wire rope catalogue quotation

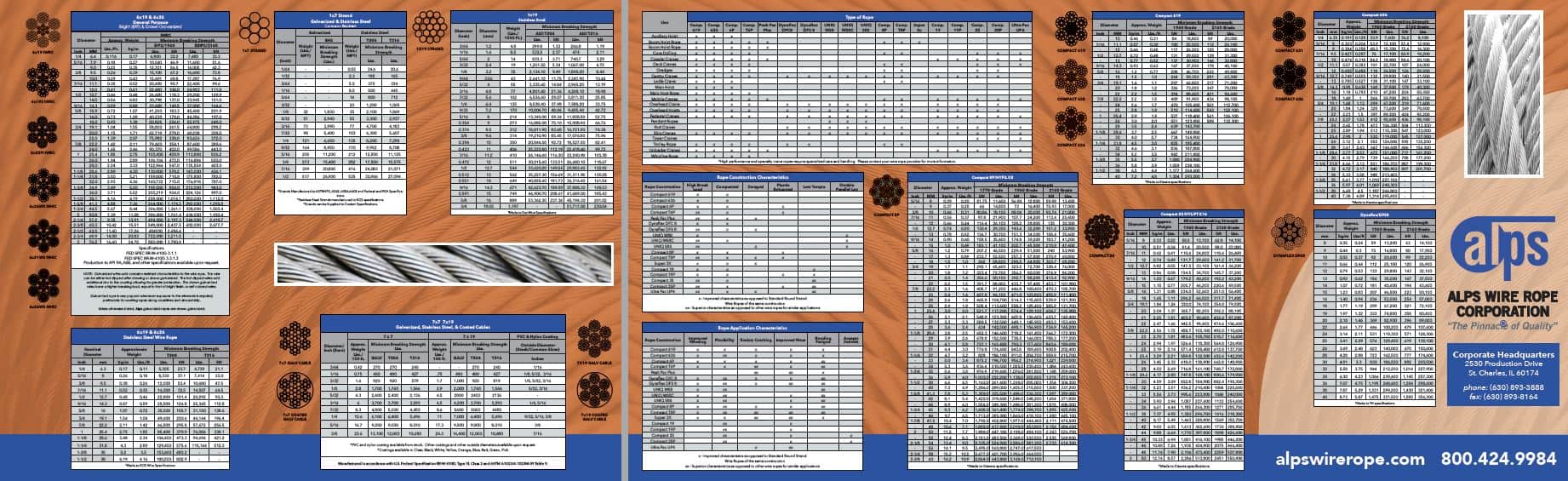

Wire rope strength in the United States is typically shown in tons of 2,000 lbs. The wire rope strength is shown as minimum breaking force (MBF). This is a calculated strength that has been accepted by the wire rope industry. When tested on a tensile machine, a new rope will break at a value equal to- or higher than – the minimum breaking force shown for that rope. The published values apply to new, unused rope. A rope should never operate at – or near- the minimum breaking force. The minimum breaking force of the rope must be divided by the design factor required for the application to determine the maximum load allowed on the rope. During its useful life, a rope loses strength gradually due to natural causes such as surface wear and metal fatigue.

Fatigue resistance involves fatigue of the wire used to make up a rope. To have high fatigue resistance, wires must be capable of bending repeatedly under stress – for example, as a loaded rope passes over a sheave during operation. Increased fatigues resistance is achieved in a rope design by using a large number of wires. It involves both the wire properties and rope construction. In general, a rope made of many wires will have greater fatigue resistance than a same – size rope made of fewer, larger wires because smaller wires have a greater ability to bend as a rope passes over a sheave or around drums. To overcome the effects of fatigue, ropes must never bend over sheaves or drums with a diameter so small as to bend wires excessively. Standard for specific applications contain requirements for minimum sheave and drum sizes. Every rope is subject to metal fatigue from bending stress while in operation, and therefore the rope’s strength gradually diminishes as the rope is used.

