wire rope lifting slings can be used in vertical, choker and basket hitches. They can also be equipped with a variety of attachments and fittings to accommodate almost any overhead lifting application.

Although wire rope sling fittings and attachment can be reused, the wire rope itself is not repairable. If a wire rope sling fails an inspection, it is to be properly destroyed and disposed of

It is important to inspect wire rope slings regularly and to keep a record of all sling inspections. At Tri-State Rigging Equipment we offer a full range of rigging inspection and repair services. The standards that govern wire rope sling inspection are OSHA 1910.184 and ASME B30.9. It is recommended that wire rope rigging slings first undergo an initial inspection when you receive the lifting sling from the manufacturer. The purpose of this initial inspection is to:

Wire rope slings, bridles and assemblies should also be inspected by a designated and qualified individual every day before use to make sure that the sling is in working condition and will lift its rated capacity. The person performing the inspection should examine all the wire rope, fastenings and attachments on the wire rope sling. The inspector is looking for visual indications of any defects, deformities and general damage that might affect the integrity of the sling.

Depending on your application, it may be recommended that you perform these visual inspections more than once a day. If the wire rope sling is used many times throughout the day, by multiple individuals, across multiple shifts, it is imperative that the sling be inspected before every shift change and before any change in lifting application.

ASME standards further require a thorough periodic inspection to be performed at least once a year by either a professional service provider, or by a Qualified Person. In addition, written records must be kept until the next periodic inspection. The rejection criteria for periodic wire rope sling inspections are as follows:

10 or more randomly distributed broken wires in one rope lay, or 5 or more broken wires in one strand in one rope lay, for strand-laid grommets and single part slings.

If your wire rope sling shows any of the rejection criteria above, you must remove the sling from service, and it must be destroyed. Properly destroying rigging equipment is imperative because you can be held accountable for damage done by people who find and use your discarded slings. Therefore, lifting slings deemed not suitable for service must be destroyed beyond use and beyond repair. The process for destroying a wire rope sling is as follows:

The purpose of daily and periodic wire rope sling inspections is not to get anyone in trouble but rather to gain knowledge of the frequency of use, severity of conditions, and nature of lifts, and consider how all these factors affect your wire rope sling. The most important reason to perform daily and periodic wire rope sling inspections, however, is to keep you and your coworkers safe.

Tri-State Rigging Equipment is a custom manufacturer, service provider and distributor for all wire rope lifting slings serving clients from coast to coast, Canada, Mexico and especially focused in the states of Missouri, Illinois, Indiana, Iowa, Kansas, Nebraska, Arkansas, Mississippi, Tennessee, Kentucky, South Carolina, Florida, and Oklahoma.

Wire rope slings have been used extensively for years and were once the industrial lifting sling of choice. Wire rope slings, sometimes referred to as wire cable slings are more robust and durable than nylon slings and also have higher temperature limits.

Wire rope slings with an independent wire rope core (IWRC) can withstand contact and exposure temperatures up to 400 degrees (F). Wire cable slings with fiber cores should never be exposed to temperatures in excess of 180 degrees (F). Wire rope slings of all types should never be used at temperatures below -40 degrees (F). Wire rope rigging slings with fiber cores (FC) are rated at reduced capacities when compared with an equivalent size, wire choker with an independent wire rope core (IWRC). They are generally fabricated from 6 x 19 or 6 x 37 construction wire cable. The constructional numbers refer to the number of strands (6) that are helically wound around a core. The core supports the strands of the wire rope lifting sling and can either be an independent wire rope core (IWRC) or a fiber core (FC) made from hemp or sisal. Smaller diameter wire rope slings feature 6 strands with 19 wires in each strand. Larger diameter industrial lifting slings will generally feature 6 strands with 37 individual wires in each strand. The 6 x 37 construction is more flexible than the 6 x 19 construction, but not as abrasion resistant.

Wire cable lifting slings used by the crane, rigging and material handling industries are available in many different styles and constructions to meet your needs. Custom made slings and special order slings are shipped daily from our factory. The most popular wire lifting slings are Single Body slings featuring a 6 x 19 or 6 x 37 Construction, Extra Improved Plow Steel (EIPS) Wire Rope with an Independent Wire Rope Core (IWRC). These slings are sometimes referred to as wire chokers, Permaloc wire rope slings, wire cable slings, Flemish eye slings, single leg slings, eye and eye slings or eye & eye slings due to the loop or eye that is formed on each end of the wire sling.

