wire rope clamp specification supplier

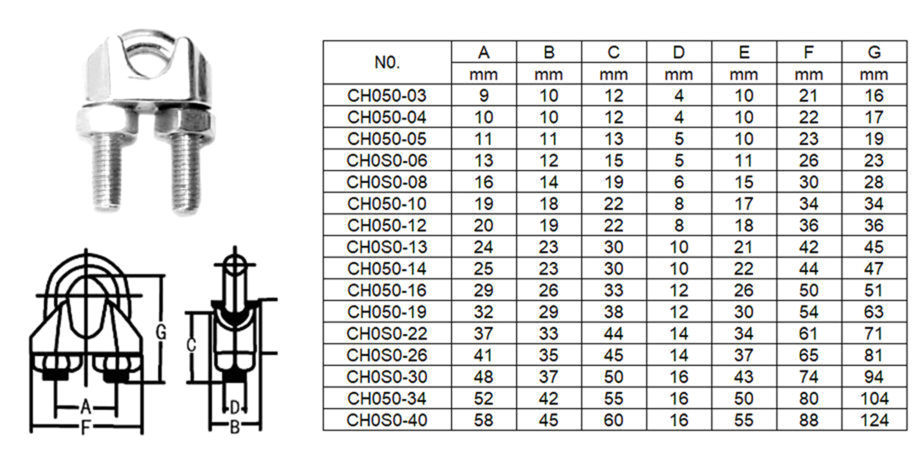

Manufacturer of wire rope clips made from stainless steel and die-cast zinc materials. Grip and U-bolt clips are offered. Available in various wire rope diameters with drop forged, hot galvanized, self-colored and zinc plated finishes. Suitable for tillers and cables. Clips are also distributed. Serves the transportation, mining, railroad, construction, architectural, fitness, automotive, marine, OEM, military, display, signage, lighting, security and recreation industries. Some clips meet military specifications and are made in the USA.

US based company with manufacturing in US and China. ISO 9001:9002, ISO 9001:2000 & ISO/TS 16949 certified manufacturer & distributor of clips including automotive clips, stainless steel clips & wire rope clips. Products are available in different sizes. Capabilities include aluminum die casting, investment casting, iron sand casting, steel forging, sheet metal stamping and forming, plastic injection molding and aluminum extrusion. Services include CAD model development, stress analysis, mechanical & chemical lab tests & prototyping service. Local US customer service handles project from beginning to end.

Wire rope clips are widely used for making end terminations. Clips are available in two basic designs; the U-Bolt and fist grip. The efficiency of both types is the same.

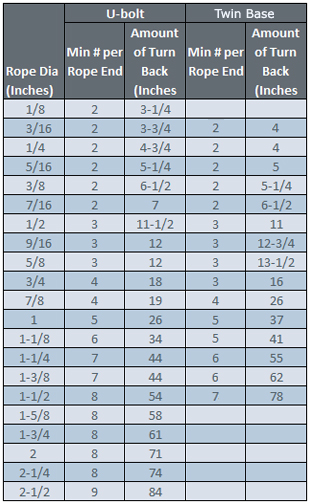

When using U-Bolt clips, extreme care must be exercised to make certain that they are attached correctly; Incorrect installation can reduce the working load limit by 40%. Below are general guidelines for installing wire rope clips.

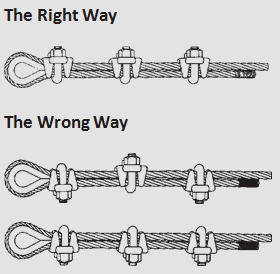

The saddle shall be placed on the live end of the wire rope, with the U-bolt on the dead-end side—Remember the well-known saying: “Never saddle a dead horse.” Use at least two or three wire rope clips to secure the ends properly to the length of the rope, and tighten nuts evenly one by one until reaching the recommended torque.

