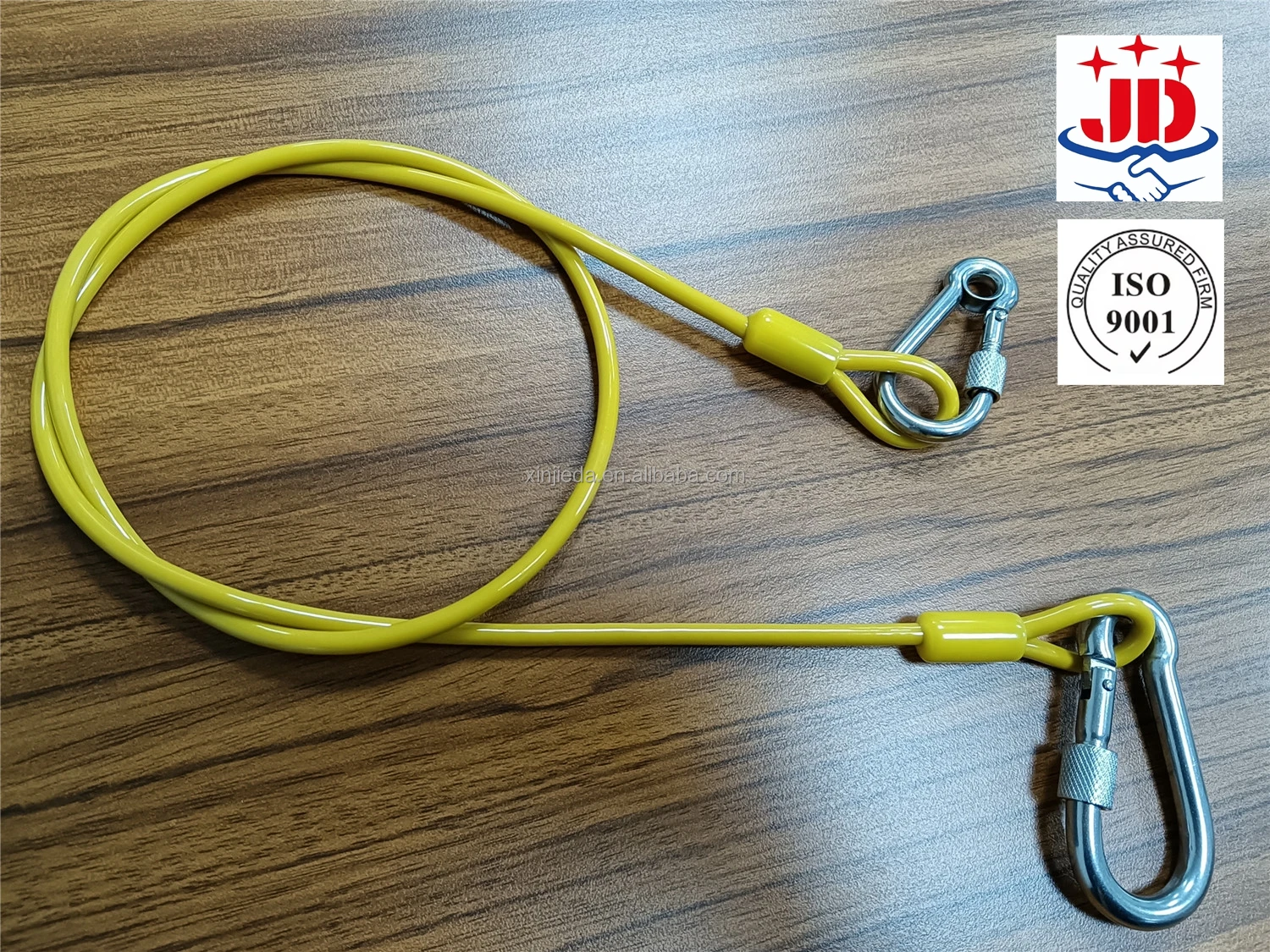

wire rope carabiner free sample

The French Creek 30 Foot Stainless Steel Wire Rope SRL with Carabiner designed for extreme durability. Offering high mobility and an extended range of motion with no slack to prevent tripping. The cast aluminum housing makes this SRL extremely durable. The fully enclosed braking system and internal deceleration system help keep debris out of internal workings. The periodic factory inspections extend the life of the unit and ensure there is an extra set of eyes ensuring safety. This SRL is classified as a Class B

Of course ,we have to know your application firstly and a number of factors have to be considered, such as work load, safety abrasion, environment ,cycle life, flexibility, , cost, When we design the steel wire cable assembly.