There are different grades and strengths of steel used to manufacture the individual wires that make up the sling. The most popular for sling fabrication is (EIPS). Metallurgists continue to improve the tensile properties of steel with new, corresponding designations such as EEIPS (Extra-Extra Improved Plow Steel). Single leg, Flemish Eye/Mechanical Splice, Wire Slings provide additional security, superior to return loop wire slings should the swage sleeve become damaged during use. Single Body Wire Cable slings are available in 15 different types which feature different combinations of plain loops, three types of thimbles (crescent, standard and slip through) and rigging hooks. Thimbles greatly improve sling longevity by protecting the rope at connection points. We offer two types of single leg wire slings that feature a sliding choker hook that is placed between the sling eyes. Industrial lifting slings with sliding choker hooks make removal of the cable sling from the load, quick and easy. Type 14 lifting slings feature a lifting loop on one end and a thimble on the opposite end to engage the sliding choker hook. Type 15 lifting slings features plain loops each end. View the 15 single leg wire sling types available .

We will not sell you a sliding choker hook without a hook latch, but there are many that will! Stainless Steel Wire Rope Slings provide the sling user with improved corrosion resistance and are also readily available. Cable Laid Wire Rope Slings with a galvanized finish are also available. Cable Laid Wire Slings are much more flexible than equivalent sized, single body wire slings. The flexibility of industrial lifting slings that feature a cable laid construction is a direct result of the small diameter, aircraft cable used in the fabrication of the wire sling. Size for size, cable laid lifting slings are not as strong as equivalent sized, single body, wire chokers. Cable laid wire slings can be equipped with many of the same options available for single body slings.

In addition to our standard lifting slings, custom made slings are also readily available. Cable laid slings are also referred to as Ultra flexible cable laid slings, steel strand and E-Z Flex Cable Laid wire rope slings. Wire Rope Bridle Slings are available in two leg bridle, three leg bridle and four leg bridle designs. A master link is used to collect the multiple wire cable sling legs, while providing a connection point to the hoist line. Bottom “connectors” such as masterlinks or eye hoist hooks (with latches) are most commonly used to engage the load. Custom made bridle slings are also readily available.

In addition to wire bridles we also offer a complete line of strand laid grommets and swaged socket assemblies. Slingmax® Wire Rope Slings are as revolutionary to wire cable slings as Twin-Path® Extra, high performance fiber slings are to polyester roundslings. That makes sense, because both products are patented inventions from the mind of Dennis St. Germain, Sr. Without a doubt, Mr. St. Germain has done more for the sling, crane and rigging industries than any other. It all started years ago with the Tri-Flex® Sling which provides professional riggers with a great combination of strength and flexibility. Tri-Flex® wire rope slings provide substantial savings due to the materials used and the tremendous labor savings realized in the fabrication process. Tri-Flex® cable slings were also the genesis of T&D Ultra-Flex® slings which are used extensively in the power generation, transmission and distribution industries.

Gator-Laid® wire rope slings and Gator-Max® wire cable slings are the most efficient, heavy lift slings available. Both the Gator-Laid® wire slings and Gator-Max® lifting slings feature 12 parts of wire in the sling eye and meet all the requirements of the Wire Rope Technical Board and the United States Navy. Gator-Flex® wire rope slings and Gator-Flex® wire rope grommets are heavy lift slings used extensively by the oil and gas industries for both land based and off shore rigging. Gator-Flex® wire slings offer sling users the greatest flexibility available for a heavy lifting sling. Gator-Flex® grommets not only provide flexibility, but can be fabricated for applications requiring minimum sling lengths.

Like all of our nylon web slings and polyester round slings, wire rope slings need to be inspected on a regular basis to ensure the safety of sling users. Poor inspection practices can lead to devastation, injury and death. Please refer to the inspection and usage information that is available in our Rigging Resource Guide or on our web site. Read and understand the warnings that accompany all our products. Remember, ignore a warning leads to much mourning.

All wire chokers shipped from Lift-It have a heavy duty, metal sling tag attached. There is no additional charge for this as we have always felt it is our duty to provide robust sling tags. Others may use cloth or synthetic materials which sometimes come off the sling, before it’s even used! Others fill in the information with magic marker that is not so magic. The tag is just as important as the wire cable, the way the Flemish eye is fabricated and the way the mechanical sleeve is swaged. If a vendor wants to charge you extra for a metal tag, run as fast and as far as you can from them and contact the sling experts at Lift-It Manufacturing, where profit margins are not maximized by supplying labels that should be used on clothing.

While wire cable slings are more robust and durable than nylon lifting slings or polyester roundslings, wire slings are not cut proof. Wire slings need to be protected from damage like all industrial lifting slings. Only materials of sufficient strength, thickness and construction must be used to prevent damage. Do not use gloves or cardboard. Use protection devices that have been designed to resist the effects of cutting and abrasion. Wire Rope Saddle Protectors are readily available; Click Here

Midco Sling has served the heavy lifting needs of customers throughout Texas, Oklahoma, New Mexico, Arkansas and Louisiana since 1976. Specializing in lifting products ranging from fall protection to synthetic slings, Midco Sling carries products from the industry’s most reputable vendors including Crosby, Capital Safety, and Bridon American.

