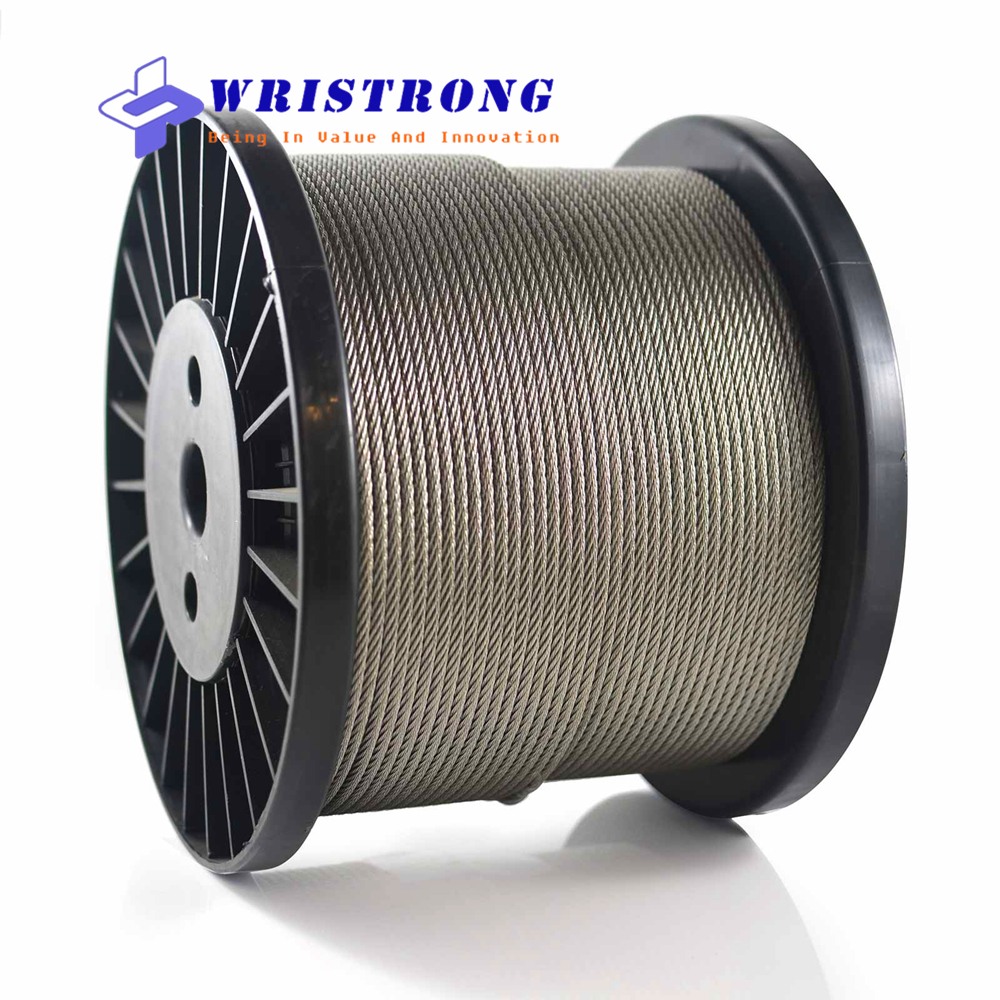

wire rope cable splicing made in china

A wide variety of wire rope splicing machine options are available to you, such as steel wire descaling machine, hydraulic scrap shears and die casting machine.You can also choose from multifunctional, crimping wire rope splicing machine,As well as from paper, wood, and metal. and whether wire rope splicing machine is cutting, punching, or bending.

After years of hard work and practice from skilled technicians, we have formed advanced manufacturing technique for braided rope and twisted rope, like 8-strand braided rope, 16-strand braided rope, 24-strand braided rope, 32-strand braided rope; 3-strand rope, 4-strand rope, etc. Owning the domestic and foreign advanced production equipment and independent right to import and export, our products are sold to many countries and regions around the world and are very popular with our customers. With Ji’nan Yaoqiang airport to the north, and Jinghu, Jingfu highway and national road 105 to the east, it enjoys a perfect location and smooth traffic.