General ,use a 5 to 1 or 3 to 1 safety factor when we design it, example :breaking load is (1000N) 100kg, Safetyfactor is 5:1 (200N) Breaking strength should never be considered the rope"s working load.

There is a standard language used in the technical specifications of carabiners but this is not well understood. This article is an attempt to clarify some common markings that appear on carabiners. It should be noted that there is significant industry and international variation in the common use of these terms.

This image from the UIAA (http://www.theuiaa.org/upload_area/files/1/UIAA121-Connectors_2.jpg) demonstrates the test methods for the ratings typically seen on carabiners.

If 100 carabiners are submitted for destructive testing then the measured strengths will vary considerably. Inconsistencies in the manufacturing process may result in larger variations. The batch test results can be plotted on a histogram showing the probability of breaking at particular strengths and this curve should approximate a “normal distribution” or “bell curve”.

Many carabiner manufacturers state that they use “3-sigma” to determine their MBS values. This means that the MBS is actually the mean breaking strength less 3 times the standard deviation (3σ).

Statistically, this also means that 0.3% of samples will lie outside this range and therefore half of these (0.15% or 1.5 in every thousand) may break below the MBS stamped on the carabiner.

Material behaviour under load is normally characterised by stress vs strain curves. Two terms that are useful in describing this behaviour are Elastic and Plastic Deformation. When an carabiner is stressed by applying tension along the spine it will begin to ‘stretch’ at a relatively low force. If the carabiner returns to its ‘normal’ shape once the stress is removed then we can describe this stretching as ‘Elastic Deformation’. As the stress becomes more significant this ‘stretching’ may enter an irreversible range known as ‘Plastic Deformation’. This image shows a carabiner that failed above its MBS during a pull test. The hinge pin pulled through the host however the body has definitely undergone plastic deformation.

So, carabiners should not fail below their MBS however they will undergo irreversible deformation before reaching this point. Also, it is perfectly reasonable to expect that repeated heavy loading will fatigue the material and result in failure below the MBS.

Working Load Limit (WLL) is a term used by manufacturers to indicate the maximum force that should be applied to a carabiner in normal use, regardless of industry. The ratio of MBS to WLL is referred to as the Design Factor (DF). Many carabiner manufacturers specify a DF of 4 which implies a WLL of a quarter of the MBS. Manufacturers state the WLL to ensure that the carabiner is not subjected to significant fatigue and remains in the range of normal elastic deformation.

Safe Working Load (SWL) is typically determined by dividing the MBS of a carabiner by the Safety Factor (SF) required for a particular use. As stated above it possible that an entertainment rigger may calculate a different SWL for a particular use of a carabiner than the value determined by a rescue technician.

A particular steel carabiner has a 3-sigma rated long-axis MBS of 50kN. The manufacture has specified a DF of 4 for this connector, regardless of use.

This carabiner has a WLL of 12.5kN and this value should never be exceeded in normal use – regardless of industry or application. If this value is exceeded it should not fail below the MBS however it should then be removed from service and destroyed.

An entertainment rigger, working in a certain country is required by the industry code-of-practice to use a SF of 10 for flying performers and thus, determines the SWL of this carabiner is 50kn/10 = 5kN.

The ladder safety system is a wire rope type permanent fall protection system for climbing fixed ladders or vertical structures. The system consists of galvanized top and bottom brackets, galvanized steel cable, an energy absorber integrated in the top bracket and a stainless steel cable fall arrester (the fall arrester is sold separately). Brackets are designed for ladder rungs but can be easily adapted to most structures. A 5/16-in.(8.3 mm) or 3/8-in. (9 mm) steel cable is suspended on the brackets, tensioned and contained approximately every 25 ft. (7.5 m) by cable guides which are designed to minimize cable vibration and wear.

A stainless steel cable fall arrester with internal spring-loaded cam can be attached or removed from the cable at any point. It is secured with a compatible carabiner, supplied with the slider, to the frontal attachment point on any approved ladder climbing harness. The user is free to climb and descend with full use of the hands. In the event of a fall, the fall arrester will quickly cam on the cable and arrest the fall. Free fall distance is minimized by a close coupled attachment. The top mounting bracket incorporates a shock absorber, further reducing impact force on the

The ladder safety system is a wire rope type permanent fall protection system for climbing fixed ladders or vertical structures. The system consists of galvanized top and bottom brackets, galvanized steel cable, an energy absorber integrated in the top bracket and a stainless steel cable fall arrester (the fall arrester is sold separately). Brackets are designed for ladder rungs but can be easily adapted to most structures. A 5 ⁄16-in. (8.3 mm) or 3 ⁄8-in. (9 mm) steel cable is suspended on the brackets, tensioned and contained approximately every 25 ft. (7.5 m) by cable guides which are designed to minimize cable vibration and wear.