Established over 40 years ago in North Texas, Midco Sling now manufacturers and distributes wire rope from 3 locations to more conveniently serve customers across the Southern States. Midco Sling retains branch locations in Dallas, San Antonio and Longview. These locations allows Midco to stock a wide array of specialty lifting products and enables Midco to efficiently meet a wide range of manufacturing needs.

Wire rope slings have been used extensively for years and were once the industrial lifting sling of choice. Wire rope slings, sometimes referred to as wire cable slings are more robust and durable than nylon slings and also have higher temperature limits.

Wire rope slings with an independent wire rope core (IWRC) can withstand contact and exposure temperatures up to 400 degrees (F). Wire cable slings with fiber cores should never be exposed to temperatures in excess of 180 degrees (F). Wire rope slings of all types should never be used at temperatures below -40 degrees (F). Wire rope rigging slings with fiber cores (FC) are rated at reduced capacities when compared with an equivalent size, wire choker with an independent wire rope core (IWRC). They are generally fabricated from 6 x 19 or 6 x 37 construction wire cable. The constructional numbers refer to the number of strands (6) that are helically wound around a core. The core supports the strands of the wire rope lifting sling and can either be an independent wire rope core (IWRC) or a fiber core (FC) made from hemp or sisal. Smaller diameter wire rope slings feature 6 strands with 19 wires in each strand. Larger diameter industrial lifting slings will generally feature 6 strands with 37 individual wires in each strand. The 6 x 37 construction is more flexible than the 6 x 19 construction, but not as abrasion resistant.

Wire cable lifting slings used by the crane, rigging and material handling industries are available in many different styles and constructions to meet your needs. Custom made slings and special order slings are shipped daily from our factory. The most popular wire lifting slings are Single Body slings featuring a 6 x 19 or 6 x 37 Construction, Extra Improved Plow Steel (EIPS) Wire Rope with an Independent Wire Rope Core (IWRC). These slings are sometimes referred to as wire chokers, Permaloc wire rope slings, wire cable slings, Flemish eye slings, single leg slings, eye and eye slings or eye & eye slings due to the loop or eye that is formed on each end of the wire sling.

There are different grades and strengths of steel used to manufacture the individual wires that make up the sling. The most popular for sling fabrication is (EIPS). Metallurgists continue to improve the tensile properties of steel with new, corresponding designations such as EEIPS (Extra-Extra Improved Plow Steel). Single leg, Flemish Eye/Mechanical Splice, Wire Slings provide additional security, superior to return loop wire slings should the swage sleeve become damaged during use. Single Body Wire Cable slings are available in 15 different types which feature different combinations of plain loops, three types of thimbles (crescent, standard and slip through) and rigging hooks. Thimbles greatly improve sling longevity by protecting the rope at connection points. We offer two types of single leg wire slings that feature a sliding choker hook that is placed between the sling eyes. Industrial lifting slings with sliding choker hooks make removal of the cable sling from the load, quick and easy. Type 14 lifting slings feature a lifting loop on one end and a thimble on the opposite end to engage the sliding choker hook. Type 15 lifting slings features plain loops each end. View the 15 single leg wire sling types available .

We will not sell you a sliding choker hook without a hook latch, but there are many that will! Stainless Steel Wire Rope Slings provide the sling user with improved corrosion resistance and are also readily available. Cable Laid Wire Rope Slings with a galvanized finish are also available. Cable Laid Wire Slings are much more flexible than equivalent sized, single body wire slings. The flexibility of industrial lifting slings that feature a cable laid construction is a direct result of the small diameter, aircraft cable used in the fabrication of the wire sling. Size for size, cable laid lifting slings are not as strong as equivalent sized, single body, wire chokers. Cable laid wire slings can be equipped with many of the same options available for single body slings.

In addition to our standard lifting slings, custom made slings are also readily available. Cable laid slings are also referred to as Ultra flexible cable laid slings, steel strand and E-Z Flex Cable Laid wire rope slings. Wire Rope Bridle Slings are available in two leg bridle, three leg bridle and four leg bridle designs. A master link is used to collect the multiple wire cable sling legs, while providing a connection point to the hoist line. Bottom “connectors” such as masterlinks or eye hoist hooks (with latches) are most commonly used to engage the load. Custom made bridle slings are also readily available.

In addition to wire bridles we also offer a complete line of strand laid grommets and swaged socket assemblies. Slingmax® Wire Rope Slings are as revolutionary to wire cable slings as Twin-Path® Extra, high performance fiber slings are to polyester roundslings. That makes sense, because both products are patented inventions from the mind of Dennis St. Germain, Sr. Without a doubt, Mr. St. Germain has done more for the sling, crane and rigging industries than any other. It all started years ago with the Tri-Flex® Sling which provides professional riggers with a great combination of strength and flexibility. Tri-Flex® wire rope slings provide substantial savings due to the materials used and the tremendous labor savings realized in the fabrication process. Tri-Flex® cable slings were also the genesis of T&D Ultra-Flex® slings which are used extensively in the power generation, transmission and distribution industries.