The body is comprised of 7-parts of wire rope, but since the core rope is not actually spliced into the body, it is disregarded in the strength calculations.

Hot Tags: heavy lift grommets and cable laid wire rope slings, China, suppliers, manufacturers, factory, customized, wholesale, price, in stock, made in China, round wire rope sling, Chain sling assembly, turnbuckle with hook and eye, closed steel thimble, aluminum hourglass sleeve, Soft Eye Wire Rope Sling

Wire ropes can be seen everywhere around us, they are made of strands or bundles of individual wires constructed around an independent core, suitable for construction, industrial, fitness, commercial, architectural, agricultural, and marine rigging applications.

Wire rod is made from high carbon steel wires(0.35 to 0.85 percent carbon) in a hot rolling process of a required diameter, usually from 5.5mm to 8 mm.

Wire rod is drawn to the required diameter by the 1st drawing machine after descaling dust and rust, adding mechanical properties suitable for application.

Positioning the wires different or the same size lay in multiple layers and same direction, or cross lay and diameter is maintained by one-third of the rope size.

So in theory, it is very simple to manufacture wire ropes. However there are many more details that must be closely monitored and controlled, and this requires time and experienced personnel since it is a super complicated project you cannot imagine.

A Chinese finger provides a quick and fast means of (temporary) terminating different kinds of steel wire rope. The grips can be used for reeving and pulling of steel wire rope onto blocks or cranes. They are made from woven mesh galvanized steel wires leading to a very flexible and easy to handle termination

Scope. This section applies to slings used in conjunction with other material handling equipment for the movement of material by hoisting, in employments covered by this part. The types of slings covered are those made from alloy steel chain, wire rope, metal mesh, natural or synthetic fiber rope (conventional three strand construction), and synthetic web (nylon, polyester, and polypropylene).

Cable laid endless sling-mechanical joint is a wire rope sling made endless by joining the ends of a single length of cable laid rope with one or more metallic fittings.

Cable laid grommet-hand tucked is an endless wire rope sling made from one length of rope wrapped six times around a core formed by hand tucking the ends of the rope inside the six wraps.

Cable laid rope sling-mechanical joint is a wire rope sling made from a cable laid rope with eyes fabricated by pressing or swaging one or more metal sleeves over the rope junction.

Master link or gathering ring is a forged or welded steel link used to support all members (legs) of an alloy steel chain sling or wire rope sling. (See Fig. N-184-3.)

Diagram indicates Forms of Hitch and Kind of Sling. Eye&Eye Vertical Hitch. Eye&Eye Choker Hitch. Eye&Eye Basket Hitch (Alterates have identical load rations). Endless Vertical Hitch. Endless Choker Hitch. Endless Basket Hitch (Alternateve have identical load ratings). Notes: Angles 5 deg or less from the veritcal may be considered vertical angles. For slings with legs more than 5 deg off vertical, the actual angle as shown in Figure N-184-5 must be considered. Explanation of Symbols: Minimum Diameter of Curvature. Represents a contact surface which shall have a diameter of curvature at least double the diameter of the rope from which the sling is made. Represents a contact surface which shall have a diameter of curvature at least 8 times the diameter of the rope. Represents a load in a choker hitch and illustrates the rotary force on the load and/or the slippage of the rope in contact with the load. Diameter of curvature of load surface shall be at least double the diameter of the rope.

Diagram indicates Form of Hitch and Vertical Hitch. Kind of Sling. Eye&Eye Vertical Hitch Not Applicable. Eye&Eye Choker Hitch Not Applicable. Eye&Eye Basket Hitch (Alternates have identical load ratings). Endless Vertical Hitch Not Applicable. Endless Choker Hitch Not Applicable. Endless Basket Hitch (Alternates have identical load ratings). Notes: For vertical angles of 5 deg or less, refer to Figure N-184-4 ""Basic Sling Configurations with Vertical Legs"". See Figure N-184-4 for explanation of symbols.