Step 1. Turn back a specified amount of rope from the thimble or loop. The first clip must be placed one bridge width from the turned back rope tailor dead end of the rope, Apply U-Bolt over dead end of wire rope – live end rests in the saddle (Never saddle a dead horse!) Tighten nuts evenly, alternate from one nut to the other until reaching the recommended torque.

Step 3. When three or more clips are required, space additional clips equally between the first two – take up rope slack – tighten nuts on each U-Bolt evenly, alternating from one nut to the other until reaching recommended torque.

In accordance with good rigging and maintenance practices, the wire rope end termination should be inspected periodically for wear, abuse, and general adequacy. Periodically re-tightening of the nuts must be done at 10.000 cycles (heavy usage), 20.000 e.g. every 3 months, 6 months, annually.

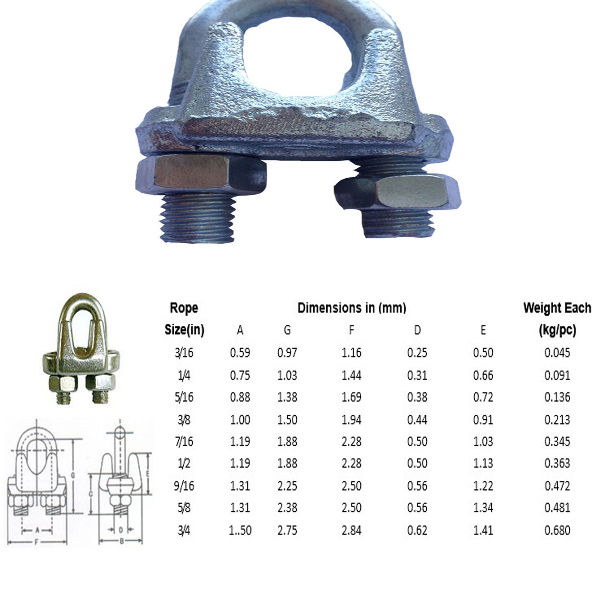

Malleable clips are to be used for making eye termination assemblies only with the right regular lay wire rope and only for light-duty uses with small applied loads, such as handrails, fencing, guard rails, etc.

If you have any wire rope clips questions, you can contact us by email at info@hilifting.com. We will be glad to share with you more useful information.

Wire rope clips are made of forged steel to form a U-shaped bolt with a saddle and two nuts to hold the wire rope in place. The wire rope is then threaded through the U-shaped bolt to secure it in place and protect it from fraying. They are recommended to use for overhead lifting applications.

These wire rope clips are drop forged, meaning that the clip is made of one continuous piece of metal that is formed by pouring molten steel into a mold. This helps to create a stronger clip shape with smooth edges.

The clip is then hot-dipped galvanized with a layer of zinc to protect it from rust and corrosion, extending the life of the clamp and increasing its durability.

Elite Sales is a premier drop forged wire rope clip supplier with sizes ranging from 1/8” to 2 ½”. All clips meet Federal Specification FF-C-450, Type 1, Class 1. Get in touch with us today!

Malleable wire rope clips are best for light-duty and other general-purpose applications, such as guard rails, fencing, and other wire rope securements. The clip is made of malleable steel which forms a U-shaped bolt with two nuts and a saddle to hold the wire rope in place. This protects the wire rope from fraying and wear.

Elite Sales offers rope clips ranging in size from 1/16” to 1 1/8” and varying dimensions for numerous types of applications and uses. Each piece is made to meet Federal Specification FF-C-450, Type 1, Class 2.

Ready to buy malleable wire rope clips? Reach out to Elite Sales, the premier hardware distributor, and wholesaler for a great deal on top-quality products.

Looking for a wood clamp or a bar clamp to level up your woodworking workshop and skills? Look no further! At Alibaba.com, you can browse an endless variety of wholesale wire rope clamps and find the perfect fit for you regardless of experience.

If you are looking to further your woodworking skills, woodworking clamps such as the spring clamps can be your next best investment! Head over to Alibaba.com to get your brand new wire rope clamps for your next pet project! Who knows, this purchase may be the catalyst to your future greatness!