A stainless steel cable fall arrester with internal spring-loaded cam can be attached or removed from the cable at any point. It is secured with a compatible carabiner, supplied with the slider, to the frontal attachment point on any approved ladder climbing harness. The user is free to climb and descend with full use of the hands. In the event of a fall, the fall arrester will quickly cam on the cable and arrest the fall. Free fall distance is minimized by a close coupled attachment. The top mounting bracket incorporates a shock absorber, further reducing impact force on the worker and the structure. An uninjured worker can quickly recover and climb down the structure to safety with complete protection.

Almost all styles of climbing (save bouldering and free soloing) require carabiners. If you are looking to buy individual ones you are most likely a traditional climber, or hoping to become one. If you only sport climb, then you"ll want to have a look at our locking carabiner advice guides instead, as well as our quickdraw review. While carabiners might not seem that expensive when purchased individually ($6-15), you end up needing a lot of them when traditional climbing and twenty can cost you as much or more than a rope. They do tend to have a long lifespan compared to soft goods like a harness or rope, so make sure you purchase something you like as you might be using it for the next ten plus years.

Climbing carabiners are manufactured out of stainless steel or aluminum. Steel ones are stronger and more durable than aluminum ones, but they also weigh twice as much (or more!) and are mainly used for fixed draws or anchors. All of the products that we tested in this review are made of aluminum.

Aluminum carabiners are anodized to increase their resistance to corrosion and to dye them different colors. The anodized layer is microscopically thin and doesn"t increase the strength of the aluminum, but it does prevent the metal from deteriorating, particularly when/if the user exposes it to salty water and air. The anodized layer will wear off the rope bearing surface fairly quickly, but it still protects the rest of it. Even if yours are anodized, if they are ever exposed to salt water be sure to wash them thoroughly afterward as it will quickly deteriorate the metal.

Another advantage to anodizing is that you can have one color for the top of a quickdraw or alpine draw and another color for the bottom. If you buy a preassembled draw they usually come this way already, but when setting up a rack of "alpine" or "extendable" draws (two carabiners on a tripled-up shoulder length sling) you should also do this, because the steel of a bolt, piton or even a nut wire will quickly gouge the soft aluminum. If the rope bearing surface does get gouged, there"s a possibility that it can snag the sheath of your rope and in extreme cases lead to rope failure. As an example, the Mad Rock Ultra Light Wire comes in red and silver, so you can easily distinguish which side is for clipping gear and which side is for the rope.

Cold forging is the original method of making carabiners whereby the rod of aluminum is bent into the desired shape and then stamped in a die at room temperature. In the hot forging process, the rod and forge dies are heated before stamping, which typically allows a manufacturer to create a lighter product with a more intricate design. If you compare a cold-forged vs. a hot-forged model, it is easy to tell which is hot-forged as it will have a more sculpted look. I-beam or cut-out spines can be created with both processes. In this review, the Wild Country Helium, Mad Rock Ultra Light, and the Black Diamond Oz are hot-forged.

CAMP uses only cold forging for their CAMP Photon Wire and Nano 22 models because they feel it results in fewer irregularities in their product and it"s more reliable than hot forging. A climber might never actually notice the difference between the two methods. Most hot-forged models are more expensive, except that our Best Buy winning Mad Rock Ultra Light ($6) is actually hot forged. And while our Top Pick for Lightweight Black Diamond Oz is hot-forged, the even lighter Nano 22 is not.

In perusing other reviews and message boards, we noticed some concern about hot-forged models being less durable. People are grumbling that their gear used to last ten years and is now wearing out in one or two. This is not necessarily a result of the forging method but of how much metal is used in the process. A lighter weight model, hot or cold forged, will have less material overall, specifically on the rope bearing surface, which leads to quicker grooving. If you are more concerned with the longevity over the weight, choose a big and beefy model like the Petzl Ange L, which has a large rope-bearing surface and should last a while. If you"re fascinated by this topic and want to learn more, and have a spare 30 minutes, check out DMM"s factory tour.

Improving gate technology has always been a top engineering concern for manufacturers, and climbers. The enhanced designs of the last few decades have created safer, lighter, and snag-free gates. The two main types of gates are solid or bar stock gates, and wiregates. Note that we tested only wiregate models in this review, as they are lighter and better suited to traditional climbing, but cover both in our quickdraw review.

