wire rope clamp dimensions brands

With sincerity and hard work of our professionals, we have carved a niche for ourselves in this domain by manufacturing highly durable gamut of Wire Rope Clamp.

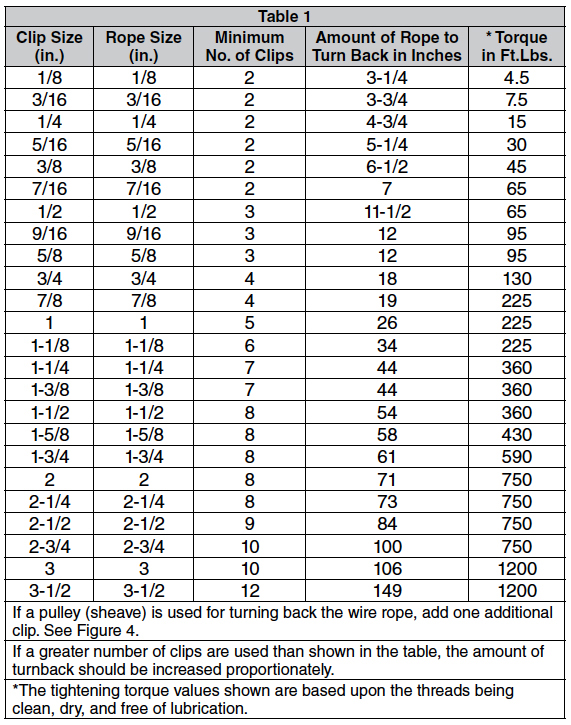

Efficiency ratings for wire rope end terminations are based upon the minimum breaking force of wire rope. The efficiency rating of a properly prepared loop or thimble-eye termination for clip sizes 1/8” through 7/8” is 80%, and for sizes 1” through 3-1/2” is 90%.

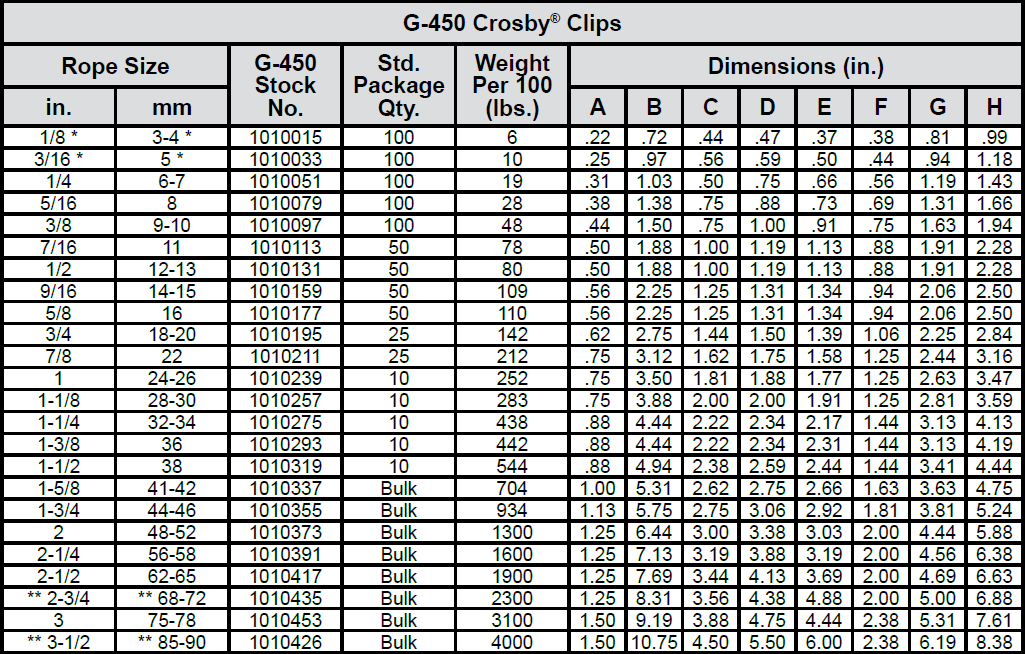

The number of clips shown (see Table 1) is based upon using RRL or RLL wire rope, 6 x 19 or 6 x 36 Class, FC or IWRC; IPS or XIP, XXIP. If Seale construction or similar large outer wire type construction in the 6 x 19 Class is to be used for sizes 1 inch and larger, add one additional clip. If a pulley (sheave) is used for turning back the wire rope, add one additional clip.

The number of clips shown also applies to rotation-resistant RRL wire rope, 8 x 19 Class, IPS, XIP, XXIP sizes 1-1/2 inch and smaller; and to rotation-resistant RRL wire rope, 19 x 7 Class, IPS, XIP, XXIP sizes 1-3/4 inch and smaller. For other classes of wire rope not mentioned above, we recommend contacting Crosby Engineering to ensure the desired efficiency rating.

For elevator, personnel hoist, and scaffold applications, refer to ANSI A17.1 and ANSI A10.4. These standards do not recommend U-Bolt style wire rope clip terminations. The style wire rope termination used for any application is the obligation of the user.For OSHA (Construction) applications, see OSHA 1926.251.