Gator-Laid® wire rope slings and Gator-Max® wire cable slings are the most efficient, heavy lift slings available. Both the Gator-Laid® wire slings and Gator-Max® lifting slings feature 12 parts of wire in the sling eye and meet all the requirements of the Wire Rope Technical Board and the United States Navy. Gator-Flex® wire rope slings and Gator-Flex® wire rope grommets are heavy lift slings used extensively by the oil and gas industries for both land based and off shore rigging. Gator-Flex® wire slings offer sling users the greatest flexibility available for a heavy lifting sling. Gator-Flex® grommets not only provide flexibility, but can be fabricated for applications requiring minimum sling lengths.

Like all of our nylon web slings and polyester round slings, wire rope slings need to be inspected on a regular basis to ensure the safety of sling users. Poor inspection practices can lead to devastation, injury and death. Please refer to the inspection and usage information that is available in our Rigging Resource Guide or on our web site. Read and understand the warnings that accompany all our products. Remember, ignore a warning leads to much mourning.

All wire chokers shipped from Lift-It have a heavy duty, metal sling tag attached. There is no additional charge for this as we have always felt it is our duty to provide robust sling tags. Others may use cloth or synthetic materials which sometimes come off the sling, before it’s even used! Others fill in the information with magic marker that is not so magic. The tag is just as important as the wire cable, the way the Flemish eye is fabricated and the way the mechanical sleeve is swaged. If a vendor wants to charge you extra for a metal tag, run as fast and as far as you can from them and contact the sling experts at Lift-It Manufacturing, where profit margins are not maximized by supplying labels that should be used on clothing.

While wire cable slings are more robust and durable than nylon lifting slings or polyester roundslings, wire slings are not cut proof. Wire slings need to be protected from damage like all industrial lifting slings. Only materials of sufficient strength, thickness and construction must be used to prevent damage. Do not use gloves or cardboard. Use protection devices that have been designed to resist the effects of cutting and abrasion. Wire Rope Saddle Protectors are readily available; Click Here

Lift-All Permaloc slings are made using the Flemish Eye splice technique to form the eyes. Unlike the simple return loop method that places 100% of its strength on the swaged sleeve, Permaloc slings have reserve strength should the sleeve become damaged in use.

* Do not exceed rated capacities. Sling capacity decreases as the angle from horizontal decreases. Slings should not be used at angles of less than 30°. Refer to the Effect of Angle chart in the General Information section of our catalog.

* Do not exceed rated capacities. Sling capacity decreases as the angle from horizontal decreases. Slings should not be used at angles of less than 30°. Refer to the Effect of Angle chart in the General Information section of our catalog.

* Do not exceed rated capacities. Sling capacity decreases as the angle from horizontal decreases. Slings should not be used at angles of less than 30°. Refer to the Effect of Angle chart in the General Information section of our catalog.

* Do not exceed rated capacities. Sling capacity decreases as the angle from horizontal decreases. Slings should not be used at angles of less than 30°. Refer to the Effect of Angle chart in the General Information section of our catalog.

Wire rope slings are common components of wire rope assemblies that serve as a point of attachment for cranes, hooks and hoists in many heavy lifting or pulling applications.

Unlike synthetic or fiber slings, wire rope offers increased resistance to wear and abrasion and can be used for both hot and cold materials as well as in corrosive applications such as those in marine, construction, aerospace, manufacturing, assembly, transport, shipping and other industries where wire rope slings are commonly used. Wire ropes fitted with slings in these applications also serve to improve connectivity and prevent fraying of the rope. Though the majority have predetermined dimensions, they may be adjustable to accommodate for a change in the size of cargo while maintaining a secure fit.

Slings are most commonly constructed simply by looping or folding the end of a wire rope back onto itself and holding it in place with a firm fitting such as a clamp. Alternatively the folded segment of wire may be braided or twisted along the main body of rope and otherwise held in place through welding or similar processes.

The rope itself is composed of cold drawn filaments that are twisted or braided into strands which in turn are helically wrapped around a core. The multilayered formation of wire rope acts as a safety measure as individual strands are more likely to fail than the rope as a whole, allowing the other strands to act as a backup.

Additional considerations include the wire rope sling"s dimensions, fatigue strength, its ability to bend without distortion, to withstand abrasion and environmental conditions as well as the intended use for the sling. Wire rope slings are stress tested during manufacturing to determine breaking point and safe usage guidelines which should be carefully considered.