Today"s solid gates are much improved from older models. Virtually all solid gates on the market today are "keylock." Instead of a pin on the end of the gate that latches on a notch in the nose, now the nose itself latches on a groove in the barrel of the gate. Since it does not have that notch in the nose, a keylock design won"t snag on your rope when unclipping or catch your gear or bolt. One rare but dangerous scenario that can occur with a notched nose is a "nose clip." This occurs when a carabiner isn"t clipped on the bolt properly to begin with, or if it shifts as the climber moves past it, leaving the notch hooked precariously on the lip of the bolt. While rare, this can result in gear failure at loads of less than 10% of the closed gate strength (<2 kN.) This small amount of force is easily reached in a fall or even a bounce test. In part to help avoid this scenario, most sport-climbing specific quickdraws now have keylock bar gates at least on the top, and often on the bottom too.

Wiregates are over 20 years old now and have become the preferred type of gate for traditional climbing. The single loop of metal weighs less than the bar, pin, and spring of a solid gate, and can shave 7 grams or more off the total weight. These weight savings are crucial, particularly since you carry a lot of carabiners when trad climbing - and because your camming devices already weigh a lot. Another advantage of the wiregate is that it"s less prone to icing up than a solid gate in cold conditions, and they are the preferred model for ice and alpine climbing. Since the wire is much narrower than the bar, they also have a larger gate opening than a similarly sized solid gate model, and a wider opening is also useful when climbing with gloves on or when using multiple ropes.

Wiregates are less prone to "gate flutter," a rare but serious issue. When a carabiner catches a fall, the forces generated cause the gate to vibrate. The more mass in the gate, the more vibration, and the gate itself can flutter open and closed. The strength of a carabiner with an open gate is roughly 2/3 of its closed gated strength, anywhere from 7 kN to 10 kN. This level of force can be achieved in a real-life fall and could result in the piece failing. While this is a rare phenomenon overall, it is even rarer in wiregates than solid ones.

The downside to a wiregate is that on most models there is still an exposed notch in the nose that the wire latches on, just like the old-style solid gates. More and more companies are devising ways to eliminate this notch, effectively creating wiregate/keylock hybrids, which is the best of both worlds. Wild Country has buried the notch in the nose of its Helium model, and Black Diamond has developed a stainless steel wire hood that is swaged around the notch of the Oz, protecting the notch from catching on anything. Petzl uses a single wiregate on its Ange model that fits in a slot similar to keylocking bar gates. Whatever the method, the advantages are real. In addition to reducing snags, they also protect the wiregate from scraping open against the rock. We should note, however, that it can be challenging to fit these noses in tight situations, like bolts stuffed with rappel slings or pitons with narrow openings.

Both solid and wiregates can be straight or bent. Most climbers tend to find bent gates easier to clip than straight gates, and that"s why you"ll find them on the rope end of a quickdraw, but according to Petzl, there is a higher risk that the rope will become unclipped from a bent gate model in a fall. Check out their great info-graphic for tips on how to avoid dangerous clipping situations.

The tension on a gate determines the clipping action: fast and snappy, stiff and slow, or soft and easy. This is often a personal preference, though it is very important that there is some spring tension that returns the gate to its fully closed position. In solid gates, that tension is created by a spring in the barrel of the gate, and in wiregates, it"s created by the pivoting of the wire itself. That tension can decrease over time, due to the build-up of dirt or grime, or due to corrosion. An open gate reduces the strength by roughly 2/3rds (see Strength section below) and creates the potential for the rope to come unclipped or the carabiner to break in a fall. If your gates become "manual" and no longer close on their own, wash them according to the manufacturer"s instructions and lubricate the joints.

Most climbing gear is CE certified. This certification is from the European Committee for Standardization (CEN), which requires gear to meet certain standards to be sold in the EU. Even though the U.S. has no set standards for climbing gear, most American manufacturers build to this specification and are CE certified in order to sell their products overseas. All of the models we tested in this review are CE certified. To check if your own gear is, look for a CE and four numbers stamped or printed on the side. If it"s not, as long as it meets the minimum strength requirements below (also stamped or printed on the side) it should be alright.

Another consideration is the rope bearing surface. When the rope catches your fall, it is bent around the basket of the carabiner. The wider the basket, the gentler the bend on the rope and the less impact it has on it. So, for sport climbing, where you might be taking repeated falls on the rope in the same place, a wider rope bearing radius is preferred. Same is true for setting up a top rope anchor.

