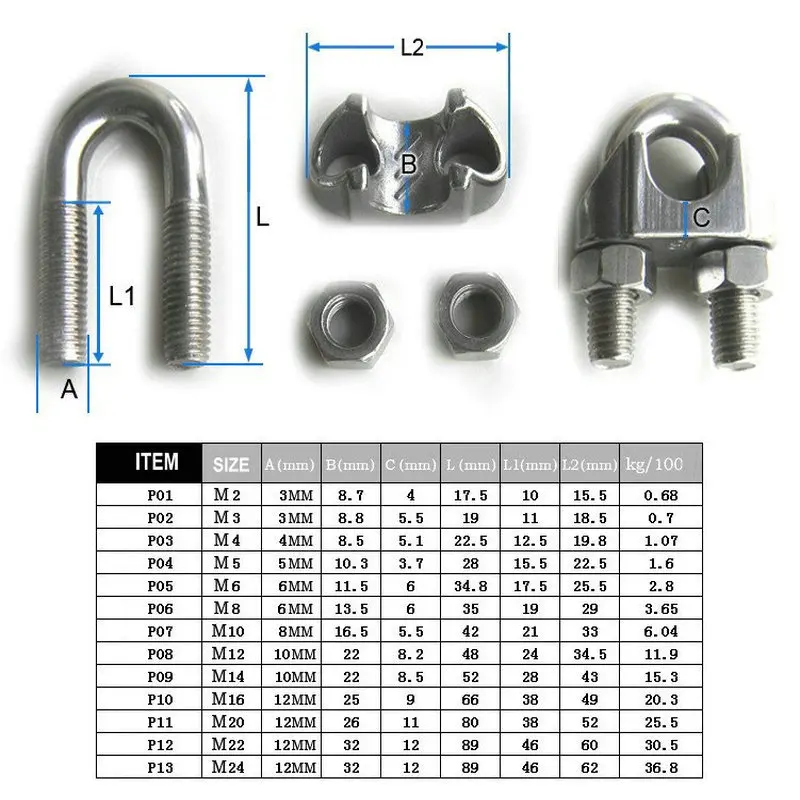

wire rope clamp dimensions in stock

Murphy offers many sizes of wire rope clips in 4 different fabrications: zinc plated, stainless steel malleable, galvanized drop forged, and stainless steel drop forged.

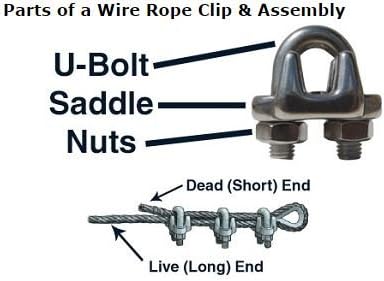

You can use wire cable clips to secure the loose ends of your wire ropes. They often have nuts, u-shaped bolts, and cast saddles. You can put the wire rope in the bolt and then place the saddle over the bolt’s rope. By using the nuts, you can then secure the rope in its place.

There are a couple of ways to make the process stronger. For example, if you have a cable coated with vinyl, then you can take off the vinyl in the place where you put it in the wire rope clip.

We offer our clips in a range of materials, which gives you more options. You can use the clips for semi-permanent or permanent applications, or just temporary ones. You can use your hand tools to secure them to your stainless steel wire rope. They are also cost-effective.

You can count on our company to offer sturdy and long-lasting clips, so you can secure your loose ends well. We have good knowledge of the requirements of various industries, allowing us to offer you the best products. You can expect our wire rope clips to last for a long time.

With so many different kinds of rope clips and ropes to choose from, we know making a choice can be difficult. Luckily, Murphy Industrial Products, Inc. is here to help. Feel free to contact us today if you want to know more about our stainless steel wire rope clips and related products.

Wire rope grip in marine grade stainless steel, strong and hard-wearing clamp for creating loops in stainless steel cable, easy to install and is ideal for highly corrosive environments.

Wire Rope Grips are used on wire rope eye-loop connections or complete loops, end-to-end connections, where socketing or splicing is not feasible or when a temporary joint is required.

Before installation it is best to check you have the correct size clamp to match your stainless steel wire rope. Incorrect matching could result in serious injury or damage.

To create a simple loop or thimble loop, turn back the required amount or wire rope to create your loop. Starting approximately one grip base width in from the dead end of your rope place the U-bolt over the dead end and attach the grip base. Apply the fixing nuts - taking time to alternate between the two nuts as you tighten to ensure an even fixing.

For instances where you need to use 2 wire rope grips. Repeat the same instructions as above, placing the second grip as close to the thimble or loop as possible. Ensuring you place the U-bolt over the dead rope and fixing the grip base evenly.

When using three or more clamps ensure you have spaced them evenly, making sure you have taken up any slack in the rope between the two end grips before tightening your additional rope grips.

Once fitted we recommend you load test your wire rope assembly with a load that is equal or greater than the expected load. Check that all the nuts are secure.

The Green Pin® Wire Rope Clip is a wire rope clip, generally to EN 13411-5 Type B. This wire rope clip is safer to work with as the ribs on the bearing surface of the clip prevent sliding of the wire rope. Furthermore, the wire rope clip is made from high tensile steel, while galvanization ensures its long-term durability. The Green Pin® Wire Rope Clip is available in a range for wire rope diameters of 3 up to 78 mm.