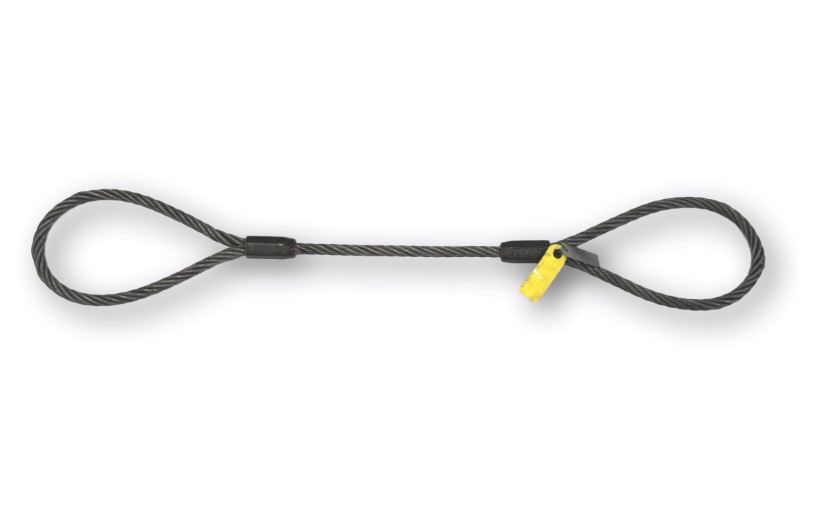

The term sling can refer to one of two configurations for lifting and hoisting apparatus. Slings as wire rope fittings involve the addition of a loop at the end of a length of wire through which hooks and other apparatus may be looped or fastened. The term may also apply to a length of cable that has this same “U” or teardrop shaped eye, but on either end of the cable.

Popular materials for wire rope and sling construction include aluminum, nickel alloy, bronze, copper and titanium, although steel and stainless steel are the most common due to their increased strength and availability.

Like stranded wire ropes, the slings that they attach too are strictly regulated and must be inspected regularly as mechanical failure puts both machinery and employees at serious risk. To prevent such disruptions, it is important to select the proper sling for a given application.

Suncor Stainless manufactures an extensive line of superior stainless steel chain, wire rope assemblies and rigging hardware to serve the industrial and marine markets. Mil. Spec swage fittings and cable assemblies are also available. We are large enough to offer consistent top quality stock and custom-made products at economical prices, yet small enough to offer excellent customer service and technical expertise.

Alan Baird Industries, Inc. is a leading manufacturer of wire rope assemblies, mechanical cable assemblies, plastic coated cables and aircraft cables. Established in 1973, we supply products for the medical devices, consumer items, mechanical devices, robotics and instruments markets.

Backed by more than 50 years of experience in the lifting & rigging supplies business, Ashley Sling fabricates wire rope (Galvanized & Stainless Steel Wire Rope, Metric Crane Ropes, Regular or Compacted Strand) in many configurations. We can assist in selection and offer wire rope slings as well.

Assembly Specialty Products is a leading wire rope manufacturer of cable assemblies, mechanical cable assemblies and plastic coated cables. We serve a variety of industries including construction, mining, aircraft, trucking and many more.

We are a reliable source for a wide range of wire rope needs. We provide wire rope assemblies that can be designed to fit your unique specifications, and are manufacturers of fiber rope in both natural and synthetic materials. We are a division of Steelstran/The Atlantic Group.

With over 100 years combined sales experience in the rigging industry, we offer wire rope & accessories, including standard rope, rotation resistant rope, compacted rope, aircraft cable (stainless, galvanized & coated), crimping/swaging tools & sleeves, cable cutters & grippers and special end fittings.

BEN-MOR CABLE manufactures wire rope, wire rope slings, wire rope clips and cutters, plus a variety of other products including aircraft cables, coated cables, cable assemblies, chains and hardware. We also feature pet products. We pride ourselves on our just-in-time delivery and topmost quality control.

Since 1984, Bishop Lifting Products has fabricated and distributed high-quality lifting products, including wire rope, wire rope slings, cordage and rigging tools. We serve a variety of industries, including aeronautical, construction, manufacturing, oil field and transportation companies.

At Central Wire Industries, our mission is to build a company that values innovation and is committed to customer service. We are a market leader in the production of specialty wire and its components including ropes, cables and strands. We are devoted to delivering quality and maintaining the highest of standards.

Certified Slings is a supplier of a wide variety of wire rope and related products—wire rope slings, stainless steel wire rope, wire rope cutters, wire rope clips and aircraft cable. Additional rigging supplies such as chain slings, cargo restraints, hoists and mining supplies are also available.

Chicago Hardware and Fixture is a manufacturer of wire rope and chain fittings, industrial and marine hardware and allied products. We maintain sales offices and warehouses in several cities to ensure efficient service nationwide.

Trust Commercial Group Lifting Products as a wire rope supplier with more than 60 years of experience. The variety of industries The Commercial Group serves with lifting & rigging equipment includes automotive, steel, construction, utilities and government. As a complete full line manufacturer of wire rope slings, chain slings, nylon slings & Slingmax high performance synthetics, you’re covered!

With more than 40 years of experience in design of specialty wire and custom cable products, Cooner Wire continues to view customer service and superior quality as the focal point of our efforts. We also maintain a large warehouse stock. Continued expansion has made Cooner Wire an excellent source for standard and non-standard cable assemblies, harnesses, and molded cable assemblies.