You can even get a beam clamp to suspend or secure fixtures, wires, threaded rods, and other hardware to beam flanges. They offer secure fixing without the need for welding and drilling, making it the perfect purchase for your next DIY project! Find affordable cable clamps made with quality materials on Alibaba.com!

On the other hand, if you would prefer to work with drilling and welding for your pet projects, you may browse our massive selection of metal clamps and welding clamps. The metal clamps will provide a more durable option to the other wire rope clamps you can find on the market! Find the most suitable product for your needs and level of expertise today on Alibaba.com and get free shipping and further discounts on your purchase!

Based on the catalog breaking strength of wire rope, Crosby wire rope clips have an efficiency rating of 80% for 3-4mm to 22mm sizes, and 90% for sizes 24-26mm through 90mm.

Meets or exceeds all requirements of ASME B30.26 including identification, ductility, design factor, proof load and temperature requirements. Importantly, these wire rope clips meet other critical performance requirements including fatigue life, impact properties and material traceability, not addressed by ASME B30.26.

With sincerity and hard work of our professionals, we have carved a niche for ourselves in this domain by manufacturing highly durable gamut of Wire Rope Clamp.

Murphy offers many sizes of wire rope clips in 4 different fabrications: zinc plated, stainless steel malleable, galvanized drop forged, and stainless steel drop forged.

You can use wire cable clips to secure the loose ends of your wire ropes. They often have nuts, u-shaped bolts, and cast saddles. You can put the wire rope in the bolt and then place the saddle over the bolt’s rope. By using the nuts, you can then secure the rope in its place.

There are a couple of ways to make the process stronger. For example, if you have a cable coated with vinyl, then you can take off the vinyl in the place where you put it in the wire rope clip.

We offer our clips in a range of materials, which gives you more options. You can use the clips for semi-permanent or permanent applications, or just temporary ones. You can use your hand tools to secure them to your stainless steel wire rope. They are also cost-effective.

You can count on our company to offer sturdy and long-lasting clips, so you can secure your loose ends well. We have good knowledge of the requirements of various industries, allowing us to offer you the best products. You can expect our wire rope clips to last for a long time.

With so many different kinds of rope clips and ropes to choose from, we know making a choice can be difficult. Luckily, Murphy Industrial Products, Inc. is here to help. Feel free to contact us today if you want to know more about our stainless steel wire rope clips and related products.

Wire rope clips, also called wire rope clamps, consist of a U-shaped bolt, a metal saddle piece, and two nuts. They are used in wire rope loop assemblies and are ideal for field installations. We offer several models to meet your specific needs.

U-bolt Clips.There is only one correct method for attaching U-bolt clips to wire rope ends, as shown in TheRightWayimage below. The base of the clip bears on the live end of the rope; the “U” of the bolt bears on the dead end.

Compare this with the incorrect methods. Five of the six clips shown are incorrectly attached—only the center clip in the top view is correct. When the “U” of the clip bears on the live end of the rope, there is a possibility of the rope being cut or kinked, with subsequent failure.

Wire Rope ClampsOffering you a complete choice of products which include wire rope u clamps, stainless steel 304 u clamps, galvanized u clamps, u clamp, u clamps and ms forged clamps.

We supply a quality range of Wire Rope Clamps that is used to fix the loose end of the loop back to the wire rope. It consists of a u-shaped bolt, a forged saddle and two nuts. Three or more clamps are usually used to terminate a wire rope. Available in standard specification, these can also be customized as per the requirements of our clients. These find application in various industries such as cement plant, chemical industry and oil industries.

We offer Stainless Steel 304 U Clampswhich are manufactured with using high grade stainless steel. These U clamps easily cater to distinct needs of our customers.

We hold specialization in providing a broad array of Galvanized U Clampsto the clients. These products are manufactured using premium grade raw material, which is procured from trustworthy vendors of the market. We offer these products in different sizes, shapes and other specifications to our respected patrons. Post production, these products are checked on predefined parameters by our quality controllers.