Why don"t we supply clamps with safety locking nuts? We fully understand these concerns. In reality, if the clips are used properly – and that means properly tightened, it is not possible for the nuts to spontaneously loosen. The reason is that there is always strong counter-pressure caused by elasticity of ropes. The fact is that the clips were designed by much smarter people than we are without washers or locking nuts - and this applies to all types of rope grips. Also, we have never received any feedback that nuts were loosening when installed on the rope, on the other hand, losing nuts during transportation in a pack or pocket is quite common. My personal experience (OL5Y) proves that they will not loosen on the rope, if properly tightened.

The loose end of a wire is looped back and threaded through the wire rope clamp. The nuts on the clamp are then tightened to secure the end. Two to three clamps are used for a secure fitting. The u-bolt must always be placed on the load-bearing side of the wire rope. This protects the rope against crushing.

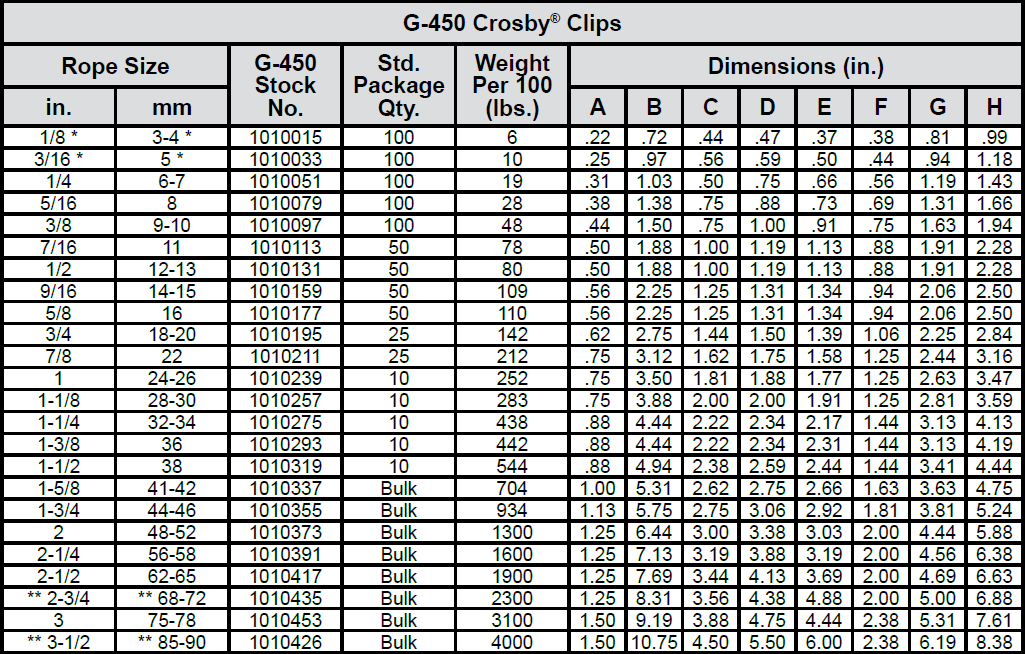

Bishop Lifting stocks 3 styles of Forged Wire Rope Clips for use as Wire Rope end Fittings. G-450 Red-U-Bolt® Clips, G-429 Fist Grip Clips and G-460 Soft Eye Bundle Clip, and the G-461 Thimble Eye Bundle Clip. Bishop Lifting is a proud distributor for the Crosby group including their line of wire rope clips.

Wire Rope Clips are used for forming eyes in the ends of wire rope by following an installation procedure provided by Crosby® and OSHA 1926.251. ASME states that when used for lifting wire rope clips shall be drop-forged steel of single saddle (u-bolt) or double saddle clip. Malleable cast iron wire rope clips shall not be used. The use of wire rope clips to fabricate slings is generally prohibited as per ASME B30.9. Efficiency ratings of a properly prepared loop or thimble eye terminations for clip sizes 1/8" through 7/8" is 80%, and sized 1" through 3-1/2" is 90%. U-Bolt style clips are not recommended for elevator, personnel hoist and scaffold applications, refer to ANSI A17.1 and ANSI A10.4. Consult the manufacturer before installing wire rope clips on plastic coated or plastic impregnated wire rope.

Before installing the wire rope clips make sure that you have the proper size clips and that the turnback is the proper length based on manufacturer"s recommendations. Place the wire rope clips on in the proper sequence, and make sure that you torque all of the wire rope clips evenly. The saddle of the wire rope clip should be placed on the live end of the wire rope, and the u-bolt should be placed on the dead end. Make sure that you use at least the minimum number of wire rope clips, proper spacing, and turnback length recommended by the manufacturer. Also make sure you torque the wire rope clips to the torque values recommended by the manufacturer. After assembly make sure that you test the connection to at least the anticipated working load, and the check and retighten the wire rope clips to the recommended torque values.

Crosby wire rope clips can be reused if they were installed properly and can pass inspection in between uses. Wire rope clips will wear out over time when they are reused. Check the threads for stretch and corrosion and check the saddle area for wear, deformation, and corrosion. The u-bolt must fit into the base without requiring a forceful change in u-bolt spread. The wire rope clip assembly must be properly installed and capable of being torqued to the proper values. The roddles (ridges) in the clip base must be undamaged, and the clip assembly must be retorqued after the initial load application to the specified torque values.

8613371530291

8613371530291