Coordinated Equipment is a distributor of a vast range of wire rope, aircraft cables, wire rope slings, plus wire rope and chain hardware. Our on-site testing can handle 80-8,000,000 pounds. We can also secure fiber ropes, crane and snatch blocks, material handling products, safety products, and more.

Our doors opened in 1986, and we have grown to one of the largest stocking distributors of steel wire rope & submersible pump cable in the US. We offer shipping to your location, work site or shop and installation and removal of steel wire rope in select locations. We have the best prices on steel wire rope, submersible pump cable and manila rope.

DCL Mooring & Rigging is a leading distributor of high-quality wire rope, cable assemblies and wire rope assemblies. Since 1945, we have provided a variety of quality products designed for the practically endless requirements of today"s high-speed material handling operations.

Delta Rigging and Tools, Inc consists of several companies you"ve come to rely on - Industrial Hoist Services, Delta Wire Rope, American Sling, B&H Air Tools, Port Rentals, Coastal Wire Rope, Kelly Wire Rope and D & M Wire Rope - have united under a new banner. So while our expanded capabilities offer the promise of a new day, we"ll continue to provide the service you"ve come to expect.

Euro Products, owned and operated by Brdr. Markussen and Randers Reb in Denmark, manufactures the Blue Line hardware as well as steel wire rope, combination rope and synthetic rope for commercial fishing and industrial use.

For over 65 years, Feeney has pioneered industry-leading cable rail systems and other architectural & rigging products. We are known for our very high quality, and we constantly strive to simplify the way our customers work with us & our products. We think you will find our CableRail, DesignRail®, and Quick-Connect® products easy to use, with features & benefits that are innovative and compelling.

Fehr Bros. Industries is a distributor of quality wire rope, wire rope assemblies, wire rope slings, stainless steel wire rope, aircraft cable, turnbuckles, rigging hardware, chains, and much more. Our name has been recognized in the U.S. since 1949.

Fortune Rope & Metal Company, wire rope supplier & customer fabricator, serves various customer needs from one cable assembly to high volume production runs. Capabilities include custom cable assemblies, aircraft cable, wire ropes, coated cable, cut to length cable, chain, fittings, hardware & tools for many industrial & commercial sectors. 3 strategic locations with large stock to best serve you!

Kentuckiana Wire Rope and Supply, Inc. has provided quality rigging products since 1981. Independently owned and operated, KWR is proud to represent the highest quality manufacturers in the industry. We specialize in the fabrication of wire rope, web and chain slings. We offer safety inspections and seminars to meet the needs of our customers. KWR is here to supply all of your rigging needs.

As Sling Manufacturers, Hanes Supply"s sling production now includes chain slings, nylon slings, SlingMax slings and wire rope slings. Hanes Supply, Inc., has over 80 years experience splicing wire rope and manufacturing slings, as well as providing quality products to industry and the construction trades. Our expert staff is here to help you create lifting solutions for your lifting needs.

Gator-Laid®, Gator-Max®, Tri-Flex® and T & D Ultra-Flex® wire rope slings can be obtained through us. We also handle the Tri-Flex® sling system, which is composed of 9- to 27-part slings for big lifts and the Gator-Flex® endless 9-part wire rope slings.

Indusco Wire Rope & Fittings is a leading supplier of wire rope, cable assemblies, wire rope assemblies, mechanical cable assemblies and aircraft cables. We serve industrial suppliers, contractors, mining companies, logging operations, transportation companies, military operations and more.

Search our interactive catalog for rope & cordage and find helpful guides for rope selection. We supply wire & fiber ropes, chain, slings & fittings. Choose from our manila, nylon & polypropylene cordage in various strengths & constructions, plus polyester blends, braided ropes, twines, cords & more.

Innovative Assembly Design has an outstanding reputation for high quality customer service and we pride ourselves on having product support that is unmatched throughout the industry. We are now one of the leading suppliers and distributors of wire rope, aircraft cable, hardware, chain, and more. Innovative Assembly Design works hard to not only meet industry standards but exceed them, we do this so you can be sure that the product you receive is one of the best on the market.

Lift-All® has a solid reputation as a leader in slings and other below-the-hook devices. We manufacture wire rope slings; web, round, boat, chain and mesh slings; and lifting beams and custom devices. Contact us for your wire rope needs.

At Liftpro, lifting, weighing and rigging devices are custom manufactured daily. With over 30 years of professional lifting experience, we provide web slings, chain slings, wire rope slings, wire rope inventory, rigging hardware and more. Professional training is available on site at your facility.

Metro Wire Rope Corp. is a leading supplier of wire rope, cable assemblies, wire rope assemblies and aircraft cables. We stock over 1,000 tons of wire rope and maintain large quantities of general-purpose wire ropes in bright, galvanized and stainless steel.