Crushing is the effect of external pressure on a rope, which damages it by distorting the cross-section shape of the rope, its strands or core -or all three. Crushing resistance therefore is a rope’s ability to withstand or resist external forces, and is a term generally used to express comparison between ropes. When a rope is damaged by crushing, the wires, strands and core are prevented from moving and adjusting normally during operation. In general, IWRC ropes are more crush

resistant than fiber core ropes. Regular lay ropes are more crush resistant than lang lay ropes. 6-strand ropes have greater crush resistance than 8-strand ropes or 19-strand ropes. Compacted strand ropes are more resistant than standard round-strand ropes.

When a load is placed on a rope, torque is created within the rope as wires and strands try to straighten out. This is normal and the rope is designed to operate with this load-induced torque. However, this torque can cause both single part and multiple part hoisting systems to rotate. Load induced torque can be reduced by specially designed ropes. In standard 6 and 8- strand ropes, the torques produced by the outer strands and the IWRC are in the same direction and add together. In rotation-resistant ropes, the lay of the outer strands is in the opposite direction to the lay of the inner strands, thus the torques produced are in opposite directions and the torques subtract from each other.

Alps Wire Rope® is your favorite provider of General Purpose, Elevator, Specialty Crane, Oilfield, Marine and Industrial Cables. Please select one of our Product Brochures below for more information regarding each individual product. Just click the download buttons below.

We understand that there are many factors that go into choosing the correct sling, wire rope, rigging hardware or lifting device for a lift! Let our sales team help!

Have a steel sheave, pulley, wire rope, or application question?Ready to start a new project? Have a requirement you need met? Know your sheave specification and need custom pricing? You’ve found the right resource. eSheaves engineers are ready to answer your inquiry, work on your request for quote, or assist with the particulars of a new custom engineered project.

Over the years, Usha Martin Europe successfully developed a preferred selection of trawl and purse seine fishing wire rope. All designed and produced for safe and maximum performance.

Industrial fishing ropes are subjected to a lot of wear and abrasion, especially trawling ropes. As a result, we design our fishing wire ropes towards increased abrasion resistance and reduced pulley wear.

A major deteriorating factor for fishing ropes is corrosion. Therefore, we offer our range of fishing wire ropes with choice of galvanization and lubricant to ensure further extension of rope service life. Always based upon your application and environmental circumstances. But we do not stop there. Based upon your specific application, we design and select the correct construction, including careful selection of strands and wire diameter.

Fishing wire ropes are always on supply at our facility in Dordrecht, reporting to a worldwide network of customers. Some examples are the 6×7, 6×19 and the 6×26 construction.

Would you like to invest in high-quality fishing wire rope? Then you should get in contact with us by sending an e-mail to info@ushamartineurope.com or calling +31 (0) 180745099. It is also possible for us to fabricate solutions that are tailored to your specific situation. That is how we can help a variety of sectors with our steel wire ropes.

We understand that there are many factors that go into choosing the correct sling, wire rope, rigging hardware or lifting device for a lift! Let our knowledgeable sales team help you with a quote for your specific job. Please provide as much information possible about the lift so we can ensure that the right products are quoted. Need something custom? We have an in-house engineering team that can help!

Landmann Wire Rope Products can boast of having the largest selection of wire rope and rigging/fastening products on the west coast USA. Our diverse product lines are one of our many strengths that you, the dealer, can take advantage of.

Use our thorough list of wire rope manufacturers and suppliers in Ontario to examine and sort top wire rope manufacturers with previews of ads and detailed descriptions of each product. Any wire rope manufacturers can provide wire rope products to meet your company"s specific qualifications. An easy connection to reach wire rope manufacturers through our fast request for quote form is provided as well. This source is right for you whether it"s for cable railing, marine rigging, or any other wire rope needs.

Hercules Wire Rope & Sling Co., Inc., is a complete rigging facility specializing in Wire Rope, Slings, Cordage, Chain, and Fittings. Carrying a full line of industrial and marine supplies,Herculescan meet your most demanding needs.

8613371530291

8613371530291