Product Description:We offer Stainless Steel 304 U Clampwhich are manufactured with using high grade stainless steel. These U clamps easily cater to distinct needs of our customers.

We supply a quality range of U Clamps that is used to fix the loose end of the loop back to the wire rope. It consists of a u-shaped bolt, a forged saddle and two nuts. Three or more clamps are usually used to terminate a wire rope. Available in standard specification, these can also be customized as per the requirements of our clients. These find application in various industries such as cement plant, chemical industry and oil industries.

MS Forged Clampsoffered by us to the needs of the customers by way of supplying genuine – tested materials at extremely reasonable rates. However forged clamps materials are always supplied with the test certificates and can be supplied in bulk quantity as well as retail quantity as per customers requirements forged clamps are supplied by us to various industries we proudly state that customers come back to us – with regular orders, not with rejection complaints.

The Crosby Group provides product users with “Red” U-Bolt Clips and forged Fist Grip Clips. Our wire rope clips meet the Federal Specification Number FF-C-450, considered the industry standard.

Compared to cast iron clips, forged clips provide a greater rope bearing surface and have been proven to be more consistent in strength and durability. Whether wire rope forged clips perform efficiently or not depends on whether the manufacturing practices were done properly.

First Grip Clips, for example, provide a saddle for both the live and the dead-end of the wire. This results in needing fewer forged clips for each termination. However, this is not the case with malleable cast iron clips. Forged wire clips reduce the possibility of hidden defects that are sometimes present in the cast iron clips. Cast iron clips should only be used in non-critical applications.

The wire rope clips are forged and galvanized, which ensures resistance to corrosion and rusting. The double saddle design eliminates the possibility of incorrect installation. The bolts are opposite one another, designed as an integral part of the clip. As a result, the nuts can be installed in such a way as to enable the operator to swing the wrench a full arc for easy installation.

The Crosby traceability system is actively used throughout all manufactured forged wire rope clips. All material analysis for each heat of steel is verified within our own laboratory.

We provide detailed warning information for all wire rope clips. Every clip is bagged or tagged with the warning information. This ensures that the information is available at the point of use for every wire rope clip during installation. The warning system is designed to attract the attention of the product user, with the goal to inform the user of the factors involved in the task and provide the user with proper application procedures.

Wire rope clips are used to fix the loose end of the loop back to a wire rope. These clips generally consist of a U-shaped bolt, forged saddle, and two nuts. The two layers of wire rope are placed in the U-bolt. The saddle is fitted over the ropes on to the bolt. The nuts secure the arrangement in place. When installing the clips, the saddle portion is placed on the load-bearing or live side. It is not to be placed on the non-load-bearing or dead side of the cable. This is to protect the stress-bearing end of the rope against crushing and abuse.

The size of the wire rope must be measured to allow selecting the proper size wire rope clip. The wire rope end must be seized prior to forming the eye to prevent the wire rope strains and core from shifting while forming the eye. The use of a soft wire to wrap the end of the wire rope is one method. Once properly wrapped, be sure to tighten the soft wire wrapping with plyers.

The number of clips required must be determined by referring to the information on the Crosby bag or on our catalog. Always use a thimble to protect the wire rope against wear and abrasion as it is used. Make sure the turn back is the proper length by using the tape measure to measure it.

As the clips are installed, it’s important to remember that the first clip is applied one base width from the dead-end, that should have been secured earlier. Always apply the U-bolt over the dead-end of the wire rope. Once the nuts are placed on the U-bolt by hand, they must then be tightened evenly. Using a torque wrench, alternate tightening from one nut to another nut until reaching the recommended torque.

The second wire rope clip is then applied as close to the loop or thimble as possible. When three or more clips are needed, space the clips equally between the first two. Take out any rope slack and place the nuts on these additional wire rope clips by hand. Tighten all of them with the torque wrench.

8613371530291

8613371530291