Miami Cordage and its Florida Wire & Rigging Works division are leading wire rope suppliers, providing a full line of wire rope products including stranded wire, plastic coated wire, stainless steel wire, wire rope slings, cable assemblies, aircraft cables, wire rope fittings, cable railing and push pull cable. Offering unmatched service, Miami Cordage also provides custom wire rope assemblies.

All Montague Latch Company wire rope and cable assemblies are made to your specifications.We assemble cable stops, cable fittings and loops. We can also assemble rings and other hardware to the cable assemblies. Please contact us with questions regarding specific applications.

Morgan City Rentals is a leading supplier of wire rope and rigging supplies, wire rope hoists, steel wire rope, wire rope sling fabrication, and rigging gear inspections for the Gulf of Mexico"s oil industry. We offer 24-hour service, delivering quality products at competitive prices.

Among the products we distribute are wire rope, wire rope slings, aircraft cable, plus wire rope thimbles and clips. With more than 45 years of experience, Olsen Chain & Cable is the choice for construction and industrial supplies. We perform inspections for cable, chain, and nylon slings.

For more than 25 years, Pacific Gulf Wire Rope, Inc. has been a leader in the wire rope and rigging industry. Our success is clearly based on long term relationships with our customers; commitment to providing the highest quality of products, along with offering the maximum in safety, service & cost efficiency to every customer.

Leading the industry in the wholesale distribution of industrial rigging equipment and supplies, Peak Trading"s product line includes aircraft cables, wire rope, wire rope slings, wire rope assemblies and cable assemblies. We are committed to your 100% satisfaction, so call us today!

Performance Wire Rope manufactures specialty cable, wire rope, and strand products. These products are manufactured from stainless steel, drawn and hot-dipped galvanized carbon steel, carbon steel, monel, inconel, tin-plated phosphor bronze, silicon tin bronze, titanium, MP35N and many other specialty alloys.

Since our inception in 1980, we have evolved into a world class supplier of battery cables, wire harnesses, and custom “value added” wiring solutions for our customers. We work with market leaders in the lawn and garden, marine, construction, agriculture, and commercial vehicle industries, and we always strive for excellence in customer satisfaction.

At Preston Cord Inc, we feel that no order is too small and we love a new challange. The majority of our customers have their own specifications when it comes to their unique product....and it is our moto to strive for excellence and superior quality in all of our ropes. Let Preston Cord Inc. make a superior product for your rope needs.

Safety Sling Company is a premier distributor of cable assemblies, wire rope assemblies and aircraft cables. Serving industries including chemical, construction, defense, marine, OEM, telecommunications, transportation and more with high quality wire and cable assemblies.

As one of the foremost global wire rope manufacturers, SLINGMAX® provides high-performance wire rope related products. Offering safety, quality and durability, SLINGMAX® can solve difficult rigging problems with premium wire rope solutions. With thorough rigging training courses provided, and wire rope cable for all types of rigging, SLINGMAX® wire rope products are versatile and cost-efficient.

Strand Core was founded in 1973 as a division of Industrial Sales in Baltimore, MD. At that time, they manufactured strand up to 1/8" in diameter, primarily for the automotive industry. We are one of the few companies on the government"s Qualified Products List for aircraft control cables and manufactures cable assemblies for helicopter rescue systems. Additionally, our products go into the automotive, aircraft, medical, marine, and construction industries.

The Good Rope Company is an industrial stocking distributor who has been serving the needs of a growing customer base since 1972. We offer wire rope, stainless steel, galvanized cable, cordage products, and related hardware items for a variety of industries.

Tie Down Engineering offers custom cable assemblies, wire rope and wire rope products at wholesale prices for bulk orders. We are committed to providing our customers with the highest quality performance products available.

With multiple Hydraulic Swaging Machines, Tway Lifting Products manufactures a full range of fabricated wire rope assemblies. Our 24,000 sq. ft. plant houses the largest Swaging Machines in The Region. We produce industry standard Eye and Eye lifting slings, winch lines and material lifting cables thru 2-1/2” diameter. Emergency service is available.

US Rigging Supply is a 35-year old ISO9001:2008 Certified Manufacturer of high performance custom cable and wire rope assemblies in long or short runs, lanyards and slings, and a Master Distributor of wire rope, aircraft cable, fittings and Factory Direct source for copper, stainless steel and aluminum swaging sleeves, wire rope clips and turnbuckles with a history of quality and customer service.

Choose US Netting for rope of all kinds for all uses, cut to order or by the spool: wire rope and cable, nylon rope, manila rope, climbing rope, polypropylene rope & more. Choose from galvanized, stainless steel, and vinyl or nylon coated cable in various diameters. If you can"t find it here, contact us, we"ll get it for you!

Founded in 1956, Unirope® has been supplying and fabricating wire rope products such as wire rope slings, wire rope cable assemblies, aircraft cables and wire rope hoists for a diverse range of construction customers. Committed to quality and safety, we put all our products through severe testing services.

