wire rope cable thimbles quotation

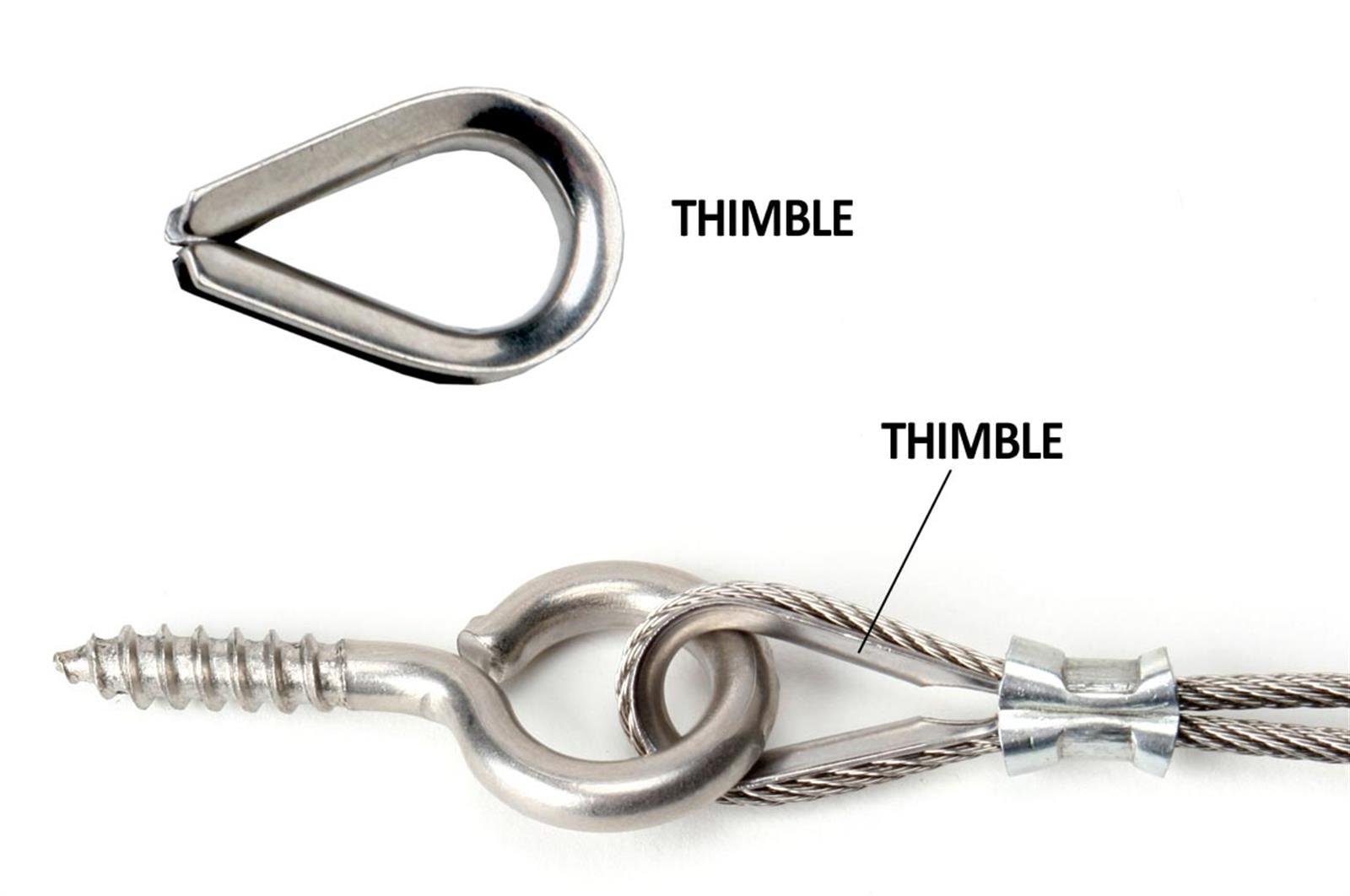

The purpose of thimbles are to underline and support the eyes made by looping the exteriors of wire ropes together. As alternatives to wire clips and swage sleeves thimbles create a durable wear surface & aid in supporting the wire rope eye by preventing pinching and fraying of the wire rope. Thimbles can be used with swage sleeves or wire rope clips.