The weight between products can vary greatly, from 19 grams (the lightest full-strength option - made by Edelrid) to 64 grams for a full size oval. You"ll want to closely consider the weight of your gear if you do any sort of multi-pitch climbing, be it sport or trad, are hiking your gear long distances into the backcountry or trying to climb light and fast on a big wall. While a few grams here or there might not seem like much difference either way, remember that between your cams and draws, a full rack of gear will have around 40 carabiners on it, and those few grams will quickly add up to ounces and even pounds saved.

The lifespan of your gear will be determined by the amount of use it gets, the way you care for it, and its exposure to corrosive elements. Our main tester"s entire set of anodized carabiners had to be replaced after a season of climbing in Thailand thanks to the corrosive effects of the sea and uniquely active limestone (she might not have washed them after getting dunked on a rappel off Ao Nang Tower either.) Once she learned how to care for her gear, she now has some that are more than ten years old and still perfectly serviceable.

Rope wear is one of the main ways they will wear out, particularly when sport climbing. Repeated lowering and top-roping causes small amounts of metal to wear away, and eventually, a pronounced groove will develop. This is different from the intentional groove that many baskets have across the rope bearing surface. This slight depression is there to guide the rope as close to its main (and strongest) axis as possible. According to Petzl, any groove caused by wear more than 1mm deep is a warrant for concern since sharp edges can start to form on the edge of the rope bearing surface; edges like these can sever your rope in a fall. Black Diamond has conducted several tests about this at their Quality Control lab - you can read more about them here and here.

Crane means any self-propelled vehicle to which has been permanently mounted or attached any crane, whether or not such vehicle was originally a truck, tractor, or other type of motor vehicle or was designed and built as a complete crane unit. However, the word "crane," as herein defined, shall not be construed to mean any truck or other vehicle equipped with or to which has been affixed any device used for the purpose of providing a means for towing other vehicles.

With dozens of companies making untold numbers of carabiners these days, it can be a real chore to navigate through countless different models to choose the one that"s right for your type of climbing. Wiregate vs. standard gate. AutoLock vs. screwgate. Ultralight vs. heavy. What biners should I use on my slimmed-down alpine rack as opposed to my daily sport cragging kit? As with most pieces of climbing gear, there is a certain amount of inherent versatility, but often certain products are better suited, and more often than not designed specifically for certain applications. As with almost anything, it"s always prudent to select the right tool for the job. This month we"ll attempt to distill the basics of carabiner usage to help you figure out what"s the right choice for your type of climbing.

I get lots of random calls from arborists, fire departments, rescue workers, marinas, yachting folks, Jeep guys and warehouse personnel wanting to know if it"s okay to use our carabiners for their particular application. The official answer is always no, not recommended. Just as all of our instructions say, our gear is "For Climbing and Mountaineering Only." But why?

What many people may not realize is the different ways that recreational gear is designed, tested and rated compared to industrial equipment. Industrial connectors are usually made of steel, are much heavier, are often much stronger, certified to different standards, and are sometimes rated differently than aluminum climbing carabiners.

Depending on what standard an industrial connector is certified to, and it’s intended application, it may be rated to either it’s Safe Working Limit (SWL) and/or it’s Minimum Breaking Strength (MBS). The steel connector on the left in the photo below has an MBS of 45kN - if it sees a load of 45kN, it will break. However, if a connector is marked with it’s SWL, it will have a safety factor included which could be anywhere from a factor of 4 and up. For example, let’s say a steel industrial connector is marked with a SWL of 10kN and is certified to an industrial standard which requires a safety factor of 4. This means that you can load the connector safely to 10kN - and that it won"t actually break until a minimum of 40kN. However, climbing gear is always rated to the load at which it will actually break. So a 20kN carabiner actually breaks at that load. There"s a big difference.

Carabiner means a connector generally comprised of a trapezoidal or oval shaped body with a closed gate or similar arrangement that may be opened to attach another object and, when released, automatically closes to retain the object.

Lanyard means a flexible line of rope, wire rope, or strap that generally has a connector at each end for connecting the body belt or body harness to a deceleration device, lifeline, or anchorage.

Rope grab means a deceleration device that travels on a lifeline and automatically, by friction, engages the lifeline and locks so as to arrest the fall of an employee. A rope grab usually employs the principle of inertial locking, cam/lever locking, or both.

Travel restraint (tether) line means a rope or wire rope used to transfer forces from a body support to an anchorage or anchorage connector in a travel restraint system.

8613371530291

8613371530291