Strand laid endless sling-mechanical joint is a wire rope sling made endless from one length of rope with the ends joined by one or more metallic fittings.

Strand laid grommet-hand tucked is an endless wire rope sling made from one length of strand wrapped six times around a core formed by hand tucking the ends of the strand inside the six wraps.

Strand laid rope is a wire rope made with strands (usually six or eight) wrapped around a fiber core, wire strand core, or independent wire rope core (IWRC).

Sling use. Employers must use only wire-rope slings that have permanently affixed and legible identification markings as prescribed by the manufacturer, and that indicate the recommended safe working load for the type(s) of hitch(es) used, the angle upon which it is based, and the number of legs if more than one.

Cable laid and 6 × 19 and 6 × 37 slings shall have a minimum clear length of wire rope 10 times the component rope diameter between splices, sleeves or end fittings.

Safe operating temperatures. Fiber core wire rope slings of all grades shall be permanently removed from service if they are exposed to temperatures in excess of 200 °F. When nonfiber core wire rope slings of any grade are used at temperatures above 400 °F or below minus 60 °F, recommendations of the sling manufacturer regarding use at that temperature shall be followed.

Sling use. Employers must use natural and synthetic fiber-rope slings that have permanently affixed and legible identification markings stating the rated capacity for the type(s) of hitch(es) used and the angle upon which it is based, type of fiber material, and the number of legs if more than one.

Safe operating temperatures. Natural and synthetic fiber rope slings, except for wet frozen slings, may be used in a temperature range from minus 20 °F to plus 180 °F without decreasing the working load limit. For operations outside this temperature range and for wet frozen slings, the sling manufacturer"s recommendations shall be followed.

Splicing. Spliced fiber rope slings shall not be used unless they have been spliced in accordance with the following minimum requirements and in accordance with any additional recommendations of the manufacturer:

In manila rope, eye splices shall consist of at least three full tucks, and short splices shall consist of at least six full tucks, three on each side of the splice center line.

In synthetic fiber rope, eye splices shall consist of at least four full tucks, and short splices shall consist of at least eight full tucks, four on each side of the center line.

Strand end tails shall not be trimmed flush with the surface of the rope immediately adjacent to the full tucks. This applies to all types of fiber rope and both eye and short splices. For fiber rope under one inch in diameter, the tail shall project at least six rope diameters beyond the last full tuck. For fiber rope one inch in diameter and larger, the tail shall project at least six inches beyond the last full tuck. Where a projecting tail interferes with the use of the sling, the tail shall be tapered and spliced into the body of the rope using at least two additional tucks (which will require a tail length of approximately six rope diameters beyond the last full tuck).

Removal from service. Natural and synthetic fiber rope slings shall be immediately removed from service if any of the following conditions are present:

A:Of course ,we have to know your application firstly and a number of factors have to be considered, such as work load, safety abrasion, environment ,cycle life, flexibility, , cost, When we design the steel wire cable assembly.

Rotation rope and non-rotation rope or rotation resistant rope. Round strand rope, compacted rope, swaged rope. Wire rope with fiber core, wire rope with IWRC(Independent Wire Rope Core). Galvanized wire rope, ungalvanized wire rope or bright wire rope. Wire rope with plastic insert, Wire rope without plastic insert. Wire rope covered with plastic.

We are the leading supplier for wire rope end terminations to the rigging industry and in addition to ferrules, we design, manufacture and supply a full range of equipment and services. Everything engineered and manufactured in Germany.

Isn’t this the dream of every ardent skier: wedeling downhill merrily and then being taken uphill again within minutes in comfort and at ease by a ropeway or gondola?

Year after year, ski lift and/or ropeway operators are faced with this challenge: to take any number of winter and summer tourists from the valley up the mountain, safely and quickly. And not only in the mountains but in the cities, too, passenger ropeways play an increasing role in the daily transport of great numbers of people. To ensure that transportation is effected safely and fast, not only the appropriate lift systems are required, but also reliable ropeway ropes for passenger ropeways. And these very ropes for ropeways are one of the specialities of Teufelberger-Redaelli.