Vanguard Steel is a leading supplier of cable assemblies, wire rope assemblies and plastic coated cables. All wire ropes and cable assemblies are fabricated by some of the world"s leading specialty steel mills to meet or exceed specifications set forth by the government and other recognized authorities.

VER Sales is a distributor of wire rope and fittings, aircraft cable and a multitude of hoisting, mountain climbing, scaffolding and safety products. The wire rope offered is in a variety of classifications, some with hemp cores, rotation-resistant types, galvanized and stainless steel.

The Voto Manufacturers Sales Company was founded in 1938 and has grown to be a leader in its field supplying top quality products to the mining, construction, steel, aluminum, drilling and industrial markets. We fabricate wire rope, chain and other hose assemblies to your drawings and/or specifications. Bulk quantities of these, and other products as well as inspection services, are available.

In business for over 30 years, Waytek offers quality electrical supplies to the automotive and wiring harness industries. Over 5,000 products in stock, and same day shipping on most orders. Browse our expansive selection of wires and cable, including marine wire, speaker cables, extension cords, jumper cables and more!

Wesco Industries Ltd experienced rigging facilities can manufacture wire rope assemblies, chain slings, synthetic slings and rope assemblies to order. With our experienced staff and backed up by our facilities Wesco Industries can perform all your testing and inspection requirements.

Wilkof Industrial Supply and Ron’s Workingman’s Store is a two-store concept developed to serve your needs. We supply sheaves, slings and wire to a wide range of customers and all wire rope can be cut to your required length. Stop by our showroom located in Canton, Ohio and you’ll see we have one of the largest inventories of quality work apparel and industrial supplies.

WireCo WorldGroup is the world"s leader in manufacturing, engineering, and distributing wire rope, synthetic rope, specialized assemblies, wire products and electromechanical cable. With true global reach, WireCo WorldGroup can deliver the right products for your equipment and application no matter where your worksite might be.

“Building a Wire Rope Products Plant in Indiana strengthened our position with the industrial sector in The Midwest and brings another manufactured product to The State. There are few plants in the country capable of producing lifting gear this heavy, the same day, and we are excited to be among the best.”

Tway Lifting Products manufactures eye & eye wire rope slings, spreaders and assemblies from ¼”-2”. We stock fittings and components that allow us to produce a full range of wire rope slings multi-leg assemblies, crane boom support cables, and bridge crane hoist ropes.

Our in-house proof testing center is used to verify the integrity of the products we manufacture. Every wire rope sling or bridle that we produce includes an OSHA appropriate DuraTag stating: size, working load limit, number of legs, and angle chart graphics. Our assemblies are manufactured to the highest standards by trained professionals. All of our wire rope slings are made from USA made products. The most common wire rope sling type is the eye and eye single leg.

Eye & Eye Wire Rope Slings are extremely strong and an excellent choice for heavy duty jobs involving not only lifting, but also hoisting, towing, or anchoring loads. The fabrication of wire slings also offers excellent abrasion-resistance and heat resistance so it can be used in extreme conditions and temperatures. Its pliable design can conform to the shape of a load for a more secure application.

Eye & Eye Wire Rope Slings are manufactured in a variety of configurations, with 6×19 and 6×36, being two of the most common. The numbers represent the number of wires making up the strand and the number of strands wrapped around the core. For example, a 6×19 indicates that there are 19 wires making up a strand, and 6 strands are wrapped around the core.

Each steel wire rope configuration will offer different benefits and will be better suited to certain applications. In general, a smaller number of large outer wires offers better wear and corrosion resistance, while a larger number of small wires provides a better level of flexibility and fatigue resistance.

We offer steel wire rope slings in both 6×19 and 6×36 configurations, depending on the diameter of the wire rope. All are in a bright (unfinished) wire rope, but other configurations are available by request. Our cable laid slings are manufactured in a 7x7x7 galvanized wire rope (composed of 7 strands of 7×7 cables), which make them extremely flexible and useful for more specialized applications.

The eye loops on our sling cable are created with a flemish splice, which is a mechanical splice where the rope cable is separated into two parts (one part has three strands, the other part has the remaining three strands plus the core), then re-laid back in the opposite direction to form the loop. The ends are then secured with a carbon steel sleeve around the entire area. Flemish splices offer the most efficient use of capacity.

The core of the wire rope used in our Eye & Eye Wire Rope Slings can be made of several different materials, including steel or natural fibers. Our steel wire rope slings are made with Extra Improved Plowed Steel (EIPS) around an Independent Wire Rope Core (IWRC) for the ultimate in strength and durability.

For more than 29 years, Pacific Gulf Wire Rope, Inc. has been a leader in the wire rope and rigging industry. Our success is clearly based on long term relationships with our customers; commitment to provide high quality products, along with offering the maximum in safety, service, & cost-efficiency to every customer. Our dedication to service and competitive pricing are the direct result of these long term relationships. Our longevity is a testament of our commitment to our customers.

8613371530291

8613371530291