1. Refer to Table 1 in following these instructions. Turn back specified amount of rope from thimble or loop. Apply first clip one base width from dead end of rope. Apply U-Bolt over dead end of wire rope – live end rests in saddle (Never saddle a dead horse!). Use torque wrench to tighten nuts evenly, alternate from one nut to the other until reaching the recommended torque. (See Figure 1)

The loose end of a wire is looped back and threaded through the wire rope clamp. The nuts on the clamp are then tightened to secure the end. Two to three clamps are used for a secure fitting. The u-bolt must always be placed on the load-bearing side of the wire rope. This protects the rope against crushing.

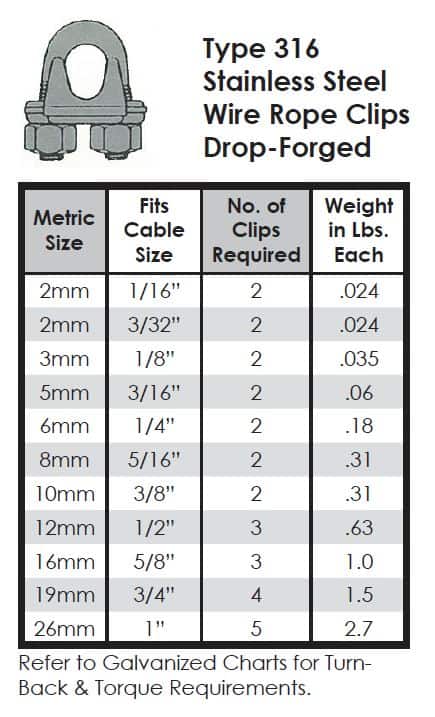

If you are interested in a Wire Rope Clip, you have come to the right place. We offer U-Clips made with stainless steel or galvanized steel. These clamps are used to apply terminations on a cable assembly.

If you are looking for swage sleeves, which fulfill similar functions, we also have those available in their own category. However, if you are interested in picking up some Wire Rope Clips, we have prepared some information that you should find useful.

As we mentioned before, Wire Rope Clamps are used for a similar function to their not-so-distant cousin, the swage sleeve/ferrule. They are used to establish dead-ends and eyes at the end of a wire cable.

While using a clip may decrease the breaking strength of a rope slightly more than a swage would, there are a few advantages over swages. A Wire Rope Clip can be removed and even reused without much wear. This makes clips ideal for less permanent fixes.

When a clip is installed properly, the decrease in the breaking strength of the wire. Eyes installed with Cable Clips will maintain 80-90% of their strength. However, when a clip is not installed properly, the decrease in breaking strength will be much more significant.

Since we just discussed the importance of installing a wire clip properly, let’s talk about what you will need to get this kind of job done. If you already work with wire cables, chances are you already have everything you need.

For the most part, Galvanized Steel is a little easier on your wallet than Stainless Steel and it will take a lot of abuse without much damage to show. However Galvanized Steel is not quite as strong as Stainless Steel and it can’t be used in jobs where the rope may be exposed to saltwater or excessive moisture.

When you are choosing your wire cable, there is a general rule of thumb. Large wires generally stand up very well to abrasion but are not as resistant to fatigue as smaller wires. The size of the rope will help to determine both its strength and flexibility.

Steel Cable Clamps are used in a wide variety of applications. They can be used in towing, loading, rigging, agriculture, and household uses just to name a few areas. The key advantage to using Wire Cable Clamps is that they can be used in any application where an eye termination may need to be removed at some point.

US Rigging are a manufacturer and master distributor of climbing ropes, fall protection equipment, and industrial rigging equipment located in Santa Ana, California. This Orange County based company is proud to provide American Made products with both safety and service in mind. US Rigging has a legacy lasting over 40 years and are known for operational excellence.

We offer a variety of Wire Rope Clips to fulfill your needs in rigging, lifting, towing, and heavy construction applications. These Cable Clips are designed to reliably splice wires with dead-end eye terminations. They are perfect for applications where you need to apply terminations that can be removed.

Wire Rope Clip also called as "U-bolt","Bull dog clip" or "Wire Clamp" is used to clamp the looped back wire rope as to form an eye. It is consisted by a U-bolt and has a saddle secured by 2 nuts. Design and Production Standards are conformed to BS EN 13411-5.

The Wire Rope Clip size are compatible with the Wire Rope diameter, inappropriate selection of wire rope clip size will cause damage to the wire rope or insufficient clamping force.

Incorrect installtion of wire rope clip will result in 40% reduction of working efficiency. Furthermore, bigger diameter of rope shall apply more wire rope clips with appropriate tail length to ensure the consistent working load limit. Below are some important guidelines for reference.

The MoorLink patented wire clamp is specially designed and developed to fit buoyancy (surface or sub-surface) to six stranded mooring wires. Each inlet is conical shaped avoiding bending damage to the mooring wire. In order to prevent the clamp sliding along the mooring wire, while allowing the lay length to vary under tension, the inside (of each clamp-half) is coated with print off medium stiff polyurethane. The clamp is easily attached to the mooring wire and is designed to carry large size buoyancy in the built-in bow shackle, preventing the buoy pig tail from twisting around the mooring line. The wire clamp is rotationally stable and the swivel limits the torque effect which is built up in the mooring wire whilst under tension.

The wire rope Mk7 insert clamp is designed for exchangeable wire imprint inserts and especially suitable for companies who want one wire rope clamp to fit several wire sizes.

Similar to the Wire stopper in its design, the hang-off clamp can be designed to fit any shackle or fitting. The Hang-off clamp comes in various sizes.

8613371530291

8613371530291