wire rope capacity table price

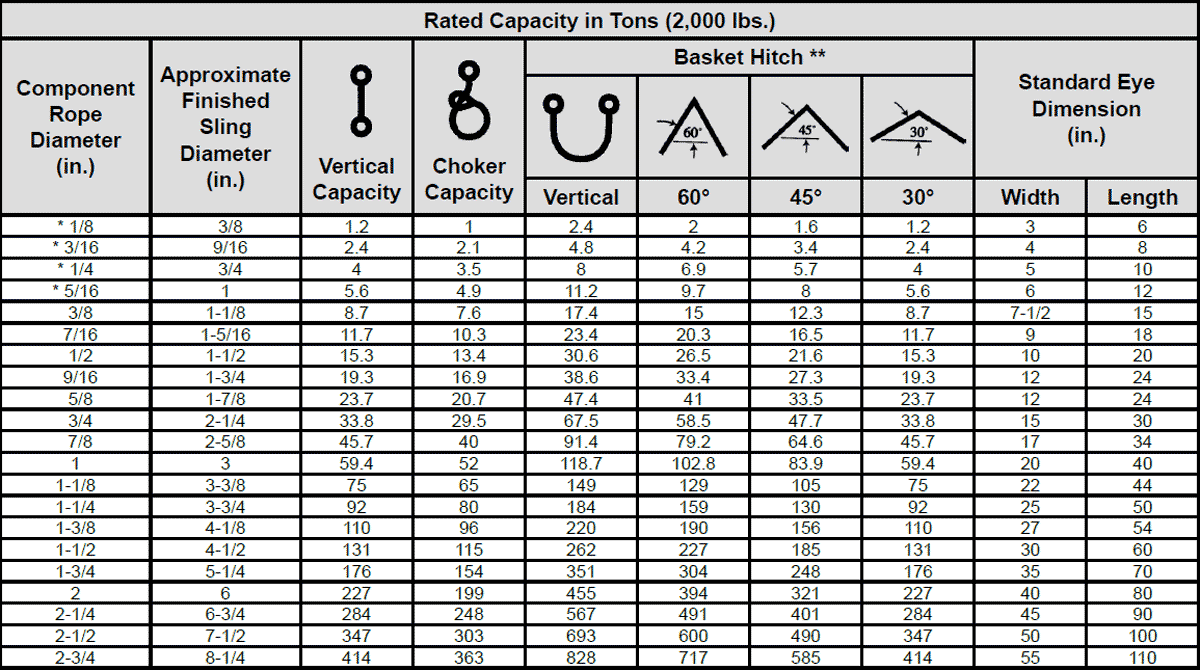

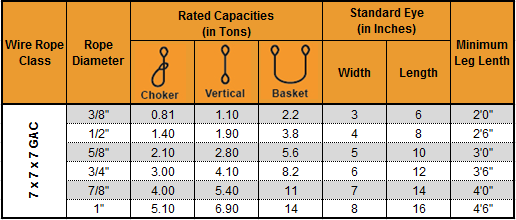

Galvanized wire rope is categorized by number of strands in its construction. We supply most of them but we concentrate on the two major categories of galvanized (and ungalvanized or bright) wire rope. These “classes” are referred to as 6x19 and 6x36. Within each category of galvanized wire rope there are different “constructions” illustrated in the tables below.

Wire rope, galvanized and ungalvanized is used for many kinds of projects and applications. No matter the application galvanized wire rope must be used properly to insure the safest working conditions. All of our galvanized wire rope is manufactured to meet or exceed Federal Specification RRW-410 and is mill certified.

All of these general purpose wire ropes are available in full reels, custom cut sizes or as part of a custom made wire rope sling. Contact us today for more information.