Our vast experience in steel wire rope manufacturing gained over two generations helps us create optimized products for all fields of use in the passenger ropeway segment.

Our high-performance steel wire ropes for passenger ropeways are developed and produced at two locations in Austria and two in Italy. We produce advanced steel wire ropes for the most spectacular ropeway projects all over the world. Our focus is set on the high requirements in terms of the rope’s service life as well as smooth running behaviour, which we meet through our special rope constructions and production technologies.

With our pioneering rope technologies such as SOLITEC® and SUPEFILL®, we can guarantee long maintenance intervals and thus less downtime, which constitutes a key factor for the success of a ropeway operator.

Our carrying ropes often do their duty throughout the entire lifetime of the ropeway system – and that with great reliability, low maintenance requirements, and the utmost riding comfort.

The provision of high performance steel wire ropes for your passenger ropeway custom-tailored to your specific needs is a fundamental prerequisite for a lasting and successful business relationship. However, TEUFELBERGER also provides additional services that render the construction or upkeep of your ropeway system significantly easier.

No matter which kind of ropeway you operate, we have the right rope for you in our product portfolio. Whether you need a rope for a funicular railway, a Funitel/Funitor, a bicable or tricable ropeway, a reversible aerial ropeway, a gondola ropeway, a chairlift or a surface lift, we have the appropriate hauling ropes, carrying ropes, tensioning ropes, as well as carrying-hauling ropes.

Rope splicing in ropework is the forming of a semi-permanent joint between two ropes or two parts of the same rope by partly untwisting and then interweaving their strands. Splices can be used to form a stopper at the end of a line, to form a loop or an eye in a rope, or for joining two ropes together.

back splice (or end splice) – A splice where the strands of the end of the rope are spliced directly back into the end without forming a loop. It is used to finish off the end of the rope to keep it from fraying. The end of the rope with the splice is about twice the thickness of the rest of the rope. With nylon and other plastic materials, the back splice is often no longer used; the rope strands are simply fused together with heat to prevent fraying.

cut splice (originally cunt splice) – A splice similar to the eye splice. It is typically used for light lines (e.g. the log-line) where a single splice would tend to come undone, the rope being frequently wet.bowdlerised to "cut splice".

long splice – A splice used to join two rope ends forming one rope the length of the total of the two ropes. The long splice, unlike most splice types, results in a splice that is only very slightly thicker than the rope without the splice, but sacrifices some of the strength of the short splice. It does this by replacing two of the strands of each rope end with those from the other, and cutting off some of the extra strands that result. The long splice allows the spliced rope to still fit through the same pulleys, which is necessary in some applications.

short splice – Also a splice used to join the ends of two ropes, but the short splice is more similar to the technique used in other splices and results in the spliced part being about twice as thick as the non spliced part, and has greater strength than the long splice. The short splice retains more of the rope strength than any knots that join rope ends.

A fid is a hand tool made from wood, plastic, or bone and is used in the process of working with rope. A variety of fid diameters are available depending on the size of rope being used. Styles of fid designs include:

A Marlinspike is a tool, usually made of steel and often part of a sailor"s pocketknife, which is used to separate strands of rope from one another. They can range in size anywhere from 3 inches to 5 feet long, with a round or flattened point.

LSG Snake Grips, as overhead pulling grips, are used to pull a new cable or wire rope with the existing cable or wire rope that is being replaced. The Lewis Snake Grips expand or contract to grip different or identical cable and/or rope sizes as per the customer’s needs.

Save time stringing up, changing and un-stringing because the LSG snake grip requires no special tools. The swivel and swing link go smoothly through blocks and prevent line twisting during cable pulling grip operation. Install new cable by using old existing cable as pulling the old line with a snake grip. The swivel and swing link allow you to separate the two side grips for replacement or changing the grip sizes.

Snake grips (aka wire grip or cable grip) are part of Lewis Pulling Grips line of products and typically are used on Oil Rigs, Drilling Rigs & Platform.

8613371530291

8613371530291