Available in standard duty, heavy duty, zinc plated, galvanized, stainless steel material. US Rigging offers a wide variety of metals and sizes to best suit your needs, Including AN100 type and Federal Spec FF-T-276 B type. gusseted. tube and nylon thimbles.

Wire Rope Thimbles are used in wire rope assemblies to keep an eye from being crushed. When a wire rope assembly is terminated with an eye or loop at the end, a cable thimble is inserted to form the eye of the loop before the rope is secured. Greater protection against wear and deformation of the wire rope eye. Longer service life.

Thimbles are designed to extend the longevity of wire rope loops by preventing fraying that can occur due to friction at the bearing point. Thimbles must be used in conjunction with either sleeves or wire rope clips in several specifications.

Fortune Rope is an industry-recognized supplier of aircraft cable, wire rope, chain, coated cable, and hardware fittings to a wide range of industrial and commercial customers who has the in-house capability to fabricate the custom cable assemblies you need — from one assembly to medium or high volume production runs.

Wire rope thimbles are used in unison with wire rope clips and swage sleeves when forming an eye to protect the wire rope from abrasion, crushing, pinching and fraying that can result from direct contact between the wire rope and whatever attaching mechanism you are using. Wire rope thimbles offer support for the wire rope and greatly increases the service life of wire ropes and wire rope slings by lessening the force exerted on the wire rope by overly aggressive bends in the cable.

Zinc plated, galvanized and stainless-steel thimbles have industry leading corrosion resistance and can therefore be used in harsh working environments. In addition, more specialized wire rope thimbles are available, such as choker thimbles, solid wire rope thimbles, and wire rope thimbles with built in clamps.

Here at Tri-State Rigging Equipment we pride ourselves on providing our customers with only the highest quality wire rope thimbles, from only the most reputable dealers. We can provide you with any rigging product on the market, so if you don’t know what you are looking for or if you don’t know exactly what you need, call or email our sales team to speak with a rigging product specialist.

Tri-State Rigging Equipment is a service provider and distributor for all wire rope cable thimbles, both stainless-steel and galvanized, for rigging and lifting serving clients from coast to coast, Canada, Mexico and especially focused in the states of Missouri, Illinois, Indiana, Iowa, Kansas, Nebraska, Arkansas, Mississippi, Tennessee, Kentucky, South Carolina, Florida, and Oklahoma.

G414 stainless wire rope thimbles is a heavy duty cable thimble. It can supply extra strength for forming reinforced eyes or loops to protects wire ropes from pinching and abrading on the inside of the loop. Hilifting also has light duty stainless steel thimble for your option.

Thimbles are used to secure guy wire , guy cable , guy strand , guy anchors & rope ,protects and offer longer service life and greater protection against wear and deformation of the wire rope eye . Used with Pre-Formed Dead ends . Thimbles are available in light and heavy duty style for strength . Heavy Duty Wire Rope Thimbles are constructed of Hot Dipped Galvanized Steel for corrosion protection .

VER Sales carries a wide variety of Wire Rope and Synthetic Rope Thimbles. If you don"t find what you are looking for listed on our site, please give us a call. It is not possible to list everything we stock and can get quickly.

The Rize Looped Cable enhances the Kwik-Loc suspension system by the addition of a pre-looped cable end. Once the wire rope is pulled around the anchor point and through the looped end of the cable, it is already secured at one end, saving time at the job site. The remaining wire rope “drop” is passed through a channel in the Rize Kwik-Loc. Then, the wire rope is either wrapped around the equipment or inserted through a fastening point and back up into the second channel of the same cable lock. The locking teeth inside the cable lock engage the wire rope which secures the equipment in place.

8613371530291

8613371530291