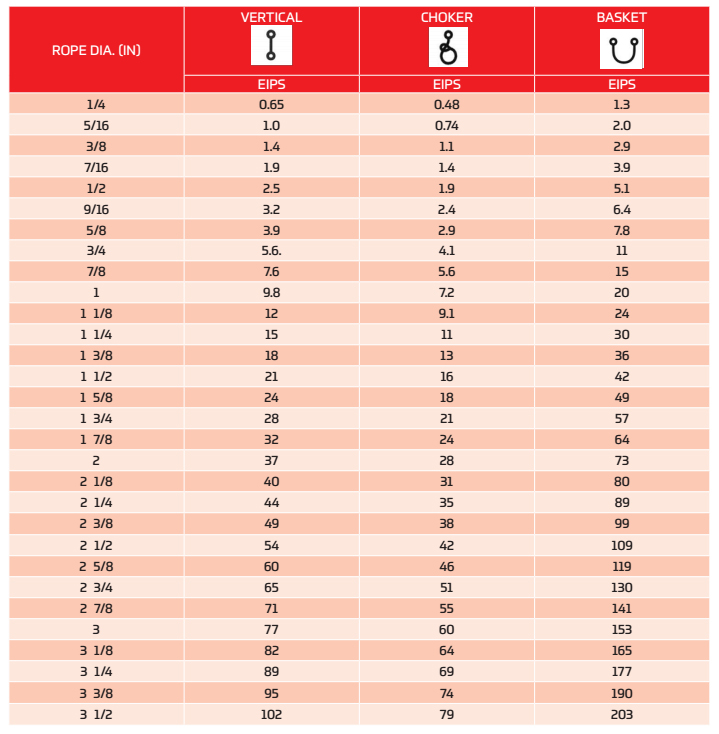

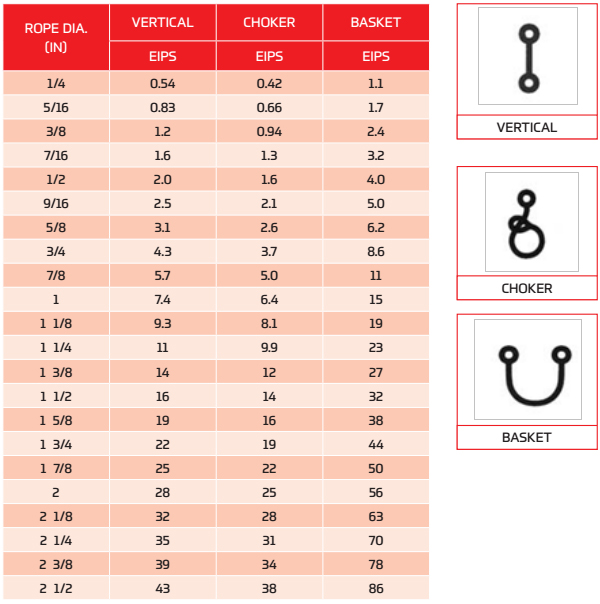

Galvanized wire rope also comes in different strength categories (IPS and EIPS) and different cores (FC or fiber core and IWRC or independent wire rope core). Relevant data for each is listed in the table below.

6x36 is a flexible general engineering wire rope readily available in galvanised, ungalvanised and marine grade stainless steel. The wire rope has an equal lay construction (warrington seale) and achieves a superior breaking load to the 6x19 construction range. The construction has been designed to give a flexible rope with a good fatigue life. A 6x36 wire rope is available with either FC (fibre core) or IWRC (independent wire rope core) and is used for a wide range of applications, examples of which are shown below:

Application: For general purpose overhead lifting, suspension, skidding, and drag lines. Used as boom hoist ropes for cranes. Ideal for rigging, mining, construction, logging, oilfield, machine moving, and aerospace

Description: Manufactured by Wire Rope Industries, the Dy-Pac strand compaction process of this Surelift line improves the rotation resistance. Tested and designed for superior quality and value. This resilient multi-strand construction crane cable provides strength and performance while improving rope fatigue life. The smooth outside strand profile creates and improves rope wear resistance, reduces sheave and drum wear, and allows the rope to run efficiently on high speed hoisting lines.

- Recovery Ropes, Tow Lines, Tow Bridles, Tow Ropes, Winch Ropes, & Winch Lines- - Recovery Ropes, Tow Lines, Tow Bridles, Tow Ropes, Winch Ropes, & Winch Lines – Main Page

LoCo (low coefficient of friction) 12×12 retains all of the features & benefits of standard Plasma® ropes with the added characteristic of a reduced coefficient of friction coating. The enhanced coating provides improved UV resistance and reduces internal heat build-up and abrasion associated with constant tension-tension fatigue, relative movement between the rope and fixed surfaces, and during cyclical bending. Cortland’s proprietary LoCo coating process ensures superior adherence to the braided Plasma rope; providing an effective bond for increased service life and wear especially in wet environments.

Plasma 12×12 is a 12-strand braided rope in which each of the 12 strands is, in turn, a 12-strand rope, or braided primary strand. Plasma is manufactured from High Modulus Polyethylene (HMPE) that has been enhanced by Cortland’s recrystallization process. This construction addresses the most critical properties of the fibers to provide very high strength translation efficiency for larger ropes. This design allows for long lay lengths, making rope that is more flexible for bending applications, easy to inspect, and can be quickly spliced using Cortland’s recommended splicing techniques for low coefficient of friction ropes.

• Tensile Strengths are determined in accordance with Cordage Institute 1500.2. Test Methods for Fiber Rope. Minimum Tensile Strength (MTS) published assumes spliced eye tenninations at each end of the rope. Weights actually calculated at linear density under state preloaded (200d’J plus 4%. Diameter and circumference size published is nominal and reflects rope size after loading (10 cycles) to 50% ofMTS. See reverse side for application and safety information .

Plasma® 12 strand is the highest strength synthetic rope available. Plasma® 12 strand is manufactured from High Modulus Polyethylene (HMPE) that has been enhanced by Cortland’s patented recrystallization process. This process is especially effective in medium to large diameter ropes where strengths are over 50% higher and creep is significantly less than that of standard Spectra® 12 strand.

Mark-10 defines accuracy as a percentage of full scale of the instrument. To determine the measurement error as an actual load value, multiply the accuracy percentage by the instrument’s capacity.

Because of the relationship between load and accuracy, we recommend selecting an instrument capacity as close as possible to the maximum measured load.

This ratchet tie down is made of imported strap, processed of dye and iron and steps of delicate finish. It is made from Heavy Dacron and polypropylene, with all species of tie-down ranging from width 1-4" and break strength 1100lbs-20000lbs . You can choose and customize the fittest hook on Tie-down. Ratchet Straps are used for tying down loads whilst transporting , shifting or moving them. They have replaced traditional jute ropes, chains and wires used for transportation and for a variety of other applications.

8613371530291

8613371530291